Paint dipping equipment for producing anchor chains

A technology of dipping paint and anchor chains, which is applied to coatings and devices for coating liquid on the surface, etc., can solve the problems of waste of resources, low utilization rate of paint, and easy corrosion of seawater at overlapping parts, so as to improve efficiency, Good effect of varnish treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

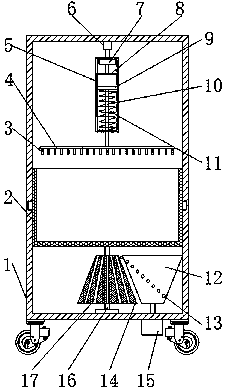

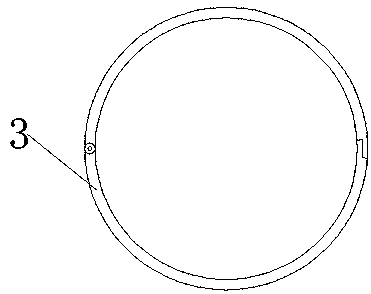

[0025] Such as Figure 1-3 As shown, the embodiment of the present invention provides a kind of dipping equipment for anchor chain production, including a processing box body 1, a servo motor 15, an electric push rod 6, a brake cylinder 7 and a paint dipping box 2, and the inside of the processing box body 1 is set There is a transmission rod 16, one end of the transmission rod 16 is rotationally connected with the inner bottom of the processing box body 1 through a bearing, the other end of the transmission rod 16 is fixedly connected with the bottom of the paint dipping box 2, and the inside of the paint dipping box 2 and the processing box body 1 The wall is connected by rotation, the outer surface of the transmission rod 16 is fixedly covered with a driven cylinder 14, and the outer surface of the driven cylinder 14 is provided with a plurality of transmission grooves 17, and the plurality of transmission grooves 17 are distributed in an annular array. A drive cylinder 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com