Automatic gum dipping system

A dipping and automatic technology, applied in the pretreatment of molding materials, wood processing equipment, manufacturing tools, etc., can solve the problems of low efficiency of bamboo dipping and low degree of automation of bamboo dipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

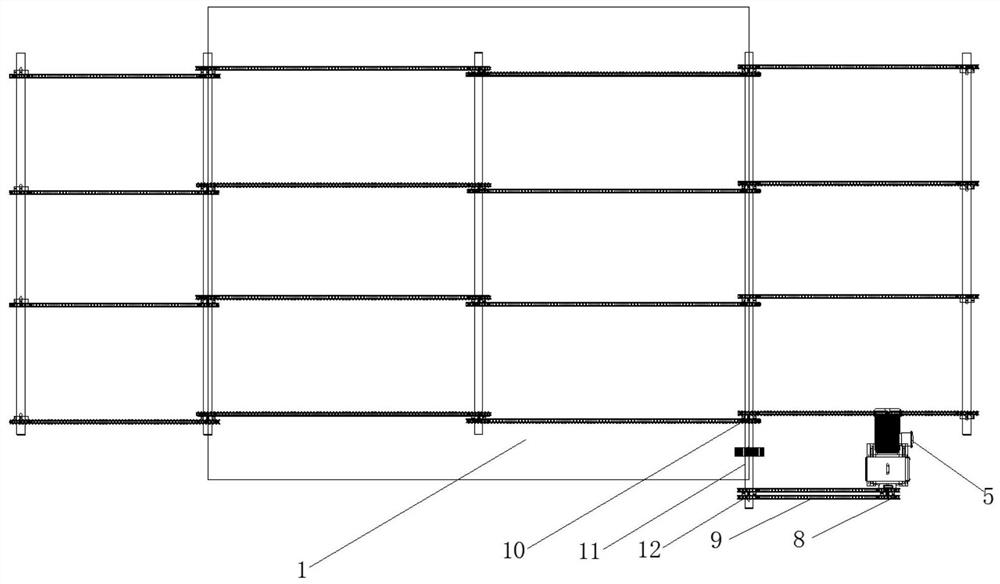

[0031]An automatic dipping system, including a glue pool, glue is arranged in the glue pool, a feed conveying chain is arranged on one side of the glue pond, a discharge conveying chain is arranged on the other side of the glue pond, the feed conveying chain and the discharge conveying A V-shaped rubber-dipped chain group is connected between the chains, and the V-shaped rubber-dipped chain group is arranged in a V shape along the inclination direction of the glue pool, and the lowest point of the V-shaped rubber-dipped chain group is located in the glue pool, and a motor is also provided. The output mechanism is in drive connection with the input mechanism of the V-shaped rubber-impregnated chain group.

[0032] Through this setting, the feeding conveying chain transports the bamboo chips to the V-shaped rubber-impregnated chain group in the direction of the glue tank, and the motor conveying mechanism is driven by the input mechanism of the V-shaped rubber-impregnated chain g...

Embodiment 2

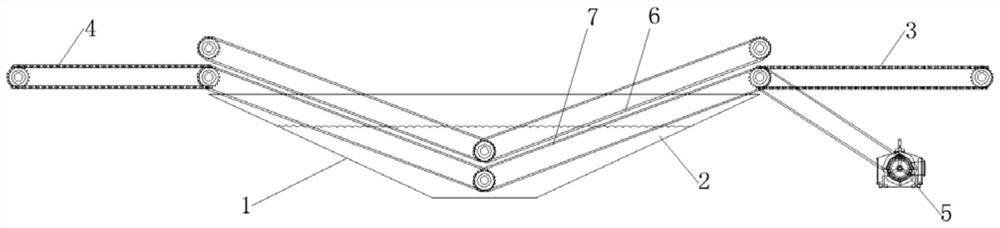

[0034] On the basis of Embodiment 1, the V-shaped rubber-impregnated chain set includes an upper clamping chain and a lower clamping chain arranged in a V shape, and the upper clamping chain and the lower clamping chain are arranged in parallel.

[0035] Through this setting, the upper clamping chain and the lower clamping chain are set in parallel and clamp the bamboo slices, ensuring that the bamboo slices remain stable during transportation, and the bamboo slices follow the movement of the upper clamping chain and the lower clamping chain into the glue pool and then leave The glue pool has completed the automatic dipping process, thereby realizing the automatic assembly line operation.

Embodiment 3

[0037] On the basis of the above embodiments, the output mechanism of the motor includes a drive shaft, a drive sprocket is mounted on the drive shaft, a drive chain is mounted on the drive sprocket, and a pair of mutually meshing gears are mounted on the drive shaft. The input mechanism of the V-shaped rubber-dipped chain group includes a driving sprocket installed on the upper clamping chain and the lower clamping chain, the driving sprocket is connected with a transmission shaft, and the other end of the transmission shaft is connected with a transmission sprocket. The drive sprocket meshes with the drive chain.

[0038] Through this setting, the drive shaft rotates the drive sprocket, and at the same time drives the intermeshed gears to move, the drive sprocket and the drive chain are meshed for transmission, the drive chain drives the intermeshed transmission sprockets to rotate, and the drive shaft follows the rotation to make the drive sprocket rotate. The driving sproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com