Synchronous temperature-increasing mushroom house device and its synchronous temperature-increasing cultivation method specially used for Agaricus blazei

A mushroom house and mushroom bed technology, which is applied in the field of edible fungus cultivation, can solve problems such as unreasonable structure of heating and heat preservation stoves, inability to achieve uniform temperature in the mushroom house, unfavorable cultivation and management of Agaricus blazei, etc., and achieve significant yield increase effect and good fruiting body quality , good warming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

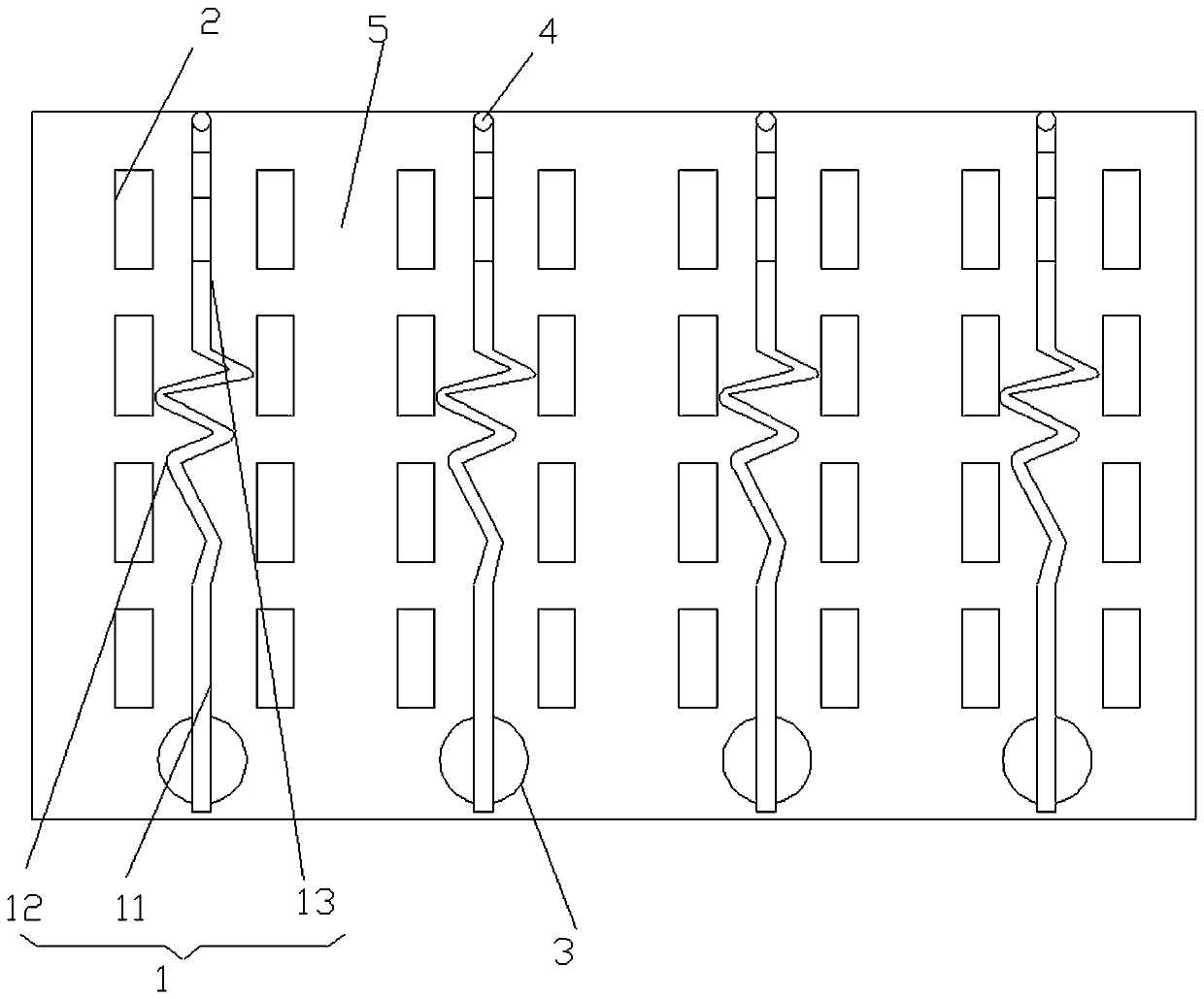

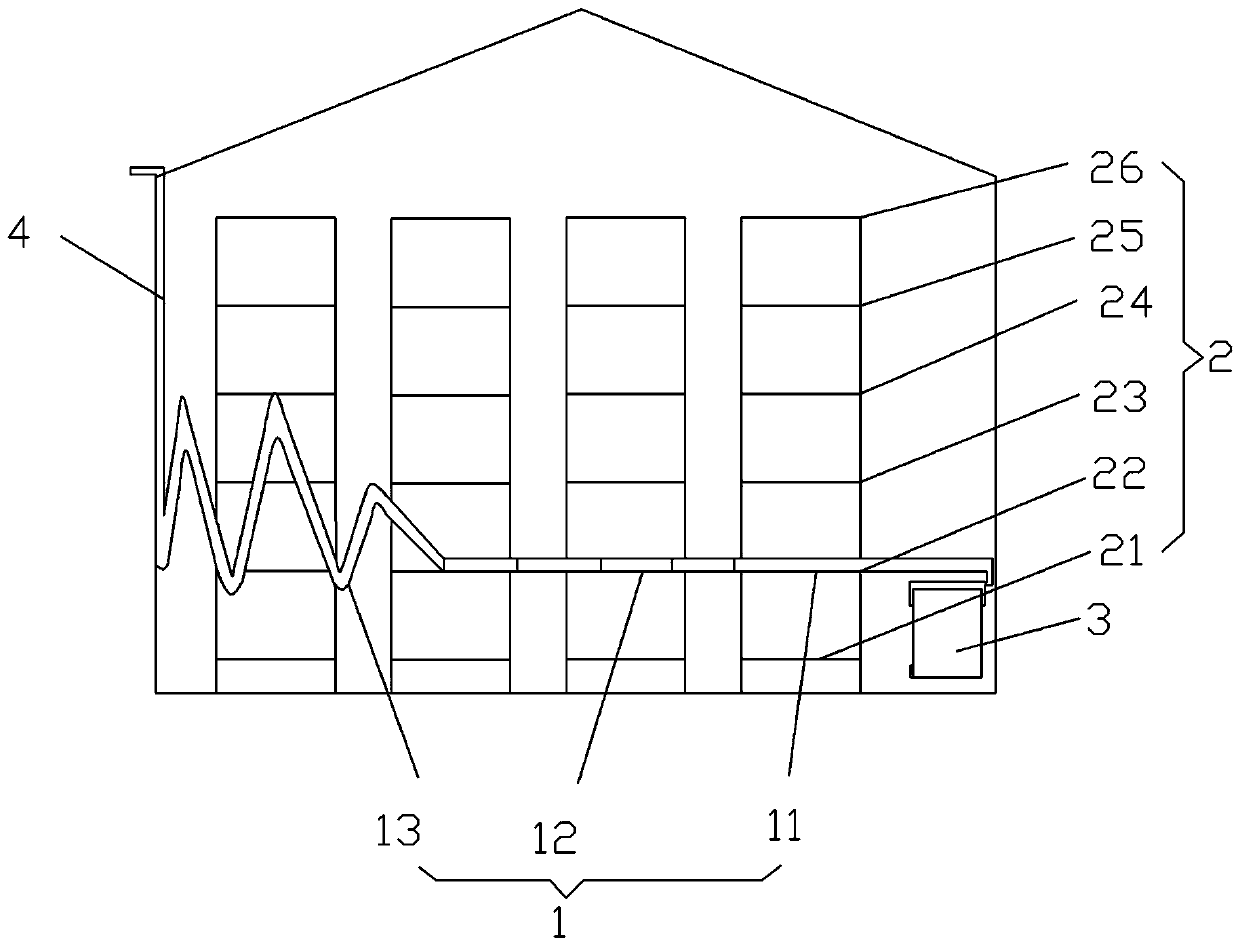

[0040] A synchronous temperature-increasing mushroom house device dedicated to Agaricus blazei, including a mushroom house with walls and a roof, the mushroom house is built facing south from the north, and is characterized in that:

[0041] The length of the mushroom house is 12 meters, the width is 7.5 meters, and the height is 3.5 meters. At least 8 rows of mushroom bed frames (equivalent to 4 vertical mushroom frames) are arranged in each mushroom house along the length direction, and each row of mushroom beds The bed frame is 6 layers of mushroom beds, and the height interval between each two layers of mushroom beds is 60 cm. A channel is formed between two adjacent rows of mushroom bed frames along the width direction of the mushroom house. The temperature-increasing channel for synchronous heating of the mushroom bed frame on the side and the management channel for managing the growth and picking of Agaricus blazei on the mushroom bed frame on both sides;

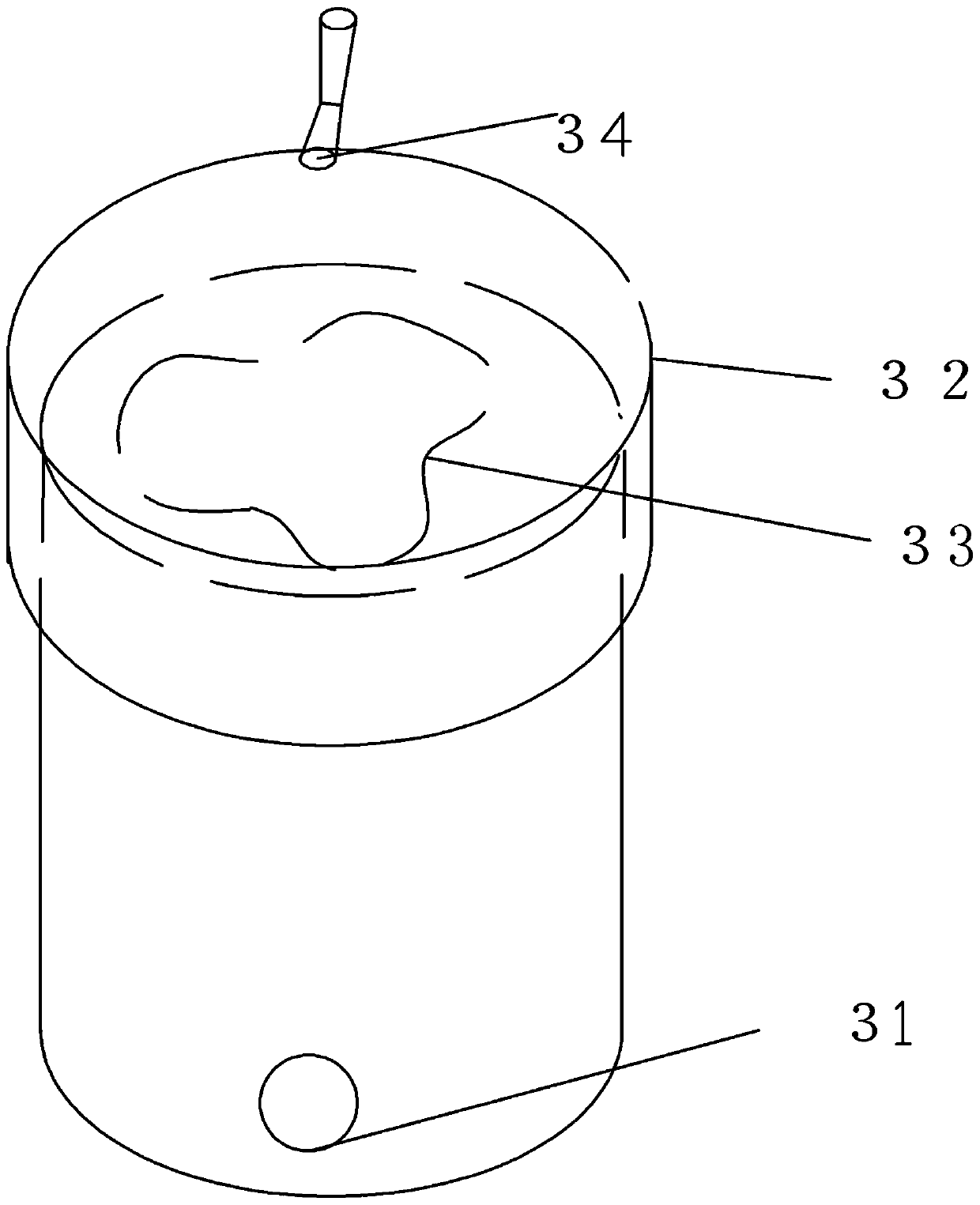

[0042] The s...

Embodiment 2

[0070] A synchronous temperature-increasing mushroom house device dedicated to Agaricus blazei, including a mushroom house with walls and a roof, the mushroom house is built facing south from the north, and is characterized in that:

[0071] The length of the mushroom house is 18 meters, the width is 8.0 meters, and the height is 4.0 meters. There are 12 rows of mushroom bed frames 2 (equivalent to 6 vertical mushroom frames) in each mushroom house along the length direction. Each row of mushroom beds The bed frame is 6 layers of mushroom beds, and the height interval between each two layers of mushroom beds is 50 cm. A channel is formed between two adjacent rows of mushroom bed frames 2 along the width direction of the mushroom house. The temperature-increasing channel for simultaneous temperature increase of the mushroom bed frame 2 on both sides and the management channel for managing the growth and picking of Agaricus blazei on the mushroom bed frame on both sides;

[0072...

Embodiment 3

[0097] A synchronous temperature-increasing mushroom house device dedicated to Agaricus blazei, including a mushroom house with walls and a roof, the mushroom house is built facing south from the north, and is characterized in that:

[0098] The length of the mushroom house is 18 meters, the width is 8.5 meters, and the height is 4.5 meters. There are 12 rows of mushroom bed frames 2 (equivalent to 6 vertical mushroom frames) in each mushroom house along the length direction. Each row of mushroom beds The bed frame is a 6-layer mushroom bed, and the height interval between each two layers of mushroom beds is 50-60 cm. A channel is formed between two adjacent rows of mushroom bed frame 2 along the width direction of the mushroom house, and the channels are alternately provided with A warming channel for synchronously increasing the temperature of the mushroom bed frames 2 on both sides and a management channel for managing the growth and picking of Agaricus blazei on the mushroo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com