Production method of ultra-low phosphorus if steel

A production method, ultra-low phosphorus technology, applied in the manufacture of converters, etc., can solve the problems of unfavorable vacuum decarburization, reduce the oxidation of ladle slag, etc., achieve environmental hazards, easy operation, low consumption of steel materials, and high dephosphorization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0052] The invention provides a production method of ultra-low phosphorus IF steel, which adopts a process route: converter smelting-ladle refining-vacuum refining-continuous casting, and uses carbon-free ladle in the whole process; the following process parameters are controlled in each process:

[0053] (1) Converter smelting:

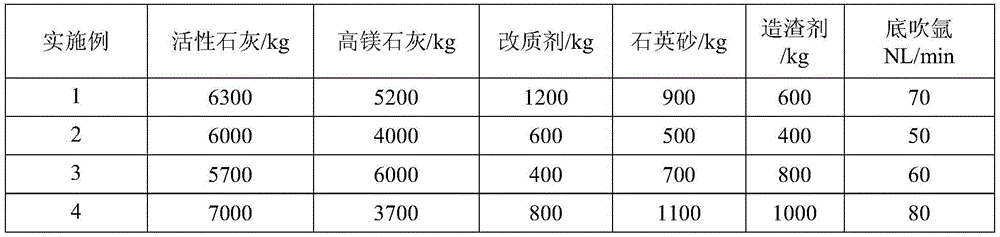

[0054] The conditions for entering the converter are shown in Table 1;

[0055] Converter smelting dephosphorization: the converter slagging material is one or more of quartz sand, slagging agent, active lime, high magnesium lime, and modifier; the addition amount is: active lime 25-30kg / t 钢 , High magnesium lime 15~26kg / t 钢 , Modifier 1~5kg / t 钢 , quartz sand 2 ~ 5kg / t, slagging agent 钢 , the specific slagging materials used and their weights are shown in Table 2; among them, the composition of the molten steel modifier: MgO≥45.0%, CaO≥8.0%, SiO 2 ≤10.0%, C≥8.0%.

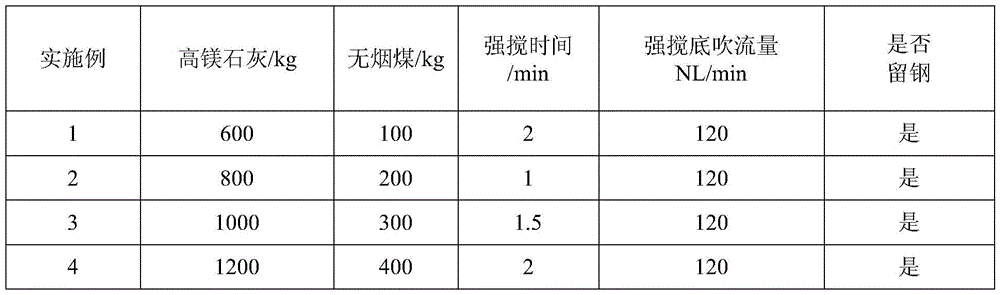

[0056] The converter blowing smelting process adopts the whole process of bottom b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com