Exhaust gas purifying apparatus

A technology of exhaust purification device and exhaust treatment device, which is applied in the direction of exhaust device, noise reduction device, electrical control, etc. It can solve the problems of not mentioning the proportion and not considering the temperature rise of the exhaust treatment device, etc., and achieve the effect of easy temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the following, various embodiments of the present invention shown in the legends are described, in which the same parts are given the same reference numerals.

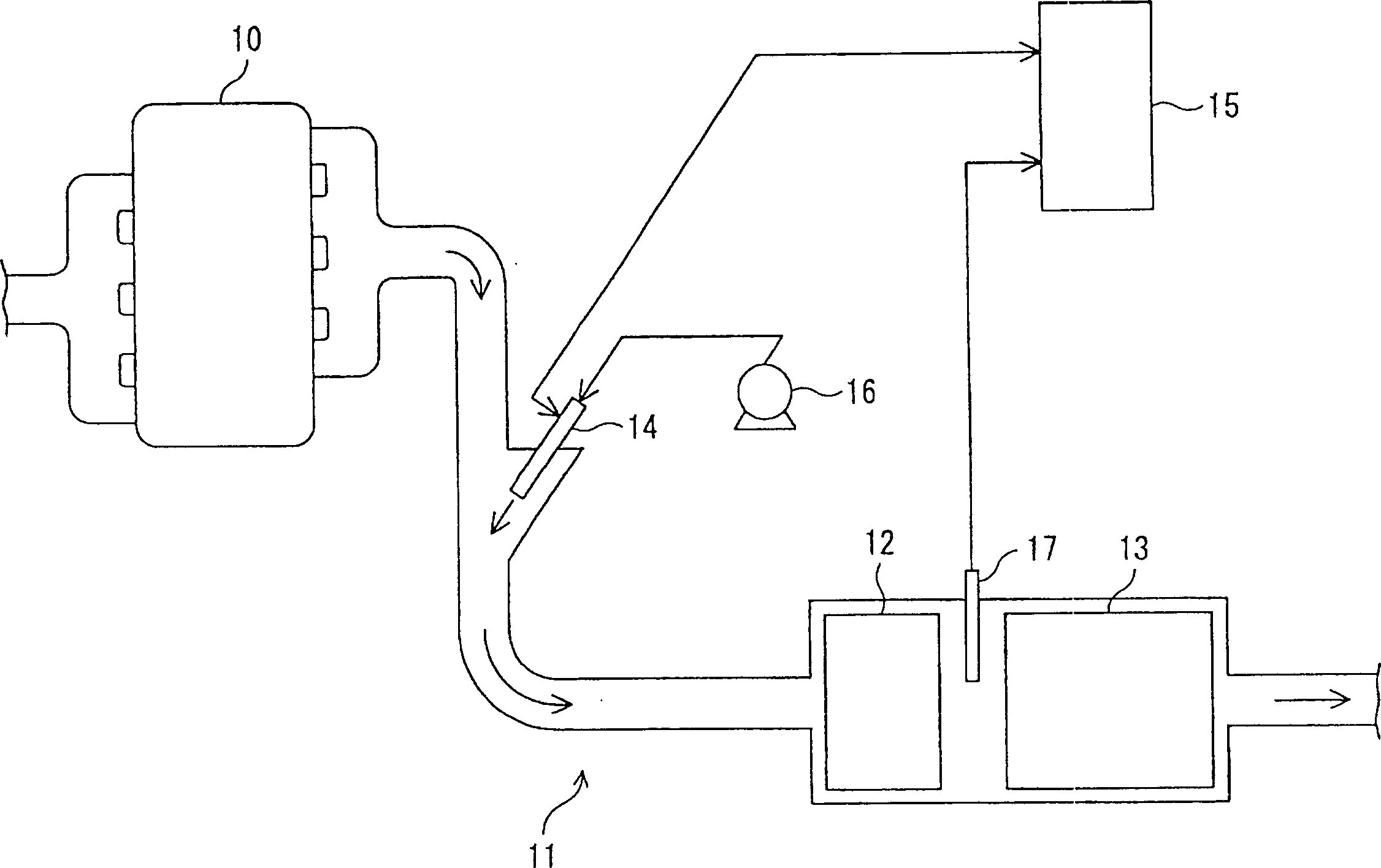

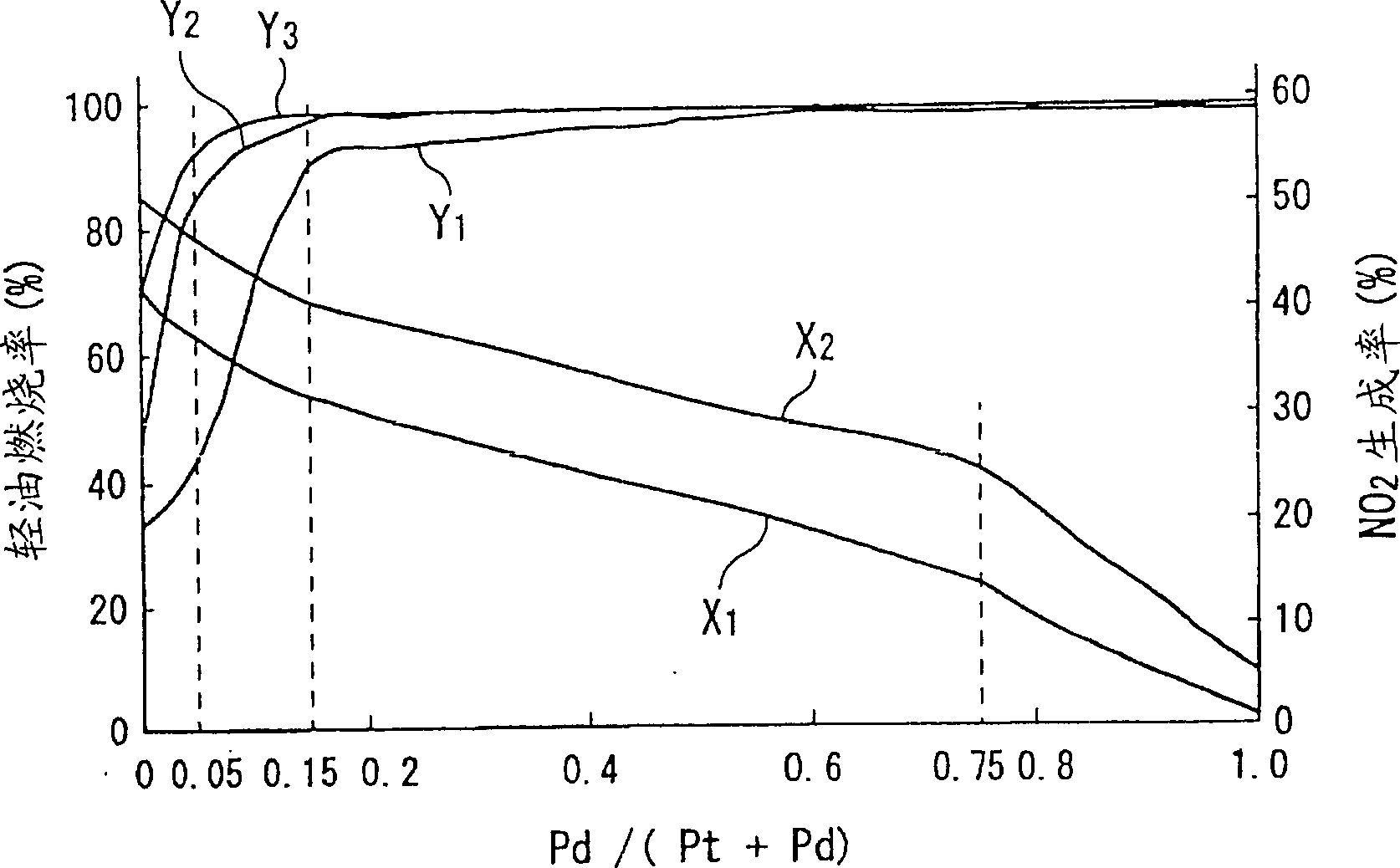

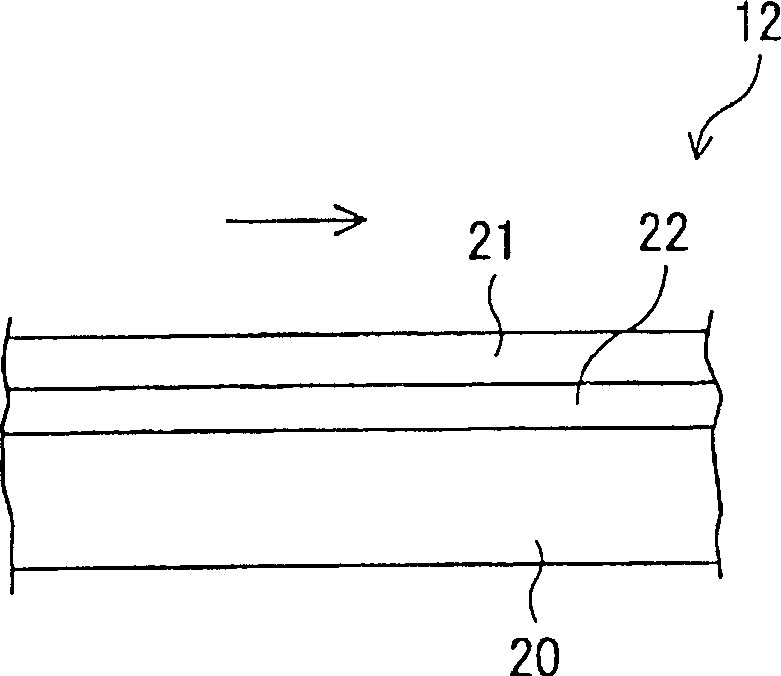

[0033] figure 1 In the exhaust passage 11 of the vehicle diesel engine 10, an oxidation catalyst device 12 and a particulate filter 13 are provided in this order from the air flow upstream side. In the oxidation catalyst device 12 , particulate platinum and palladium are carried on the surface of a honeycomb support made of cordierite using alumina as a binder.

[0034] In addition, during operation of the diesel engine 10, when the exhaust gas flowing from the diesel engine 10 to the exhaust passage 11 flows through the particulate filter 13, particulates such as dust contained in the exhaust gas are trapped and removed, It is discharged to the air flow downstream side of the particulate trap filter 13 in a purified state.

[0035] Furthermore, an injector 14 is provided on the upstream side of the air fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com