Double-heat-energy warming fermentation tank

A fermenter and thermal energy technology, applied in the field of fermenter, can solve the problems of poor warming effect, unsuitable for large-scale biogas projects, etc., and achieve the effect of not easy to lose, good warming effect, and good warming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

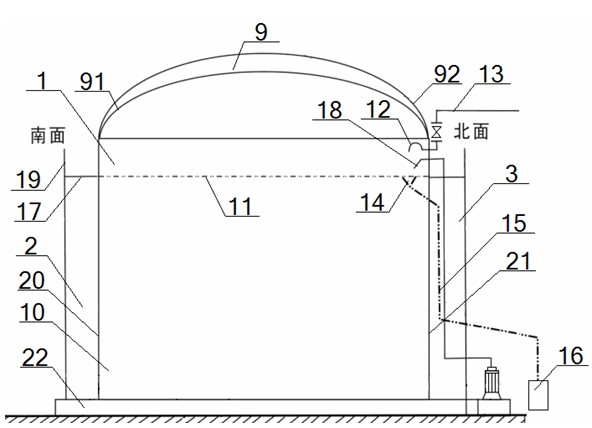

[0067] Example 1: The No. 1 solar heating room and biomass heating room are suitable for the production of straw biogas or mixed biogas of straw and feces.

[0068] see figure 2 and image 3 , a kind of double heat energy heating type fermenter, comprises fermenter 1, No. 1 solar energy warming room 4 and biological energy warming room 5, and described fermenter 1 comprises tank body 10 and the gas film 9 that top is provided with, and gas The membrane 9 includes an inner membrane 91 and an outer membrane 92. The inside of the air membrane 9 communicates with the air duct. On the side wall of the tank body 10, the position between the inner membrane 91 and the discharge height line 11 of the liquid level is provided with an air outlet 12 and a flushing hole. Shower head 18, an overflow port 14 is set below the liquid surface discharge height line 11, the gas outlet 12 communicates with the biogas pipe 13, the shower head 18 corresponds to the overflow port 14, and the overfl...

Embodiment 2

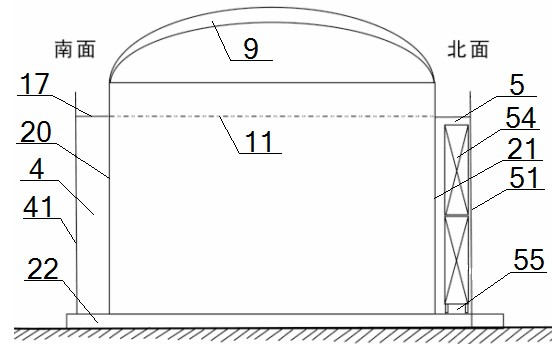

[0072] Example 2: No. 2 solar warming room and fully enclosed boiler direct heating room are suitable for the production of feces biogas.

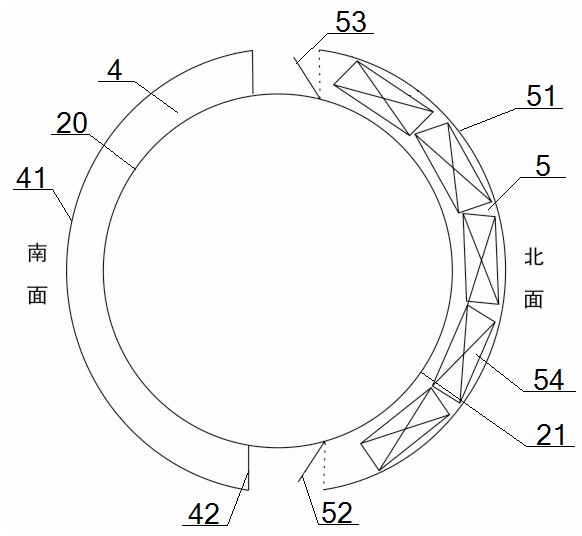

[0073] see Figure 4 – Image 6 , the basic content is the same as in Example 1, the difference is that:

[0074] A double heat energy heating fermenter, including fermenter 1, No. 2 solar warming room 6 and fully enclosed boiler direct heating room 7, No. 2 solar warming room 6 and fully enclosed boiler direct heating Room 7 is connected;

[0075] The No. 2 solar warming room 6 includes an arc-shaped transparent glass wall 41 and a closed door 42. The transparent glass wall 41 is arranged around the south side wall 20. The two ends of the transparent glass wall 41 are respectively connected to the closed door 42 and the No. The walls 71 are connected, and the top of the transparent glass wall 41 is provided with a platform 17;

[0076] The fully enclosed boiler direct heating type warming room 7 includes arc-shaped No. 2 thermal insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com