Patents

Literature

74results about How to "Improve the efficiency of dipping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production line of electrical equipment electric heating dipping and ultraviolet curing operation

InactiveCN101722129AEasy to placeEasy to controlPretreated surfacesManufacturing dynamo-electric machinesProduction lineEngineering

The invention discloses a production line of electrical equipment electric heating dipping and ultraviolet curing operation, which comprises a traction motor, an external power supply, a dipping cylinder, an ultraviolet curing lamp, a guide rail, conveying chains, a plurality of hanging devices and two segments of conductive devices; the guide rail is in a sunk arrangement, the hanging devices are arranged at intervals on the guide rails through rollers on a roller bracket, a brush holder and an electric brush are arranged at the upper part of the roller bracket, and the conveying chains are positioned below the guide rail, respectively fixedly connected with the roller bracket of the hanging devices and driven by the traction motor; the conductive devices comprise two segments of conductive copper bars and are respectively arranged at both sides of the guide rail, and the two segments of conductive devices are respectively connected with the external power supply; and the dipping cylinder is positioned below a sunk part of the guide rail, and the ultraviolet curing lamp is arranged at one side of the guide rail. The production line facilitates the placement and control for dipping equipment at each station, improves the dipping efficiency and can satisfy the requirement for mass production of dipping paint.

Owner:SHANGHAI BAOSTEEL EQUIP MAINTENANCE CO LTD

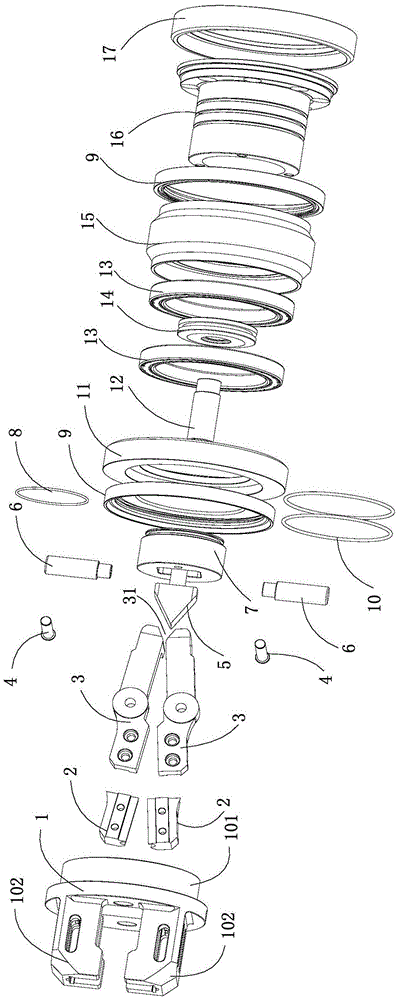

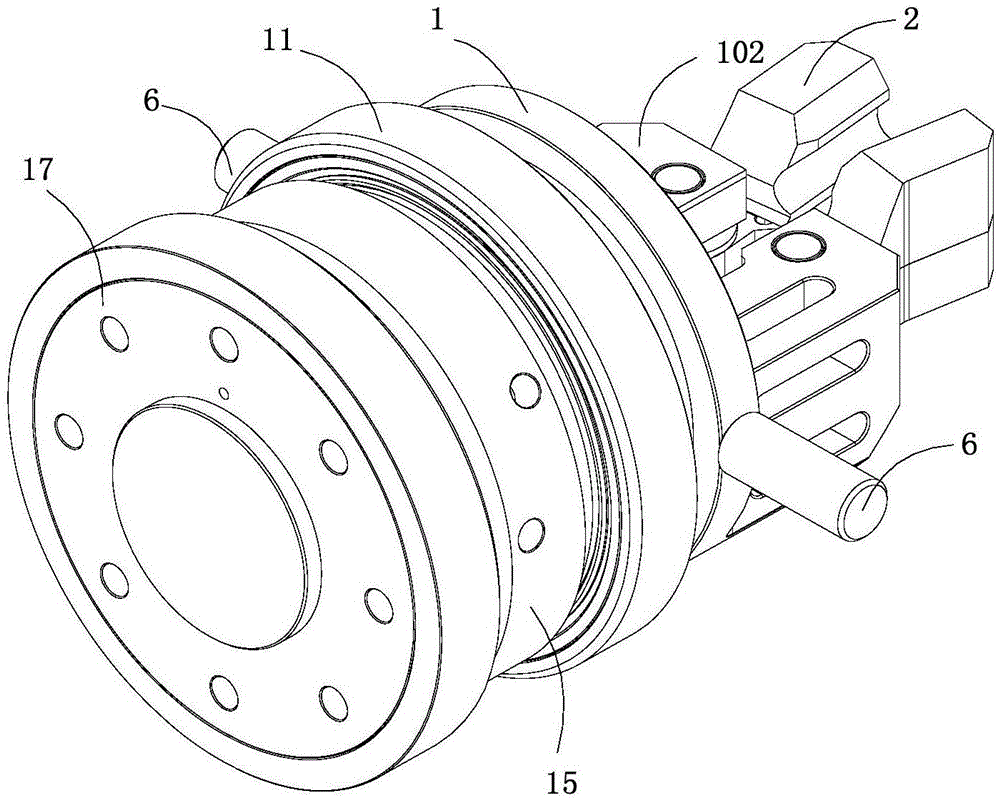

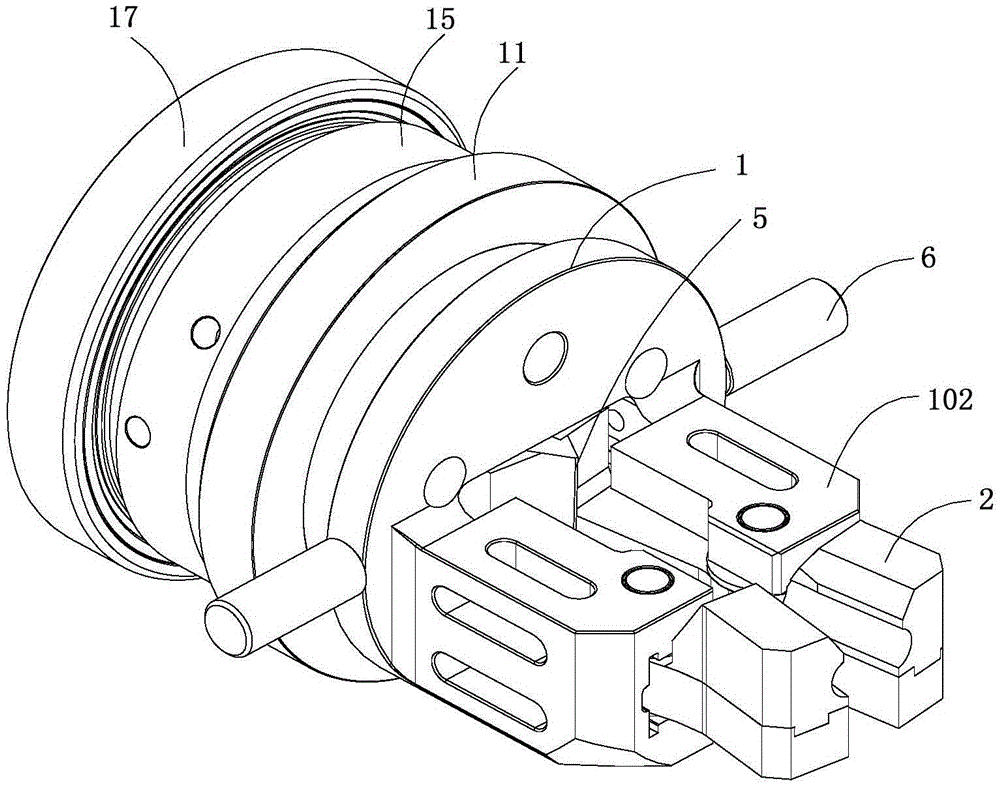

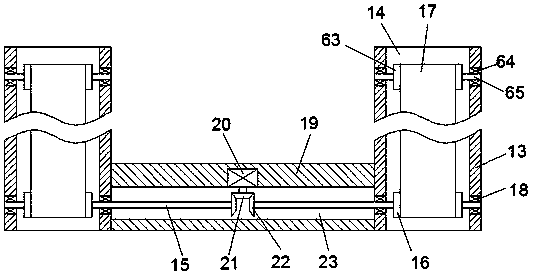

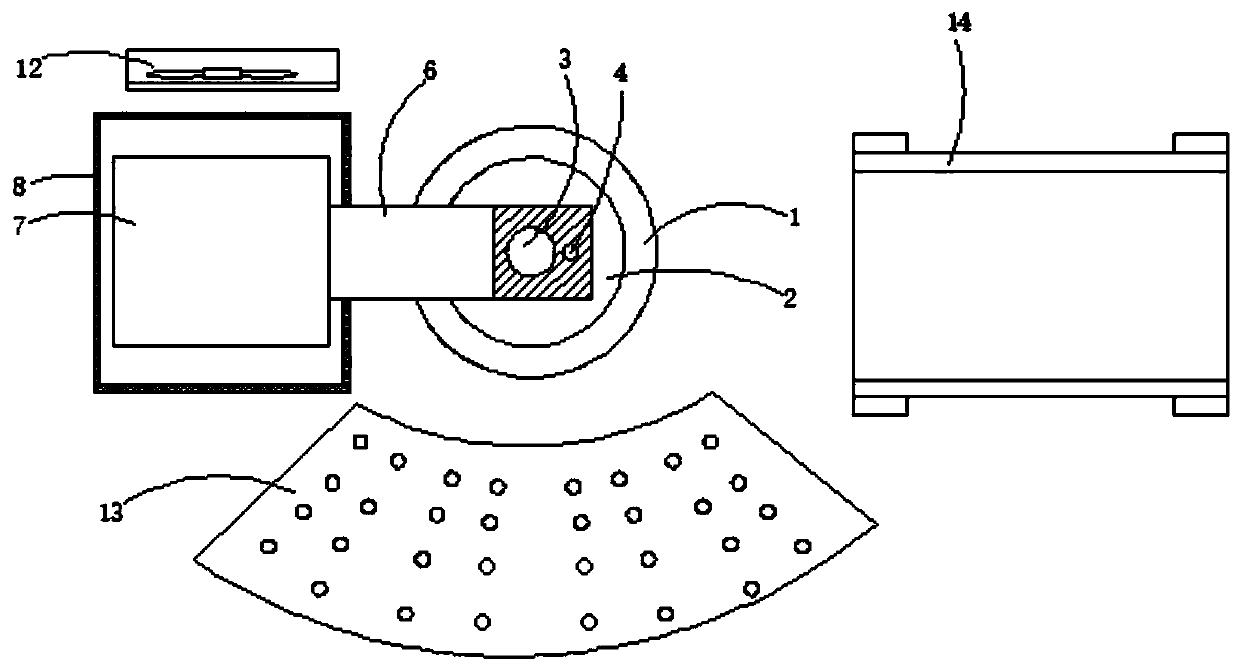

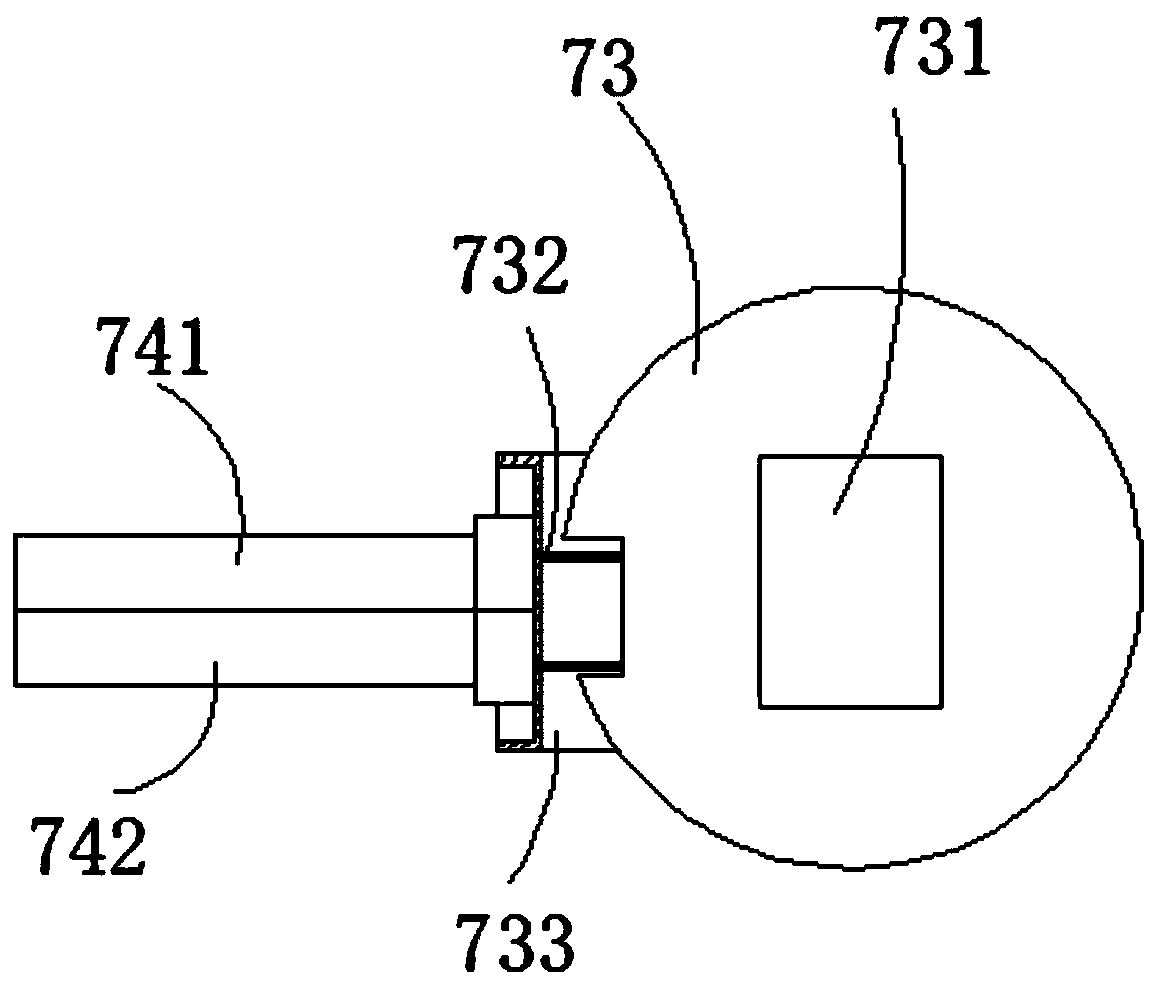

Special clamping jaw installed on mechanical arm for casting shell mold and used for slurry dipping

ActiveCN105598366APrecise structureImprove the efficiency of dippingGripping headsFoundry mouldsRobotic armEngineering

The invention discloses a special clamping jaw installed on a mechanical arm for casting a shell mold and used for slurry dipping. The special clamping jaw comprises a clamping part used for clamping a workpiece, a propping part used for propping the clamping part up so as to allow the clamping part to be enclosed, and a driving part used for pushing the propping part to rise, wherein the driving part has a driving end, the clamping part is connected with the driving part and forms an accommodating space together with the driving part, the propping part and the driving end are located in the accommodating space, and the driving end is connected with the propping part and in linkage with the propping part. The clamping jaw is mounted on the conventional mechanical arm and used in the process of slurry dipping, so automation of the process of slurry dipping is realized; and since an automatic slurry dipping manner is used for replacing a traditional artificial slurry dipping manner, slurry dipping efficiency is improved. In a preferable embodiment, the clamping jaw has a precise structure; and the pushing action of the piston rod of a cylinder is ingeniously utilized for controlling opening and closing of the clamping jaw so as to realize grabbing of the workpiece. The clamping jaw provided by the invention is mounted on a mechanical arm unit and cooperates with the mechanical arm unit to realize 360-DEG rotation, so flexibility and grabbing force can be perfectly controlled.

Owner:GUANGXING MACHINERY SCI & TECH HUIZHOU CO LTD

Textile dye cylinder easy to move

The invention discloses a dye vat for textiles which is easy to move, which comprises a dye vat body, the bottom of the inner cavity of the dye vat body is fixedly connected with a fixing plate, and the inner cavity of the dye vat body is movably connected with a dipping roller through a rotating shaft. The number of the dip dyeing cylinders is three, the two sides of the bottom of the inner cavity of the dye tank body are fixedly connected with a support base, the top of the support base is fixedly connected with a motor, and the output shaft of the motor is fixedly connected with a first gear, both sides of the bottom of the inner cavity of the dye vat body are movably connected with threaded rods through bearings. The invention can adjust the height of the lifting frame according to the needs, so that the dye vat body can be moved conveniently, which facilitates the process of feeding and unloading the dye vat body, saves a lot of time and manpower, and further improves the efficiency of textile dyeing. Improve the production efficiency of textiles and bring huge economic benefits to textile enterprises.

Owner:苏州晔鸿纺织有限公司

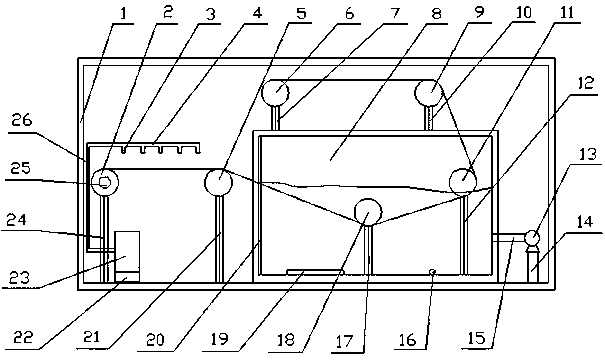

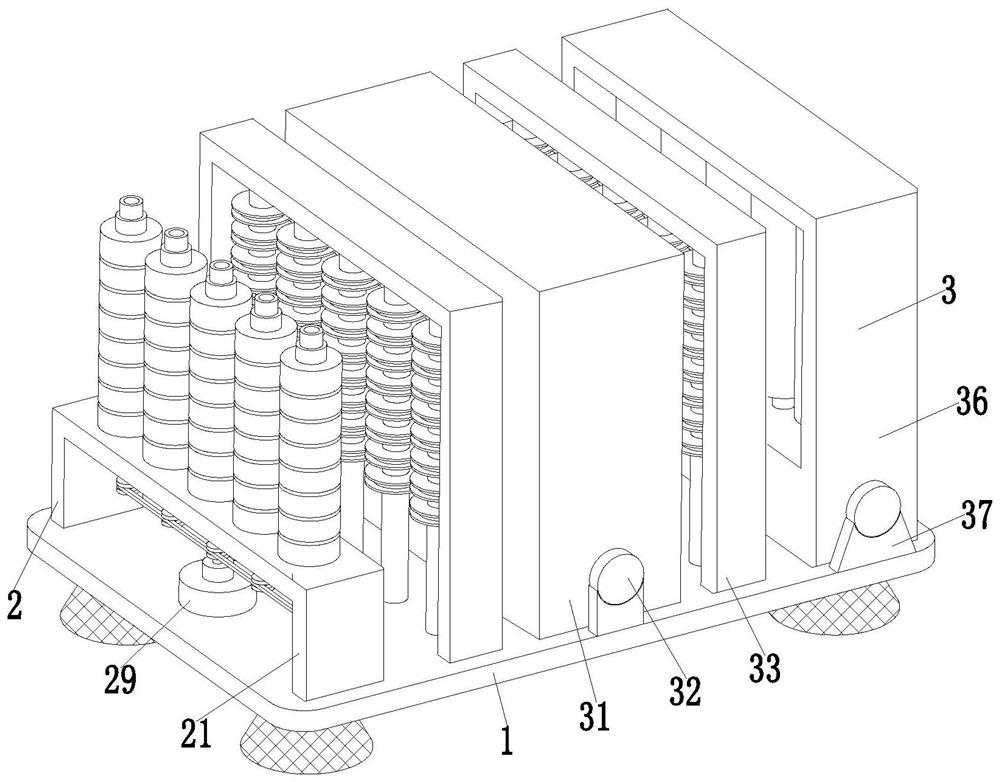

Efficient glaze dipping machine for ceramic insulators

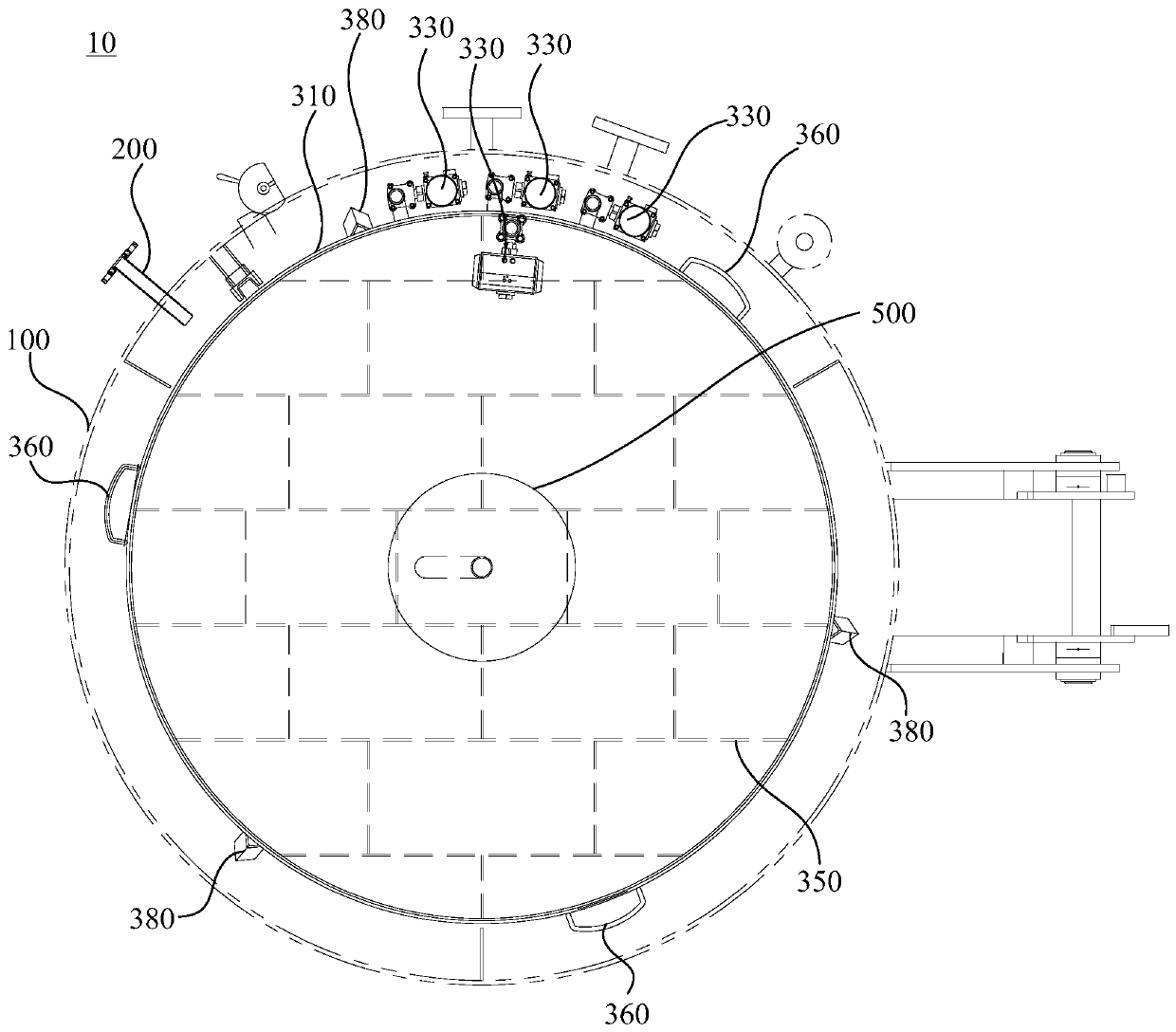

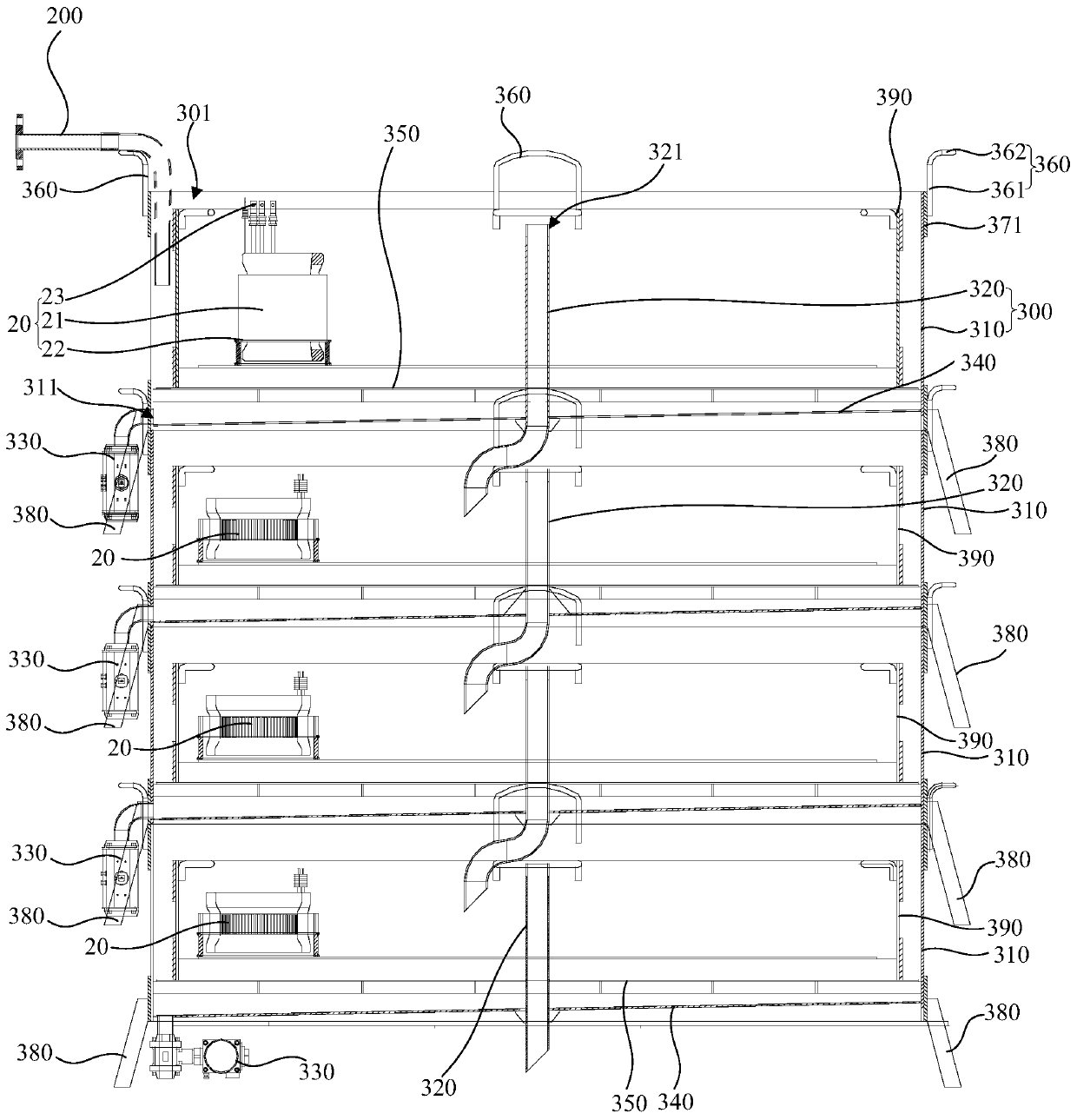

InactiveCN111391093AHigh degree of automationUnmanned operationCeramic shaping apparatusInsulatorsGlazeAssembly line

The invention discloses an efficient glaze dipping machine for ceramic insulators. The efficient glaze dipping machine comprises a glaze dipping cylinder which is arranged in the upper side end face and filled with glaze paint, wherein conveying bases are fixedly arranged on the left end face and the right end face of the glaze dipping cylinder, and the upper side end faces of the conveying basescorresponding to each other left and right are provided with circulating conveying devices capable of providing ceramic insulators for the glaze dipping cylinder in an assembly line mode. According tothe efficient glaze dipping machine for the ceramic insulators, a rotary wheel disc capable of rotating is arranged above the glaze dipping cylinder, glaze dipping devices arranged front and back arearranged on the cylindrical end face of the rotary wheel disc in an up and down and left and right symmetric mode, and then conveying belts for conveying the ceramic insulators in an assembly line mode are arranged on the left and right end faces of the glaze dipping cylinder; and according to the efficient glaze dipping machine for the ceramic insulators, the glaze dipping devices can clamp ceramic insulators which are not dipped in glaze on the conveying belt on the right side under the action of a pushing device, then the ceramic insulators are moved into the glaze dipping cylinder for rotary glaze dipping, and finally the ceramic insulators are moved onto the conveying belt on the left side to be conveyed away.

Owner:FUZHOU JINAN FENGRUMING CRAFTS CO LTD

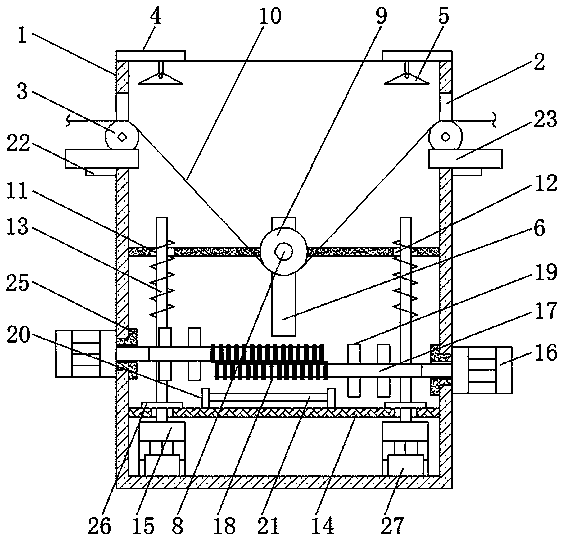

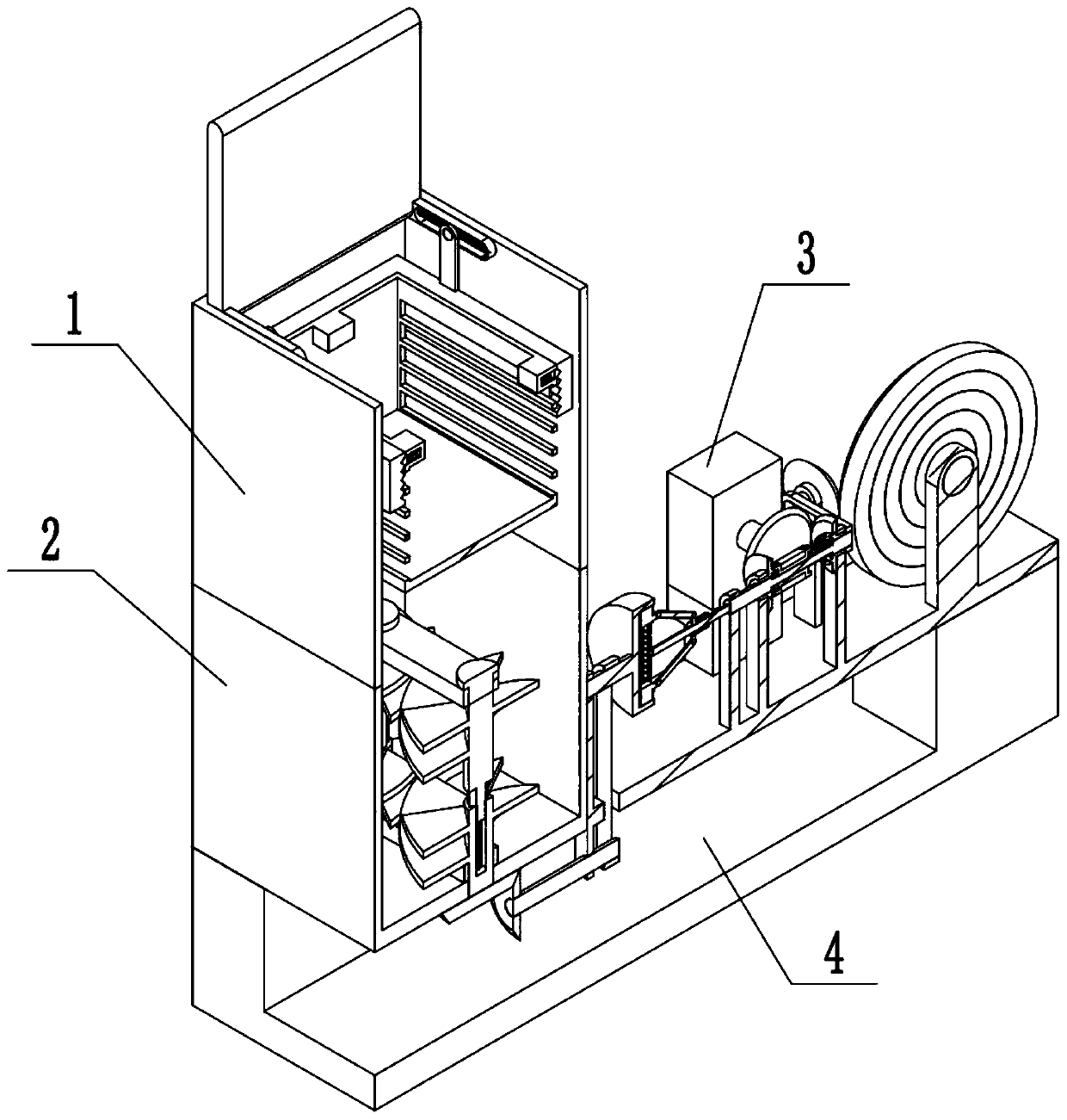

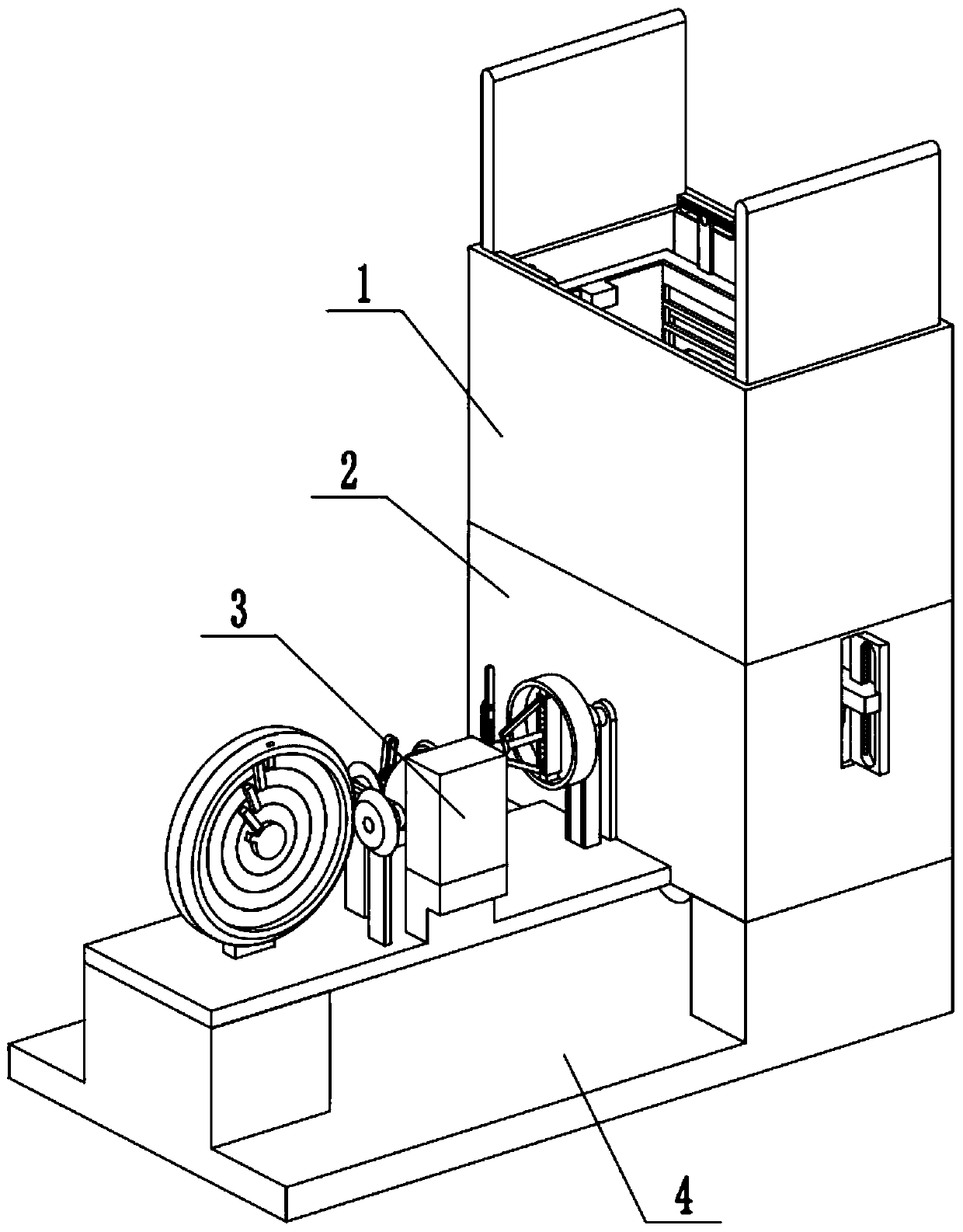

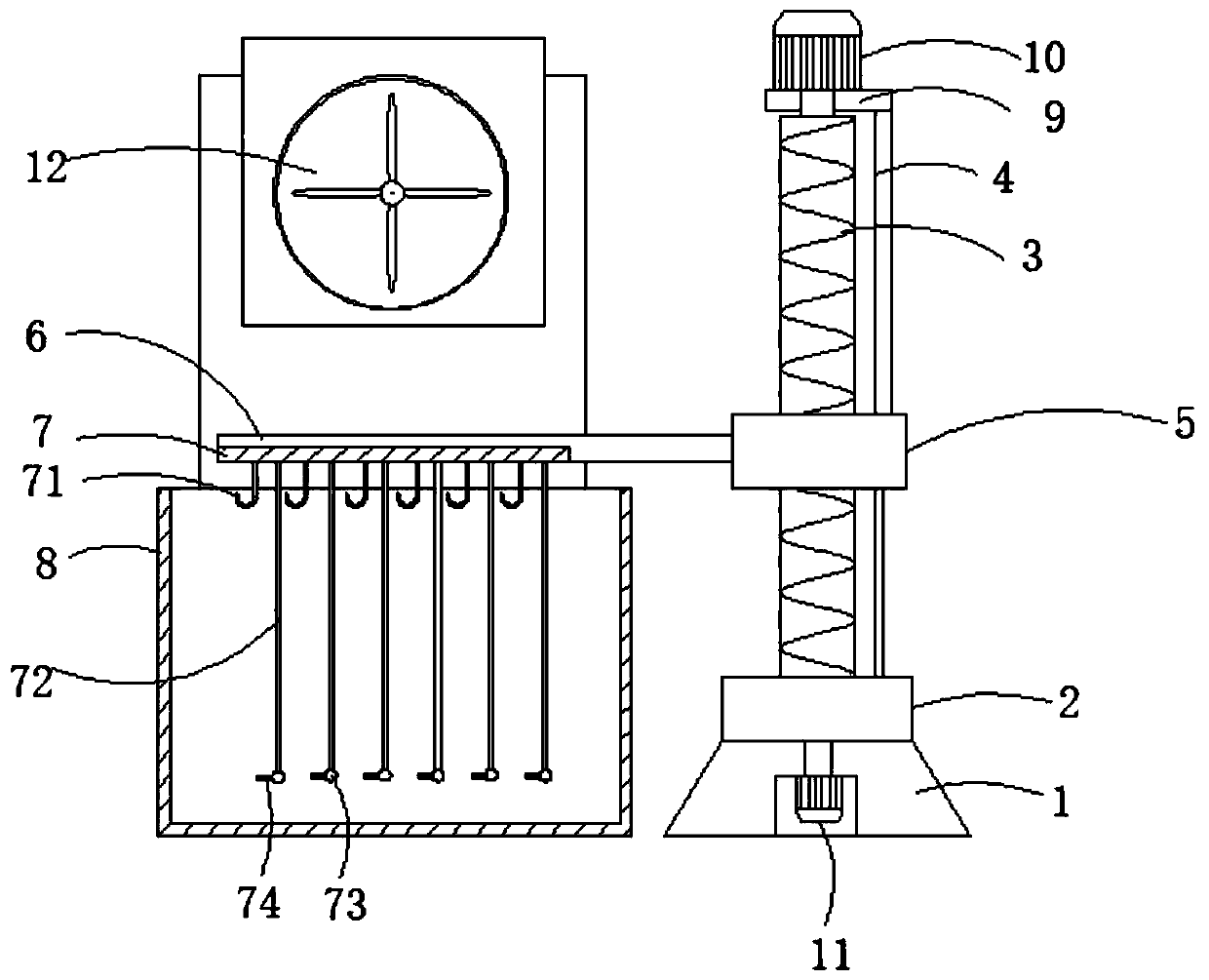

Paint dipping equipment for producing anchor chains

InactiveCN111420840ADip paint treatmentImprove the efficiency of dippingLiquid surface applicatorsCoatingsStructural engineeringAnnular array

The invention provides paint dipping equipment for producing anchor chains, and belongs to the technical field of anchor chain production processing equipment. The paint dipping equipment for producing the anchor chains comprises a processing box body, a servo motor, an electric push rod, a brake air cylinder and a paint-dipping box. A drive rod is arranged in the processing box body, one end of the drive rod is rotatably connected with the internal bottom of the processing box body through a bearing, the other end of the drive rod is fixedly connected with the bottom of the paint-dipping box,the paint-dipping box is rotatably connected with the inner side wall of the processing box body, a driven barrel fixedly sleeves the outer surface of the drive rod, a plurality of drive grooves areformed in the outer surface of the driven barrel, and the multiple drive grooves are distributed in an annular array mode. A driving plate drives a driven plate, a connecting long rod performs simpleharmonic vibration under the action of a vibrating spring, by matching with the rotation motion of the irregular speed of the paint-dipping box, even if overlapping positions between joints of the anchor chains can further be well subjected to paint-dipping treatment, and the paint dipping efficiency is greatly improved.

Owner:安徽省巢湖市凤凰锚链有限公司

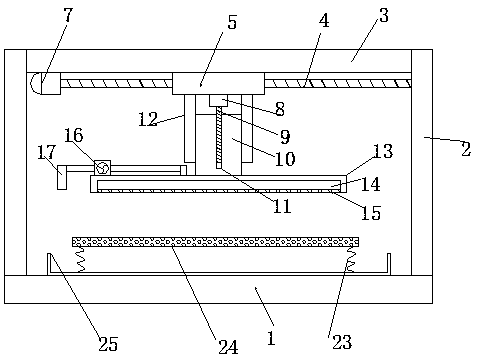

Textile cloth dip dyeing equipment with good dip dyeing effect

InactiveCN107663728AImprove the efficiency of dippingImprove dissolution efficiencyTextile treatment containersTextile treatment machine arrangementsEconomic benefitsEngineering

The invention discloses textile cloth dip dyeing equipment with good dip dyeing effect. The textile cloth dip dyeing equipment comprises a dyeing cylinder body, wherein through holes are respectivelyformed in the top parts of both sides of the dyeing cylinder body; an inner cavity of each through hole is movably connected with a first drum through a rotary shaft; both sides of the top part of thedyeing cylinder body are fixedly connected with connecting plates; the bottom part of each connecting plate is fixedly connected with a baking lamp; the bottom part of each baking lamp extends to thetop part of the inner cavity of the dyeing cylinder body; the front surface and back surface of the inner cavity of the dyeing cylinder body are respectively provided with a movable groove. The textile cloth dip dyeing equipment has the advantages that by arranging the movable grooves, movable blocks, rotary rods, a second drum, a textile cloth, lifting plates, lifting holes, threaded rods, fixedplates and first motors, the dip dyeing efficiency of the dip dyeing equipment can be effectively improved; by arranging the heating and stirring functions, the dissolving efficiency of a dyeing solution is improved, the uniformity of the dyeing solution is improved, the dip dyeing effect of the textile product is effectively improved, the quality of the textile product is ensured, and the huge economic benefit is brought for textile enterprises.

Owner:陈礼成

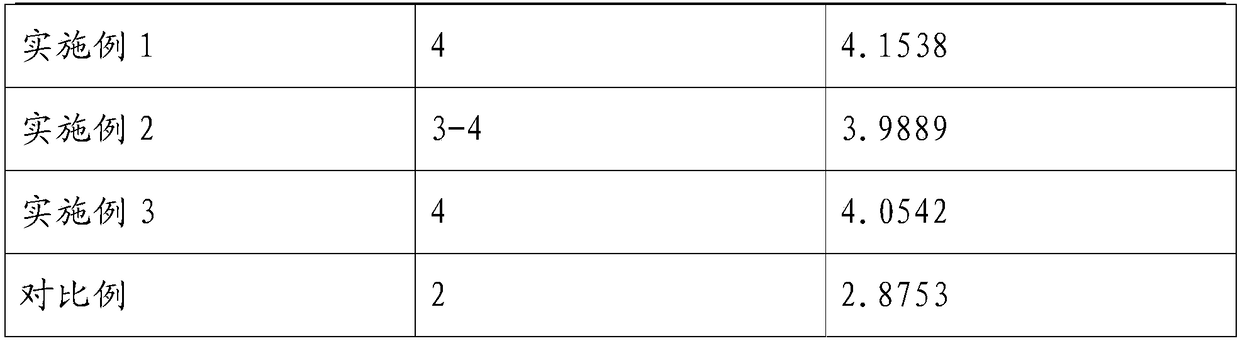

Preparation method for colorful gambiered canton silk and product and application of colorful gambiered canton silk

The invention belongs to the technical field of textile materials, relates to a preparation method, product and application of colorful gambiered canton silk and discloses novel colorful gambiered canton silk. The preparation method of the colorful gambiered canton silk comprises the steps of primary greige soaking and airing, secondary greige soaking and airing, silk boiling, soaking and airing, slurry treatment, sand washing, primary dyeing, secondary dyeing and softening. Compared with the prior art, the method is simple in process, short in production period and conforms to the modern concepts of low carbon, environmentally friendliness and energy saving; usage of consumable items in the dyeing process is saved, and the same preparation effect is achieved as well, the process cost is reduced, and the demand of a larger market group is met; the prepared colorful gambiered canton silk overcomes the defect that gambiered canton silk fabrics are single in color, the prepared colorful gambiered canton silk is high in color fastness and bright in color, and the gambiered canton silk fabrics have higher practicality and great market prospects in application to clothes.

Owner:SHENZHEN LIANGZI FASHION IND

Dipping glazing device for ceramic external surfaces

The invention discloses a dipping glazing device for ceramic external surfaces. The device includes: hydraulic cylinders, a glaze storage box, a bracket, a supporting plate and conical seats. The two hydraulic cylinders are positioned below the glaze storage box, and are respectively connected to both sides at the bottom of the glaze storage box. The bracket is located over the glaze storage box. The supporting plate is fixedly hung on the bracket, is equipped with the conical seats, and is a hollow plate. The dipping glazing device provided by the invention has the advantages of simple structure and convenient use. The dipping glazing height of ceramics is controlled through the hydraulic cylinders, the glazing height is controllable, and the efficiency of glazing to ceramic external surfaces is high.

Owner:ZHONGLI CERAMICS

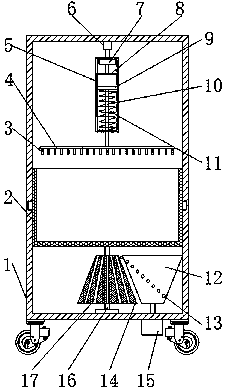

Rope head glue dipping device for rope for clothing

InactiveCN110965238AAvoid destructionAvoid inhalationTextile treatment containersTextile treatment machine arrangementsAdhesive glueElectric machinery

The invention discloses a rope head glue dipping device for a rope for clothing, and relates to the technical field of clothing. The rope head glue dipping device for the rope for clothing comprises aglue dipping box; four groups of supporting legs are mounted at the bottom of the glue dipping box by welding; first supporting plates are mounted on the adjacent side walls of the supporting legs bywelding; a protective cover is arranged above the glue dipping box; a mounting plate is mounted on the rear side of the protective cover by welding; a first motor is mounted at the bottom of the mounting plate by welding; a rotating rod is rotationally mounted on the outer wall of one side of the mounting plate; an output shaft of the first motor is fixedly connected with the rotating rod througha coupling; a connecting rod is rotationally mounted on the adjacent side walls of the protective cover; a supporting seat is mounted on the outer wall of one side of the glue dipping box by welding;and a first shell is mounted at the top of the supporting seat by welding. The rope head glue dipping device is ingenious in design, glue precipitation is effectively prevented, the glue dipping uniformity is improved to a certain extent, and the quality of rope head glue dipping is improved.

Owner:湖州邦族服饰有限公司

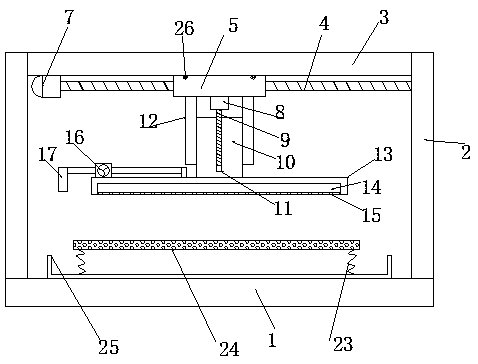

Leather dyeing device

ActiveCN109022642AImprove the efficiency of dippingSimple structureLeather/skins/hides/pelt chemical treatment apparatusHorizontal transmissionAgricultural engineering

The invention discloses a leather dyeing device. The leather dyeing device comprises a base. A mounting plate is arranged above the base. The left end and the right end of the mounting plate are fixedly connected with the base through supporting plates. A horizontal sliding block is slidably arranged on the lower end face of the mounting plate and is fixedly connected with the mounting plate through a horizontal transmission mechanism. The leather dyeing device is simple and reasonable in structure, convenient to transport and good in shock resistance; to-be-dyed leather is placed on a storageplate, the storage plate is located above a dyeing tank under the effect of reset springs, the horizontal position of a spraying disc is adjusted through the horizontal transmission mechanism, and then the height of the spraying disc is adjusted through a lifting mechanism, so that the storage plate is pressed in the dyeing tank; afterwards, dye in the dyeing tank is pumped into the dyeing disc through a liquid pump, and then the dye is sprayed towards the storage plate through spraying holes, so that active dyeing is achieved, and the leather dyeing effect is improved.

Owner:温州晨曦工艺品有限公司

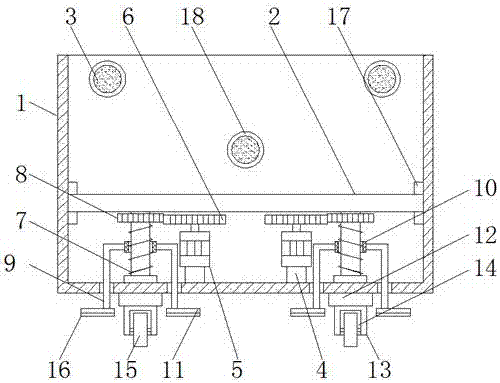

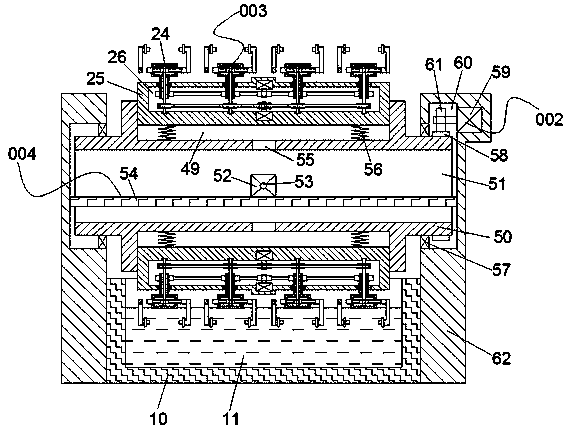

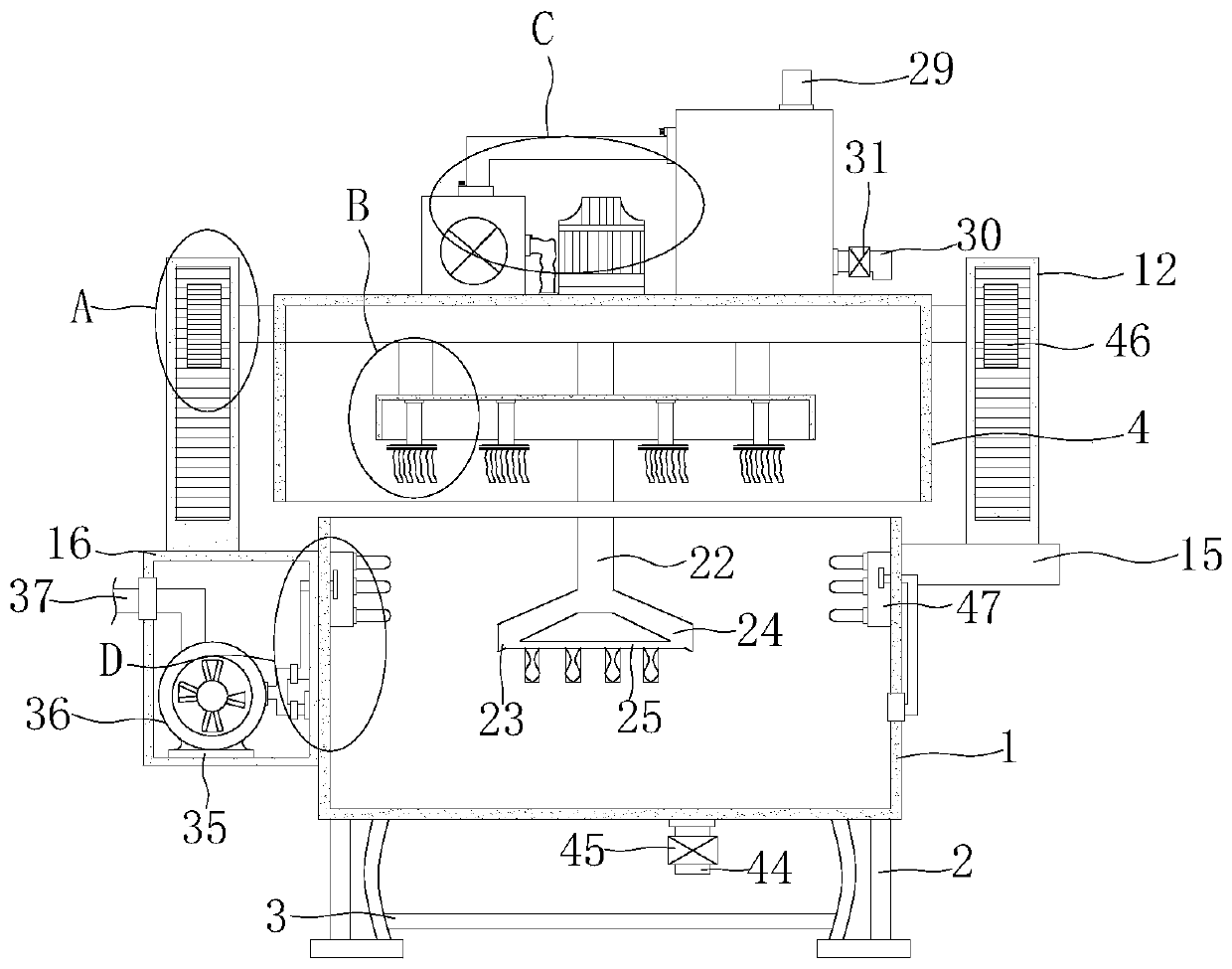

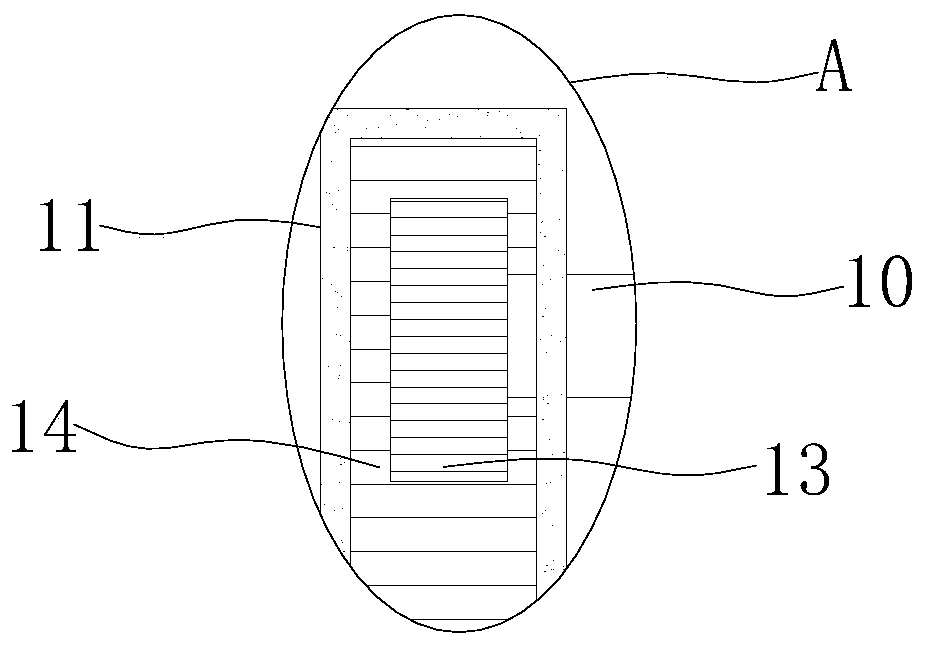

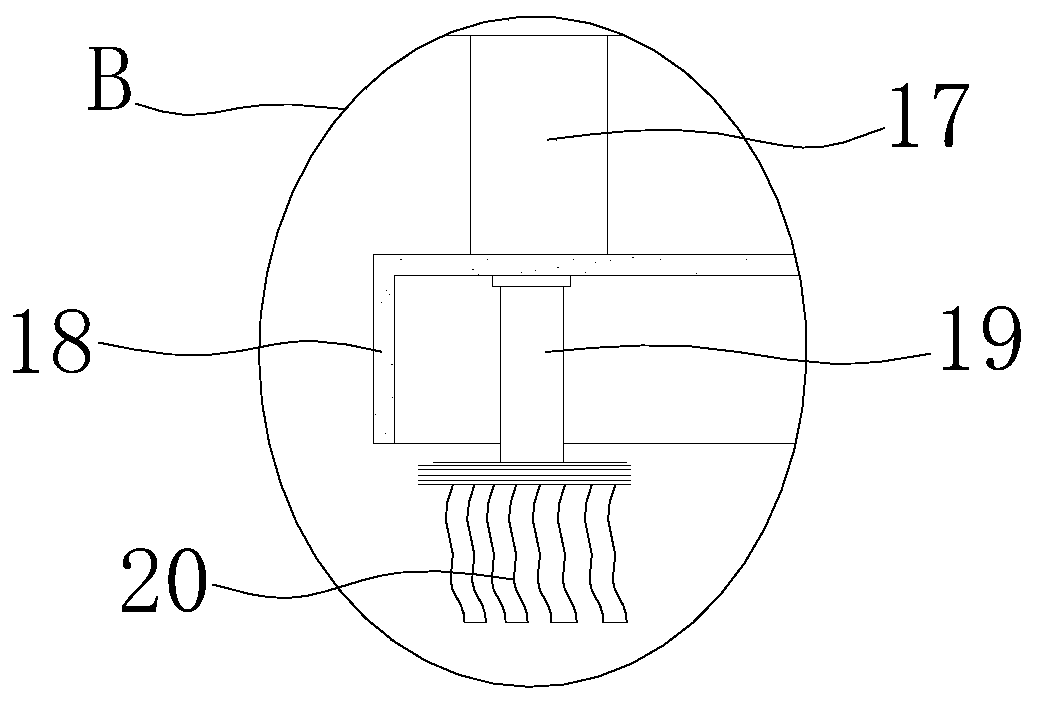

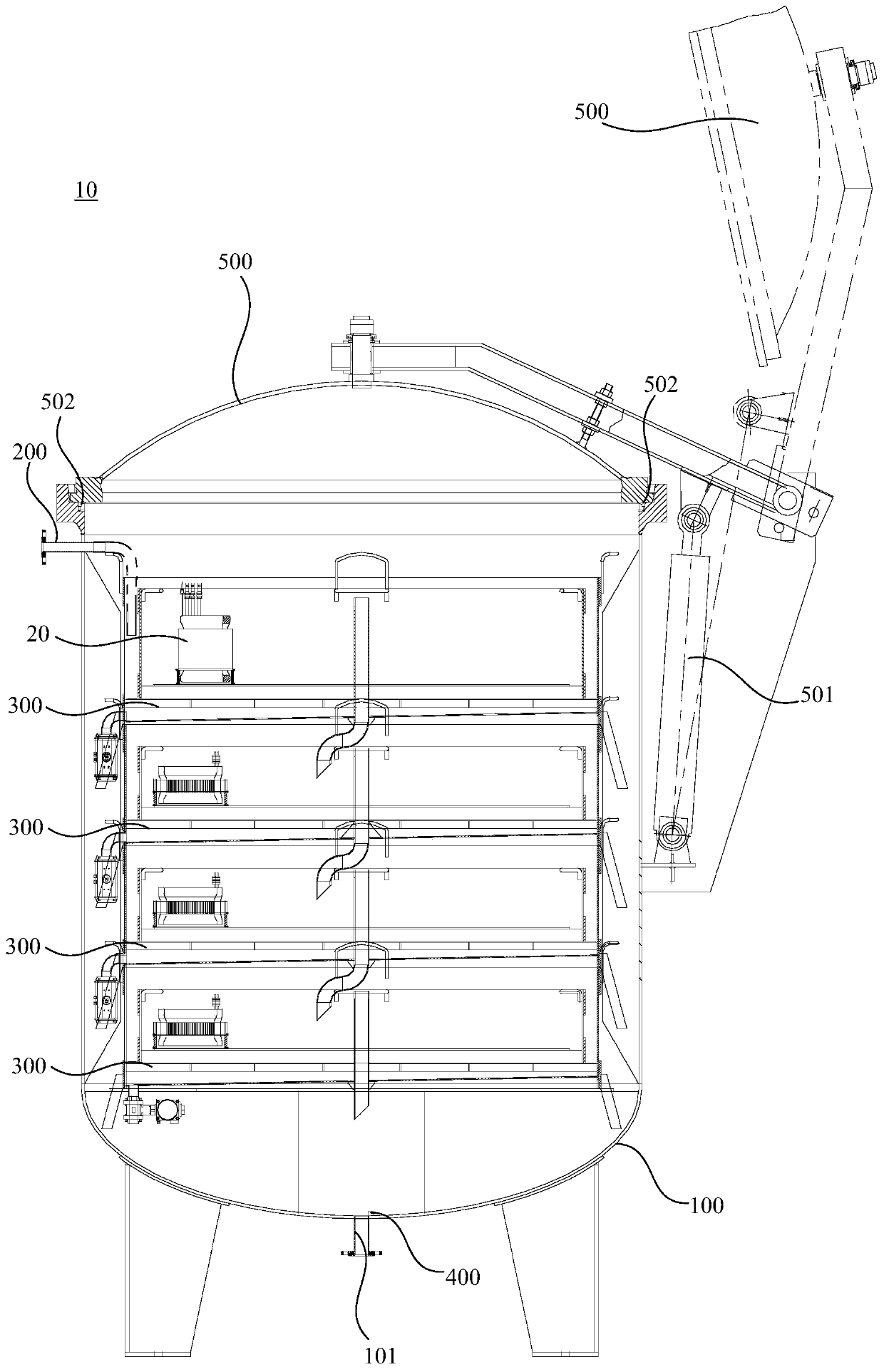

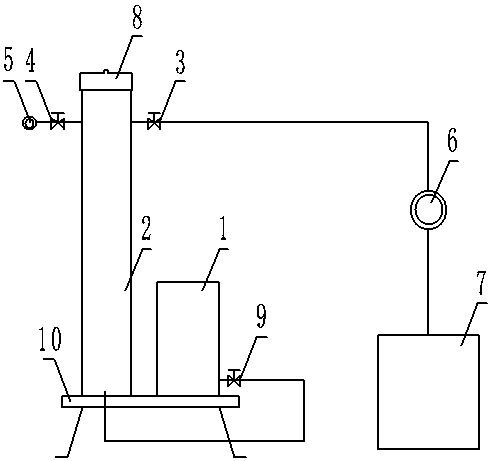

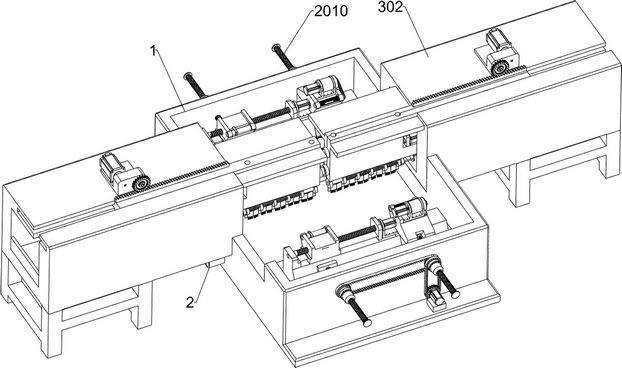

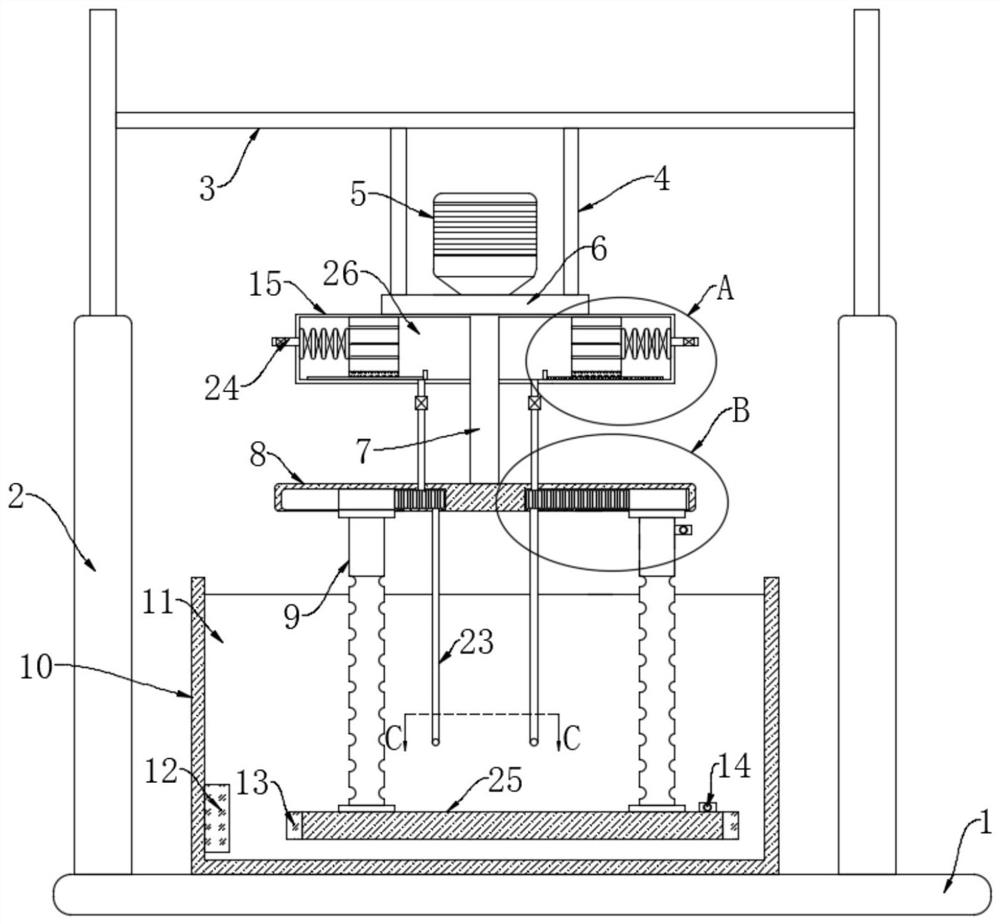

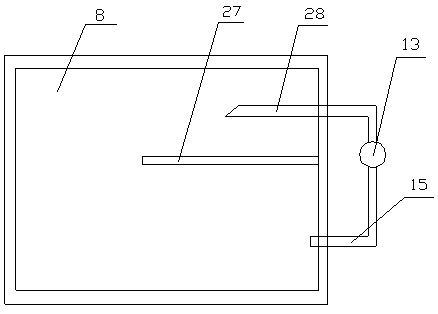

Vacuum pressure impregnating device and paint impregnating method thereof

InactiveCN109980873ALess paint lossImprove the efficiency of dippingApplying solid insulationVacuum pressureLacquer

The invention relates to a vacuum pressure impregnating device and a paint impregnating method thereof. The vacuum pressure impregnating device comprises an impregnating vessel, a paint conveying pipeand at least two paint impregnating bushes. A mode of inputting insulation paint from the upper portion of the paint conveying pipe and allowing the insulation paint to flow to the lower portion through an overflow port is employed so that the insulation paint is not required to fill the bottom portion of the impregnating vessel when the insulation paint is transmitted and the input amount of theinsulation paint is little in the same impregnating condition. The at least two paint impregnating bushes are stacked to impregnate at least layer of motor stators once so that the impregnating efficiency is high.

Owner:CHONGQING JINKANG POWER NEW ENERGY CO LTD

Vacuum varnish dipping method for oil tank oil measurement sensor plastic pipe

ActiveCN109530174AHigh mechanical strengthImprove fill rateLiquid surface applicatorsVacuum gaugesFuel tankInlet valve

The invention discloses a vacuum varnish dipping method for an oil tank oil measurement sensor plastic pipe, and belongs to the technical field of varnish dipping methods. The method comprises the following steps that S3, the vacuum degree is tested, a varnish dipping cylinder is sealed through a sealing cover, after a varnish inlet valve between the varnish dipping cylinder and a varnish storagetank is closed, a gas inlet valve and a vacuum gauge valve at the upper end of the varnish dipping cylinder are opened, then a vacuum pump is started for vacuumizing the varnish dipping cylinder for 1-2 minutes, thus, the vacuum degree in the varnish dipping cylinder is higher than -0.085MPa, the required time is recorded, the vacuum gauge valve is closed, and the varnish inlet valve is opened, sothat the varnish dipping cylinder communicates with the varnish storage tank so as to communicate with the outside; and S4, a part is subjected to varnish dipping, specifically, prepared and cured varnish is poured into the varnish storage tank, the varnish inlet valve is closed, and the sealing cover on the varnish dipping cylinder is taken down. The method is low in cost and insulation varnishconsumption, the penetration ability of insulation varnish can be improved, the filling rate of insulation varnish can be increased, defects such as pinholes, bubbles and pits in plastic pipe part substrates can be eliminated, and thus the overall mechanical strength, insulation strength and moisture and mildew resistance of the plastic pipe are improved.

Owner:四川泛华航空仪表电器有限公司

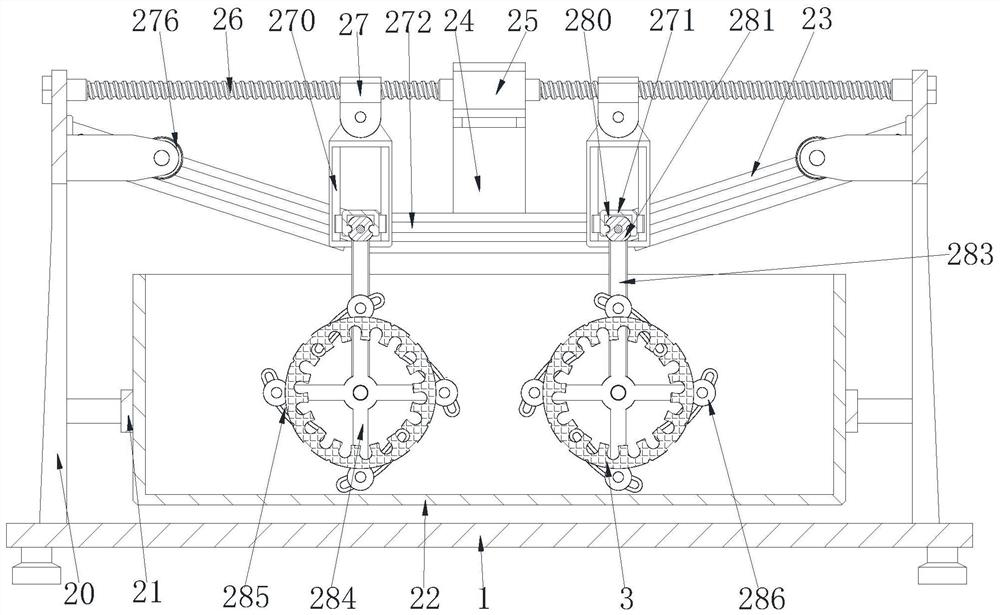

Dyeing device for non-woven fabrics for medical masks

InactiveCN111501251ARealize reciprocating stirringOptimize power outputLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsNonwoven fabricPhysics

The invention relates to the field of medical application, in particular to a dyeing device for non-woven fabrics for medical masks. The dyeing device can realize the bearing for the medical non-wovenfabrics and can adjust the quality of the born medical non-woven fabrics at the same time, can dye the medical non-woven fabrics and can adjust the dyeing effect on the medical non-woven fabrics according to the actual situation at the same time, and can realize the dyeing efficiency of the medical non-woven fabrics. The dyeing device comprises a bearing assembly, a dyeing assembly, a power source assembly and a fixed underframe. A cone gear shaft I is driven to rotate by a cone gear shaft belt, further a cone gear I is driven to rotate through a cone gear II, and then power output is facilitated. When a matching casing pipe is separated from a cone gear III, and the matching casing pipe is matched and connected with a cone gear V, the transmission relationships drive an agitating blade I, an agitating blade II, an agitating blade III, an agitating blade IV, an agitating blade mixing blade and an agitating blade VI for reciprocating rotation at the same time, then the reciprocating agitation of a dye solution is realized, and further the dyeing efficiency is conveniently improved.

Owner:郭淑琴

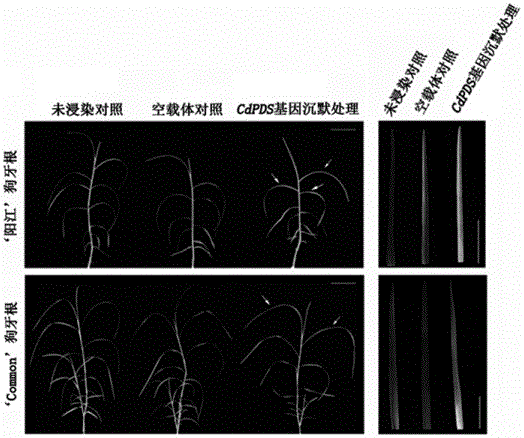

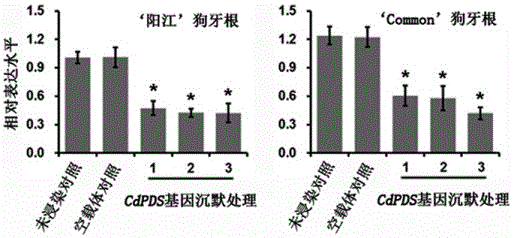

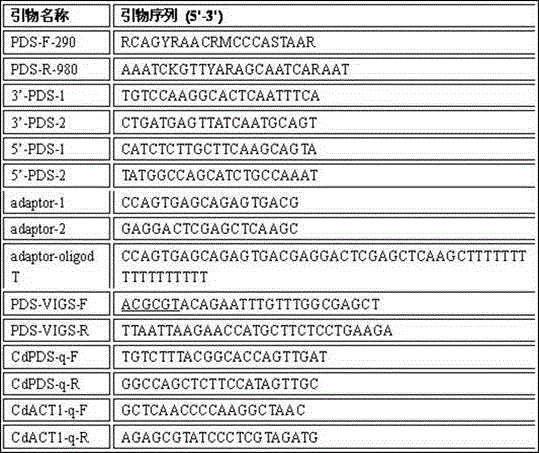

Method for efficiently and rapidly inhibiting endogenous-gene expression of cynodon dactylon

InactiveCN105671052AQuick analysisImprove the efficiency of dippingMicrobiological testing/measurementOxidoreductasesMolecular breedingCynodon dactylon

The invention discloses a method for efficiently and rapidly inhibiting endogenous-gene expression of cynodon dactylon. As genetic transformation of cynodon dactylon is quite difficult, the development of gene-function research and molecular breeding work of cynodon dactylon is seriously restricted. According to the new method, expression of endogenous genes of cynodon dactylon is specifically reduced through agrobacterium tumefaciens mediated transformation rice-tungro-bacilliform-virus-gene silencing vectors, and efficient and rapid technical means are provided for researching the gene function of cynodon dactylon. The method includes the following steps of 1, cloning of cynodon-dactylon target gene segments; 2, construction of the virus-induced gene silencing vectors; 3, cynodon-dactylon plant agrobacterium infection; 4, gene-expression-abundance molecular detection. By means of the method, expression of the endogenous genes of the cynodon dactylon can be successfully reduced by 50% or above.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

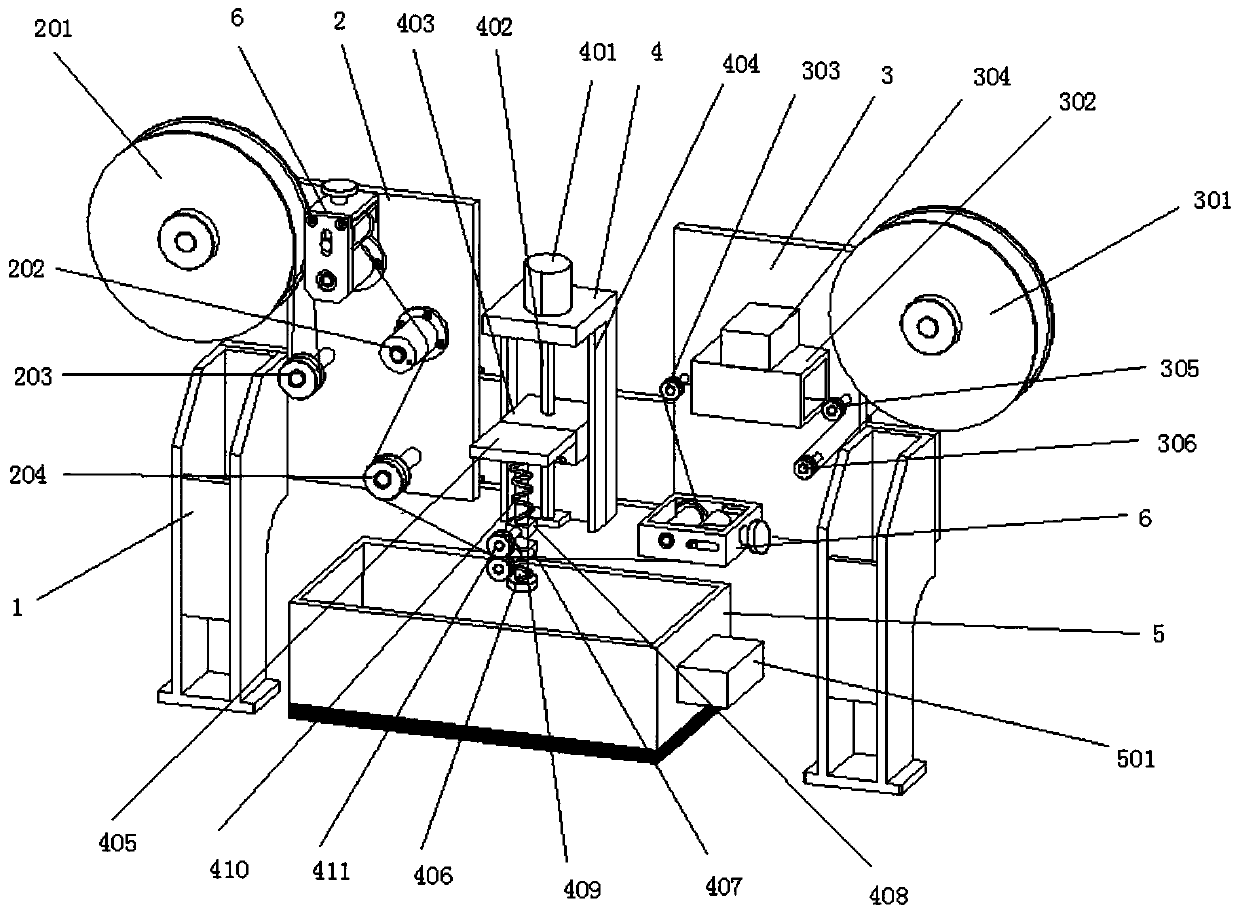

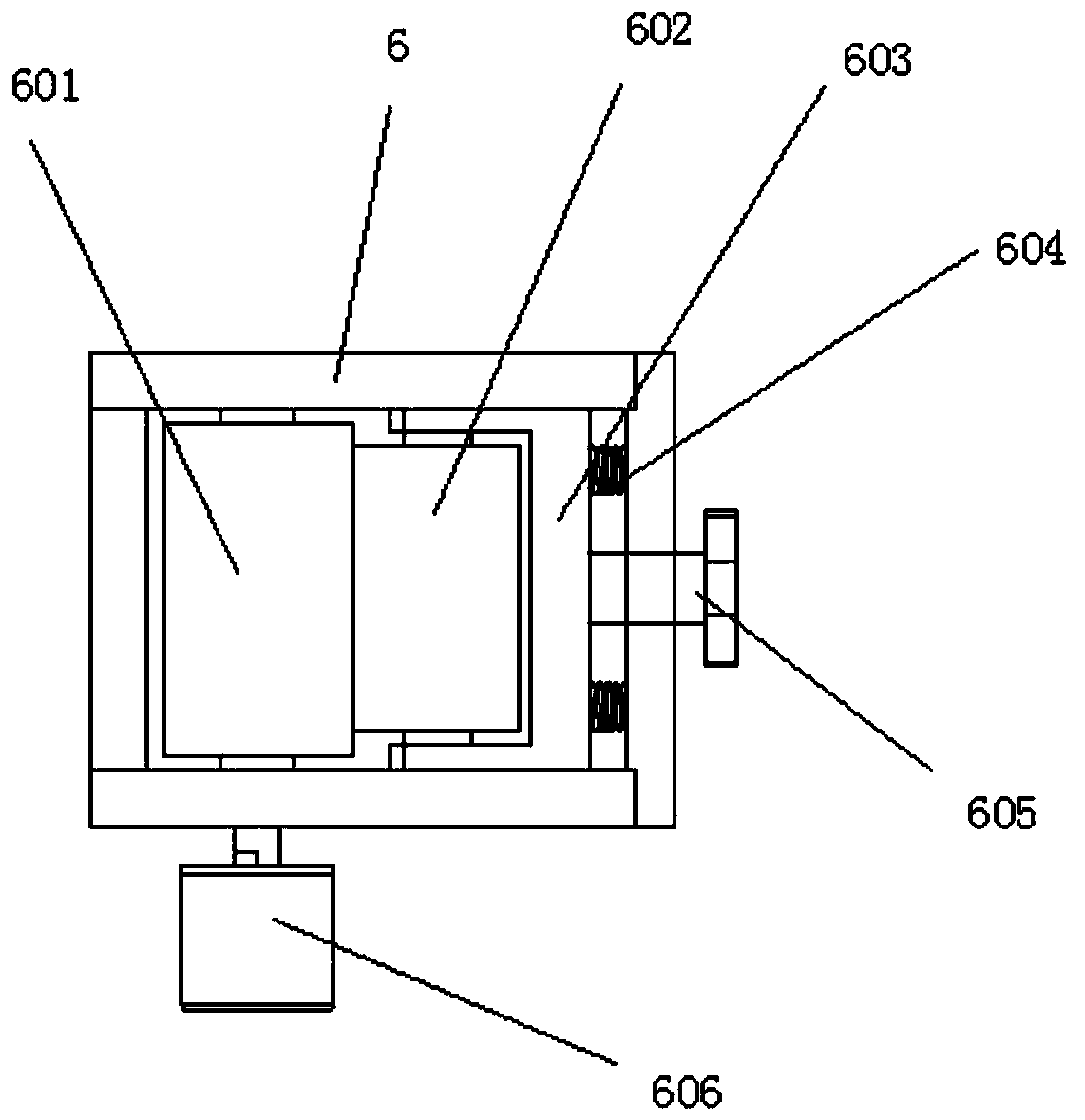

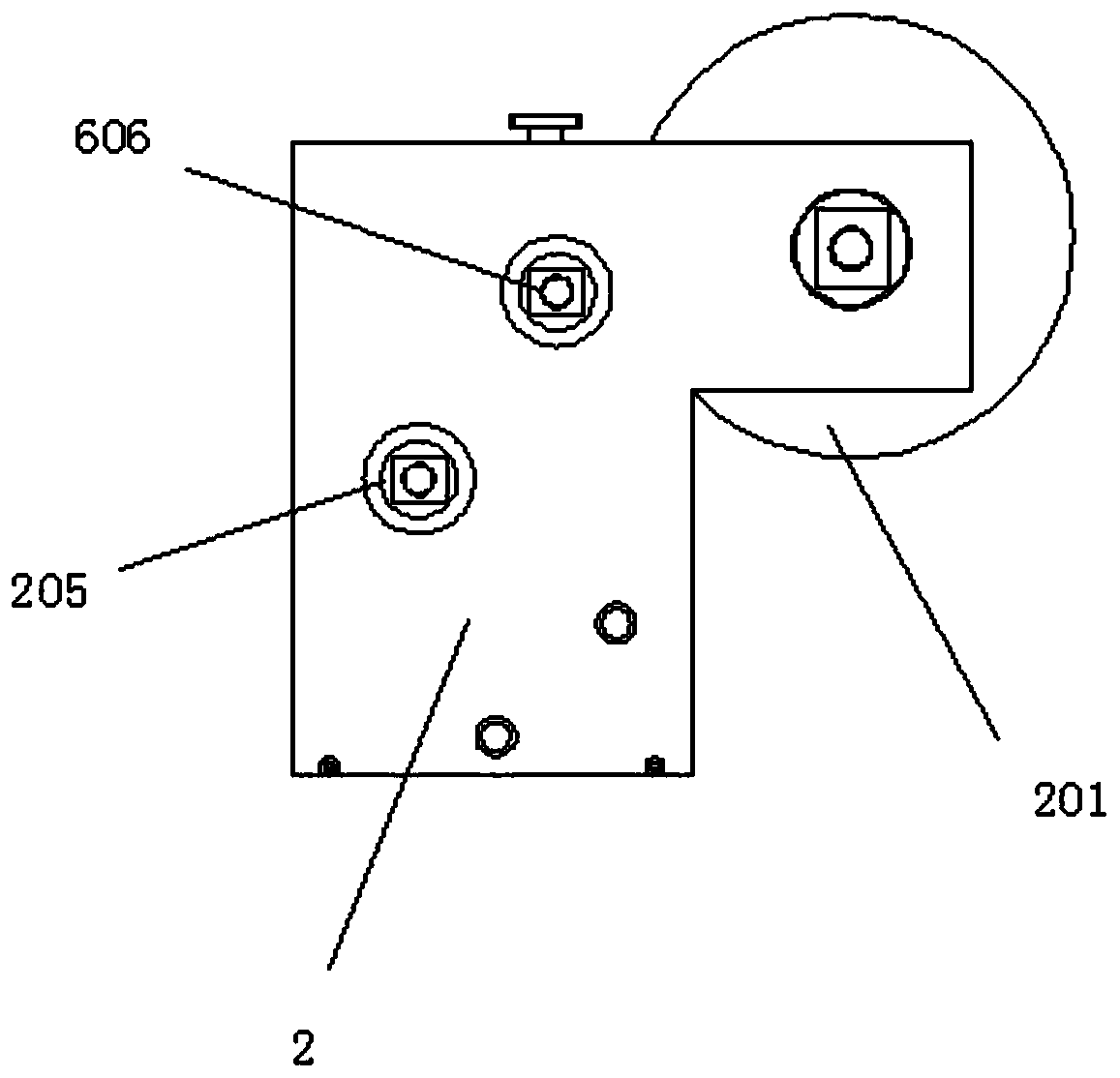

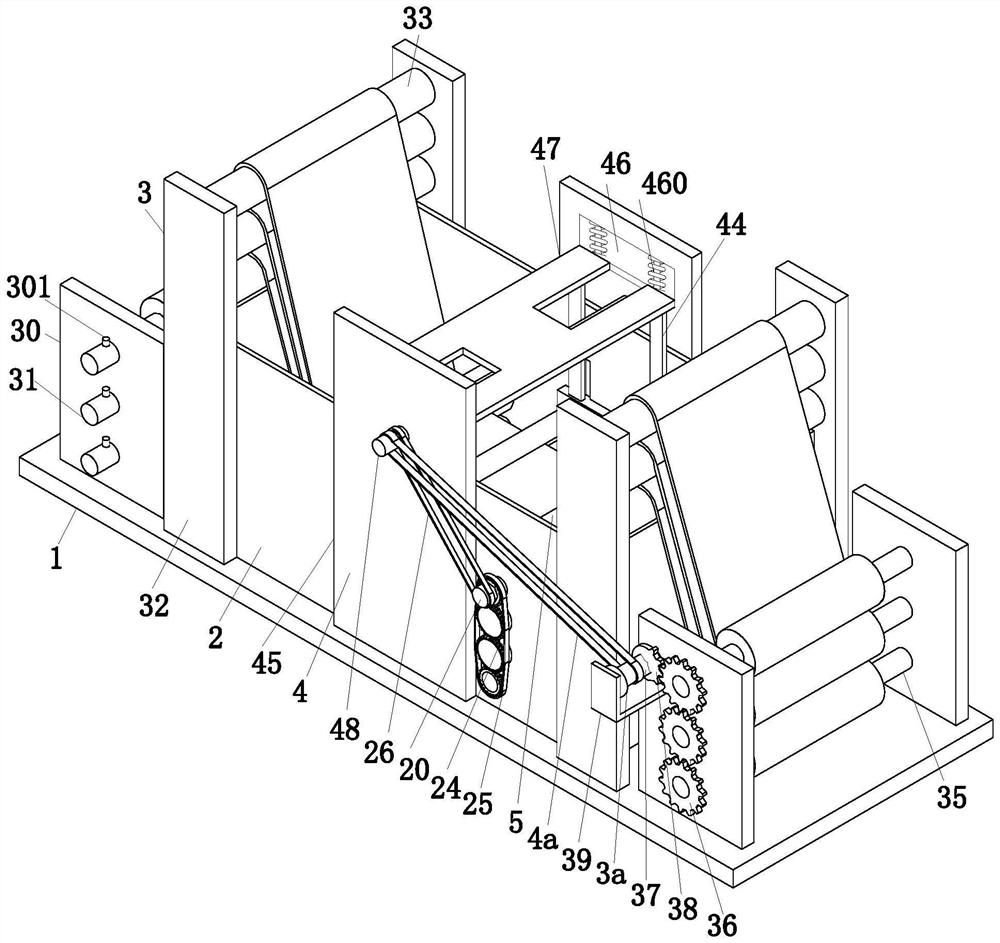

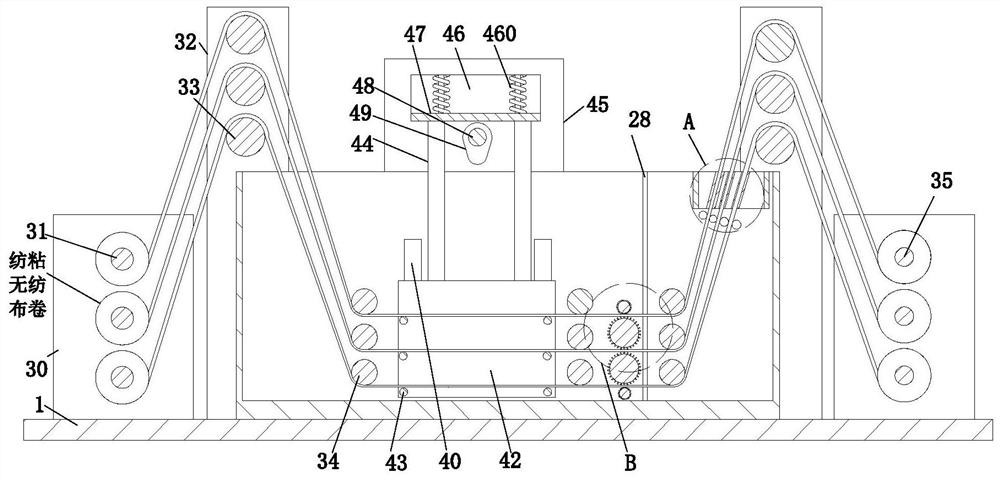

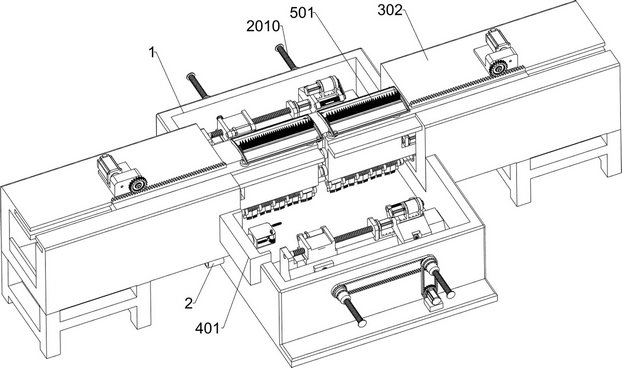

Impregnation equipment for yarn strengthening processing and use method of impregnation equipment

InactiveCN110846827AShort tripReduce adsorptionFibre cleaning/openingLiquid/gas/vapor removalYarnEngineering

The invention discloses impregnation equipment for yarn strengthening processing and a use method of the impregnation equipment. The impregnation equipment comprises a portal frame, an unwinding diskmounting frame and a winding disk mounting frame are arranged at two ends of a portal frame beam, a pressing frame is fixedly arranged in the middle of the portal frame beam, a gum storage box is arranged on the ground in the middle of the portal frame and positioned below the pressing frame, the unwinding disk mounting frame, the pressing frame and the winding disk mounting frame are arranged onthe portal frame, so that yarn discharging, impregnation and winding processes of a yarn impregnation technology are completed on the same machine, the use cost of the yarn impregnation equipment is reduced, the yarn impregnation equipment is more compact, a yarn before impregnation is swept by sweeping rollers, burrs or dust in the yarn can be effectively removed, the impregnated yarn is dried bya drying cavity, a traditional yarn drying mode by lengthening the route of the yarn is abandoned, and yarn impregnation efficiency is greatly improved.

Owner:安徽正美线业科技股份有限公司

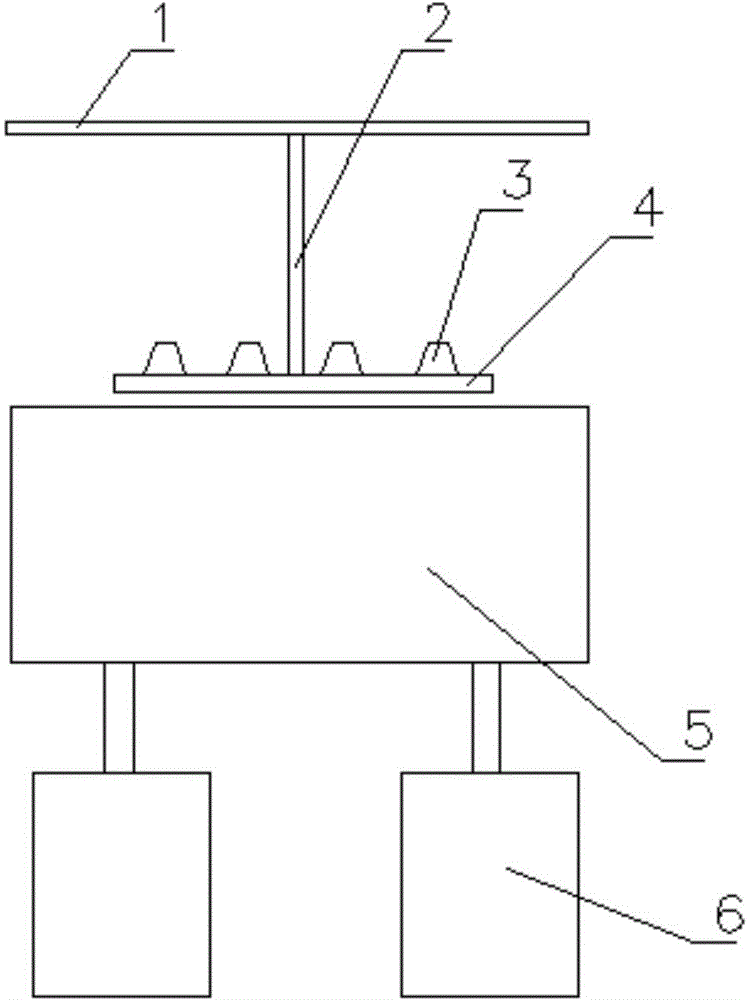

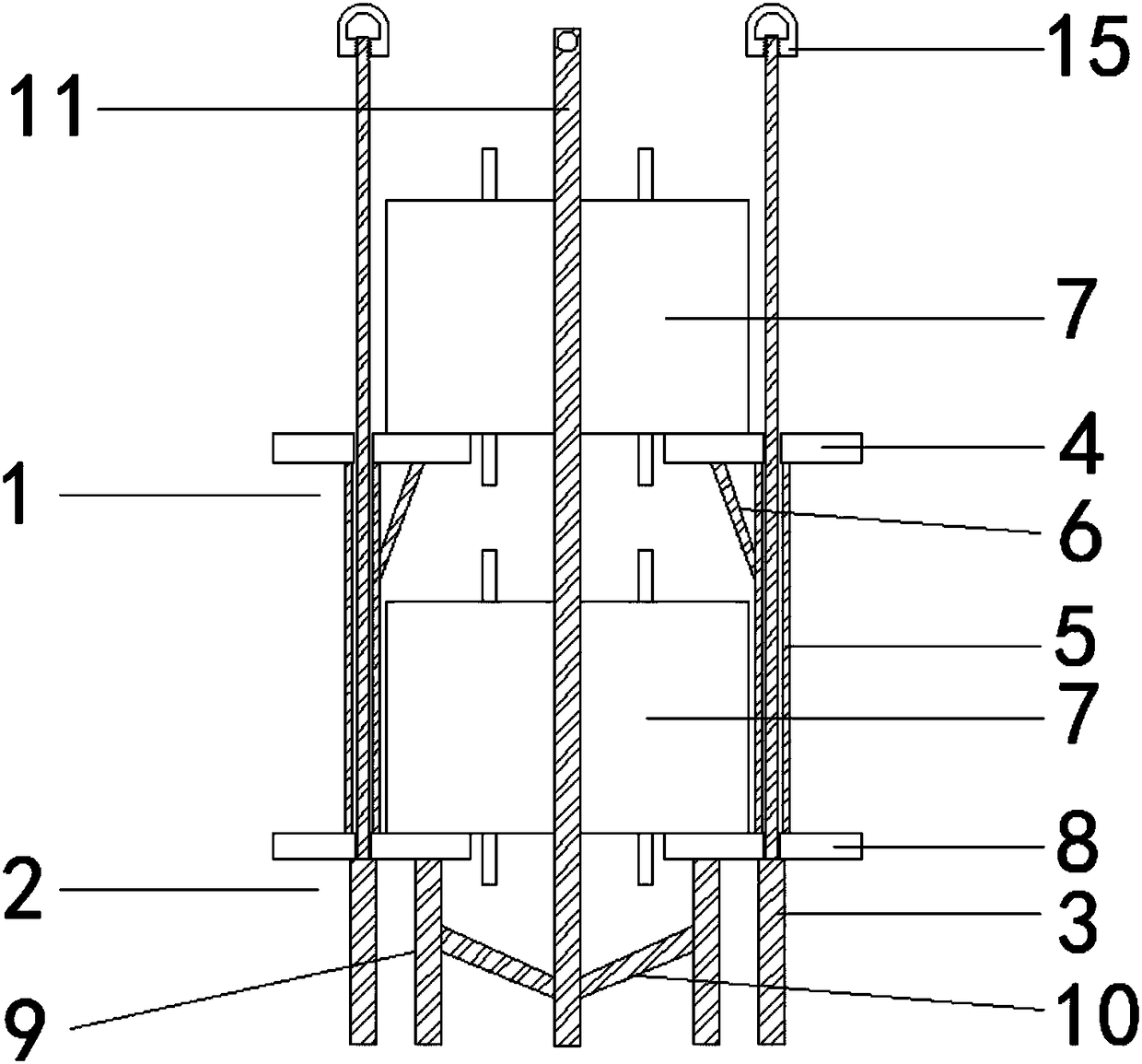

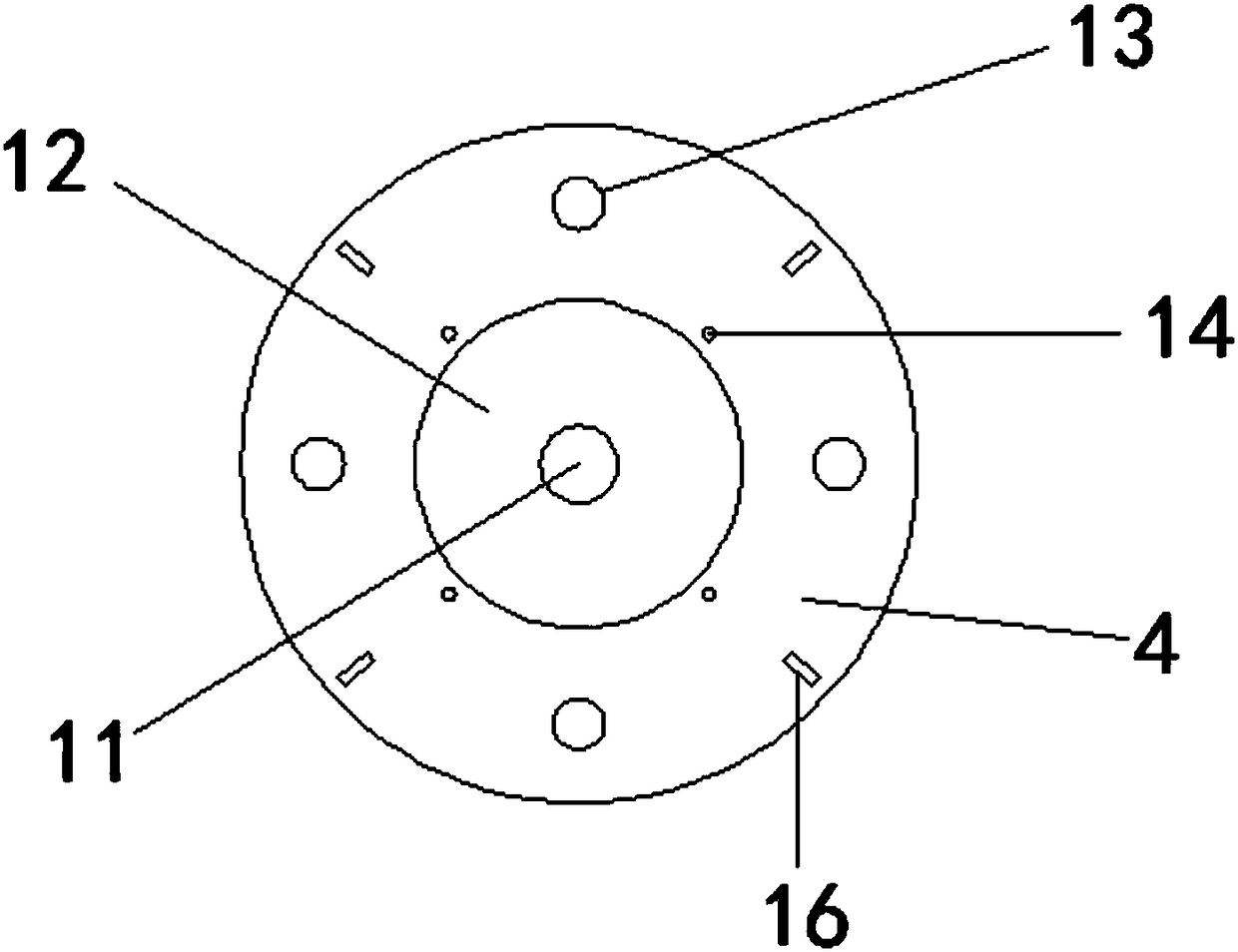

Vertical paint dipping device of motor stator

InactiveCN108462342AIncrease profitUniform thicknessManufacturing dynamo-electric machinesVacuum pressureLacquer

A vertical paint dipping device of a motor stator relates to the field of motor manufacture and maintenance. The vertical paint dipping device mainly settles problems of insufficient height space utilization, low paint dipping efficiency, insufficient height space utilization rate of an oven in drying, energy wastage and the like in a vacuum pressure paint dipping tank. The vertical paint dippingdevice mainly comprises an upper bearing part, a lower bearing part, and a hoisting rod which is used for stringing the upper bearing part and the lower bearing part together. The upper bearing part and the lower bearing part are two independent parts. Through assembling, an upper bearing plate and a lower bearing plate are connected together and a certain height is kept. The middle part of the bearing plate is provided with a hole. In paint dipping, the stator is placed on the bearing plate, and a stator winding part can penetrate through the bearing plate. When paint dipping is performed through the device, the following advantages can be realized: improving space utilization rate of the paint dipping tank and the oven, improving production efficiency, reducing energy consumption generated in a paint dipping process, and realizing uniform insulating paint film thickness.

Owner:冯珍

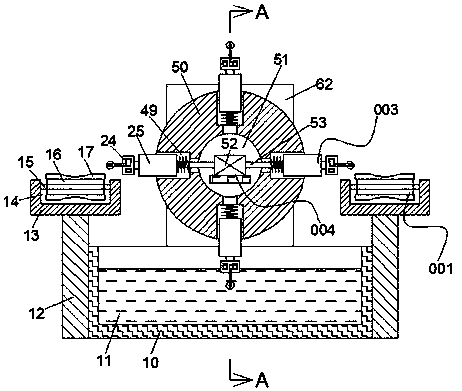

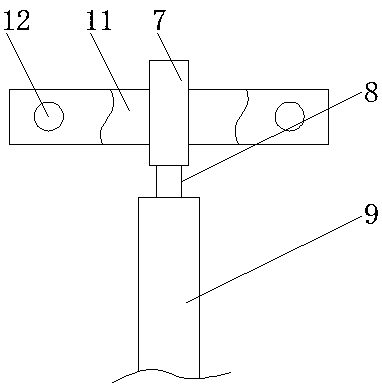

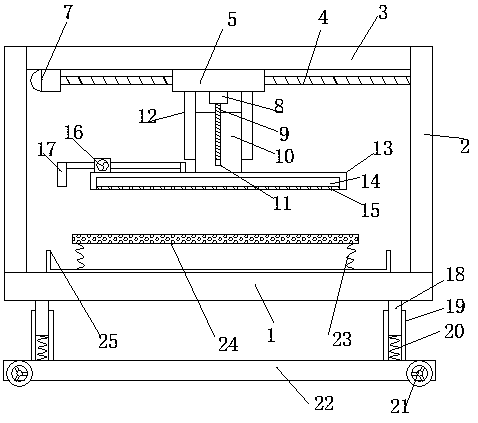

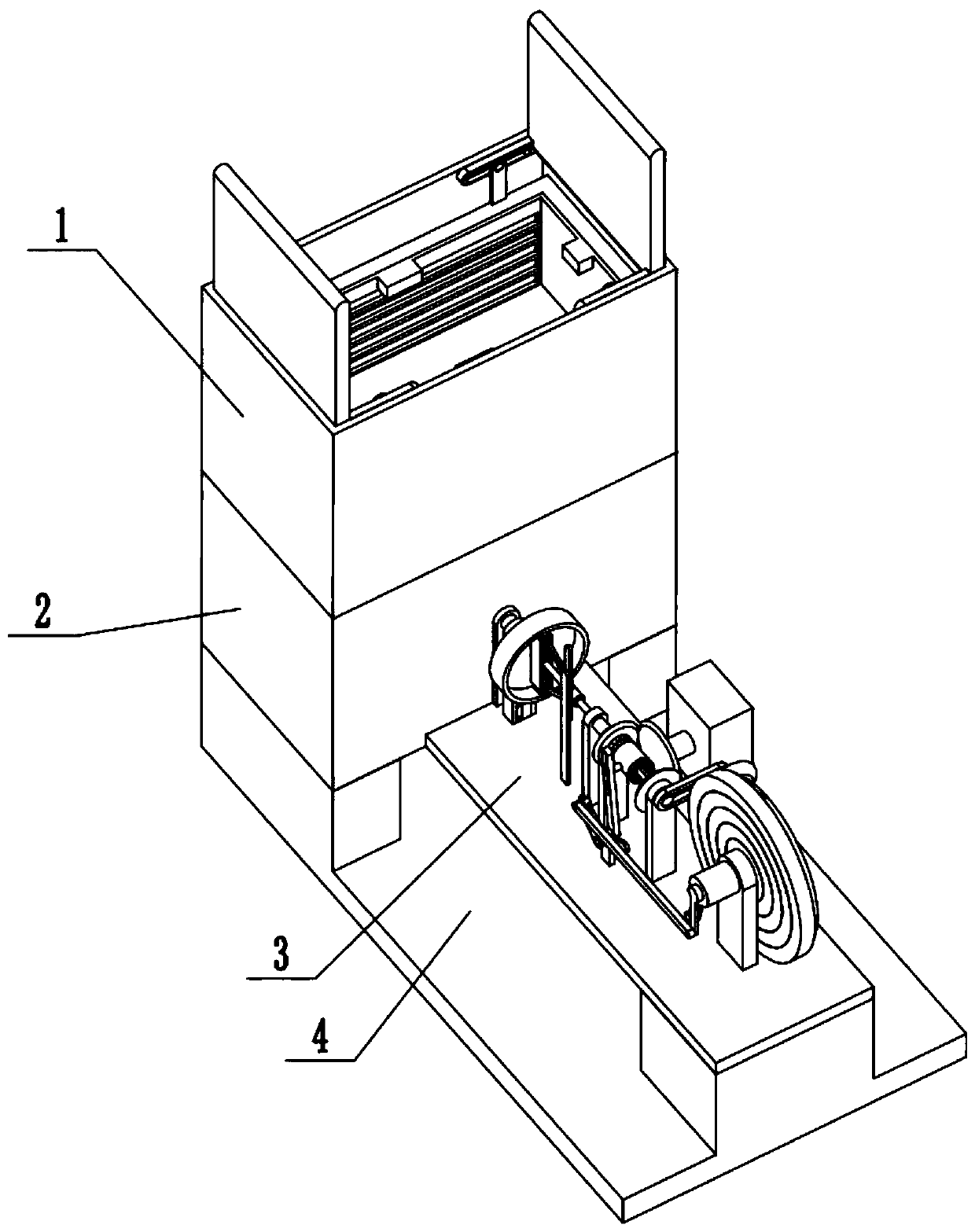

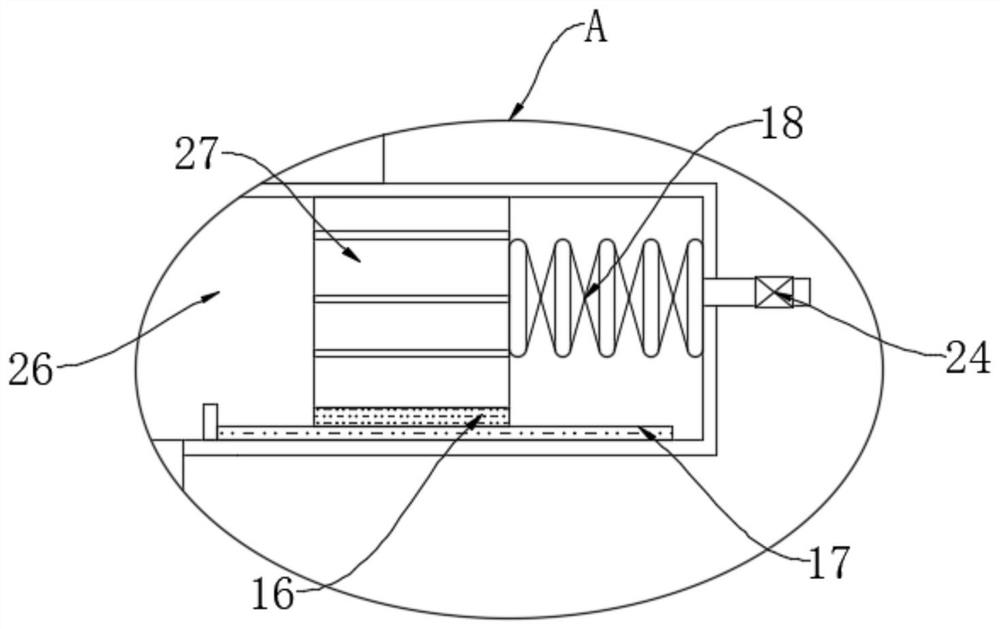

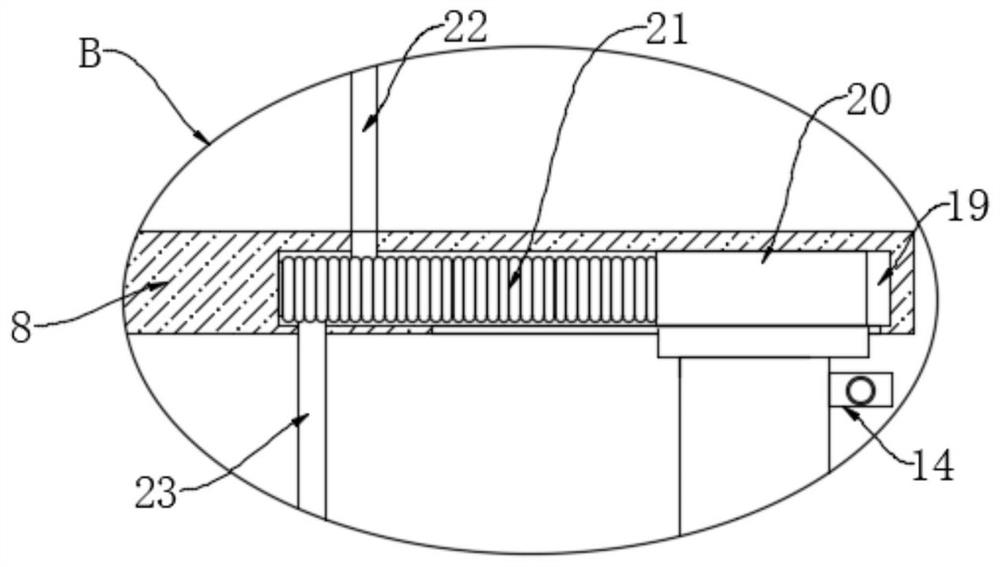

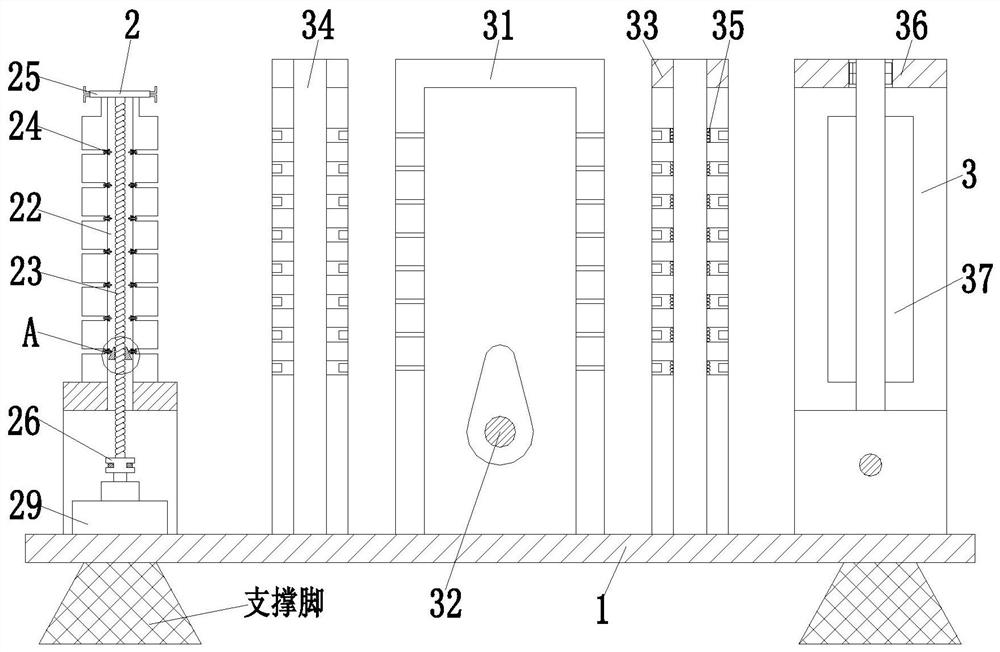

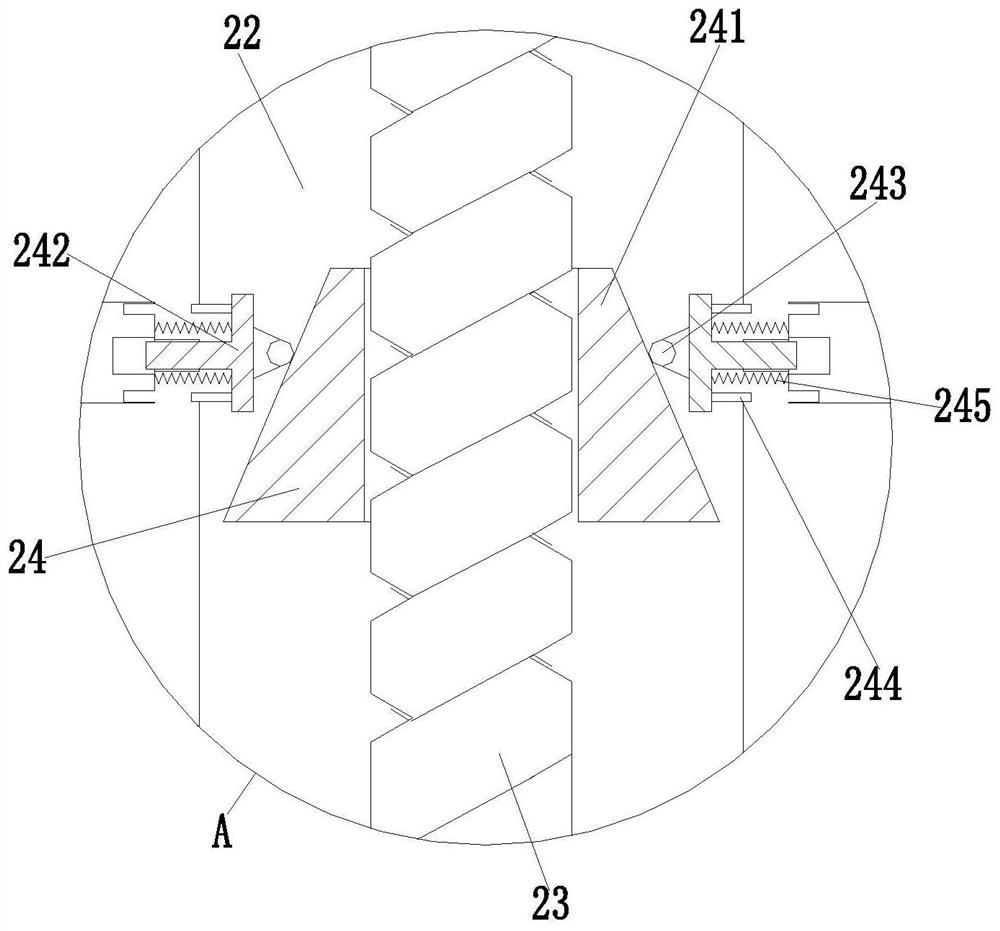

Motor stator iron core paint dipping tool

ActiveCN113452225AImprove the efficiency of dippingImprove dipping effectApplying solid insulationElectric machineMechanical engineering

The invention relates to a motor stator iron core paint dipping tool, and the tool comprises a base and a paint dipping device, wherein the paint dipping device is arranged on the base. The paint dipping tool can solve the current problems that existing paint dipping equipment cannot perform reciprocating rotation on an iron core being subjected to paint dipping, only the iron core is dipped in paint, and the paint is slowly attached to the surface of the iron core, so the paint dipping time of the iron core is prolonged, the paint is not uniformly attached to the surface of the iron core and then the normal work of the motor can be affected in the using process of the iron core; moreover, only one target is targeted at one time when an existing paint dipping device conducts paint dipping on the iron core, the iron core subjected to paint dipping is inconvenient to take and place, the paint dipping efficiency of the iron core is low, and the production efficiency of the motor is difficult to improve.

Owner:海城三鱼泵业有限公司

Preparation method of polypropylene spun-bonded non-woven fabric

ActiveCN112877960AImprove the effect of dip dyeingImprove the efficiency of dippingMechanical cleaningPressure cleaningPolymer scienceNonwoven fabric

The invention relates to a preparation method of a polypropylene spun-bonded non-woven fabric. A polypropylene spun-bonded non-woven fabric preparation device is used, and the polypropylene spun-bonded non-woven fabric preparation device comprises a bottom plate, a printing and dyeing pool, a winding mechanism, a vibration mechanism and a drying mechanism. The multi-layer polypropylene spun-bonded non-woven fabric is placed in a three-dimensional mode through the winding mechanism, so that multiple layers of the polypropylene spun-bonded non-woven fabric can be dip-dyed at the same time, and dip dyeing efficiency is improved; and meanwhile, the vibration mechanism is adopted to drive the polypropylene spun-bonded non-woven fabric to move up and down in the dip dyeing pool, dip dyeing liquid enters grid holes under the impact of up-down movement force of the polypropylene spun-bonded non-woven fabric, and therefore, the dip dyeing effect of the polypropylene spun-bonded non-woven fabric is improved.

Owner:DONGGUAN PARKER AUTOMOTIVE FIBER MATERIALS CO LTD

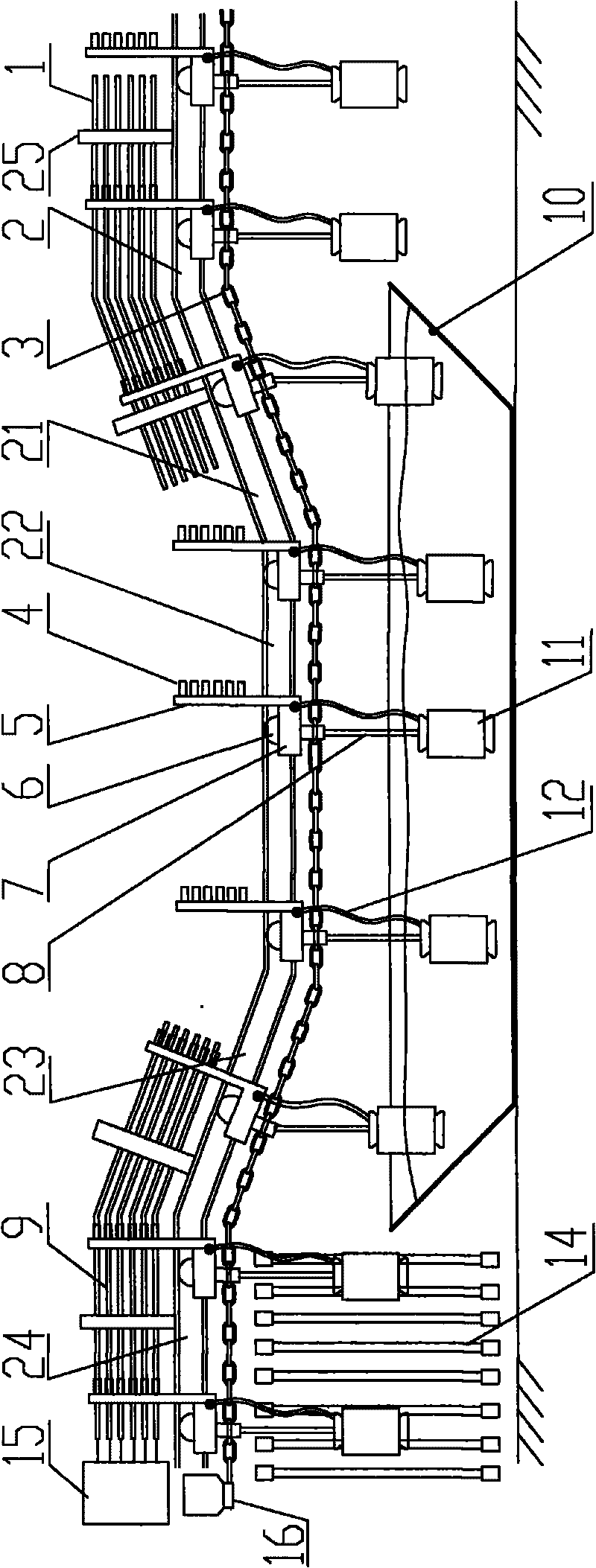

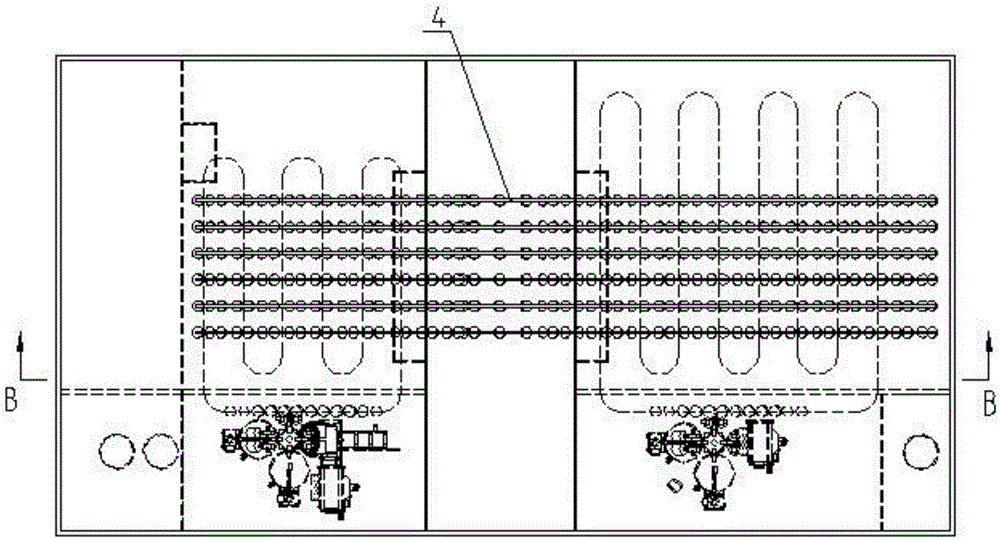

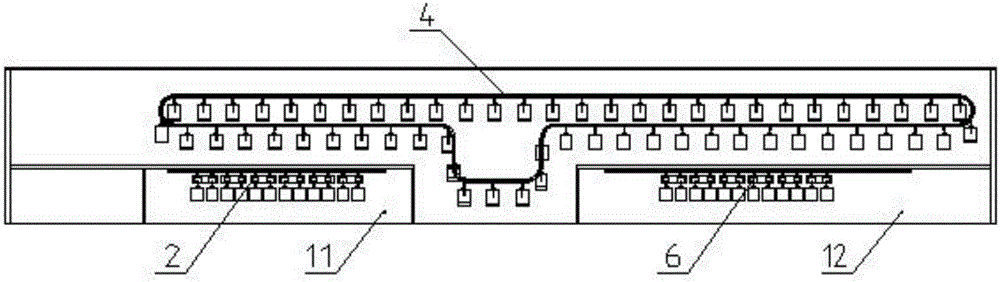

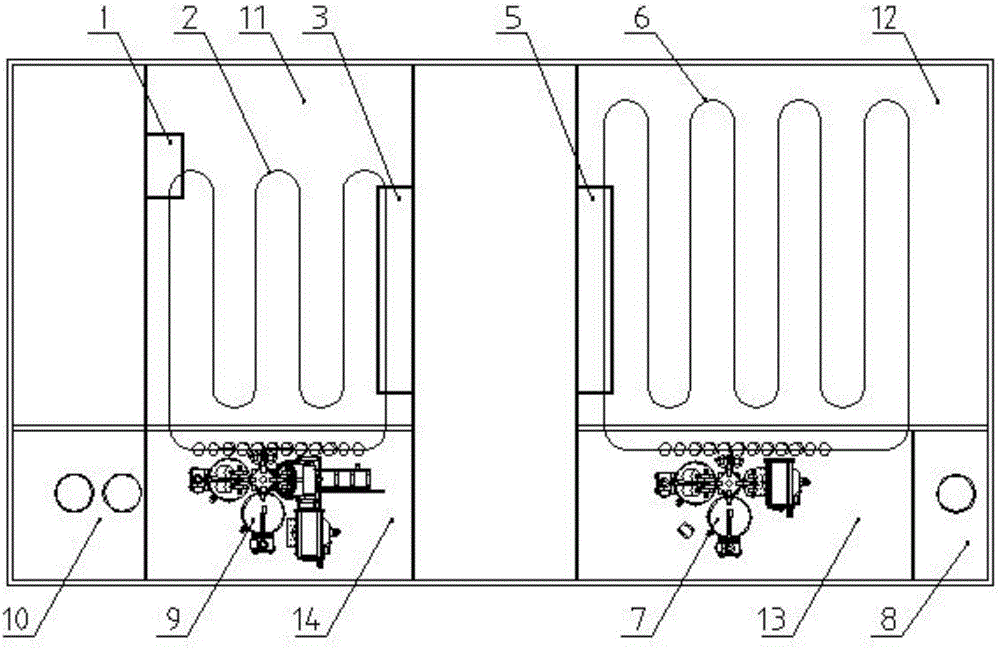

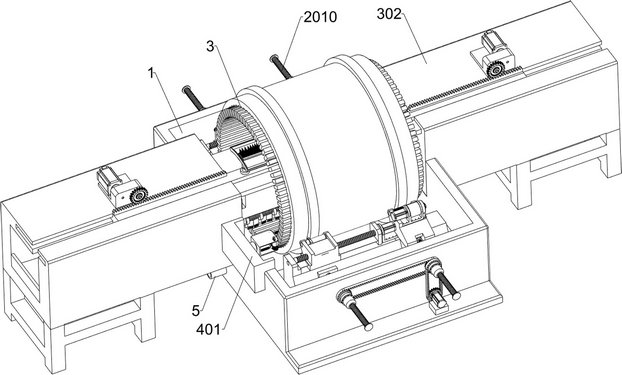

Environment-friendly and automatic staining shell-making production line for precision casting

InactiveCN106734991ASave production spaceHarm reductionMoulding toolsFoundry mouldsProduction lineStaining

The invention discloses an environment-friendly and automatic staining shell-making production line for precision casting. An automatic staining assembly line I and an automatic staining assembly line II which are opposite to each other at an interval are arranged in a lower space, and multiple buffering and drying storage lines crossing over a rapid drying chamber I and a rapid drying chamber II are arranged in an upper space; automatic staining manipulators are arranged beside the automatic staining assembly line I in an automatic staining chamber II and the automatic staining assembly line II in an automatic staining chamber I; the automatic staining chamber II and the automatic staining chamber I both adopt a closed structure to close a high-dust area; a closed dust isolating operation chamber I and a closed dust isolating operation chamber II are arranged in the rapid drying chamber I, and a closed dust isolating operation chamber III is arranged in the rapid drying chamber II; a discharging point of the automatic staining assembly line I is butted with a feeding point of the buffering and drying storage lines, and a discharging point of the buffering and drying storage lines is butted with a feeding point of the automatic staining assembly line II. The environment-friendly and automatic staining shell-making production line for precision casting occupies small area and is high in production efficiency, and the operating environment is environment-friendly.

Owner:TAIZHOU XINYU PRECISION MFG CO LTD

Continuous impregnating system for bamboo curtain board

InactiveCN110757595AAvoid curlFully heatedDrying gas arrangementsWood veneer joiningMechanical engineeringComposite material

The invention discloses a continuous impregnating system for a bamboo curtain board. The system comprises an impregnating assembly, a drying assembly, a cooling bracket and a rotating table. The impregnating assembly, the drying assembly and the cooling bracket are annularly distributed by taking the rotating table as a center to finish an impregnating step and a drying step after impregnation. The continuous impregnating system for the bamboo curtain board can combine impregnation, drying and cooling of the bamboo curtain board, so that the production efficiency of the bamboo curtain board isimproved. When the bamboo curtain board is impregnated, the bamboo curtain board can be straightened and impregnated to be prevented from being curled, so that the impregnating effect is good. Meanwhile, when the straightened bamboo curtain board is dried, the surface of the bamboo curtain board can be heated fully, so that the drying effect is good.

Owner:益阳桃花江竹业发展有限公司

A kind of preparation method and its product and application of colorful ranunculus

The invention belongs to the technical field of textile materials, and relates to a preparation method and its product and application of a colored pansy. Soaking, bruising, sand washing, primary and secondary dyeing, and softening treatment steps. Compared with the prior art, the method of the present invention has simple process and short production cycle, which is in line with the current concept of low carbon, environmental protection and energy saving; it saves the use of consumables in the dyeing process, but also achieves the same preparation effect, making The cost of the process is reduced, catering to the needs of a larger market group; the prepared colored raccoon makes up for the shortcoming of the single color tone of the raccoon silk fabric, and the colored raccoon prepared by the invention not only has high color fastness but also bright color, making the raccoon silk The application of fabrics on clothing is more practical and has great market prospects.

Owner:SHENZHEN LIANGZI FASHION IND

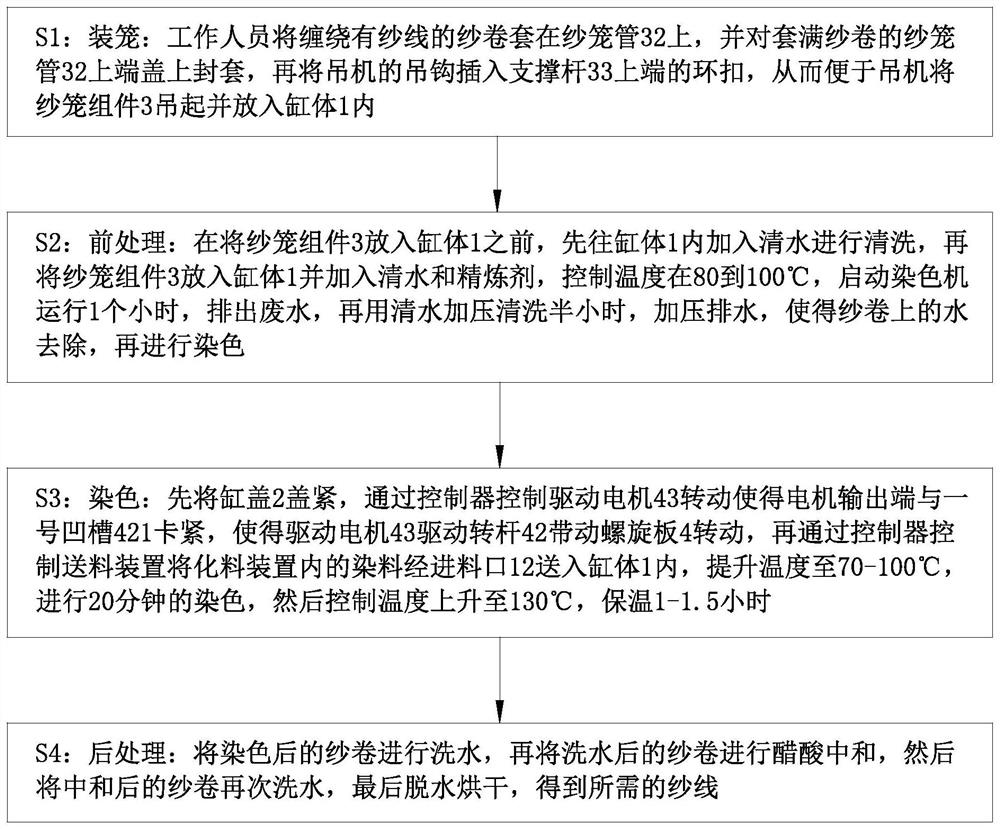

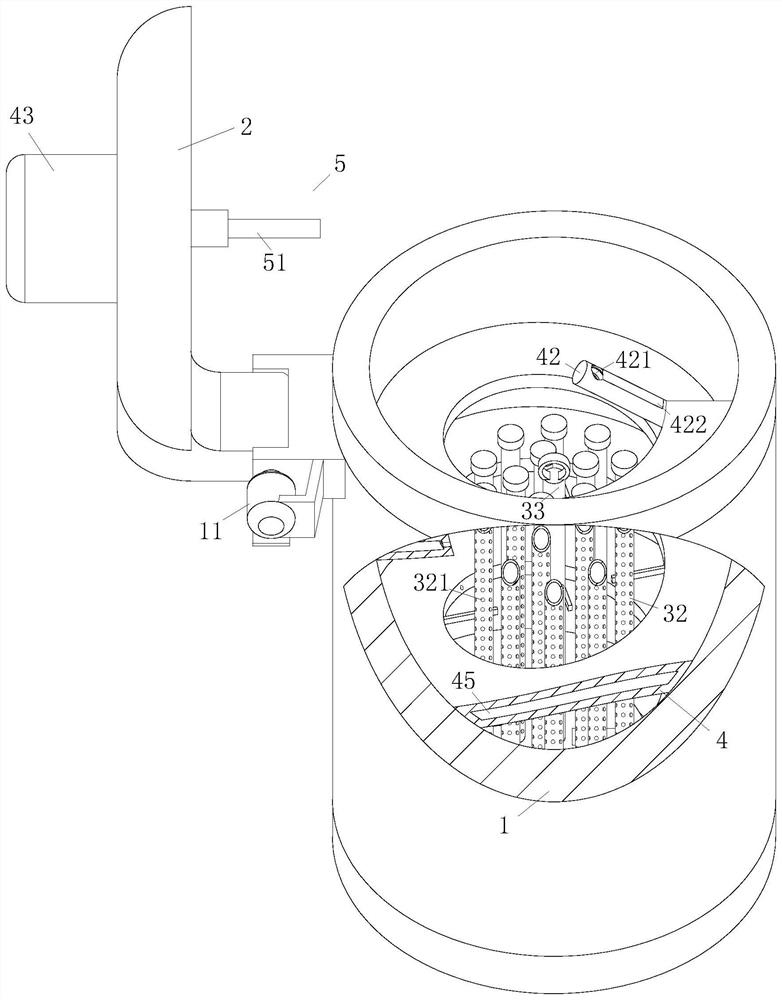

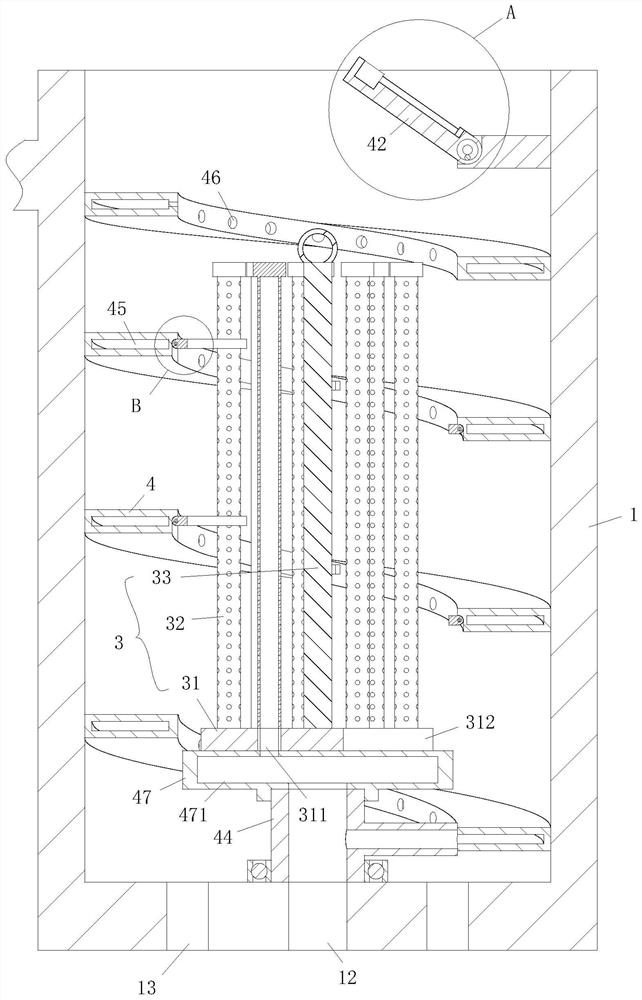

Dyeing equipment and dyeing process for regenerated polyester yarns

PendingCN113802296AIncrease flow rateSpeed up dippingTextile treatment machine arrangementsTextile treatment carriersPolyesterYarn

The invention belongs to the technical field of polyester yarn processing, and particularly relates to dyeing equipment and a dyeing process for regenerated polyester yarns. The dyeing equipment comprises a dyeing device, a feeding device, a material dissolving device and a controller; the dyeing device further comprises a cylinder body, a cylinder cover and a yarn cage assembly; The cylinder cover is hinged to the upper end of the cylinder body; the outer wall of the cylinder body is fixedly connected with a servo motor; the output end of the servo motor is fixedly connected with a hinged point of the cylinder cover and the cylinder body; and a feeding hole and a discharging hole are formed in the lower end of the cylinder body. A spiral plate is arranged and can be driven by a driving motor to rotate; on one hand, the flow speed of dye liquor is increased, so that the dip-dyeing speed of dye to yarn rolls is increased, and the dip-dyeing efficiency of the yarn rolls is improved; and on the other hand, dye particles in the dye liquor are stirred to be diffused upwards, so that the rising dye concentration is improved, the dip dyeing effect of the dye on the upper yarn rolls is enhanced, the color difference of the upper yarn rolls is reduced, and the product quality is improved.

Owner:王海波

High-carbon preservative bamboo wallboard and production method

ActiveCN106808550AImprove anti-corrosion performanceDoes not affect glossConstruction materialDomestic articlesHigh carbonPreservative

The invention discloses a high-carbon preservative bamboo wallboard production method, which comprises the steps of (1) removing tabasheer from a fresh bamboo and rolling the bamboo to obtain a silky bamboo splint; (2) drying the bamboo splint until the water content is lower than 6-9%; (3) carbonizing the bamboo splint that meets the water content requirement in a carbonization chamber at normal pressure, and selecting qualified and removing the unqualified bamboo splint after carbonization; (4) processing the qualified carbonized bamboo splint by impregnation, and drying the bamboo splint until the water content is between 13-17% after processing; and (5) processing the bamboo splint for health preserving and balancing in a health preserving room; (6) performing hot pressing moulding to obtain a bamboo sheet; (7) processing the bamboo sheet to obtain the bamboo wallboard. The invention also relates to a bamboo wallboard obtained by the above method. The bamboo preservative performance of the bamboo wallboard can be greatly improved by carbonization; the production period is short; the operation is simple; the appearance quality is high; and advantages like safety and environmental protection are provided.

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

Compensation chain plastic dipping process

InactiveCN106622850AImprove adsorption capacityImprove the efficiency of dippingPretreated surfacesCoatingsHydrogenLiquid tank

The invention relates to a compensation chain plastic dipping process. The compensation chain plastic dipping process comprises the following steps: surface treatment: firstly, a compensation chain is derusted and dried at a drying temperature of 90-120 DEG C; then, the compensation chain is put in a sealed chamber; hydrogen and oxygen mixed gas is fed in the sealed chamber; after a spark plug is ignited, the mixed gas explodes to release out a lot of heat; the transient temperature is high up to 3000-3800 DEG C; the explosion time is 0.6-0.8; on the one hand, burrs on the surface of the compensation chain are burnt off; and on the other hand, the compensation chain is preheated; and PVC plastic dipping: the compensation chain passes through a plastic dipping liquid tank, an ultrasonic homogenization channel, a curing insulation drying way and a water cooling tank in sequence; when the compensation chain passes through the plastic dipping liquid tank, the compensation chain is totally immersed by PVC plastic dipping liquid; and when the compensation chain passes through the curing insulation drying way, the curing time is 2-3 minutes, and the curing temperature is 180-200 DEG C. The plastic dipping process has the advantages of high plastic dipping efficiency and good plastic dipping effect.

Owner:重庆澳菱工贸有限公司

Explosion-proof motor stator paint dipping device

ActiveCN113746293AAvoid wastingDip paint reductionManufacturing dynamo-electric machinesElectric machineStructural engineering

The invention relates to the field of explosion-proof motors, in particular to an explosion-proof motor stator paint dipping device. The technical problems are as follows: a kilowatt-level stator is large in shape and needs to be hoisted into a large pool for paint dipping by adopting hoisting equipment during paint dipping, so that not only is the large pool body matched for paint dipping needed, but also a large amount of insulating paint is wasted after paint dipping, and the overall recycling efficiency is low. According to the technical scheme, the explosion-proof motor stator paint dipping device comprises a paint dipping pool, a supporting and driving assembly and the like; the front side and the rear side of the inner wall of the paint dipping pool are each provided with a supporting driving assembly used for supporting and adjusting the kilowatt-level stator, and the two supporting driving assemblies are symmetrically arranged. According to the invention, shallow paint dipping is carried out on the large kilowatt-level stator, so that comprehensive paint dipping work of the kilowatt-level stator can be completed by using a small amount of insulating paint, a small paint dipping pool is used, the waste of a large amount of insulating paint can be avoided, and the use of a large placing pool is reduced.

Owner:JIANGSU YALI EXPLOSION PROOF MOTOR CO LTD

Anti-corrosion paint impregnation device of cables for 5G base station construction

InactiveCN112275537AImprove dipping effectEasy flow cycleLiquid surface applicatorsCoatingsArchitectural engineeringOil paint

The invention discloses an anti-corrosion paint impregnation device of cables for 5G base station construction. The anti-corrosion paint impregnation device comprises a device plate and a paint impregnation mechanism, wherein two electric lifting rods are symmetrically mounted at the upper end of the device plate and are fixedly connected through a cross rod; a treatment box is arranged between the two electric lifting rods; the lower end of the treatment box is fixedly connected with the upper end of the device plate; a paint impregnation tank is arranged at the upper end of the treatment box; the paint impregnation mechanism comprises two vertical rods which are fixedly connected to the lower end of the cross rod; and an object carrying plate is commonly arranged at the lower end of thetwo vertical rods. When the cables are subjected to paint impregnation through the equipment, the cables can be shaken, so that the cables fully contact oil paint, and the oil paint also can be heated, so that the oil paint easily circulates in a flowing manner, and paint impregnation on the cables can be performed preferably.

Owner:黄博毅

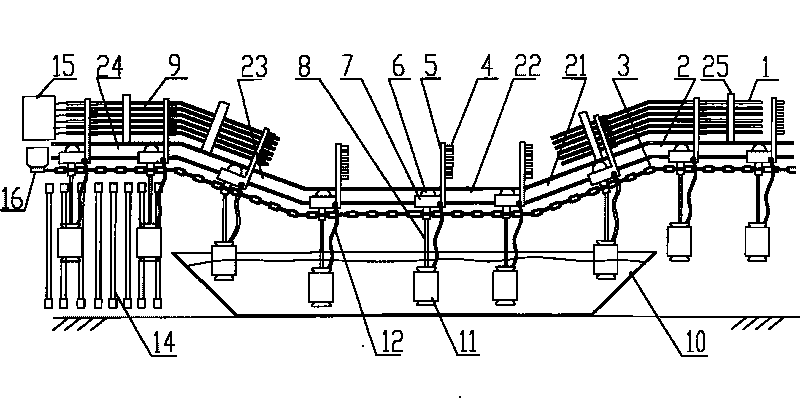

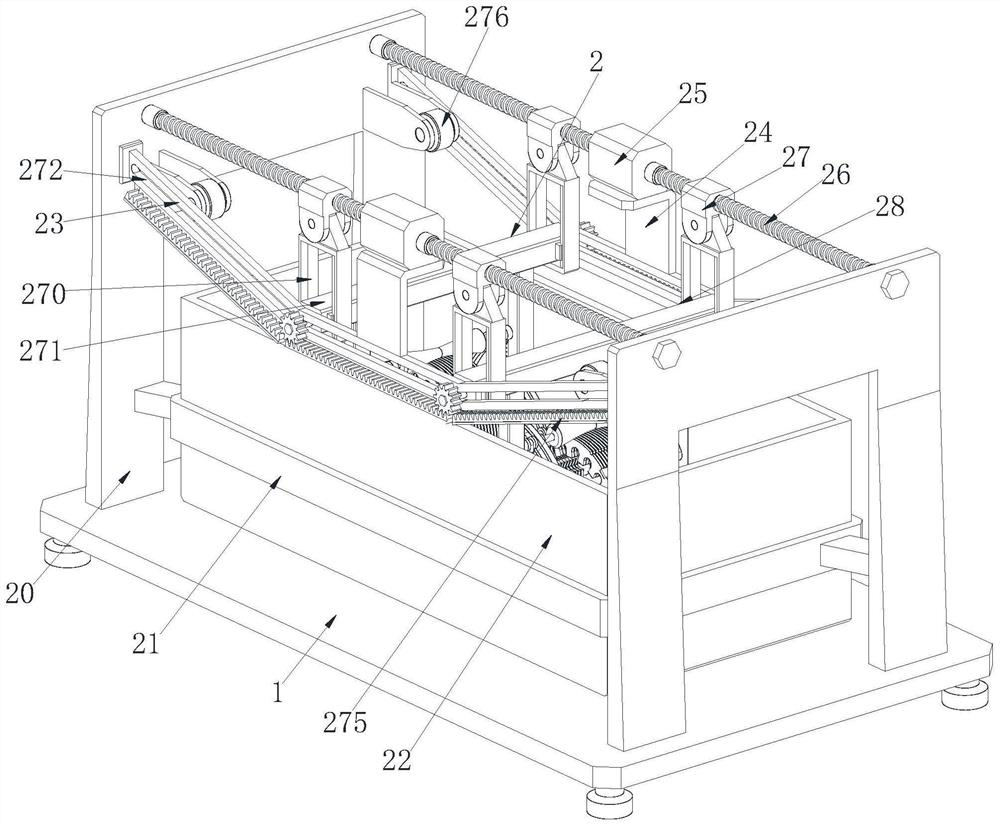

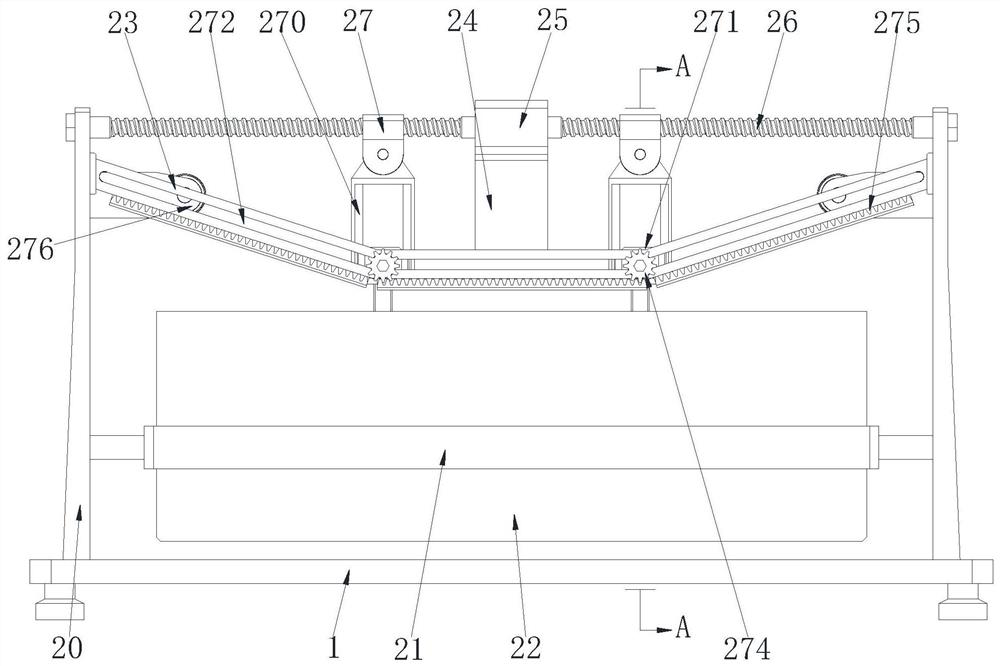

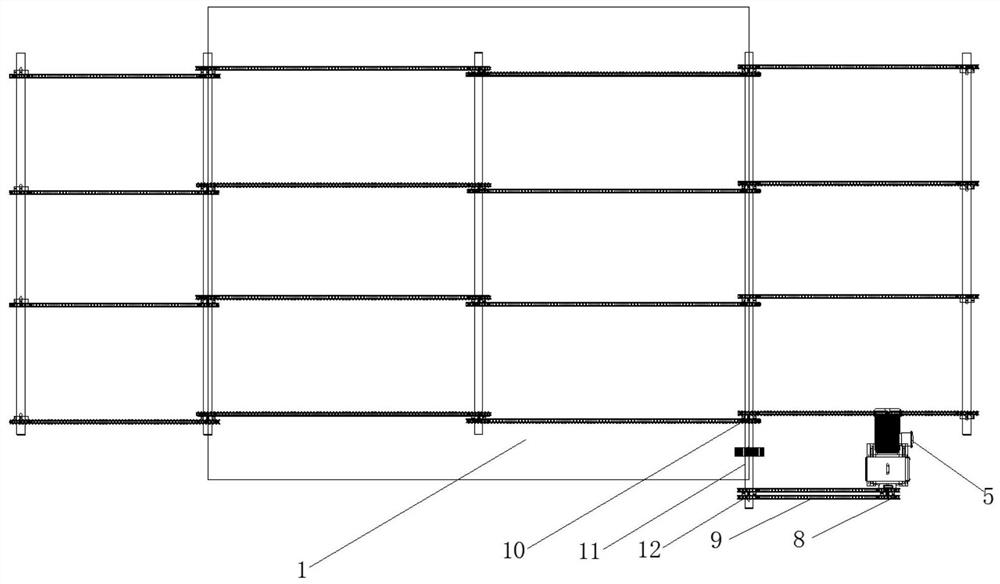

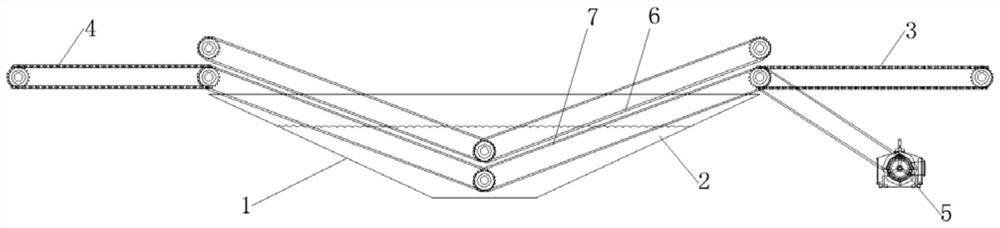

Automatic gum dipping system

PendingCN112140274AImprove the efficiency of dippingSolve the problem of low dipping efficiencyDomestic articlesLignocellulosic moulding material treatmentMechanical engineeringIndustrial engineering

The invention discloses an automatic gum dipping system, which belongs to the technical field of bamboo production and processing, and aims to provide the automatic gum dipping system to solve the problem that the gum dipping efficiency of bamboo chips is low due to the fact that the gum dipping automation degree of the bamboo chips in the prior art is low. The automatic gum dipping system comprises a gum pool; gum is arranged in the gum pool; a feeding conveying chain is arranged on one side of the gum pool; a discharging conveying chain is arranged on the other side of the gum pool; a V-shaped gum dipping chain group is connected between the feeding conveying chain and the discharging conveying chain; the V-shaped gum dipping chain group is arranged in a V shape along the inclination direction of the gum pool; and the lowest point of the V-shaped gum dipping chain group is located in the gum pool; a motor is further arranged, and an output mechanism of the motor is in transmission connection with an input mechanism of the V-shaped gum dipping chain group. The invention is suitable for the automatic gum dipping system.

Owner:HONGYA BAMBOO ERA SCI & TECH

Cotton thread dip dyeing device for cotton thread processing

InactiveCN110670274AImprove the efficiency of dippingFully dyedTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsAgricultural engineeringElectric machinery

A cotton thread dip dyeing device for cotton thread processing comprises a device body, a take-up drum, a warm air nozzle, a warm air pipe, a first conveying drum, a second conveying drum, a second support, a dye tank, a third conveying drum, a third support, a fourth conveying drum, a fourth support, a circulating pump, a mounting seat, a liquid suction pipe, a fifth support, a fifth conveying drum, a first support, an electric cabinet, a warm air blower, a take-up drum support, a take-up drum motor, a connecting pipe, a dye tank separation plate and a liquid outlet pipe; the dye tank is arranged in the middle of the inside of the device body, and the take-up drum and the first conveying drum are respectively mounted on the left side of the dye tank through the take-up drum support and the first support; the circulating pump is mounted on the right side of the dye tank through the mounting seat, and the second conveying drum and the third conveying drum are respectively mounted on theupper part of the dye tank through the second support and the third support; the fourth conveying drum is installed in the dye tank through the fourth support and positioned on the left side of the third support; and the height of the fifth conveying drum is less than that of the fourth support. According to the cotton thread dip dyeing device for cotton thread processing, the cotton threads canbe fully and uniformly dyed, and the dyeing quality of the cotton threads is guaranteed.

Owner:余庆县鸿祥棉纺有限责任公司

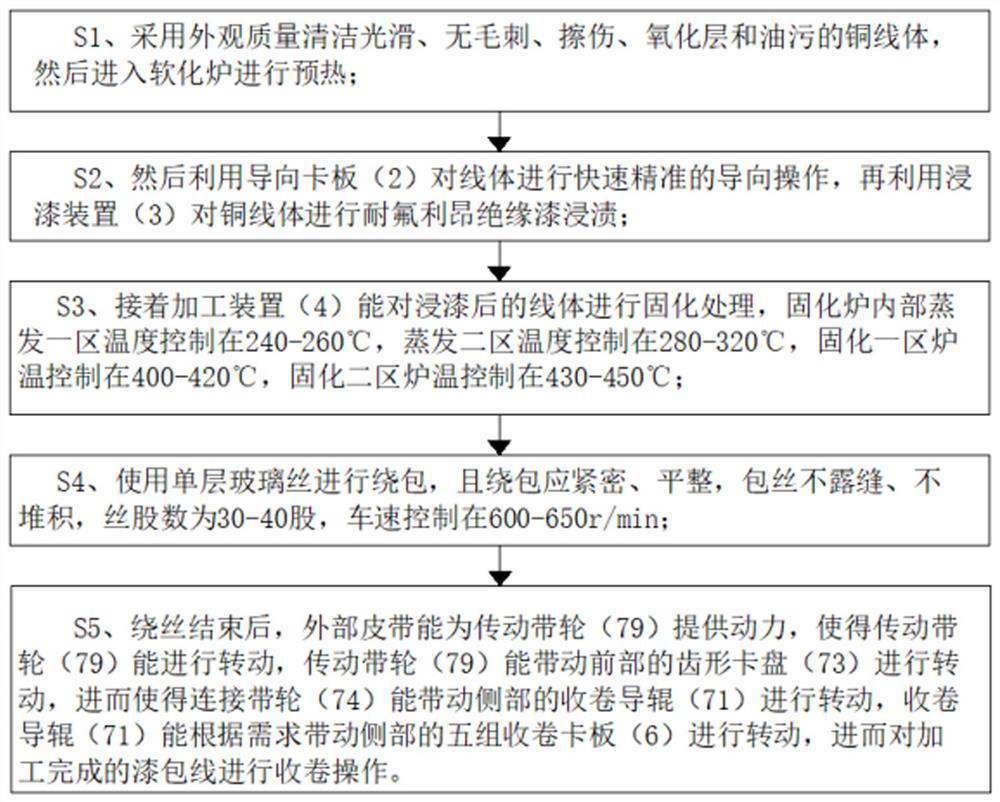

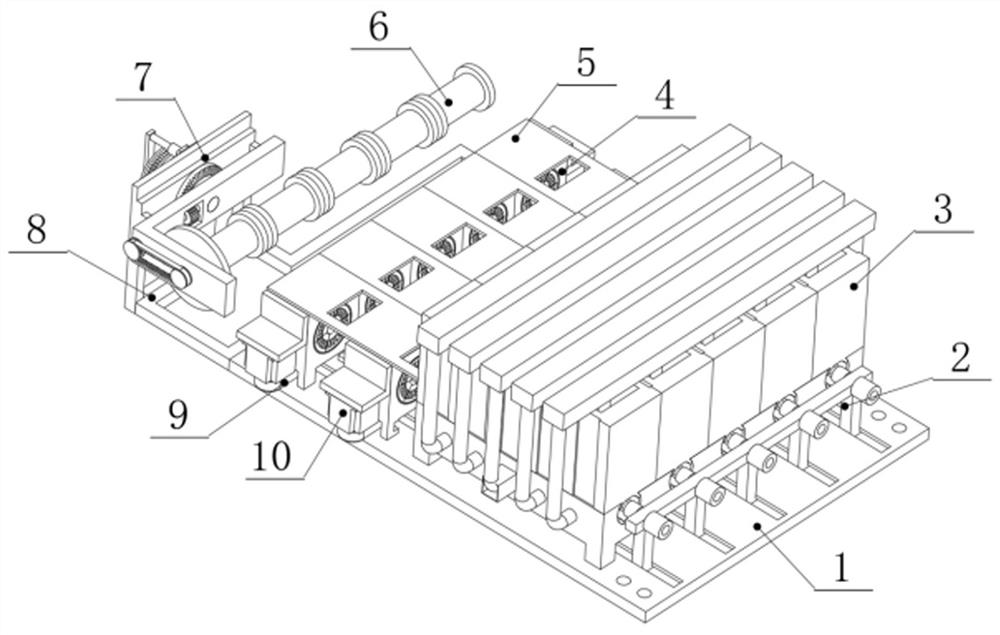

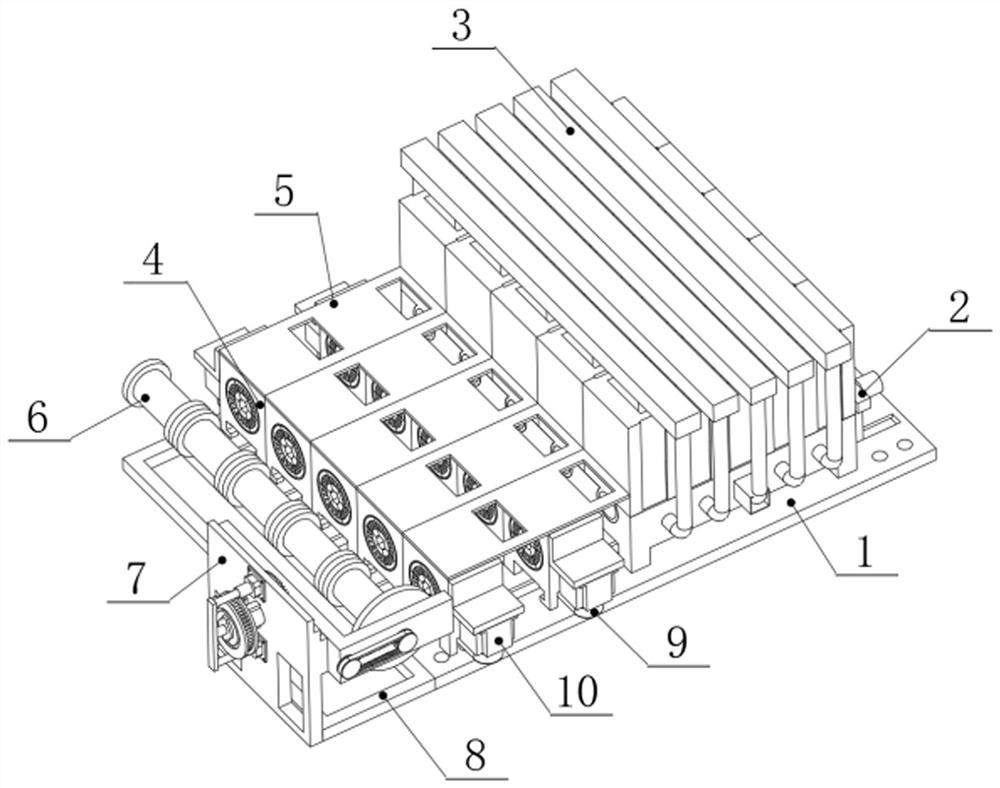

Production process and equipment of Freon-resistant composite enameled wire with glass fiber wrapping

ActiveCN114520083AImprove winding efficiencyImprove processing efficiencyFilament handlingInsulating conductors/cablesGlass fiberFiber

The invention relates to the technical field of composite enameled wire production, in particular to a production process and equipment of a Freon-resistant composite enameled wire wrapped with glass fiber, and the process comprises the following steps: a copper wire body which is clean and smooth in appearance quality and free of burrs, scratches, oxidation layers and oil stains is adopted and then enters a softening furnace to be preheated; then, the wire body is quickly and accurately guided, and the copper wire body is subjected to Freon-resistant insulating paint dipping by using a paint dipping device; then the processing device can carry out curing treatment on the wire body subjected to paint dipping; single-layer glass fibers are used for wrapping, wrapping needs to be tight and flat, and the wrapping fibers are free of seam exposure and accumulation; winding operation is carried out after wire winding is finished; the equipment comprises a supporting bottom plate, a guiding clamping plate, a paint dipping device, a machining device, a connecting clamping plate, a winding clamping plate, a winding device, a connecting bottom frame, a tooth-shaped belt and a servo motor. The preparation method is reasonable in design, simple in process and clear in process route, and the prepared finished product has excellent performance of high temperature resistance, high pressure resistance and corrosion resistance.

Owner:湘潭市霞城电工有限公司

Textile yarn batch dip dyeing fixing frame

InactiveCN113123040ASolve the problem of dyeing efficiency in dip dyeingSolve the problem of not being able to rewind at the same time and low rewinding efficiencyFilament handlingTextile treatment machine arrangementsPolymer scienceTextile yarn

The invention relates to a textile yarn batch dip-dyeing fixing frame. The fixing frame comprises a bottom plate, a spool fixing mechanism and a dip-dyeing winding mechanism, the spool fixing mechanism is arranged on the left side of the upper end face of the bottom plate, the dip-dyeing winding mechanism is arranged on the right side of the spool fixing mechanism, and the dip-dyeing winding mechanism is installed on the bottom plate. The textile yarn batch dip-dyeing fixing frame can solve the problems that an existing textile yarn-dip dyeing fixing frame cannot separate a plurality of bobbins for winding yarns in a layered mode, so that multiple strands of yarns are prone to winding and knotting in the yarn dip-dyeing process, and the yarn dip-dyeing coloring efficiency is affected, and can also solve the problems that an existing textile yarn dip-dyeing fixing frame cannot conduct batch dip-dyeing on multiple pieces of yarns, the dip-dyeing efficiency is low, the yarn cannot make thorough contact with dye liquor, consequently, yarn dyeing is uneven and insufficient, yarn quality is affected, multiple strands of yarn cannot be wound at the same time after dip-dyeing, and the winding efficiency is low.

Owner:苟旭

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com