Processing method of marble composite board

A processing method and composite board technology, applied in chemical instruments and methods, lamination devices, lamination, etc., can solve problems such as construction difficulties, stone peeling, and insufficient defoaming, so as to reduce the rate of defective products and enhance the bonding force , reduce the effect of hollowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The processing method of the marble composite board of the present embodiment, the specific steps of the processing method are as follows:

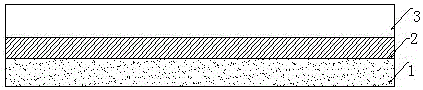

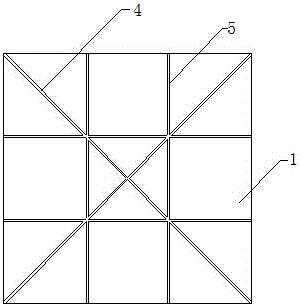

[0033] (1) Substrate processing: such as figure 1 As shown, take a 600*600 ceramic tile 1 with a thickness of 3mm, and use a mold to press out different widths when the tile 1 is pressed, and form a 1mm thick exhaust groove connected to the four sides of the tile 1 on the surface of the tile 1, as shown in figure 2 As shown, the exhaust groove includes a pair of cross-shaped exhaust grooves 4, and the four endpoints of the exhaust groove 4 coincide with the four endpoints of the tile 1, and also include two sets of connecting substrates 1 opposite two Exhaust groove 5 on the side;

[0034] (2) Material selection: cut the natural stone into the same size as the tile in step (1), and apply glue on the side of the tile 1 with the exhaust groove, so as to form the glue interlayer 2;

[0035] (3) Bonding: The cut stone 3 is bonded to...

Embodiment 2

[0042] The processing method of the marble composite board of the present embodiment, the specific steps of the processing method are as follows:

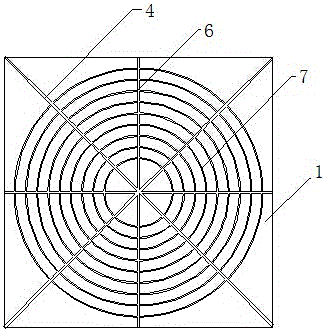

[0043] (1) Substrate processing: such as figure 1 As shown, take a 600*600 ceramic tile 1 with a thickness of 3mm, and use a mold to press out different widths when the tile 1 is pressed, and form a 1mm thick exhaust groove connected to the four sides of the tile 1 on the surface of the tile 1, as shown in 3 As shown, the exhaust groove includes a pair of cross-shaped exhaust grooves 4, and the four endpoints of the exhaust groove 4 coincide with the four endpoints of the tile 1, and also includes a group of connecting tiles 1 opposite two sides Exhaust groove 6, with the center point of tile 1 as the center, several exhaust grooves 7 distributed in concentric circles are distributed, and exhaust groove 7 intersects with exhaust groove 4 or exhaust groove 6;

[0044] (2) Material selection: cut the natural stone into the same size...

Embodiment 3

[0052] The processing method of the marble composite board of the present embodiment, the specific steps of the processing method are as follows:

[0053] (1) Substrate processing: such as figure 1 As shown, take a 600*600 ceramic tile 1 with a thickness of 3mm, and use a mold to press out different widths when the tile 1 is pressed, and form a 1mm thick exhaust groove connected to the four sides of the tile 1 on the surface of the tile 1, as shown in Figure 4 As shown, the exhaust groove is an exhaust groove 8 distributed in a spider web;

[0054] (2) Material selection: cut the natural stone into the same size as the tile in step (1), and apply glue on the side of the tile 1 with the exhaust groove, so as to form the glue interlayer 2;

[0055] (3) Bonding: The cut stone 3 is bonded to the ceramic tile 1 through glue, and the force on the surface of the stone composite board is kept uniform during the bonding process, and the bonding pressure is controlled at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com