Steel slag modification method and device of ultra-low carbon steel

A technology of ultra-low carbon steel and steel slag, which is applied in the field of refining and can solve the problems of low efficiency of steel slag modification and affecting the quality of steel plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

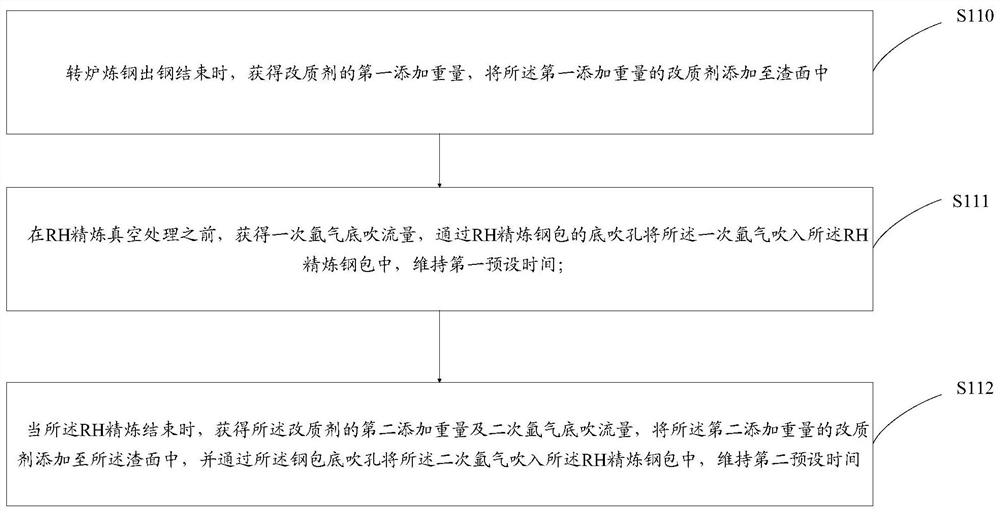

[0042] This embodiment provides a steel slag modification method for ultra-low carbon steel, such as figure 1 As shown, the methods include:

[0043] S110, at the end of the converter steelmaking tapping, obtain the first added weight of the modifier, and add the modifier of the first added weight to the slag surface; the modifier includes: aluminum, lime particles and impurities , the mass fraction of the aluminum is 50-70%, the mass fraction of the lime particles is 20-30%, and the particle diameter of the lime particles is 5-20mm;

[0044]At the end of converter steelmaking and tapping, the steel slag on the molten steel surface needs to be modified to reduce FeO and MnO in the steel slag to ensure the cleanliness of the molten steel. Then it is necessary to obtain the first added weight of the modifier. The modifier includes: aluminum, lime grains and impurities, the mass fraction of aluminum is 50-70%, the mass fraction of lime grains is 20-30%, and the particle size of ...

Embodiment 2

[0069] This embodiment provides a steel slag reforming device for ultra-low carbon steel, such as figure 2 As shown, the device includes: a first determining unit 21, a second determining unit 22, and a third determining unit 23; wherein,

[0070] The first determination unit 21 is used to obtain the first added weight of the modifier at the end of converter steelmaking and tapping, and add the modifier of the first added weight to the slag surface; the modifier includes : aluminum, lime grains and impurities, the mass fraction of the aluminum is 50-70%, the mass fraction of the lime grains is 20-30%, and the particle diameter of the lime grains is 5-20mm;

[0071] The second determining unit 22 is used to obtain a flow rate of argon bottom blowing before the RH vacuum treatment, blow the primary argon gas into the ladle through the bottom blow hole of the ladle, and maintain the first preset time;

[0072] The third determining unit 23 is used to obtain the second addition ...

Embodiment 3

[0096] In practical application, when using the upgrading method provided in Example 1 and the upgrading device provided in Example 2 to upgrade steel slag in a certain refining process, the specific implementation is as follows:

[0097] Combined blowing converter-RH-continuous casting is used to smelt ultra-low carbon steel, and the ladle capacity is 300t.

[0098] At the end of converter tapping and blowing, the oxygen activity was determined to be 550ppm. At the end of tapping, an aluminum-containing modifier was added to the slag surface. The mass fraction of aluminum in the modifier was 55%, and the average particle size of lime was 15mm. The amount of modifier added The slag layer thickness of steel slag top slag was determined to be 110mm.

[0099] When the RH enters the station to place the ladle, the argon bottom blowing is turned on for the first time, and the flow rate of the argon bottom blowing is set to 890L / min; the bottom blowing is turned off after maintainin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com