Sweet potato raw whole flour, production method and production system thereof and mechanical peeling unit

A production method and production system technology, applied in the field of food processing, can solve the problems of coarse powder, incomplete peeling, and high degree of gelatinization of raw sweet potato powder, so as to avoid gelatinization, avoid gelatinization of sweet potato starch, and improve taste good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

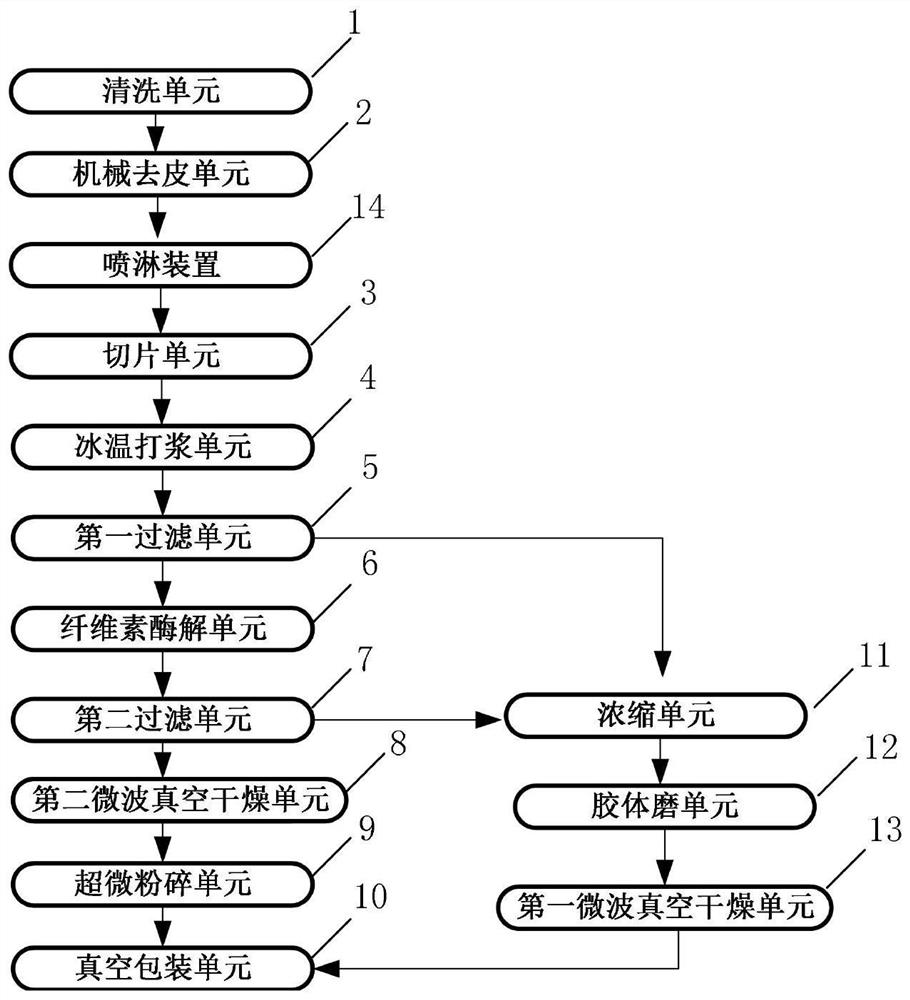

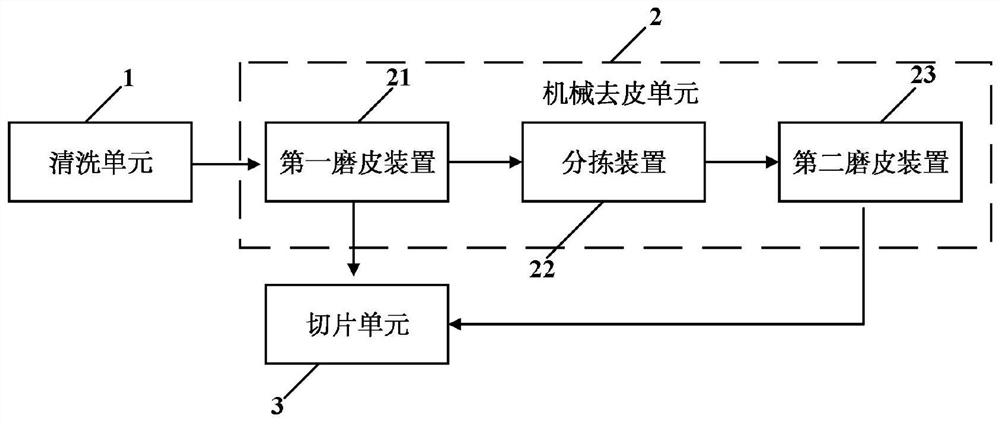

[0080]The specific process of producing whole potato powder by using the raw sweet potato powder production system provided by the present invention is as follows: the sweet potato enters the mechanical peeling unit 2 for peeling after the cleaning unit 1 cleans the surface sludge, and then enters the slicing unit 3 for slicing. , the slices enter the ice-temperature beating unit 4, mix the slices with 4°C ice water, beat with a crushing machine, and pulverize into a sweet potato slurry; the sweet potato slurry enters the first filter unit 5, and is separated into the first filtrate and the first filter residue; The first filter residue enters the cellulose enzymatic hydrolysis unit 6, and is further crushed with a masher, and is treated with cellulase at 0.3wt% of the first filter residue weight for 4 hours, squeezed and filtered to obtain the second filtrate and the second filter residue; After the first filtrate and the second filtrate are combined, enter the colloid mill un...

Embodiment 2

[0082] The specific process of producing whole potato powder by using the raw sweet potato powder production system provided by the present invention is as follows: the sweet potato enters the mechanical peeling unit 2 for peeling after the cleaning unit 1 cleans the surface sludge, and then enters the slicing unit 3 for slicing. , the slices enter the ice-temperature beating unit 4, mix the slices with 1°C ice water, beat with a crushing machine, and pulverize into sweet potato slurry; the sweet potato slurry enters the first filter unit 5, and is separated into the first filtrate and the first filter residue; The first filter residue enters the cellulose enzymatic hydrolysis unit 6, and is further crushed with a masher, and is treated with cellulase at 0.5 wt% of the weight of the first filter residue for 4 hours, squeezed and filtered to obtain the second filtrate and the second filter residue; After the first filtrate and the second filtrate are combined, enter the colloid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com