A steel silo unloading device

A technology of unloading device and steel silo, applied in the field of steel silo, can solve the problems of excessively fast cutting, dead zone of side wall, affecting the storage capacity of steel plate, etc., and achieve the effect of preventing hardening, improving fluidization capacity, and alleviating material hardening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

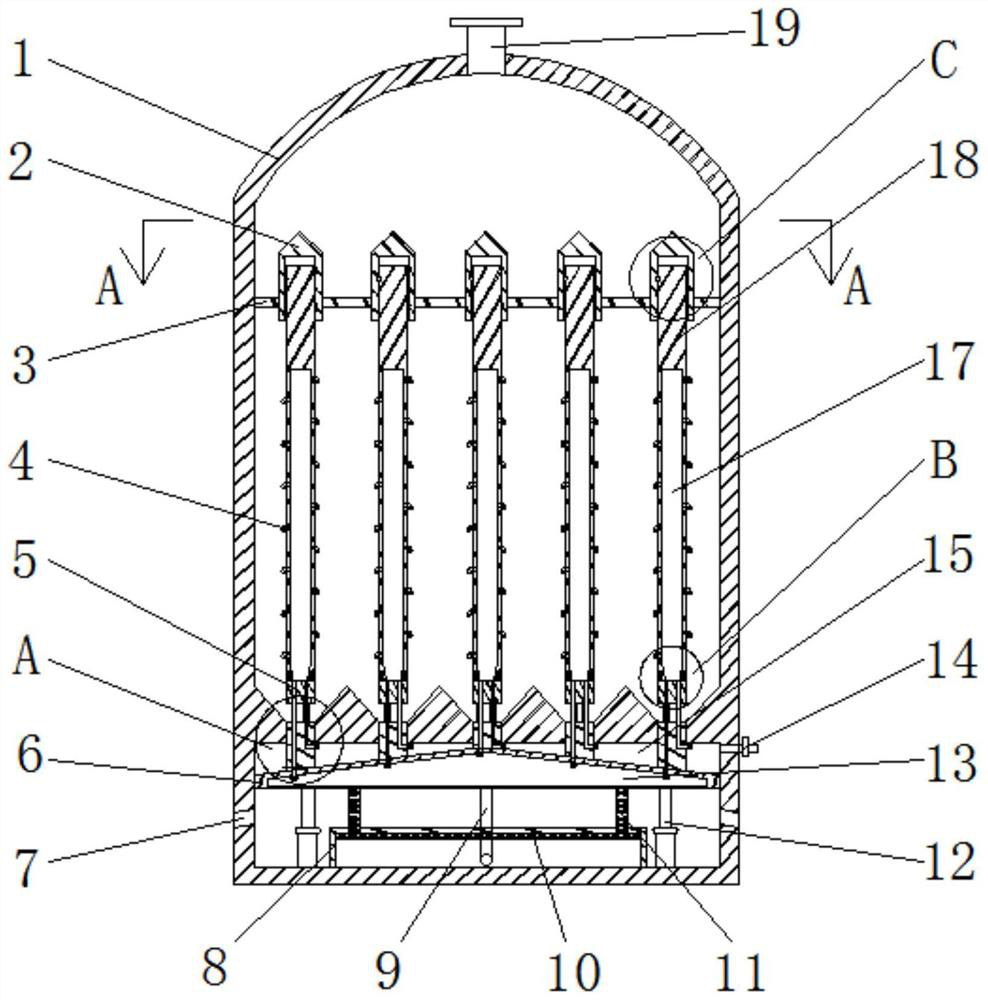

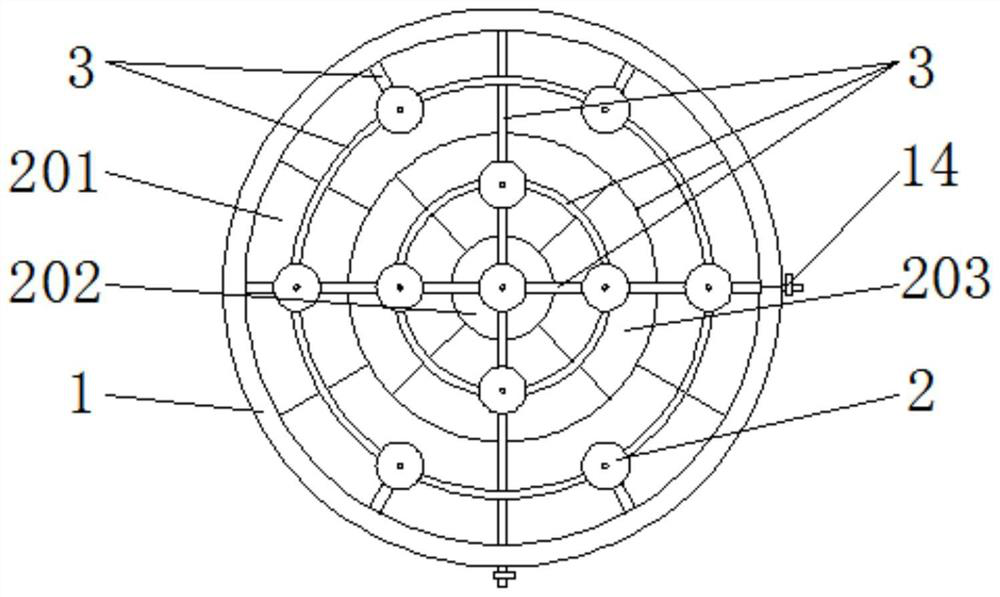

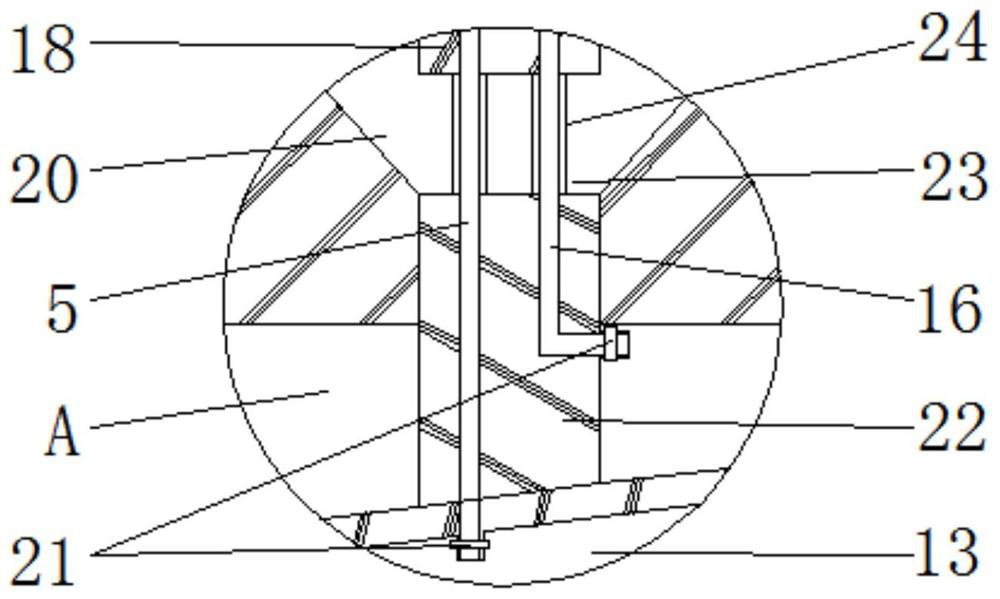

[0033] like figure 1 The shown unloading device for a steel silo includes a silo shell 1, and the upper and lower ends of the silo shell 1 are respectively provided with a feeding port 19 and a discharging port 7; There is a partition whose periphery is completely fitted with the inner wall of the silo shell 1, and the inner side of the silo shell 1 is divided into an upper chamber for storing materials and a lower chamber for installing driving components. The upper part of the partition is provided with A plurality of conical funnel-shaped unloading areas 20, and the lower part of the partition is provided with a one-to-one correspondence with the unloading area 20 and is connected with the bottom of the unloading area 20 and the lower chamber. Each of them is telescopically provided with a blocking rod 22 whose periphery is completely attached to the side wall of the discharge port. The lower end of each blocking rod 22 is jointly connected with a first piston plate 6 locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com