Motor stator iron core paint dipping tool

A technology of dipping tooling and motor stator, which is used in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of reciprocating rotation of iron core, low efficiency of iron core dipping, long iron core dipping time, etc., to ensure integrity , the effect of reducing the contact area and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

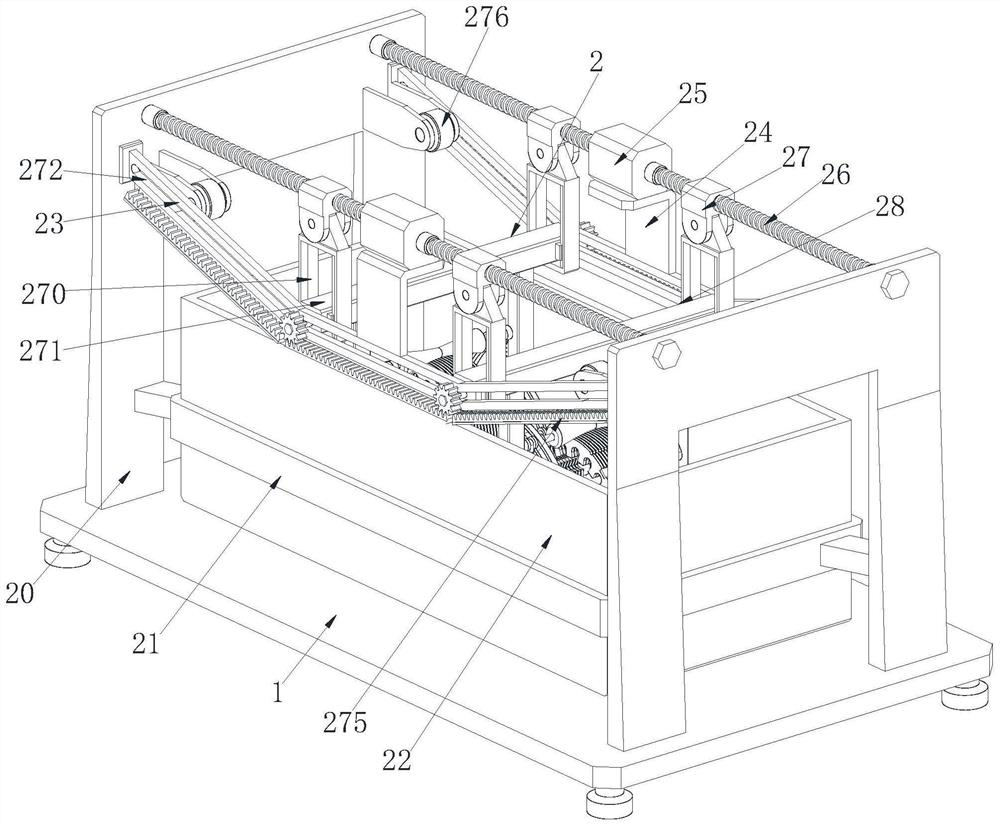

[0027] refer to figure 1 , a motor stator core paint impregnation tool, including a base 1 and a paint impregnation device 2, the base 1 is provided with a paint impregnation device 2.

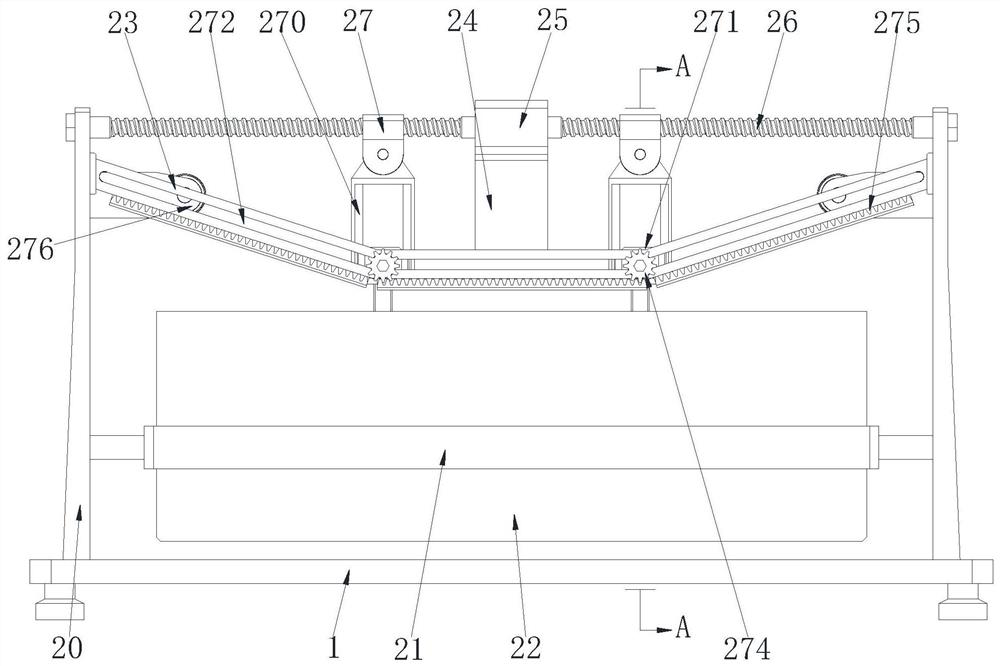

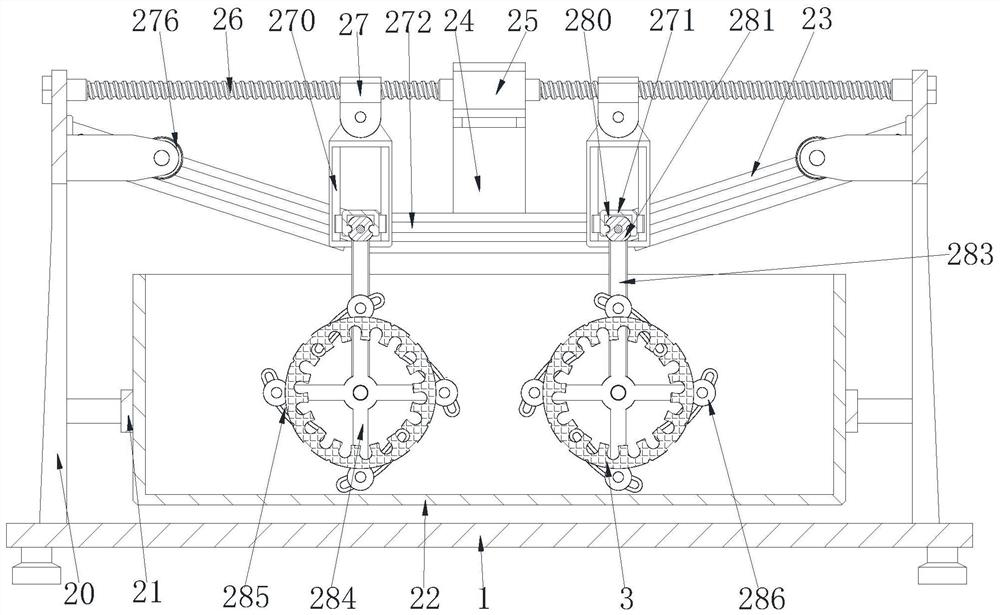

[0028] refer to Figure 1 to Figure 5 , the paint dipping device 2 includes a paint dipping support plate 20, a paint dipping bracket 21, a paint dipping tank body 22, a paint dipping pole 23, a paint dipping support plate 24, a paint dipping motor 25, a paint dipping screw 26, a paint dipping The wire block 27 and the clamping unit 28, the left and right ends of the upper surface of the base 1 are symmetrically provided with impregnated support plates 20, the lower ends of the two impregnated support plates 20 are jointly provided with an impregnated support 21, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com