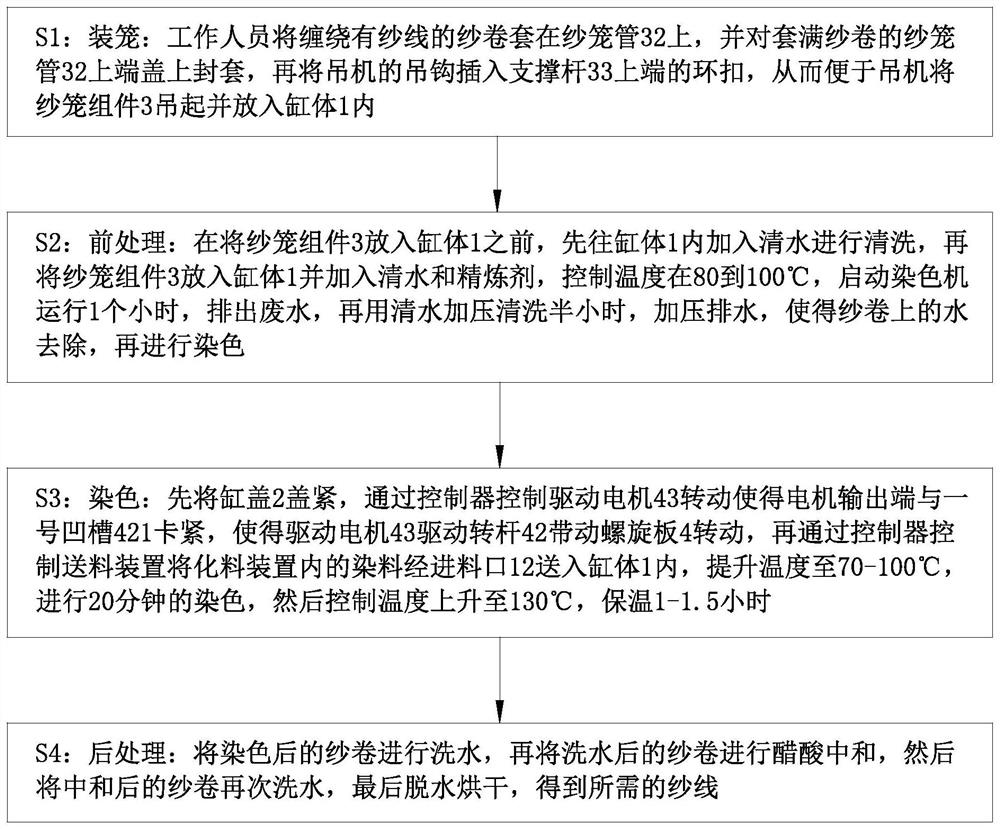

Dyeing equipment and dyeing process for regenerated polyester yarns

A kind of dyeing equipment and recycled polyester technology, which is applied in the field of polyester yarn processing, can solve the problems of upper yarn roll color difference, weakened exhaust dyeing effect, and incomplete solution, and achieve the effects of improved connection strength, enhanced exhaust dyeing effect, and improved application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

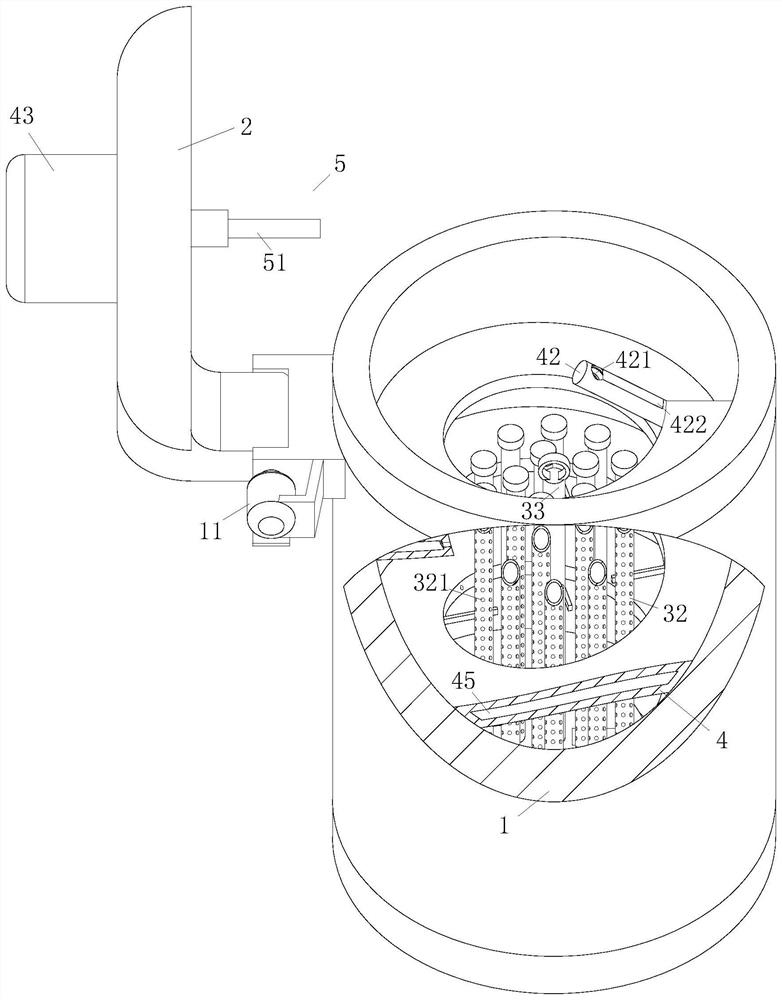

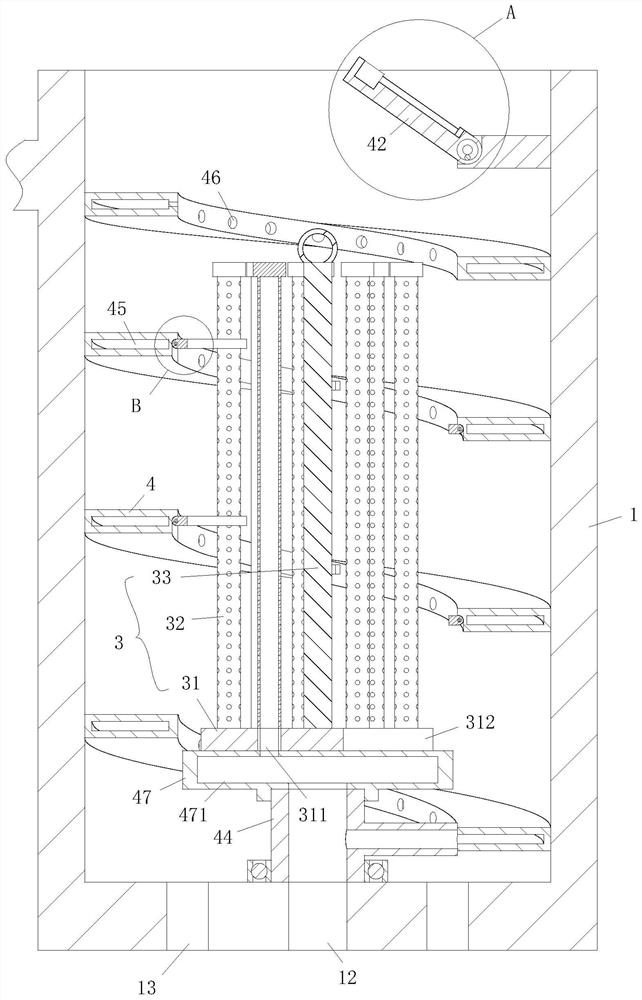

[0036] As an embodiment of the present invention, the end of the spiral plate 4 close to the feed port 12 is fixedly connected with a T-shaped tube 44, the inside of the spiral plate 4 is provided with a cavity 45, and the end of the spiral plate 4 facing the sarong tube 32 is opened. There is a through hole 46; the long end of the T-shaped tube 44 communicates with the No. 1 cavity 45, and the other two ends are respectively connected to the feed port 12 and the support plate 47; the support plate 47 is provided with a No. 2 cavity 471; the through hole 311 communicates with the T-shaped tube 44 through the second cavity 471; the surface of the sarong tube 32 is provided with a liquid outlet 321; during work, when the controller controls the feeding device, the When dyestuff is sent into feed inlet 12, dyestuff enters T-shaped tube 44 through feed inlet 12, makes a part of dyestuff enter No. 1 cavity 45 through the long end of T-shaped tube 44, makes the dyestuff in No. 1 cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com