Design method for composite solid lubrication sprocket shaft group

A technology of solid lubrication and design method, applied in the direction of engine lubrication, bearing components, shafts and bearings, etc., can solve problems such as unreliable lubrication, bearing inner sleeve wear, bearing retainer damage, etc., to reduce wear and improve load capacity. , the effect of improving life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

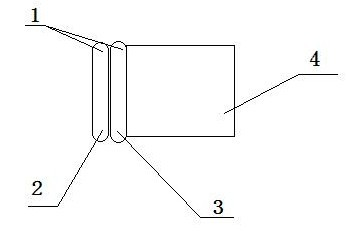

[0016] Such as figure 1 As shown, the core seal of the design method of the composite solid lubrication sprocket shaft group includes a floating seal ring 1 and a sealing flange 4, and the floating seal ring 1 is composed of two geometrically identical metal rings. One is a floating ring 3, which is fixed on the sealing flange 4; the other is a stationary ring 2, and the stationary ring 2 and the floating ring 3 are fitted together for relative movement to achieve a sealing effect.

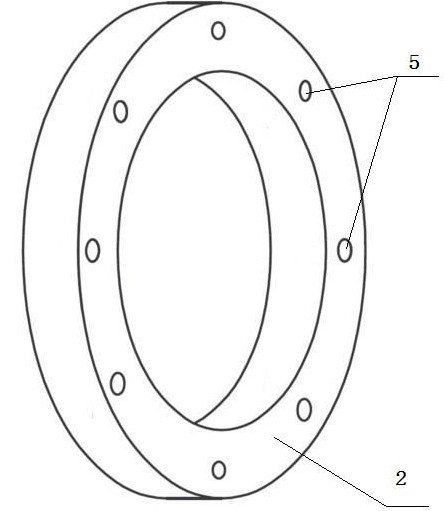

[0017] Such as figure 2 As shown, the annular latent pit 5 structure is adopted on the fitting surface of the stationary ring 2, the fitting surface of the floating ring 3 is smooth, the size of the latent pit 5 is Φ2.5mm*1mm, and the distance between adjacent latent pits 5 is 5mm. Solid lubricant is arranged in latent pit 5.

[0018] When working, the stationary ring 2 and the floating ring 3 move relatively, and the annular latent pit 5 structure is used on the bonding surface of the stationa...

Embodiment 2

[0020] The structure of this embodiment is basically the same as that of Embodiment 1, except that the bonding surface of the floating ring 3 adopts the structure of an annular latent pit 5, and there is a solid lubricant in the latent pit 5, while the bonding surface of the stationary ring 2 is a smooth surface.

[0021] The joint surface of any one of the two metal rings of the floating sealing ring 1 adopts the structure of the annular latent pit 5, which can achieve the expected effect in practical applications.

Embodiment 3

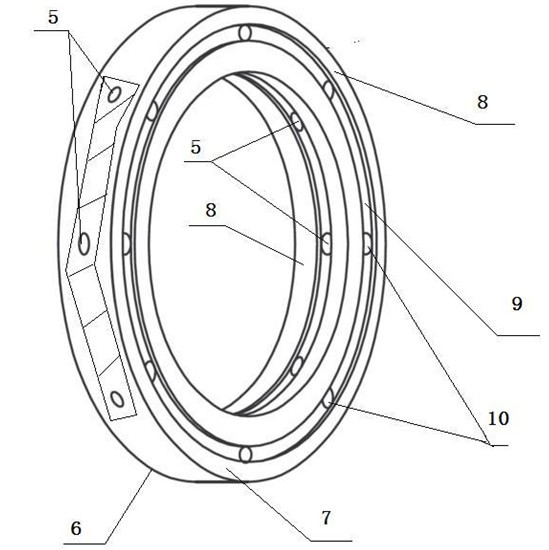

[0023] Such as image 3 As shown, the bearing 6 is a commonly used bearing, which is composed of an inner ring 7, an outer ring 8, a cage 9 and a rolling element 10, and a latent pit is used on the contact surface of the cage 9, the inner ring 7 and the outer ring 8 5 structure, there is solid lubricant in latent pit 5. The size of the latent pits 5 is Φ2.5mm*1mm, and the distance between adjacent latent pits 5 is 5mm.

[0024] During operation, the latent pit 5 structure is used on the retainer 9 of the bearing 6 to ensure sufficient composite solid lubricant compensation on the surface of the rolling elements, so that the solid lubricant transferred on the moving track of the inner and outer rings of the bearing forms a firm and reliable composite lubricant. Solid lubricating film, which improves the load capacity of the sprocket shaft group bearings, reduces wear and improves the life of the bearings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com