Patents

Literature

47results about How to "Improve the effect of dip dyeing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Genetic Transformation Method of Dreb Gene Transformation Anthurium

InactiveCN102286527AImprove the effect of dip dyeingHigh recovery rateFermentationVector-based foreign material introductionGenomic DNAMolecular breeding

The invention belongs to the field of molecular breeding and discloses a genetic transformation method for transforming anthurium with DREB gene. The method is to incise the aseptic callus of Anthurium anthurium, infect with the Agrobacterium liquid containing the recombinant plasmid pCAMBIA1301-DREBa for 10 minutes, co-cultivate for 3 days, perform antibacterial culture for 5 days, and screen to obtain hygromycin-resistant rooted shoots. . It was confirmed by PCR detection that the exogenous gene had been transferred into the genome DNA of Anthurium anthurium. The present invention establishes its genetic transformation system for Anthurium for the first time, provides theoretical basis and experimental basis for Anthurium molecular breeding, and will effectively promote its molecular breeding process.

Owner:NANJING AGRICULTURAL UNIVERSITY

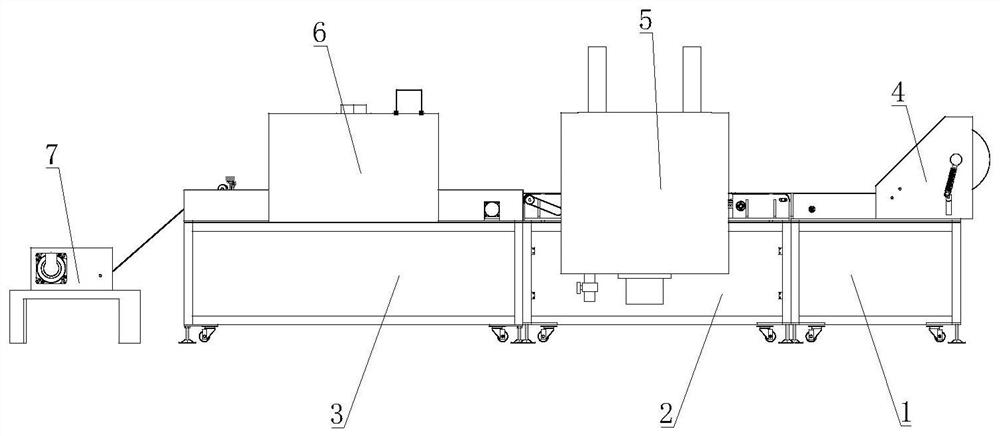

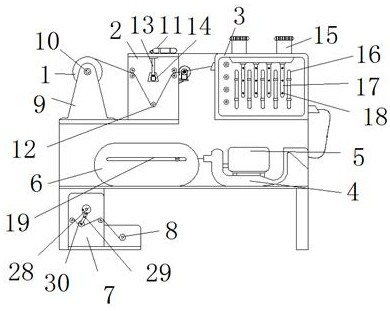

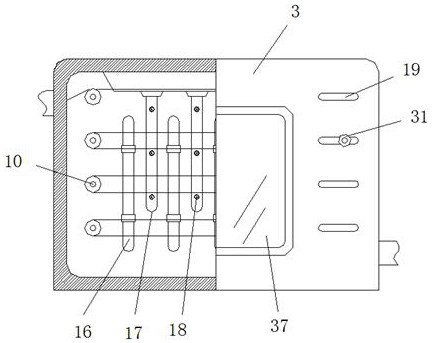

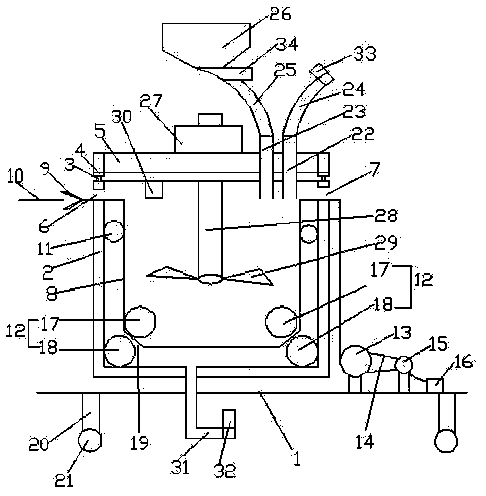

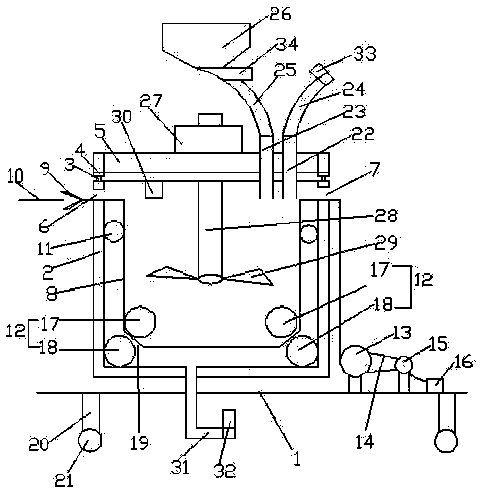

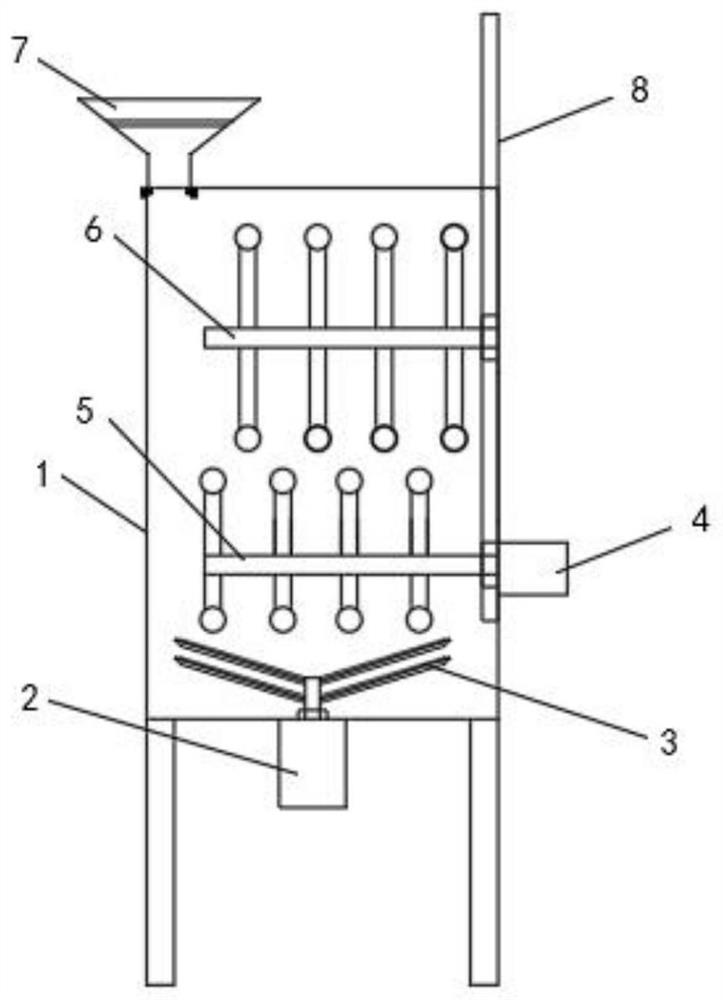

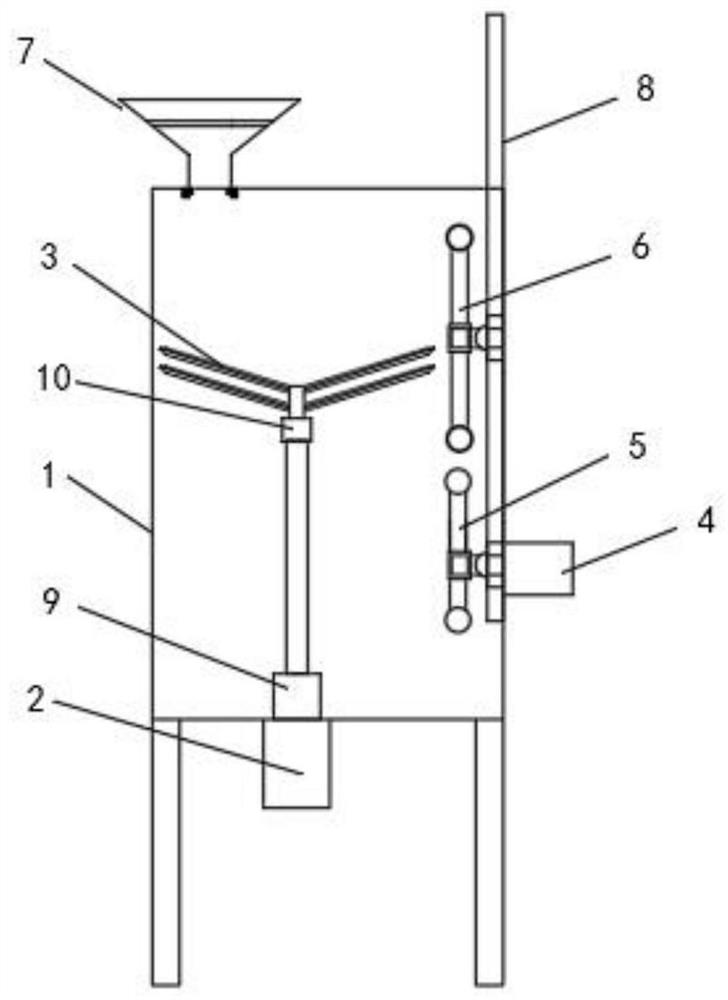

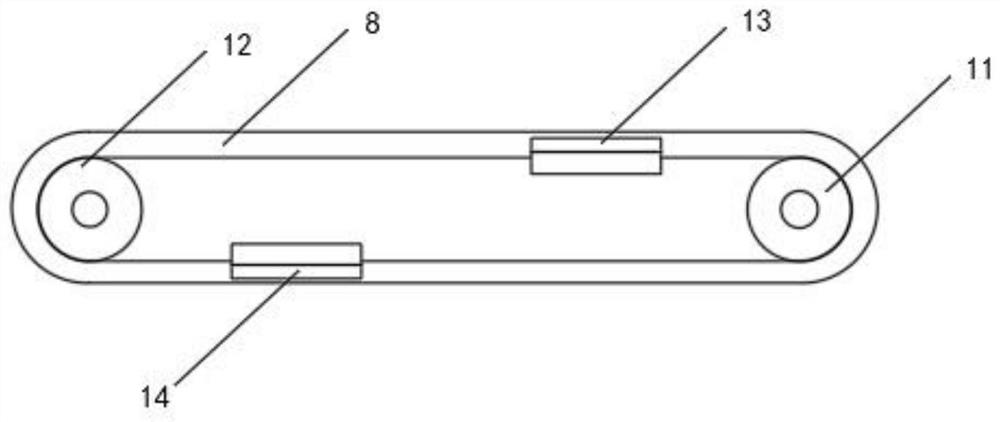

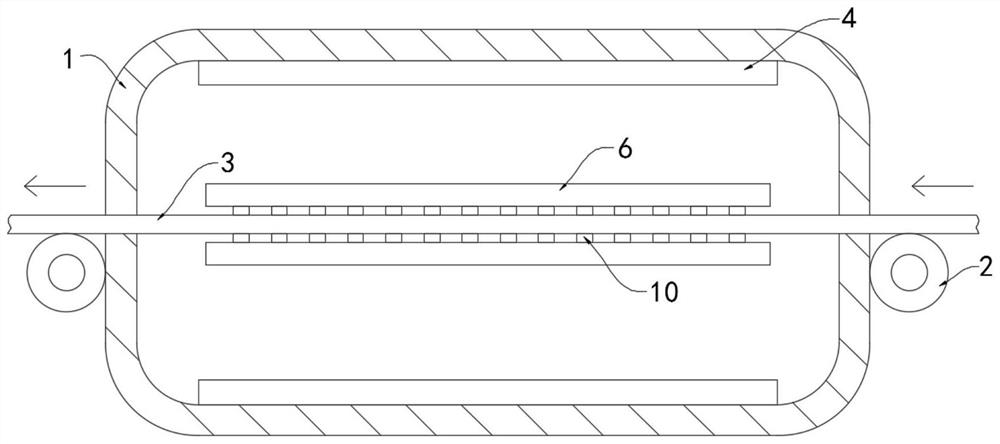

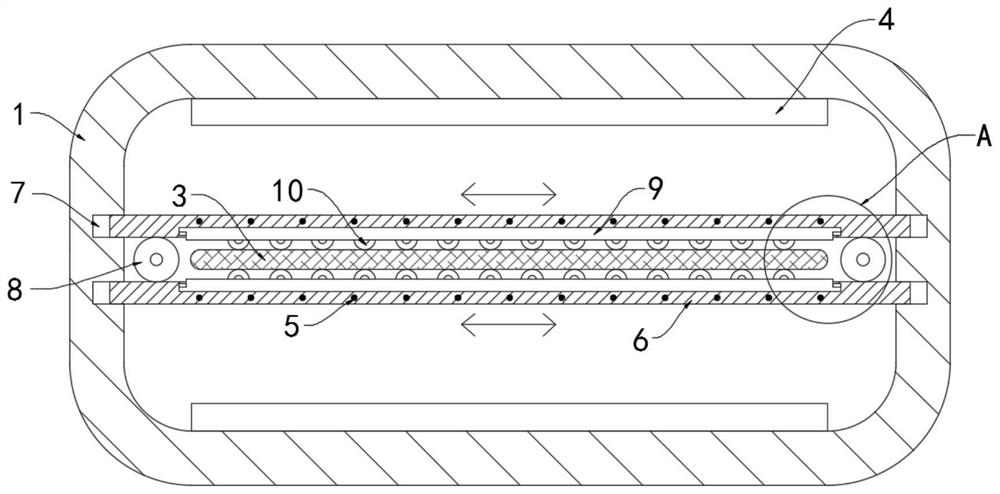

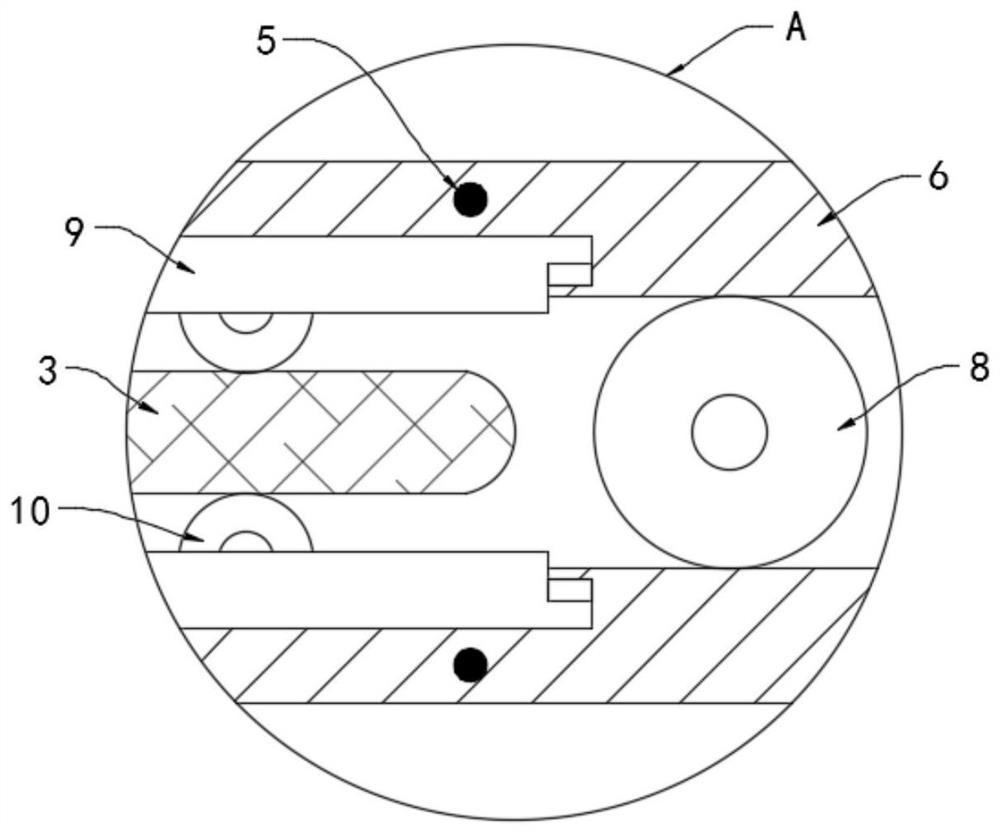

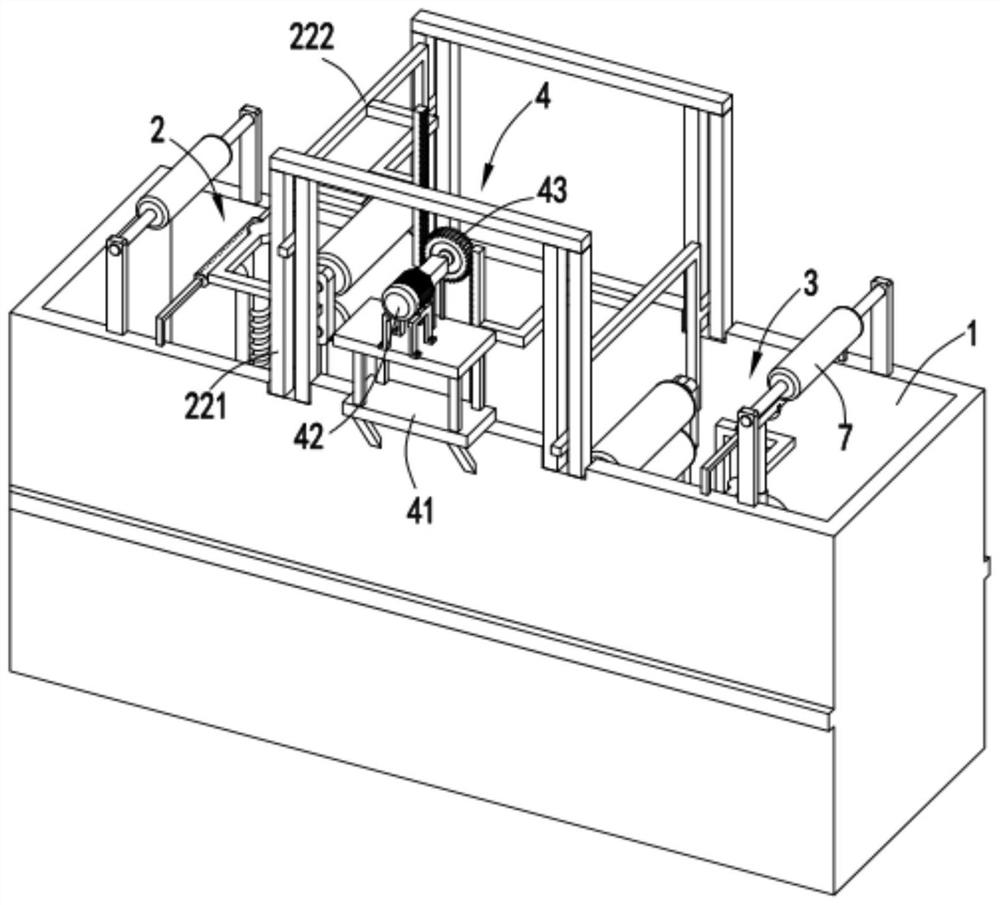

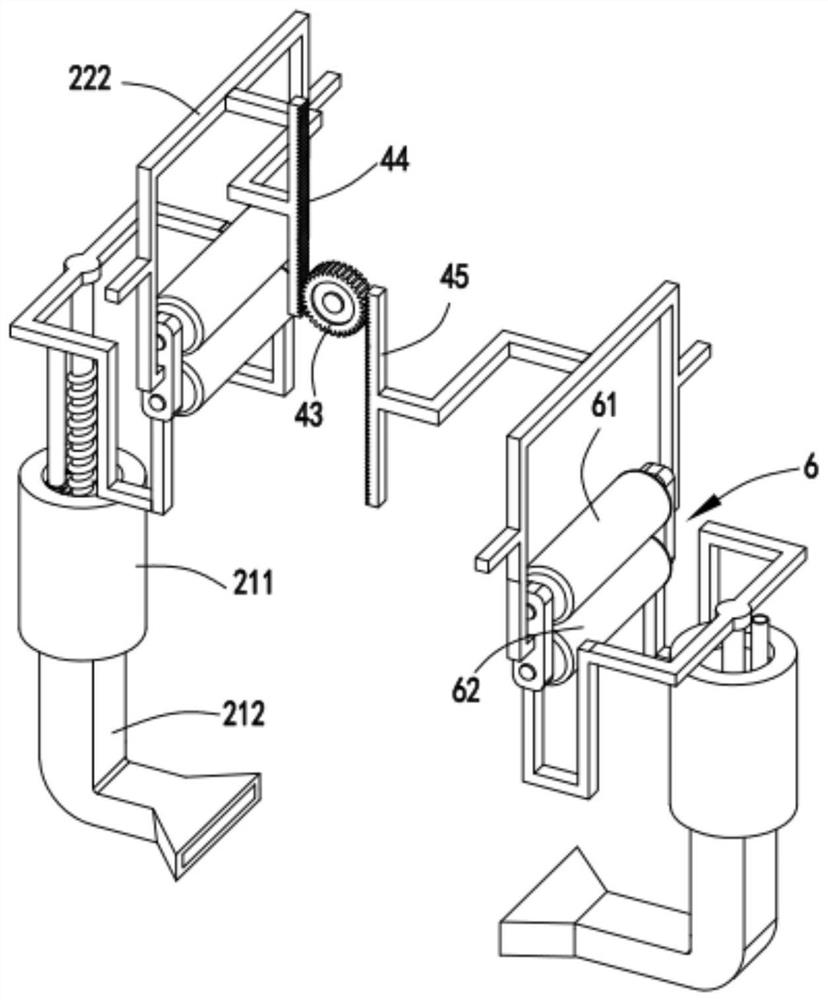

High-efficiency textile fabric printing and dyeing treatment system and process

ActiveCN109023762AAvoid the problem that the color is light and affects the dyeing effectImprove dyeing effectTextile treatment machine arrangementsTextile treatment by spraying/projectingEngineeringCoarse particle

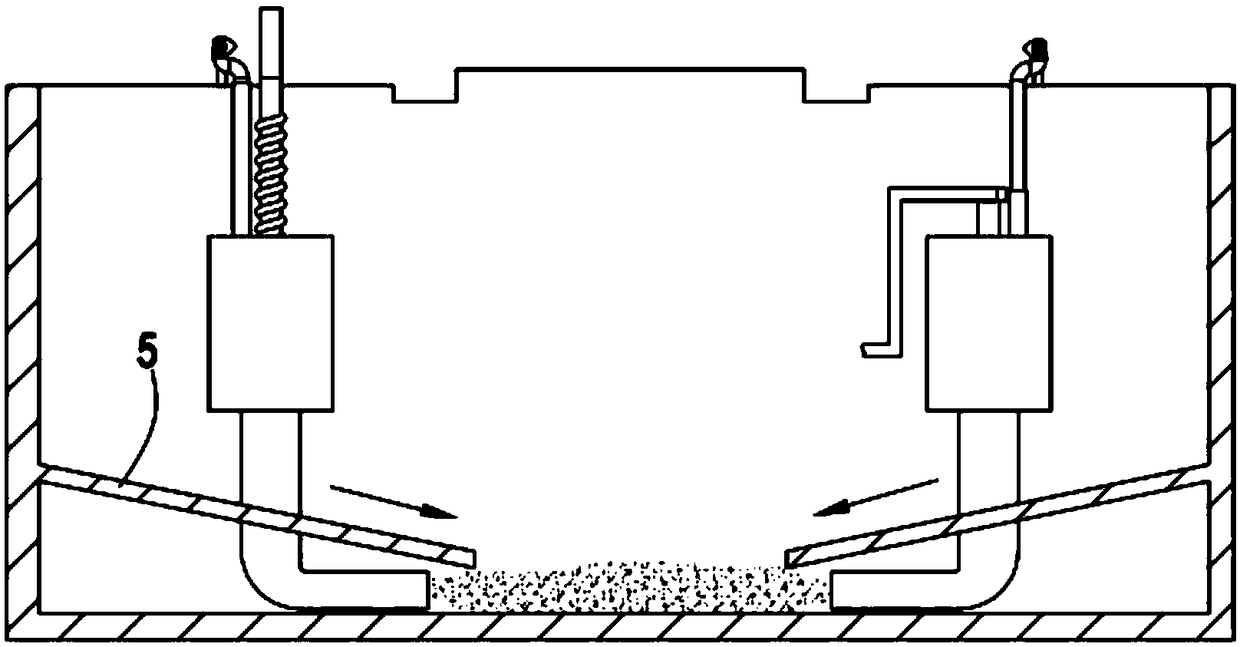

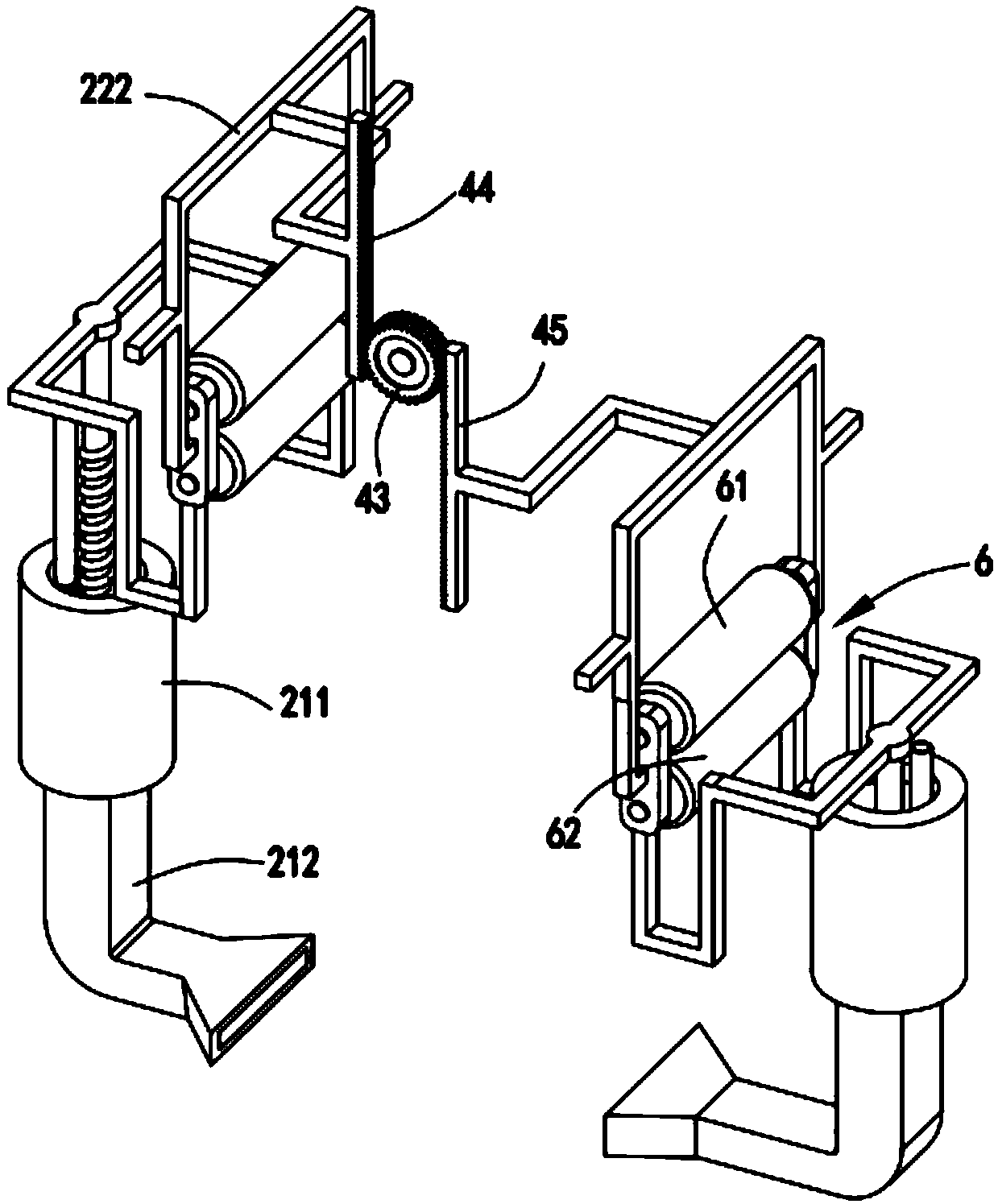

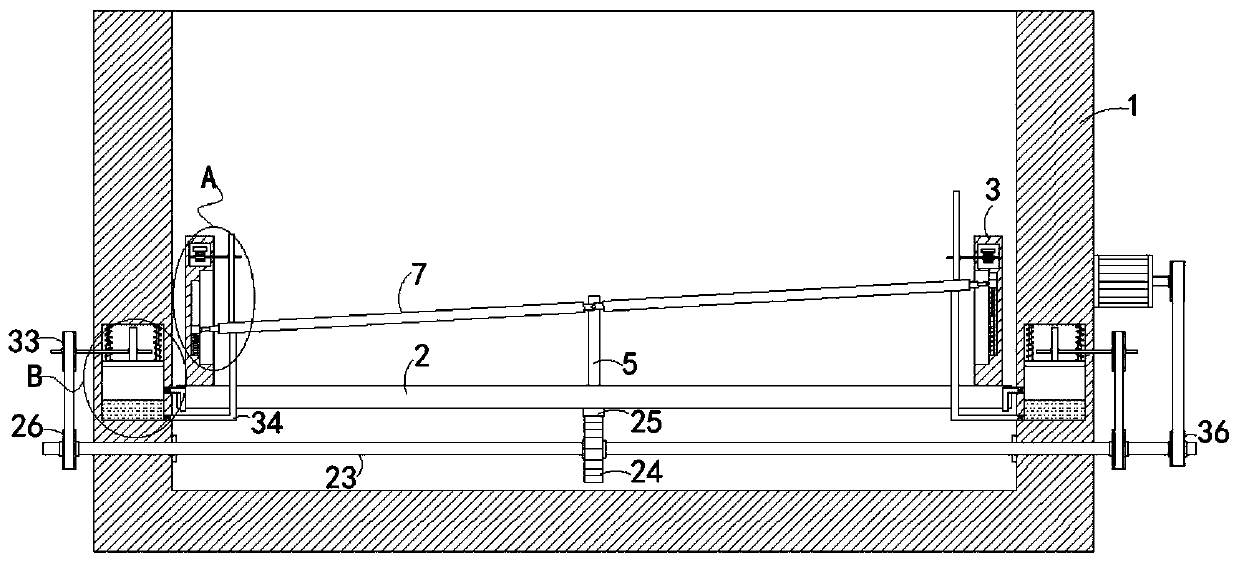

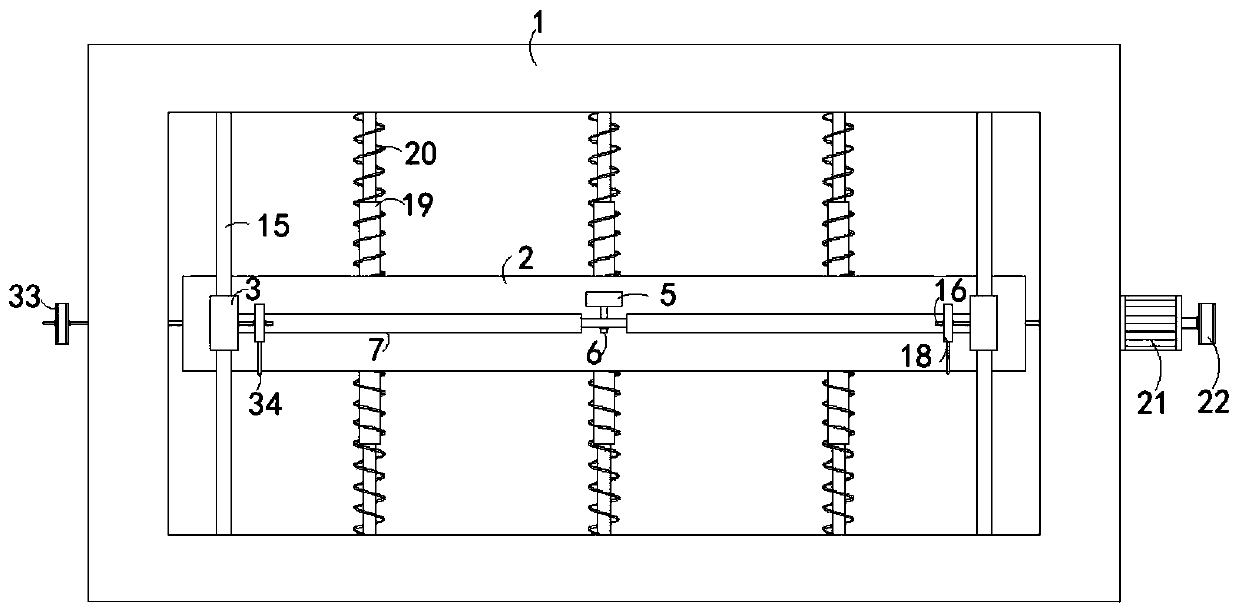

The invention relates to a high-efficiency textile fabric printing and dyeing treatment system and process. The process involves a dye box, wherein a first spray dyeing mechanism and a second spray dyeing mechanism are arranged in the dye box, and each of the first spray dyeing mechanism and second spray dyeing mechanism comprises a filtrate assembly fixed on the inner wall of the dye box, a squeezing and grinding assembly arranged in the corresponding filtrate assembly and a spray dyeing assembly arranged at the upper end of the corresponding filtrate assembly; a driving mechanism is arrangedbetween the first spray dyeing mechanism and the second spray dyeing mechanism and drives the two squeezing and grinding assemblies to rise and fall alternately, the filtrate assemblies extract a dyeliquor at the bottom of the dye box when the squeezing and grinding assemblies move upward, the dye liquor in the filtrate assemblies is squeezed to be filtered when the squeezing and grinding assemblies move downward so that the dye liquor is sprayed from a front spray dyeing assembly and a rear spray dyeing assembly to dye a fabric, and the squeezing and grinding assemblies move downward continuously after dye liquor squeezing and spray dyeing are completed to grind the coarse-particle dye remaining in the filtrate assemblies. The high-efficiency textile fabric printing and dyeing treatmentsystem and process solve the problems that the fabric dyeing mode is single, the dye liquor is stratified, the dyeing effect is poor, dyeing is nonuniform, and the dye utilization rate is low.

Owner:浙江盛邦化纤有限公司

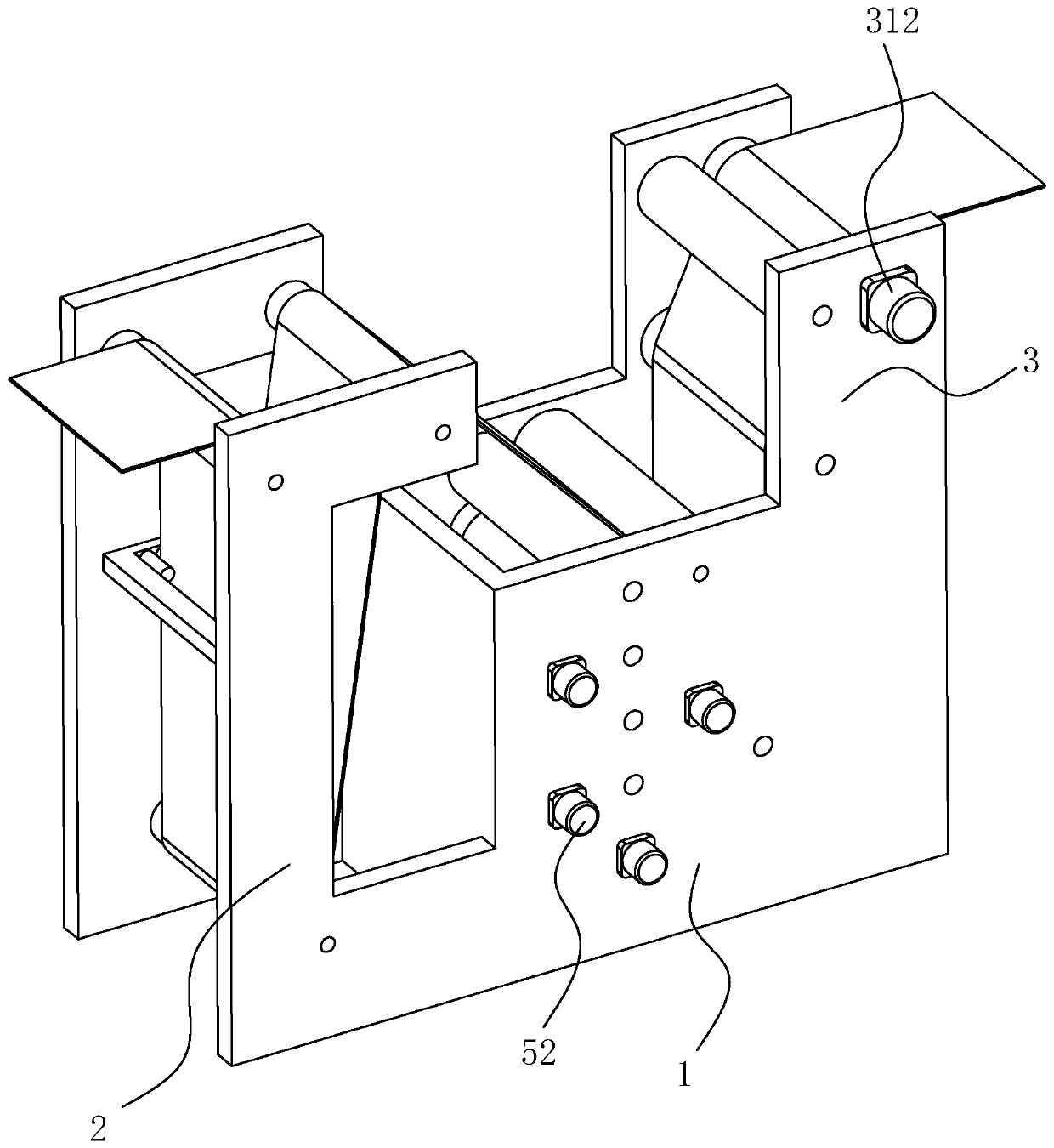

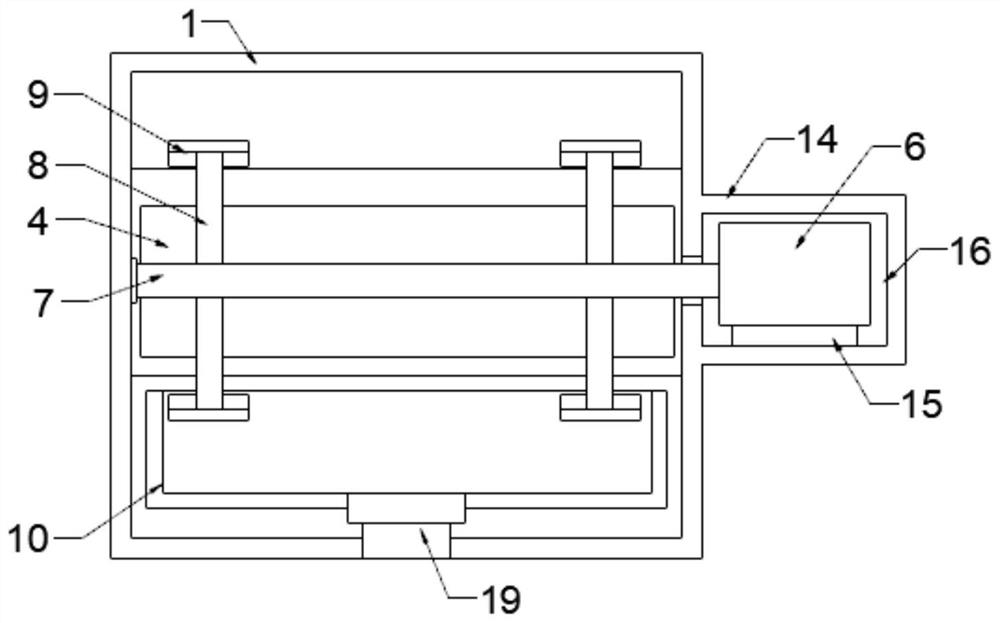

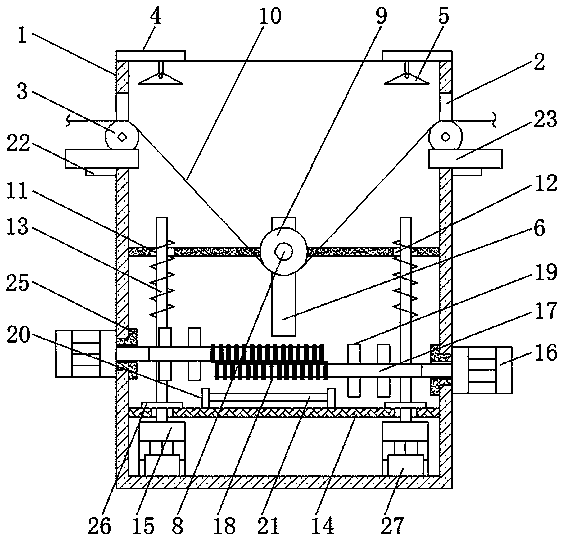

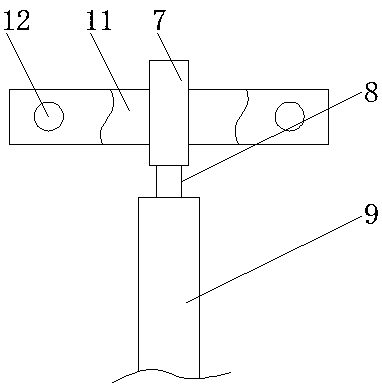

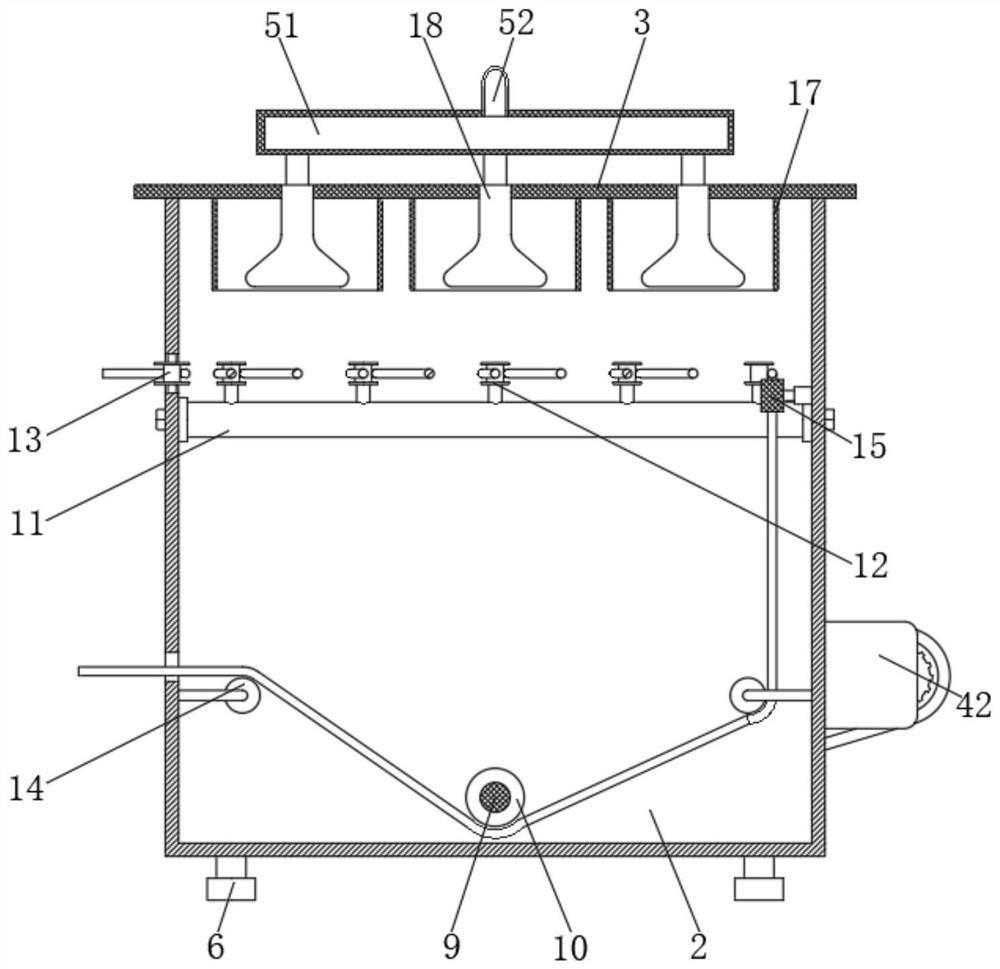

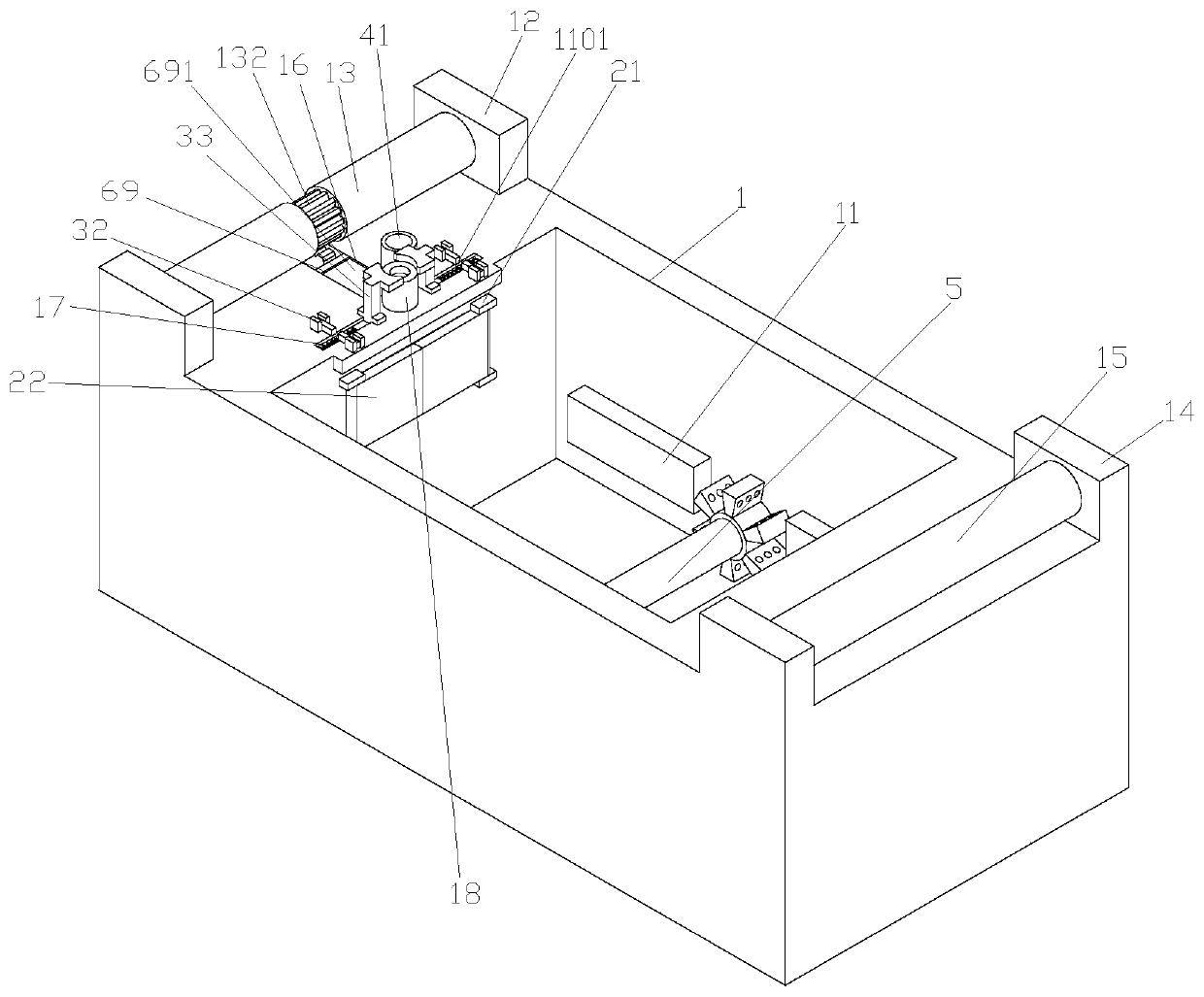

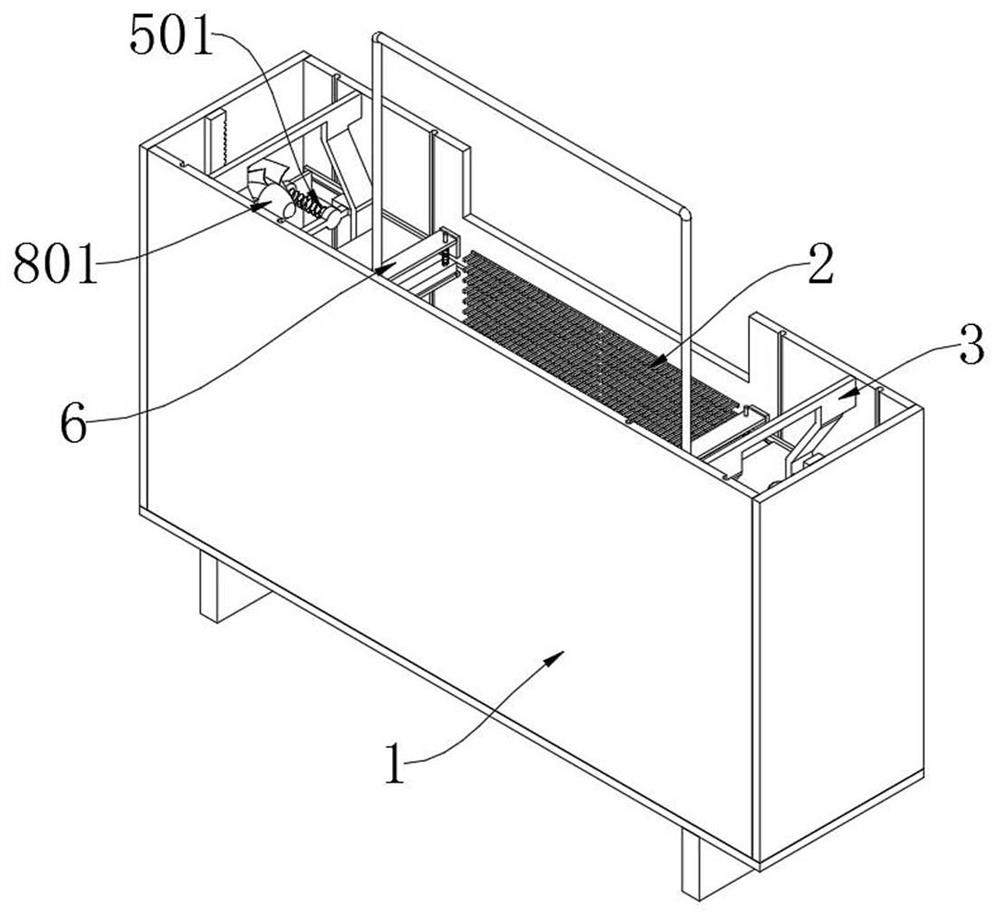

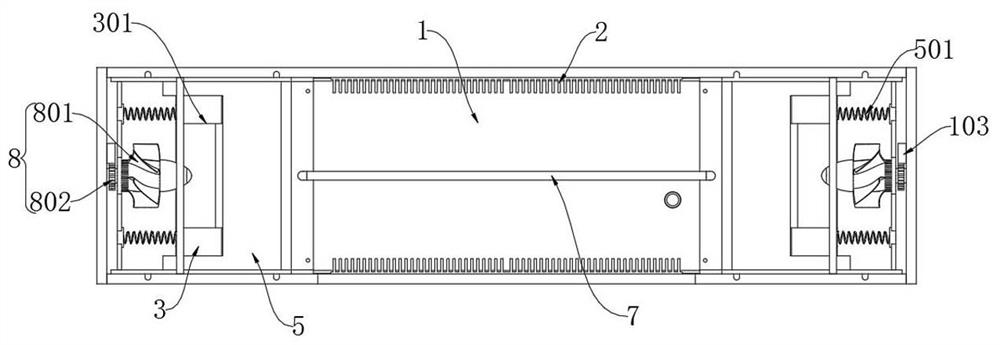

Planar fixed swing type dip dyeing device applied to fabric processing

PendingCN111088621AFully contactedImprove efficiencyTextile treatment machine arrangementsTextile treatment with treating outlet contectEngineeringMechanical engineering

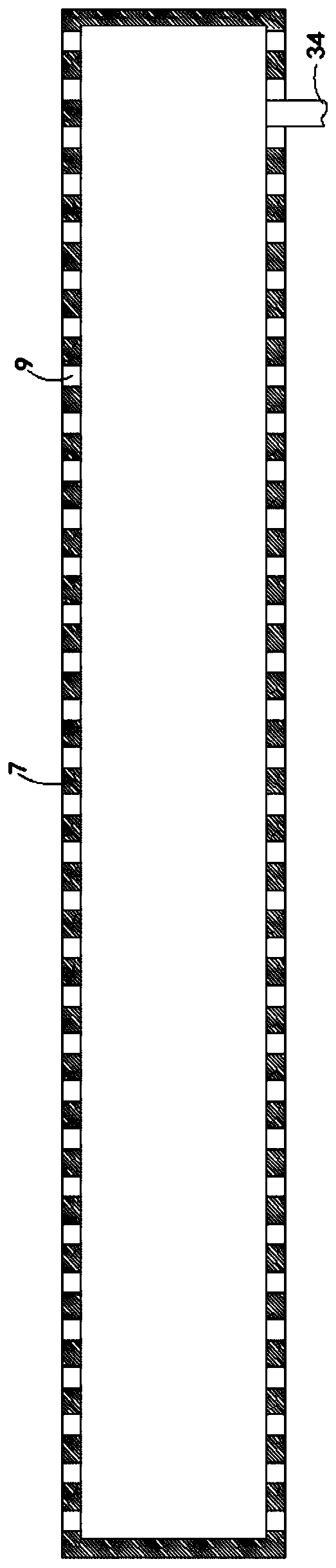

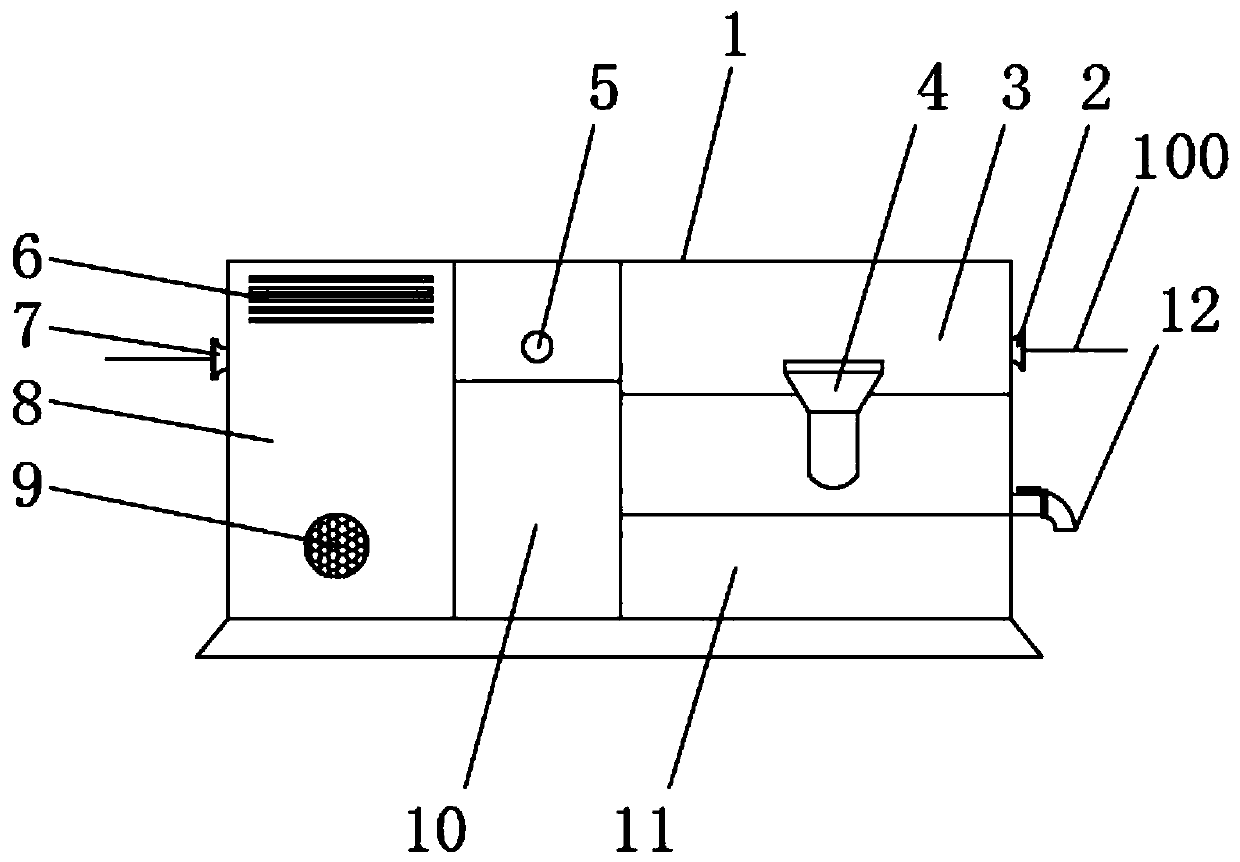

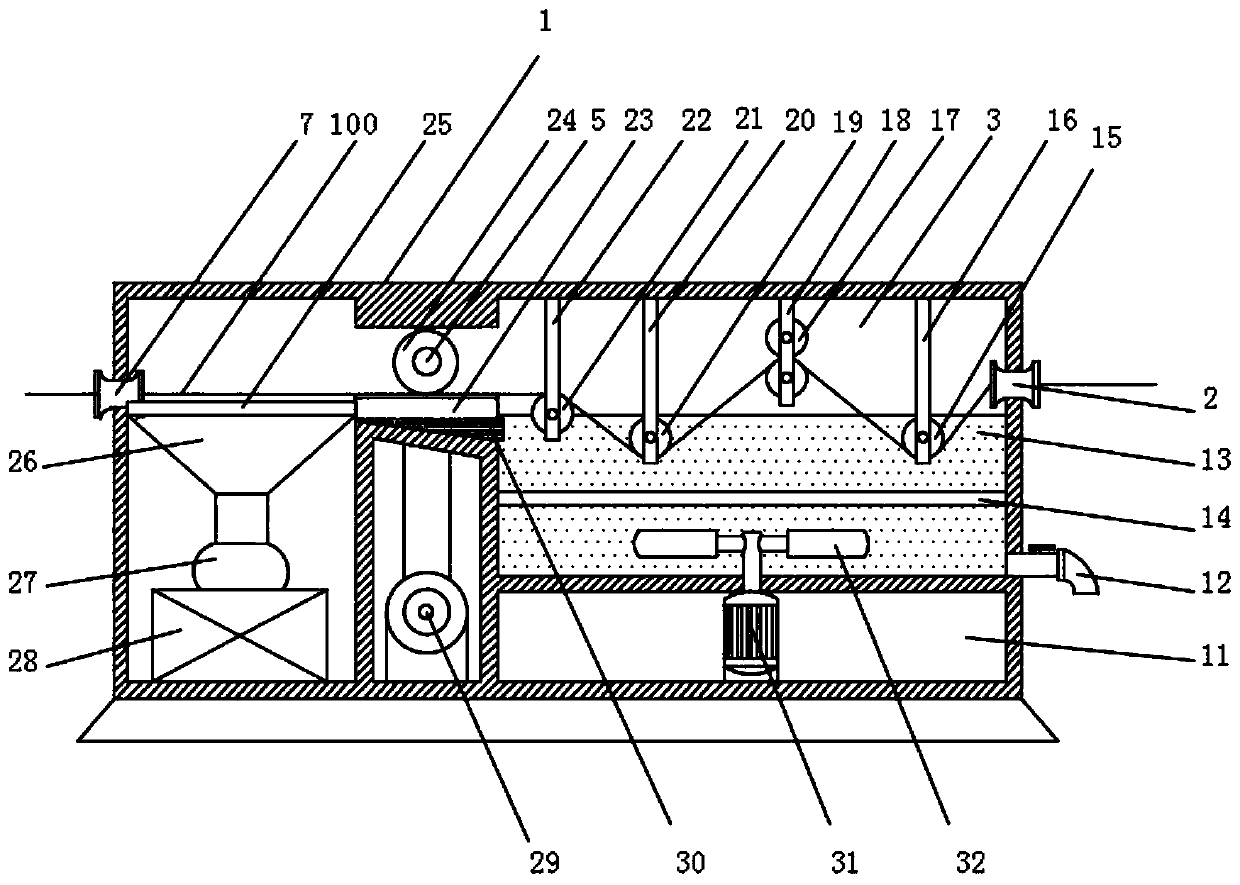

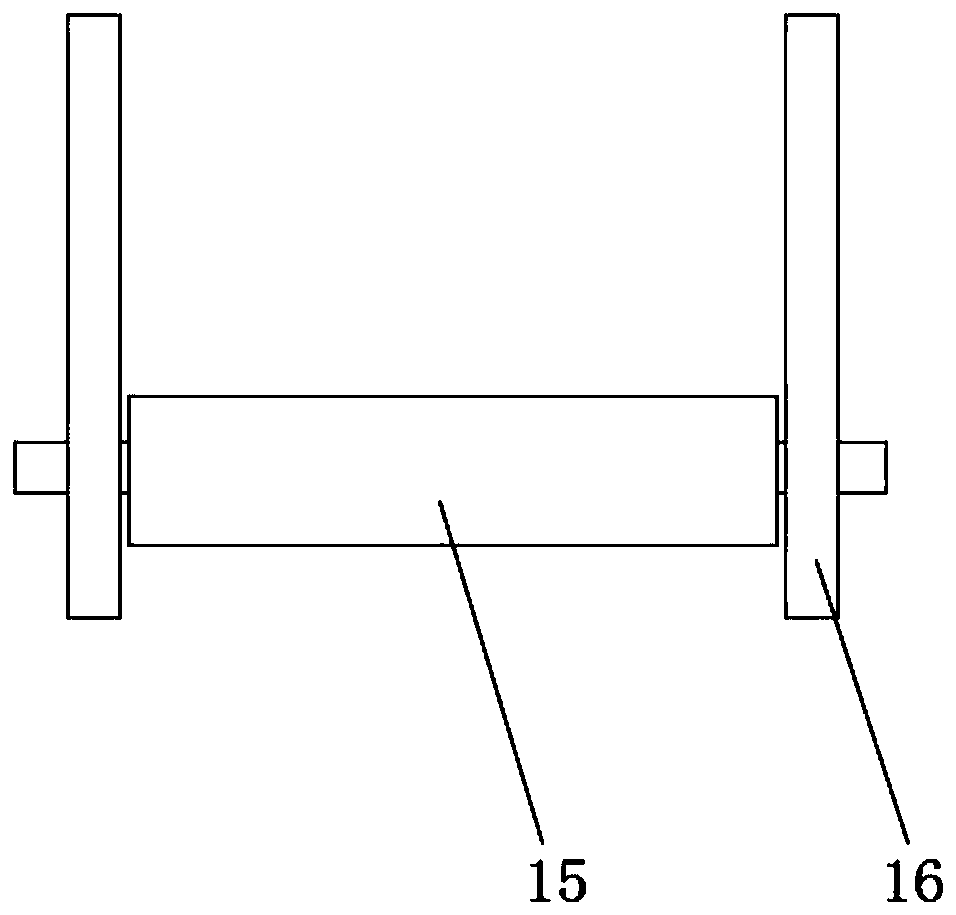

The invention discloses a planar fixed swing type dip dyeing device applied to fabric processing. The device comprises a box body, wherein a supporting plate is arranged in the box body, a plurality of elastic mechanisms are fixedly connected between the side walls of the front end and the rear end of the supporting plate and the inner walls of the front end and the rear end of the box body correspondingly, and a cloth winding mechanism is fixedly connected to the upper end of the supporting plate; vertical plates are fixedly connected to the portions, on the left end and the right end of thecloth winding mechanism, of the supporting plate, grooves are formed in the opposite side walls of the two vertical plates, sliding mechanisms are arranged on the inner walls of the grooves, the two sliding mechanisms are rotationally connected with the cloth winding mechanism, and driven mechanisms are arranged in the portions, above the grooves, of the vertical plates; the two ends of the drivenmechanisms are fixedly connected with the inner walls of the front end and the rear end of the box correspondingly, and the rotating end of the first driven mechanism abuts against the upper end of the cloth winding mechanism. According to the dip dyeing device, the effect of shaking the fabric is achieved during dip dyeing, so that the dip dyeing effect is improved; and in addition, the fabric is subjected to dip dyeing through dip dyeing liquid sprayed out of the cloth winding pipe, and the dip dyeing efficiency and the dip dyeing effect are further improved.

Owner:FUJIAN CHARME TEXTILE

Anti-pilling sportwear fabric and preparation method thereof

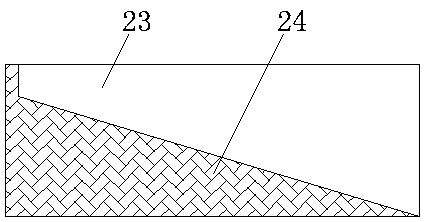

InactiveCN111235722AGood moisture conductivityKeep freshHeating/cooling textile fabricsTextile treatment machine arrangementsPolyesterProcess engineering

The present invention discloses an anti-pilling sportwear fabric. The fabric is prepared by weaving polyester fibers and modal fibers into cloth and performing sizing, oiling treatment, desizing and refining treatment, alkali decrement treatment, post-setting and drying treatment, preparation of an anti-pilling finishing agent and finishing by using a padding device; the obtained knitted fabric has the good moisture guide effect, and can rapidly discharge sweat generated when the human body moves to the surface layer of clothes to be evaporated, so that the skin is kept refreshing and the human body feels more comfortable during movement; through treatment with the finishing agent, the anti-pilling performance of the fabric is improved; the padding device performs two-dipping and two-rolling treatment on the to-be-padded fabric, so that the fabric can absorb the sufficient finishing liquid and the dip dyeing effect is good; one end of a dip dyeing box is provided with a drying box, sothat the to-be-padded fabric is directly dried after being dip-dyed and the working efficiency is improved; and the finishing agent used by the padding device can be recycled, so that the waste of thefinishing agent is reduced and the production cost is reduced.

Owner:ANHUI HENGYI TEXTILE TECH CO LTD

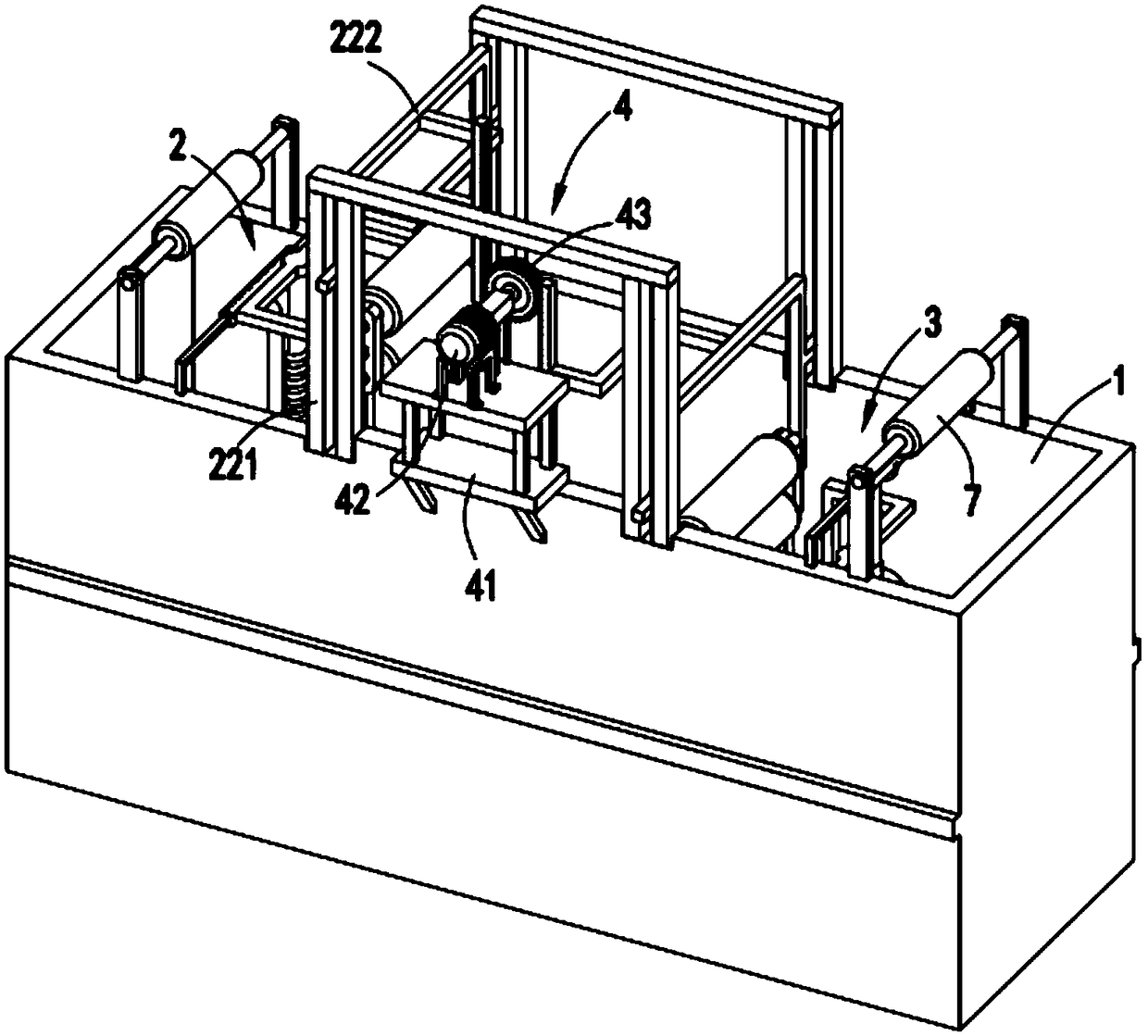

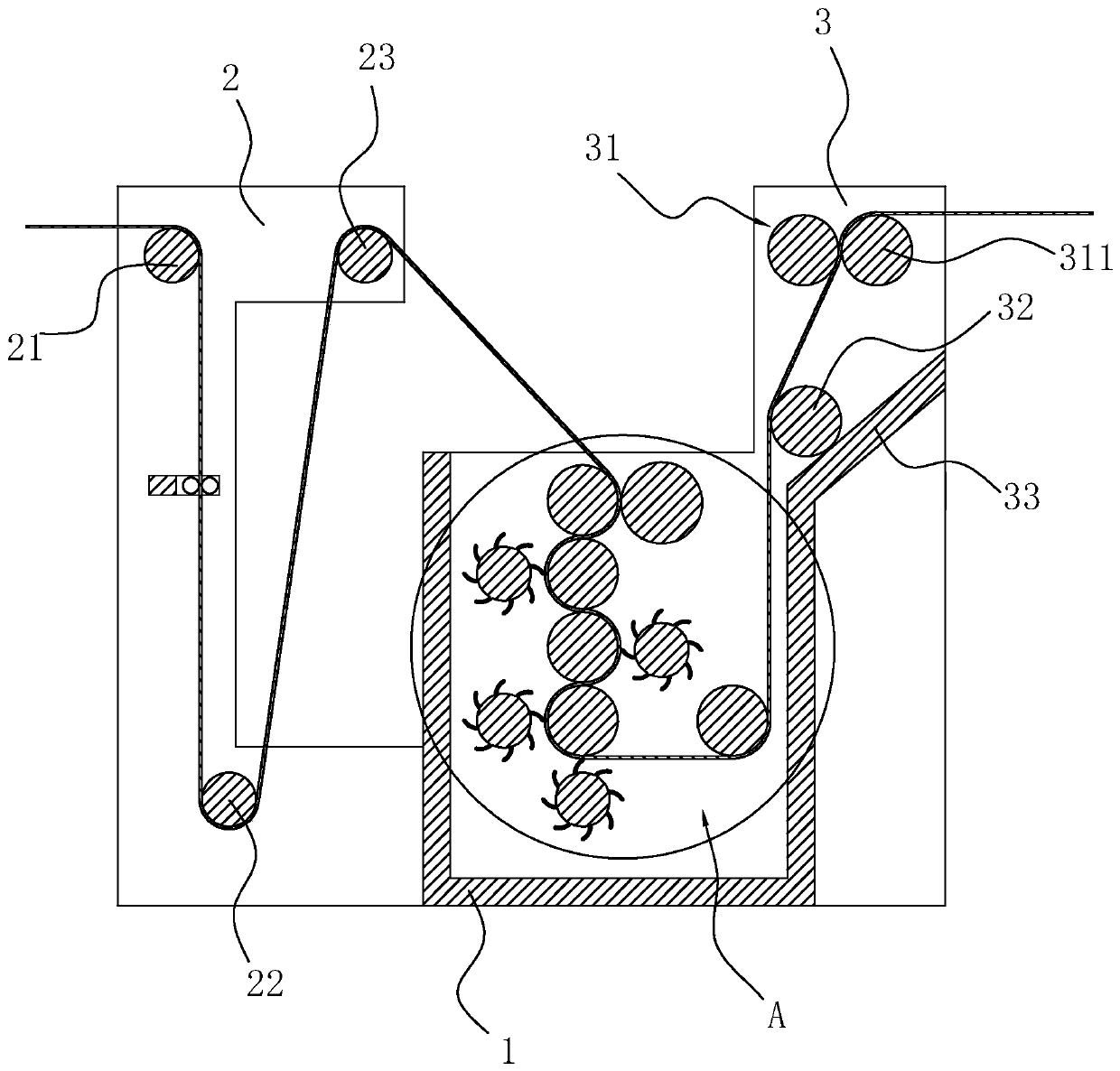

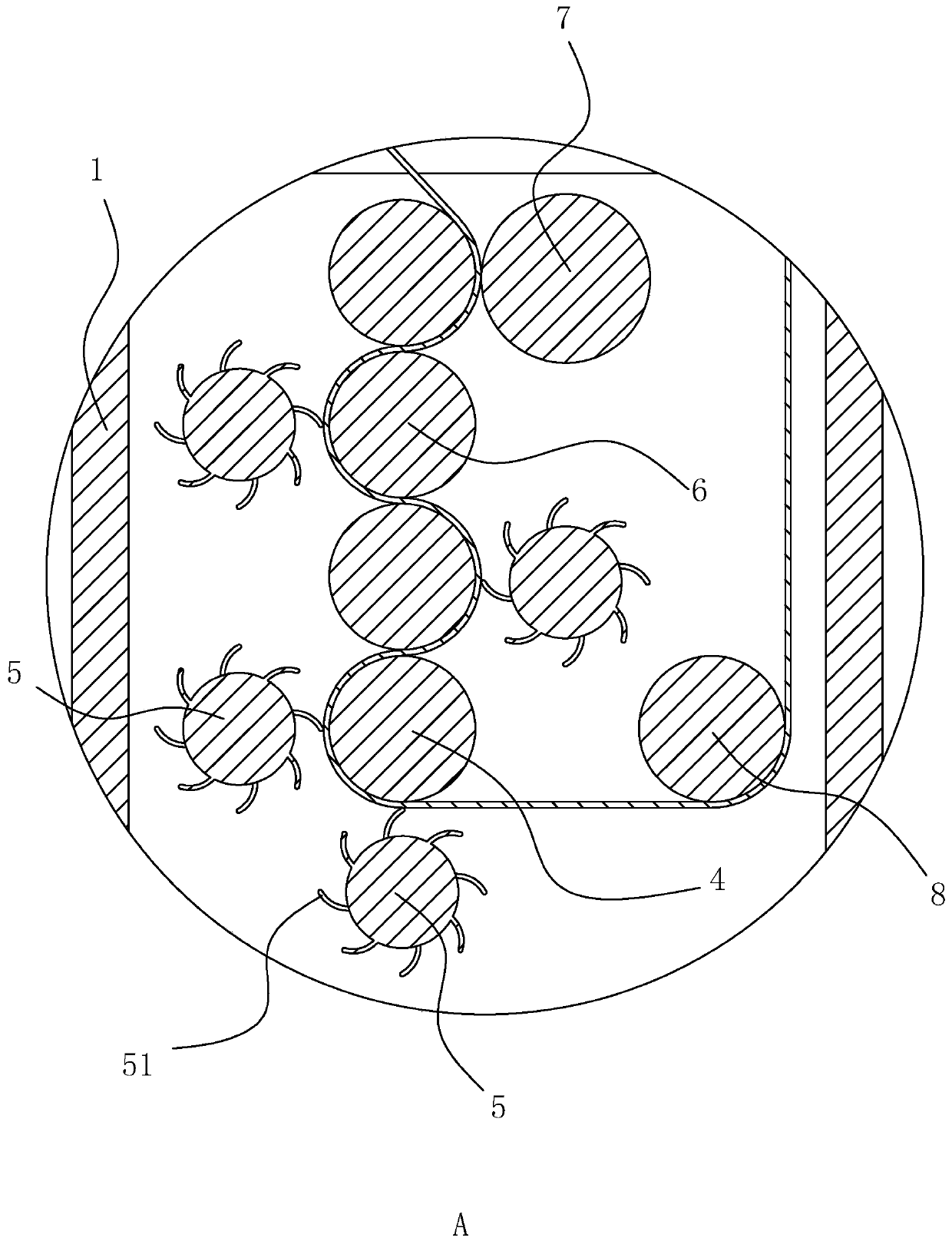

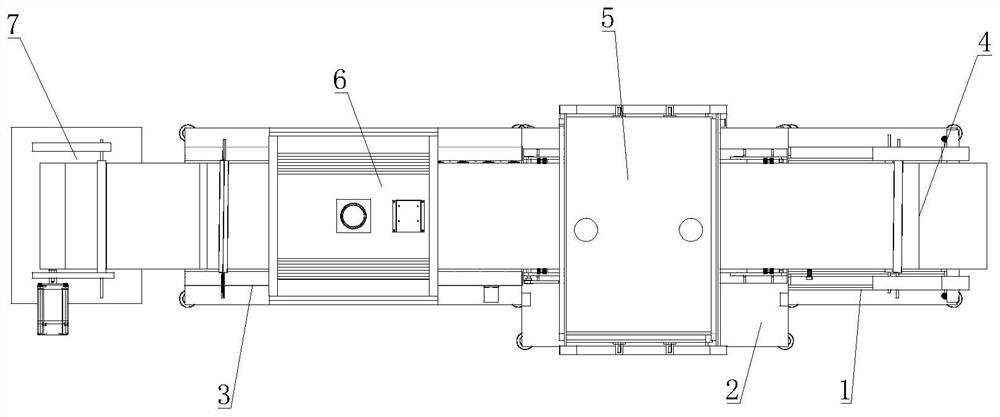

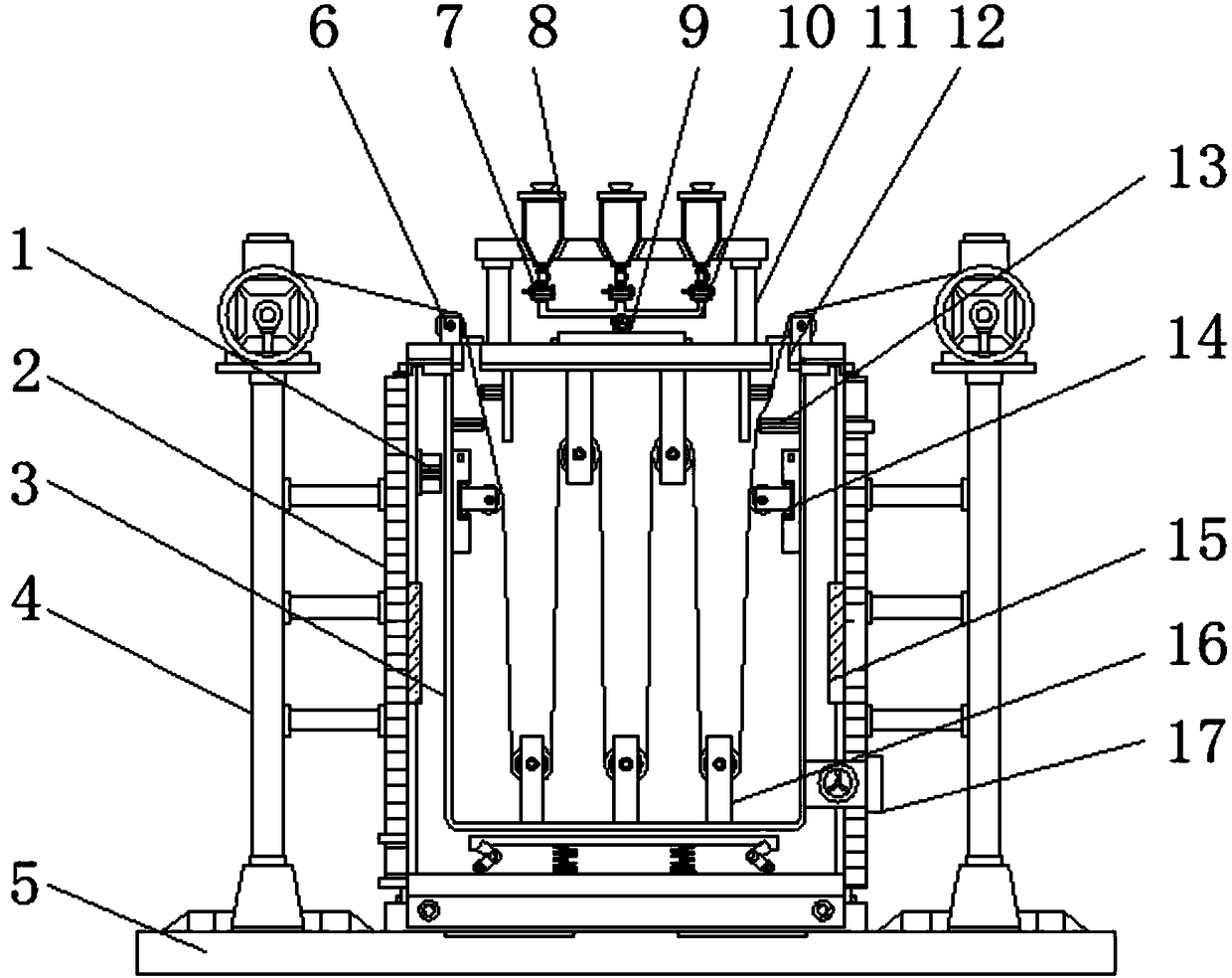

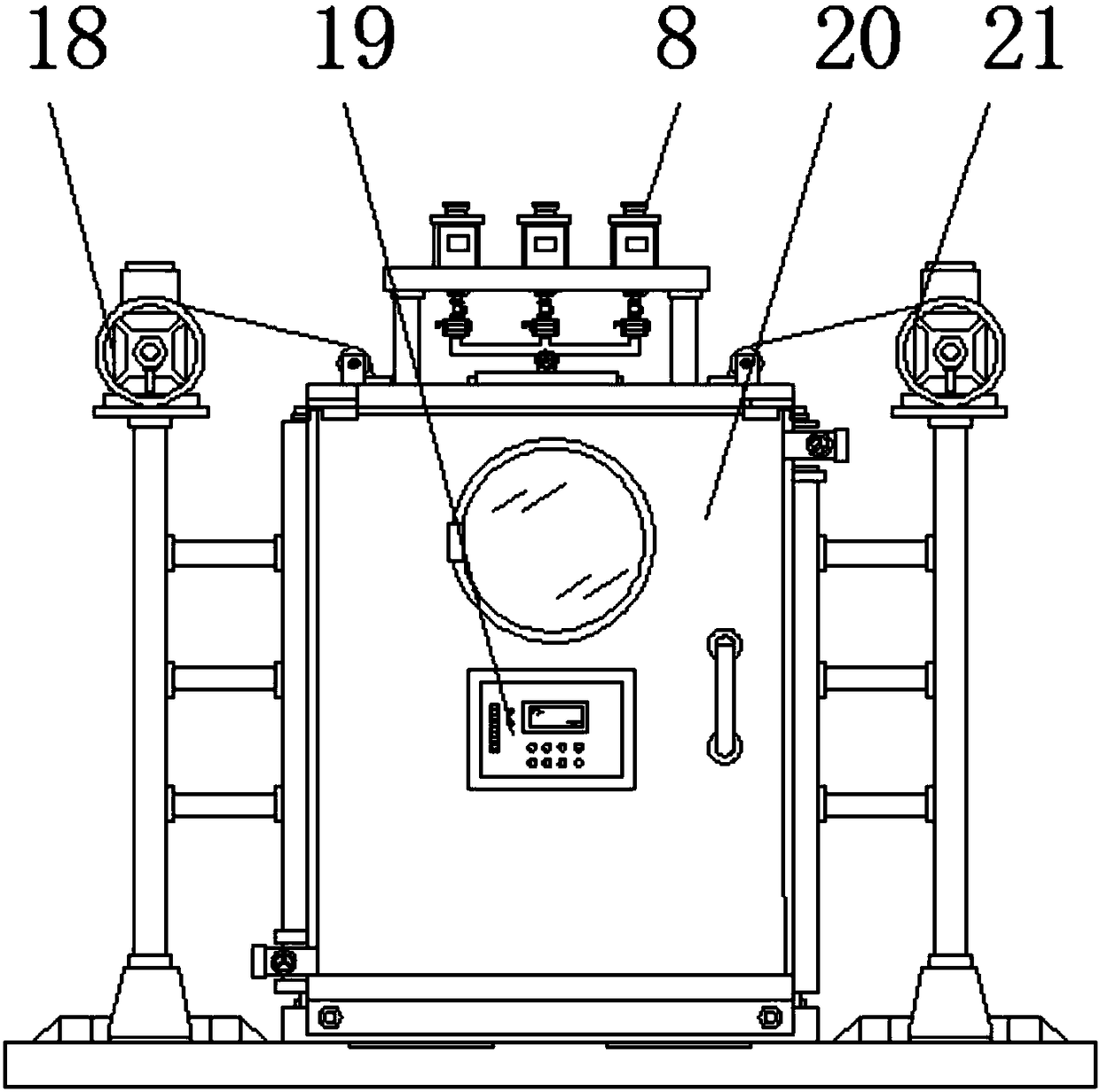

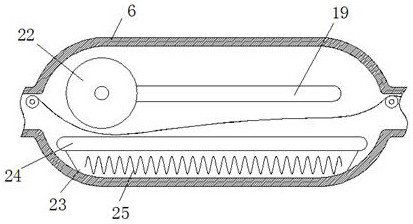

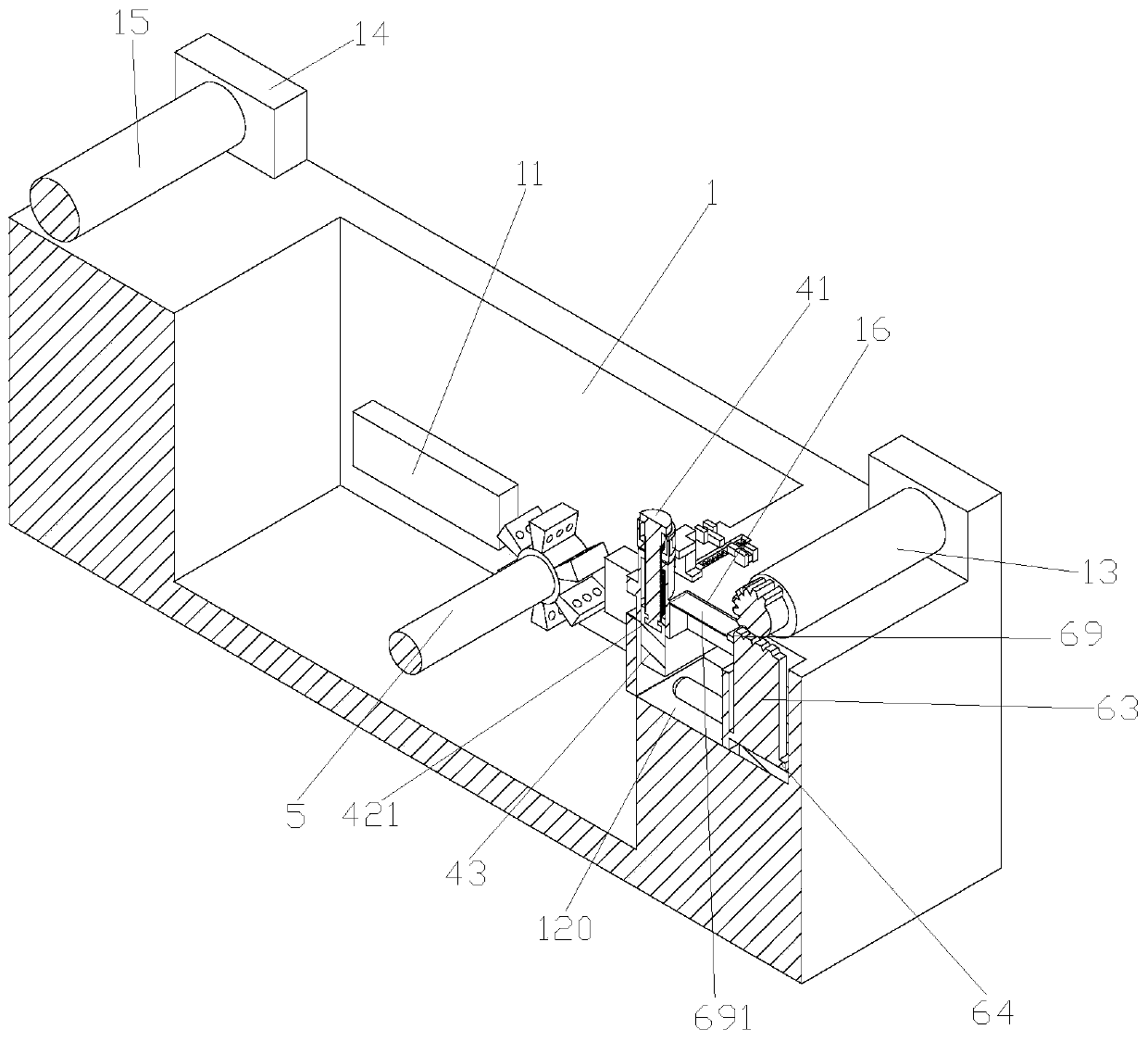

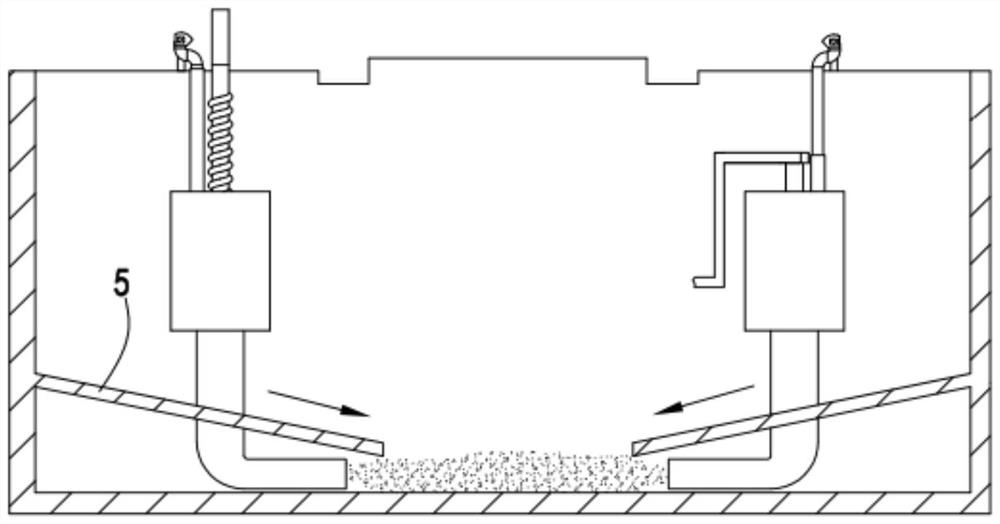

Cold dyeing device and cold dyeing process

ActiveCN111118779AImprove the effect of dip dyeingNot easy to settleTextile storage in superimposed formLiquid/gas/vapor removal by squeezing rollersProcess engineeringDyeing

The invention discloses a cold dyeing device and a cold dyeing process. According to the technical scheme, the cold dyeing device comprises a cold dyeing box, two feeding frames arranged on one side of the feeding side of the cold dyeing box, and two discharging frames arranged on one side, away from the feeding frame, of the cold dyeing box; the cold dyeing process comprises the following steps of a, configuring a dye; b, carrying out dip dyeing; c, performing stacking and color fixing; e, performing washing; and e, performing drying; and driving the dye to flow through a stirring roller, sothat solid substances in the dye cannot easily settle to the bottom of a flat washing tank, driving a material shifting plate to repeatedly extrude cloth, and improving the dip dyeing effect of the dye on the cloth fibers.

Owner:浙江中纺控股集团有限公司

Production process of antibacterial flame-retardant fabric

InactiveCN112391760AImprove processing efficiencyReduce manufacturing costFlame-proof filament manufactureConjugated cellulose/protein artificial filamentsWoven fabricFlame resistance

The invention discloses a production process of an antibacterial flame-retardant fabric. The production process includes the steps of step 1, warp yarn preparation: selecting raw materials of the antibacterial flame-retardant fabric, adding flame-retardant acrylic fibers and flame-retardant viscose into the raw materials of the fabric, carding to prepare card slivers, and spinning the card sliversinto the warp yarns through roving and spinning procedures; and step 2, weaving: weaving warp yarns in the step 1 into a fabric through a textile machine, rolling the woven fabric, and putting the rolled fabric into a cleaning and drying device for cleaning and drying processing. According to the production process of the antibacterial flame-retardant fabric, the flame-retardant acrylic fibers and the flame-retardant viscose are added into the raw materials of the fabric, so that the prepared and formed fabric has good flame-retardant performance; the woven and formed fabric is cleaned, driedand processed, and the cleanliness of the fabric is ensured before dip dyeing of an antibacterial coating in the cleaning and drying process, so that the cleaning of the fabric is ensured when the fabric is dip-dyed, and the dip dyeing effect on the fabric is improved; and cleaning and drying and dip dyeing and drying of the fabric are achieved through the same set of equipment, so that the processing efficiency of the fabric is effectively improved.

Owner:广州坤立服装有限公司

Dyeing device for fabric deep dip dyeing

PendingCN112760862AFully impregnatedDip dyed evenlyTextile treatment containersLiquid/gas/vapor textile treatmentPolymer scienceEngineering

The invention discloses a dyeing device for fabric deep dip dyeing. The dyeing device comprises a shell, a cloth pressing mechanism and a dye mechanism, wherein the shell comprises a shell, a cloth inlet, a cloth outlet, guide wheels and guide plates; the cloth inlet and the cloth outlet are formed in the two sides of the shell respectively; the two guide wheels are rotationally installed in the cloth inlet and the cloth outlet; the two guide plates are fixedly mounted on two opposite inner walls of the shell; the cloth pressing mechanism comprises a motor, a mounting rod, rotating rods and pressing pieces; the motor is slidably mounted on the side wall of the shell through a sliding mechanism; the output end of the motor is fixedly connected with the mounting rod; the multiple rotating rods are fixedly connected to the side wall of the mounting rod, and the rotating rods and the pressing piece form one pressing wheel; and the dye mechanism is used for dyeing the cloth. According to the dyeing device, the dip dyeing effect on the cloth is enhanced, all parts of the cloth are uniformly dip-dyed, the dyeing color difference of different parts of the cloth is reduced, and the attractiveness degree of the dyed cloth is improved.

Owner:李勇平

Textile cloth float dyeing device with deviation rectifying structure

PendingCN112048858AImprove dyeing efficiencyImprove dyeing effectLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsPolymer scienceEngineering

The invention relates to the technical field of textile cloth dyeing equipment, in particular to a textile cloth float dyeing device with a deviation rectifying structure. The textile cloth float dyeing device comprises a device main body, wherein the device main body comprises a float dyeing bin; a dip dyeing bin is fixedly arranged on one side of the float dyeing bin, and the bottom of the dip dyeing bin communicates with the bottom of the float dyeing bin; the other side of the dip dyeing bin is fixedly connected with a collecting bin, and a filter plate is fixedly arranged inside the collecting bin; and a control face plate is fixedly arranged on the outer wall of the float dyeing bin, and a float dyeing mechanism is arranged inside the float dyeing bin. According to the textile clothfloat dyeing device with the deviation rectifying structure, an arranged first threaded rod and an arranged first threaded sleeve are in threaded rotary connection, and when the device is used, the first threaded sleeve can be controlled to move through rotation of the first threaded rod, so that float dyeing assemblies move left and right, cloth is driven to swing inside the device in a reciprocating mode for float dyeing, the dyeing effect of the device is effectively improved, and cloth dyeing efficiency is conveniently improved.

Owner:吴兰洲

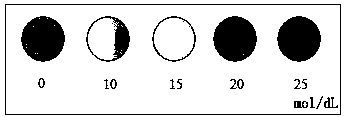

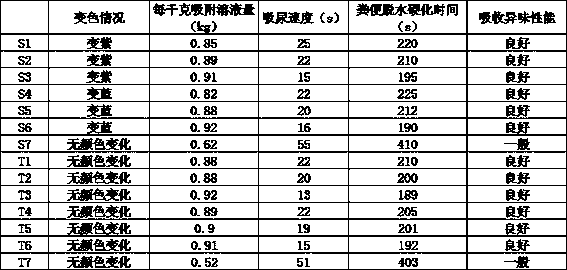

Cat litter having function of pet urine protein early warning and preparation method thereof

ActiveCN109287499AImprove the effect of dip dyeingEfficient dip dyeingAnimal housingLitterSilica gel

The invention discloses a cat litter having the function of pet urine protein early warning and a preparation method thereof. The cat litter is prepared from modified fine pored silica gel, diatomite,active carbon, a urine protein indicator agent and an antibacterial agent. A biuret reaction is applied to the preparation process of cat litter, a silica gel substrate material and the urine proteinindicator agent are scientifically proportioned according to usage quantities so as to generate a color development reaction on urine having abnormal urine protein, no color development reaction is generated on urine with a normal value, in this way, the health conditions of a pet can be reflected primarily, the pet with the abnormal urine can be brought to see a doctor and checked in time, and the effect of early warning is realized. According to the cat litter, silica gel is further modified, the hydrophilia of the silica gel is effectively improved, the effect of dip dyeing of the silica gel with the urine protein indicator agent is enhanced, and therefore the color developing reaction is obvious and easy to distinguish. Meanwhile, the novel antibacterial agent is added, the antibacterial effect of the cat litter is remarkable, continuity is good, and frequent replacement is not needed. The preparation technology is simple, costs are low, and the cat litter is suitable for application and popularization.

Owner:麦都宠医(上海)科技发展有限公司

Textile cloth dip dyeing equipment with good dip dyeing effect

InactiveCN107663728AImprove the efficiency of dippingImprove dissolution efficiencyTextile treatment containersTextile treatment machine arrangementsEconomic benefitsEngineering

The invention discloses textile cloth dip dyeing equipment with good dip dyeing effect. The textile cloth dip dyeing equipment comprises a dyeing cylinder body, wherein through holes are respectivelyformed in the top parts of both sides of the dyeing cylinder body; an inner cavity of each through hole is movably connected with a first drum through a rotary shaft; both sides of the top part of thedyeing cylinder body are fixedly connected with connecting plates; the bottom part of each connecting plate is fixedly connected with a baking lamp; the bottom part of each baking lamp extends to thetop part of the inner cavity of the dyeing cylinder body; the front surface and back surface of the inner cavity of the dyeing cylinder body are respectively provided with a movable groove. The textile cloth dip dyeing equipment has the advantages that by arranging the movable grooves, movable blocks, rotary rods, a second drum, a textile cloth, lifting plates, lifting holes, threaded rods, fixedplates and first motors, the dip dyeing efficiency of the dip dyeing equipment can be effectively improved; by arranging the heating and stirring functions, the dissolving efficiency of a dyeing solution is improved, the uniformity of the dyeing solution is improved, the dip dyeing effect of the textile product is effectively improved, the quality of the textile product is ensured, and the huge economic benefit is brought for textile enterprises.

Owner:陈礼成

Textile-fabric dip dyeing device

InactiveCN108442059AAvoid cloggingAvoid pollutionTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentPulp and paper industryScrew pump

The invention discloses a textile-fabric dip dyeing device. The textile-fabric dip dyeing device comprises a body, a dip dyeing inner barrel, frames and a bottom plate, wherein the body is fixed in the middle of the top end of the bottom plate, the frames are installed at the top end, located on the bottom plate, of the two sides of the body, a fabric discharging roller is fixed at the top end ofthe frame on one side of the body, a winding roller is installed at the top end of the frame on the other side of the body, motors are installed on the frames at one ends of the fabric discharging roller and the winding roller, both the fabric discharging roller and the winding roller are connected with the output ends of the motors, a door is hinged to one end of the body, and a control panel isfixed in the middle of the door. According to the textile-fabric dip dyeing device, as screw pumps are installed, the screw pumps can change the volume of a sealing cavity formed by internal threadedrods and linings to suck and discharge liquid, residual dye in a material collecting pipe can be sucked back to material hoppers on this basis, and it is avoided that residual materials block the material collecting pipe.

Owner:XIANGSHUI COUNTY XINHONG TEXTILE CO LTD

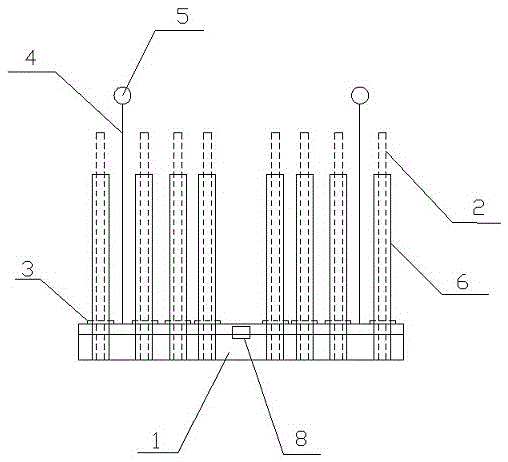

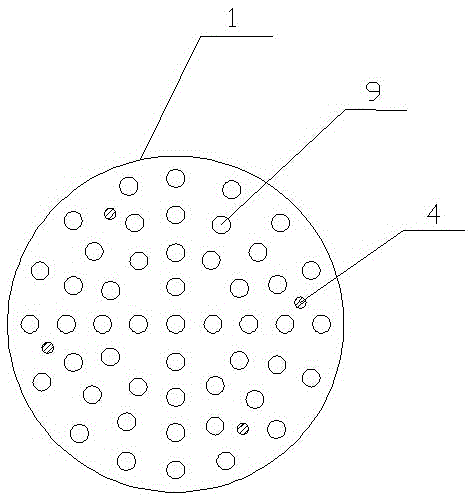

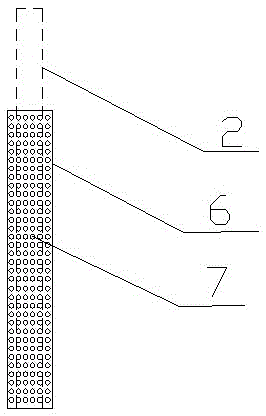

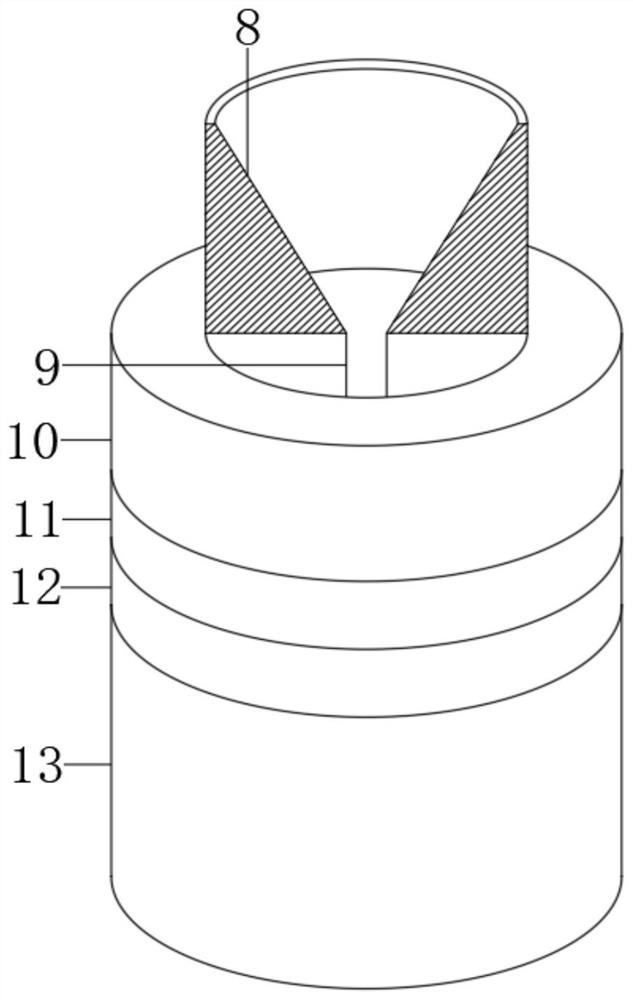

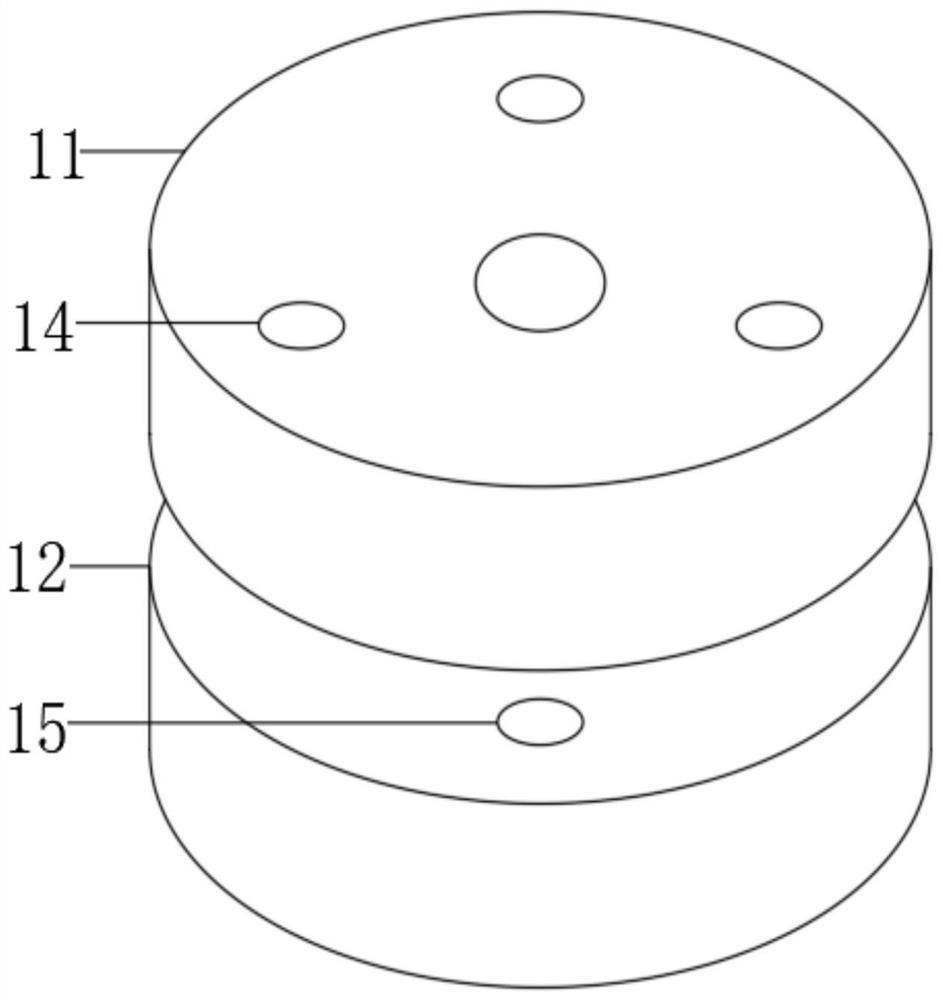

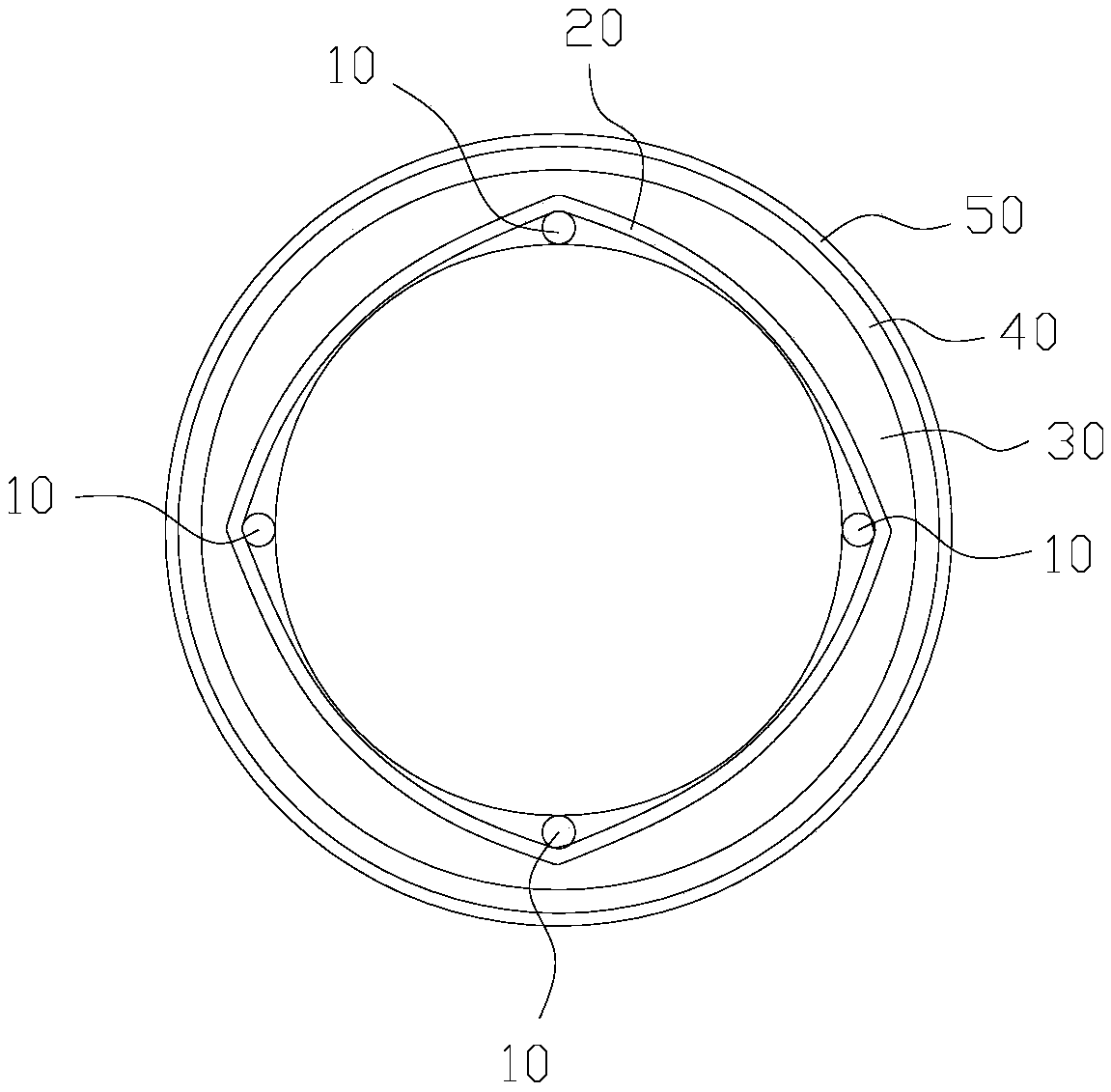

Creel for Dip Dyeing of Package Yarn

ActiveCN104047139BEasy to cleanImprove dyeing effectTextile treatment carriersYarnBiochemical engineering

The invention provides a creel for cheese dyeing. The creel for cheese dyeing comprises a base plate, a plurality of cheese rods and bottom trays, wherein the cheese rods are arranged on the base plate, the bottom trays are arranged at the lower ends of the cheese rods, the base plate is hollow, and the bottom ends of the cheese rods are arranged at the bottom ends of the base plate. Lifting rods are arranged on an upper cover of the base plate, and lifting rings are arranged at the upper ends of the lifting rods. Dyeing sleeves are arranged on the cheese rods and provided with slotted holes densely. Due to the arrangement of the lifting rods, the creel can be quickly carried by a machine. Due to the arrangement of the dyeing sleeves and the slotted holes, the interior of cheese can be dip-dyed by dyeing liquid through the slotted holes of the dyeing sleeves, and the dyeing effect of the cheese can be improved. Due to the arrangement of the hollow base plate, dyeing liquid remaining in the base plate can be conveniently cleared away by opening the upper cover of the base plate. The creel for cheese dyeing is simple in structure and reasonable in design, and improves the dip-dyeing efficiency and the dip-dyeing effect of the cheese.

Owner:WUHU FUCHUN DYEING & WEAVING

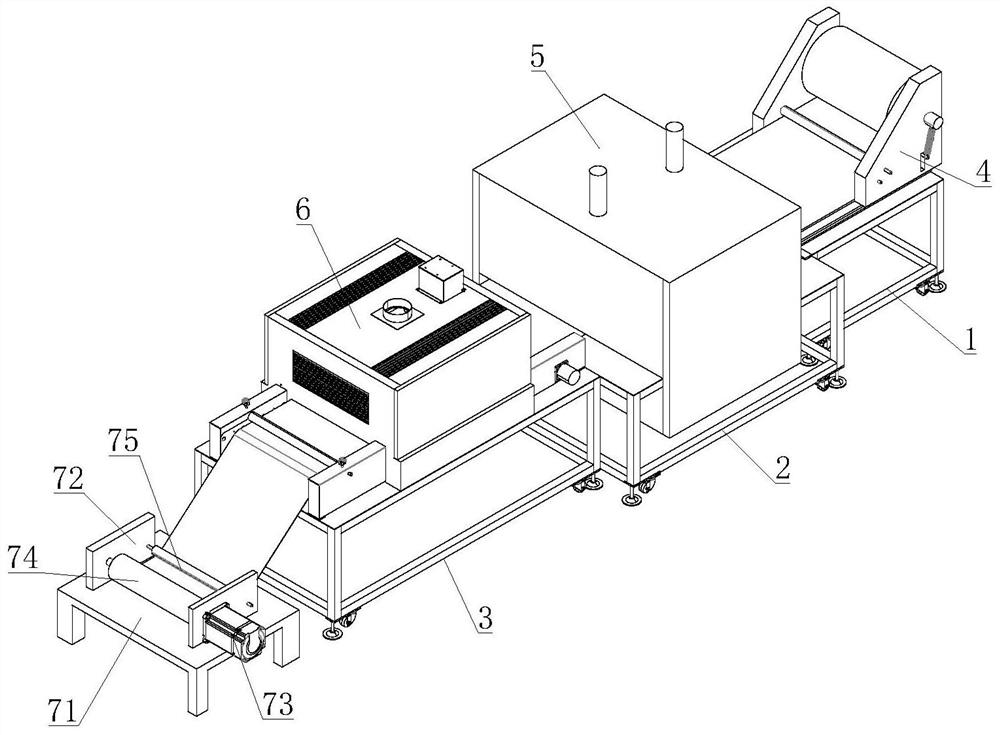

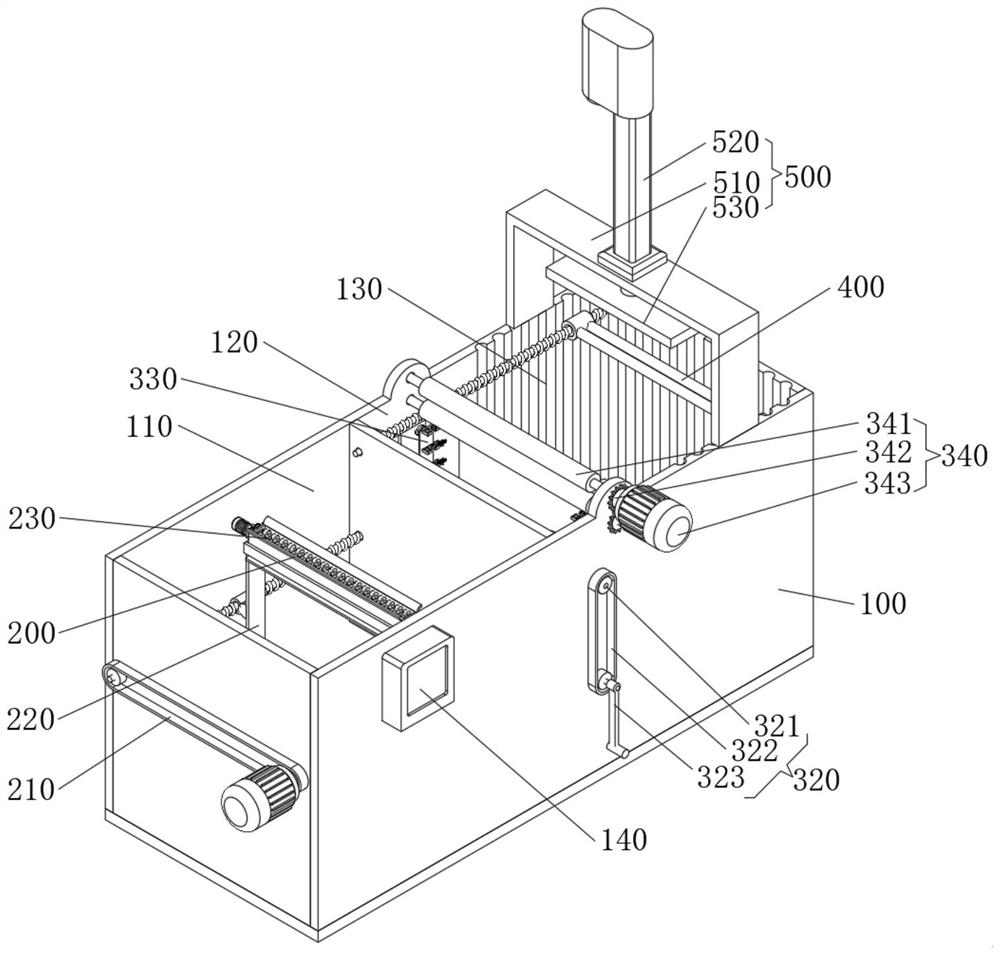

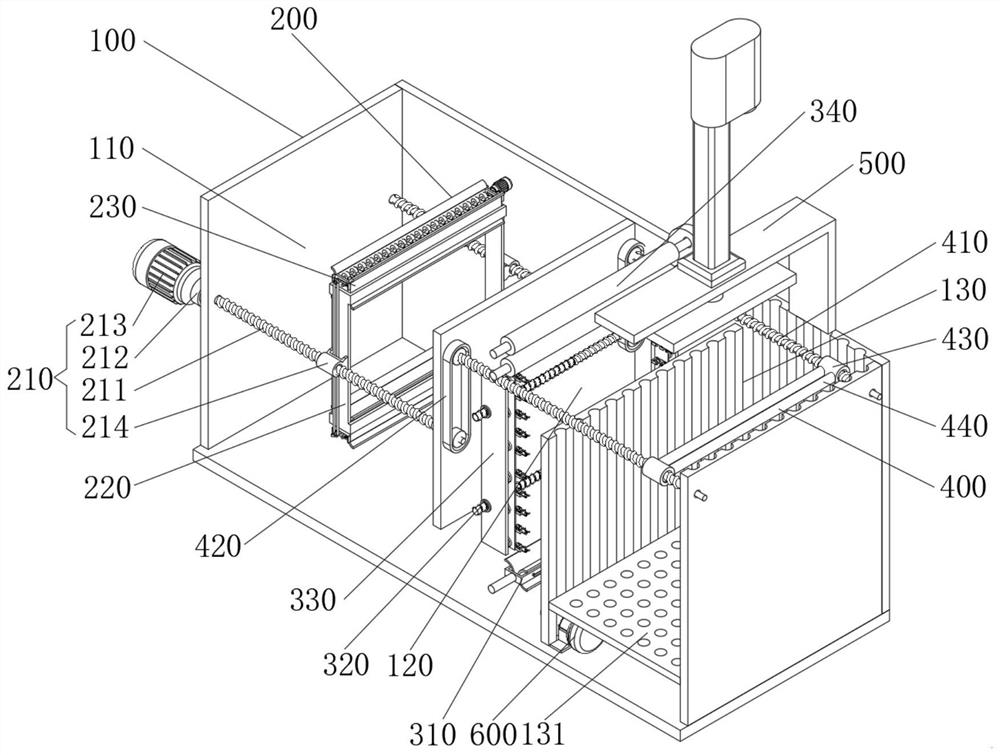

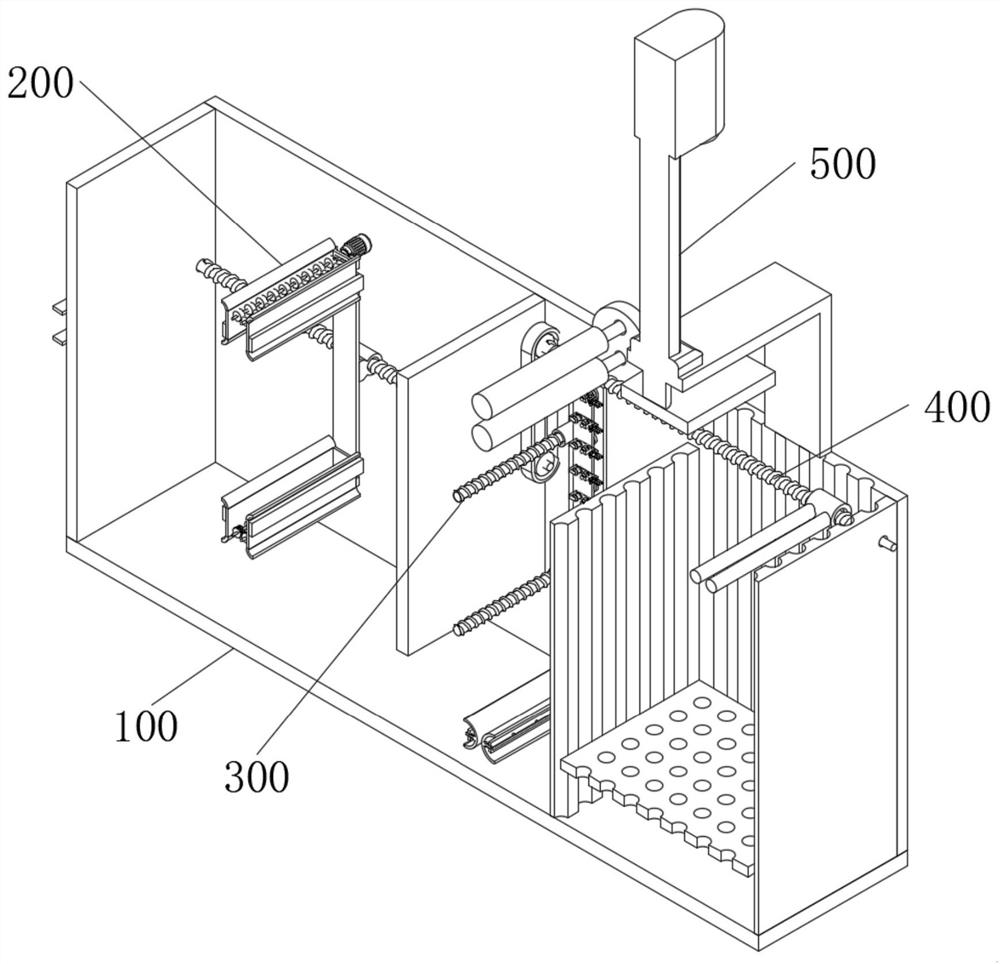

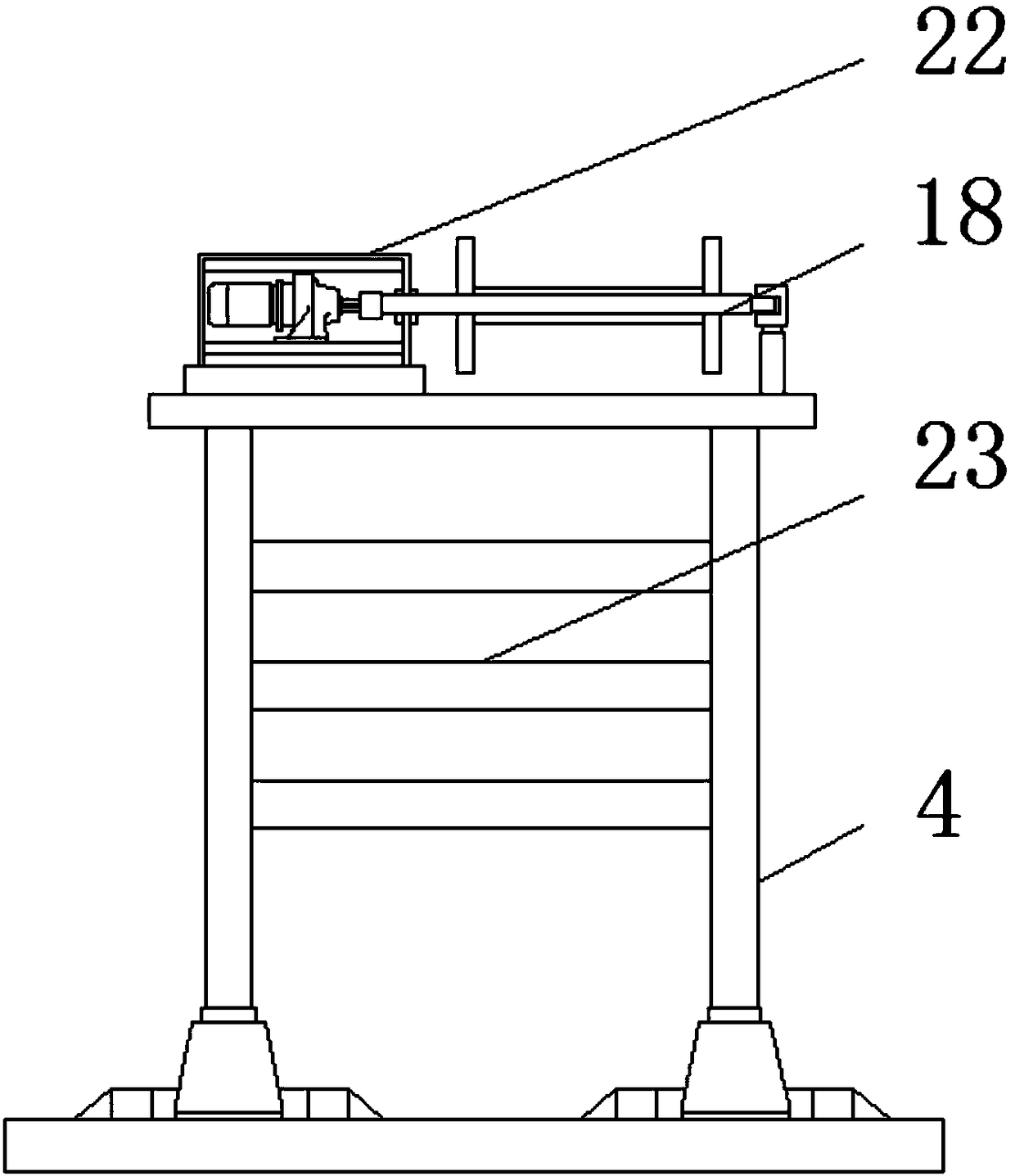

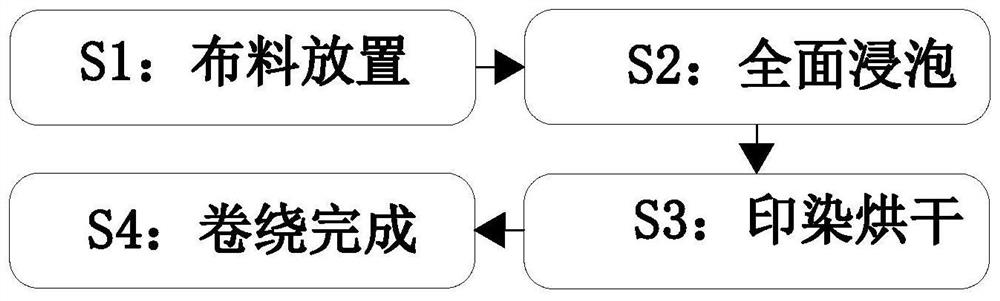

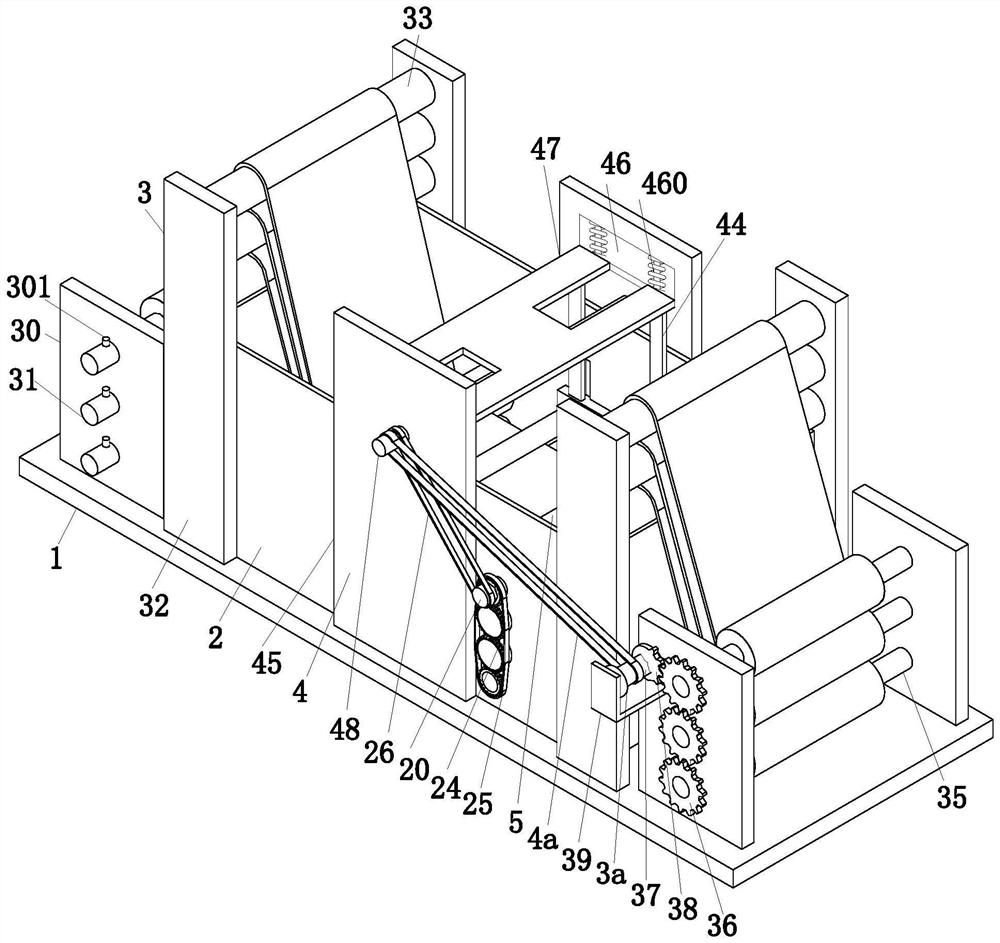

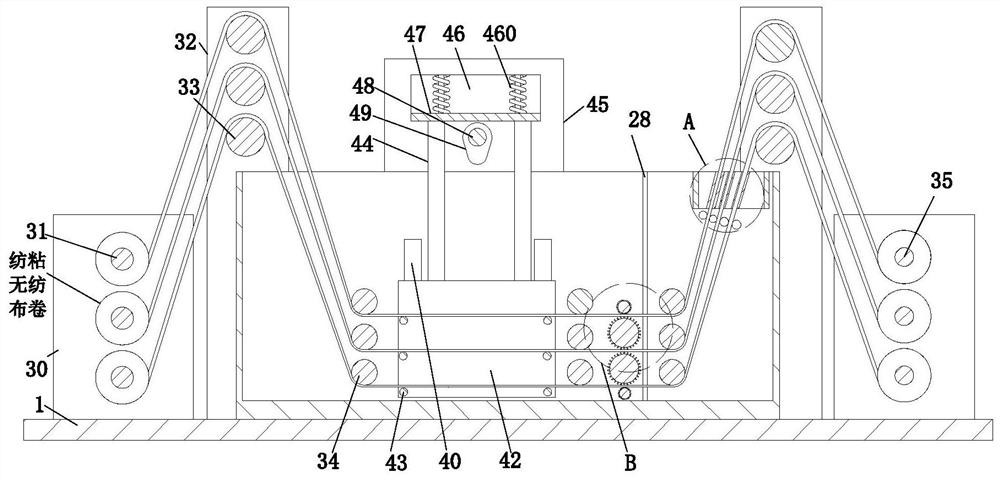

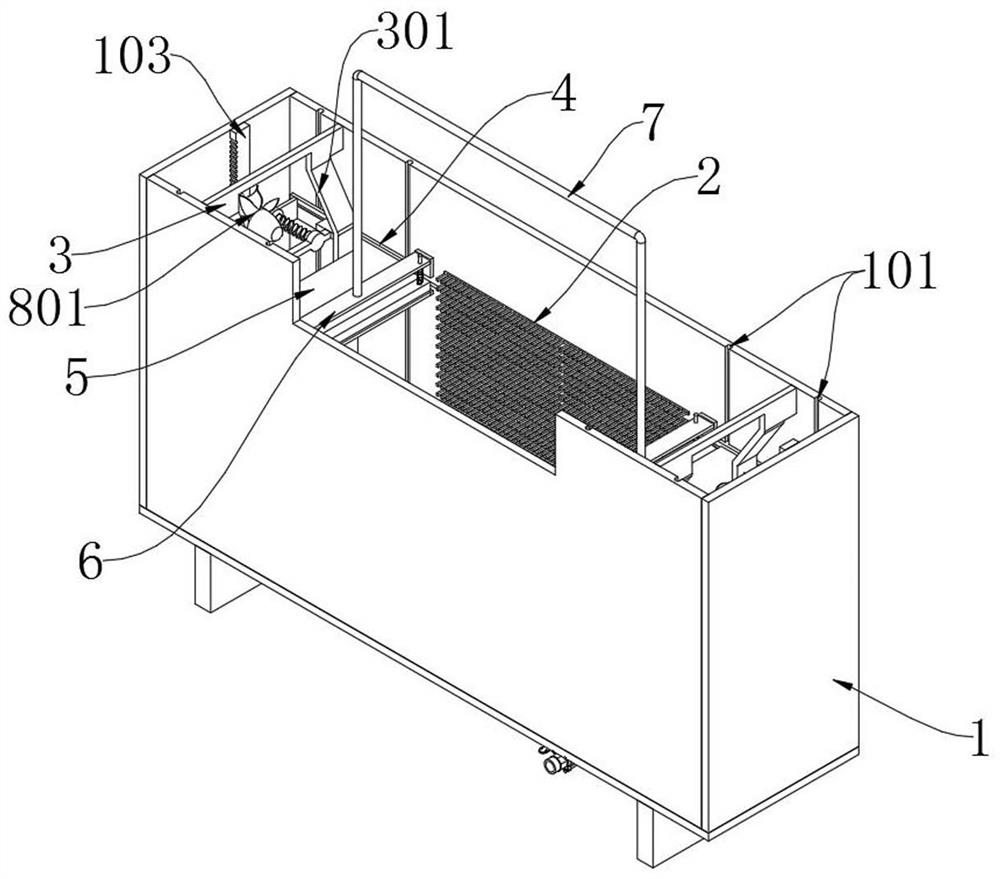

Preparation method of polypropylene spun-bonded non-woven fabric

ActiveCN112877960AImprove the effect of dip dyeingImprove the efficiency of dippingMechanical cleaningPressure cleaningPolymer scienceNonwoven fabric

The invention relates to a preparation method of a polypropylene spun-bonded non-woven fabric. A polypropylene spun-bonded non-woven fabric preparation device is used, and the polypropylene spun-bonded non-woven fabric preparation device comprises a bottom plate, a printing and dyeing pool, a winding mechanism, a vibration mechanism and a drying mechanism. The multi-layer polypropylene spun-bonded non-woven fabric is placed in a three-dimensional mode through the winding mechanism, so that multiple layers of the polypropylene spun-bonded non-woven fabric can be dip-dyed at the same time, and dip dyeing efficiency is improved; and meanwhile, the vibration mechanism is adopted to drive the polypropylene spun-bonded non-woven fabric to move up and down in the dip dyeing pool, dip dyeing liquid enters grid holes under the impact of up-down movement force of the polypropylene spun-bonded non-woven fabric, and therefore, the dip dyeing effect of the polypropylene spun-bonded non-woven fabric is improved.

Owner:DONGGUAN PARKER AUTOMOTIVE FIBER MATERIALS CO LTD

Multi-color blending dip dyeing device for textile polyester yarns

PendingCN112267231AFully impregnatedImprove the effect of dip dyeingTextile treatment machine arrangementsTextile treatment by spraying/projectingYarnPolyester

The invention discloses a multi-color blending dip dyeing device for textile polyester yarns. The multi-color blending dip dyeing device comprises a dip dyeing box, a rotating shaft, a driving mechanism and a spraying mechanism; a box cover is installed at the top end of the dip dyeing box, thread inlet holes and thread outlet holes are formed in the right side face of the dip dyeing box, foot pads are arranged at the bottom end of the dip dyeing box, a feeding pipe is arranged on the side face of the dip dyeing box, a first guide roller is rotatably connected between the inner walls of the thread inlet hole, two round rods are fixed between the left inner wall and the right inner wall of the dip dyeing box through screws, thread guide rollers are installed on the round rods, third guide rollers are mounted at the positions, corresponding to the thread guide rollers, of the inner wall of the right side of the dip dyeing box, and second guide rollers are mounted at the thread outlet holes in the inner walls of the left and right sides of the dip dyeing box; the rotating shaft is rotatably connected between the inner walls of the front side and the rear side of the dip dyeing box, and dip dyeing rollers are installed on the side face of the rotating shaft; and the driving mechanism is installed on the side face of the dip dyeing box. The multi-color blending dip dyeing device forthe textile polyester yarns facilitates full dip dyeing of the polyester yarns and is high in dip dyeing efficiency.

Owner:常熟市全申化纤有限公司

Anti-settling dyeing device capable of recycling dripping dye for textile fabric production

ActiveCN112442814AImprove the effect of dip dyeingReduce wasteMercerising of indefinite length fabricsLiquid/gas/vapor treatment of propelled fabricsPolymer chemistryDyeing

The invention discloses an anti-settling dyeing device capable of recycling dripping dye for textile fabric production. The anti-settling dyeing device comprises a feeding roller, a dip dyeing chamber, a rotating shaft, an atomizing nozzle and a fastening nut, wherein the rotating shaft is installed on the feeding roller, the rotating shaft is connected with a supporting base, a singeing chamber is arranged on the right side of the feeding roller, a limiting roller is installed in the singeing chamber through the rotating shaft, a liquid storage box is installed at the top of a scouring and mercerizing chamber, a limiting groove is formed in the scouring and mercerizing chamber, a dye box is connected with and installed on the dip dyeing chamber, a flow guide spray head is installed on theinner wall of the dip dyeing chamber, a limiting groove is formed in the side wall of a drying chamber, a supporting table is installed at the bottom of the drying chamber, and a transmission disc isinstalled on the inner side of a leveling chamber. The anti-settling dyeing device capable of recycling the dripping dye for textile fabric production is provided with the singeing chamber and the scouring and mercerizing chamber, and textile fabric is pretreated before dip dyeing, so that the textile fabric has better dip dyeing performance.

Owner:安徽来远控股集团有限公司

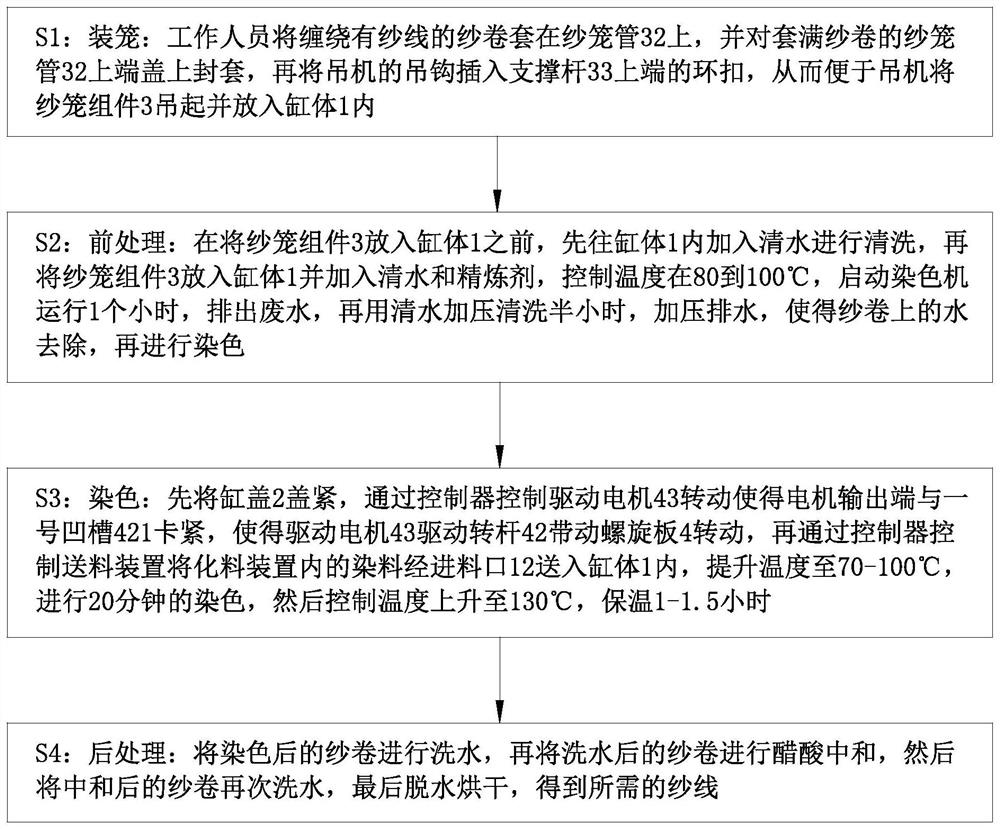

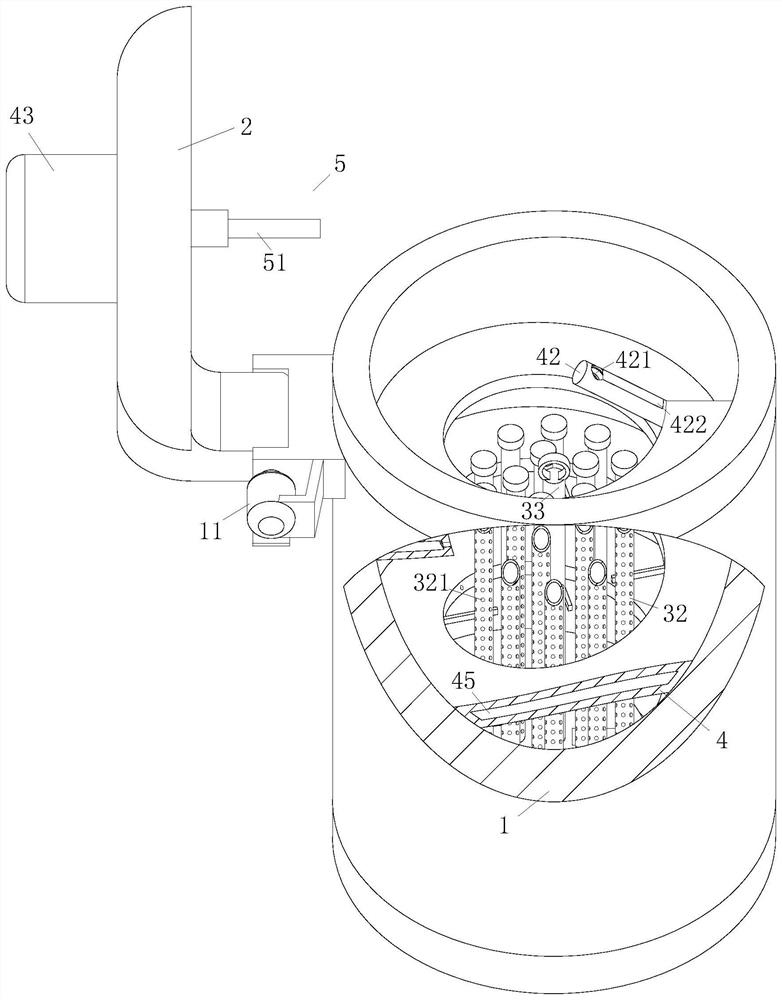

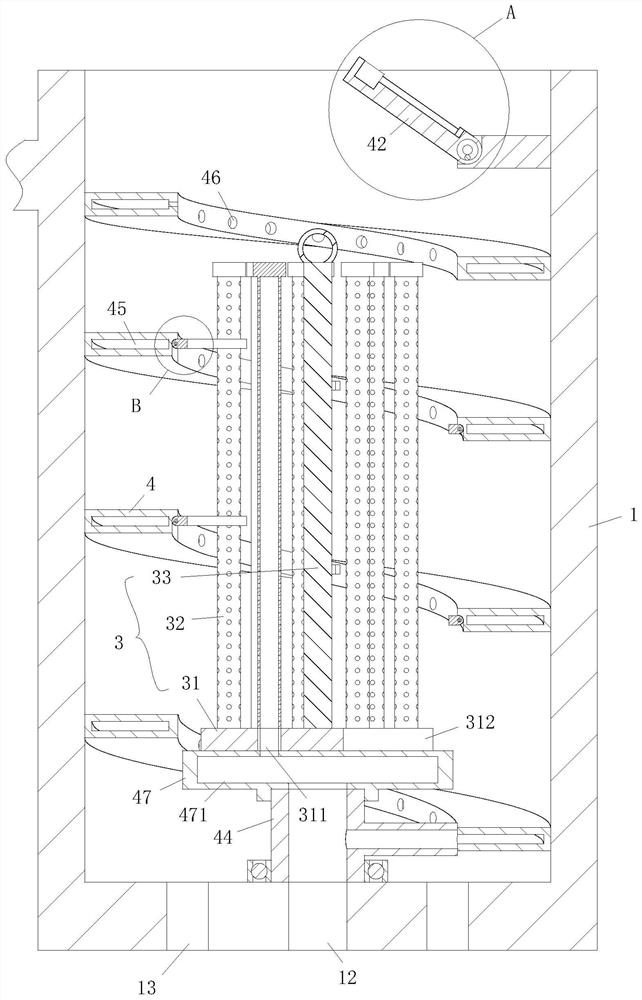

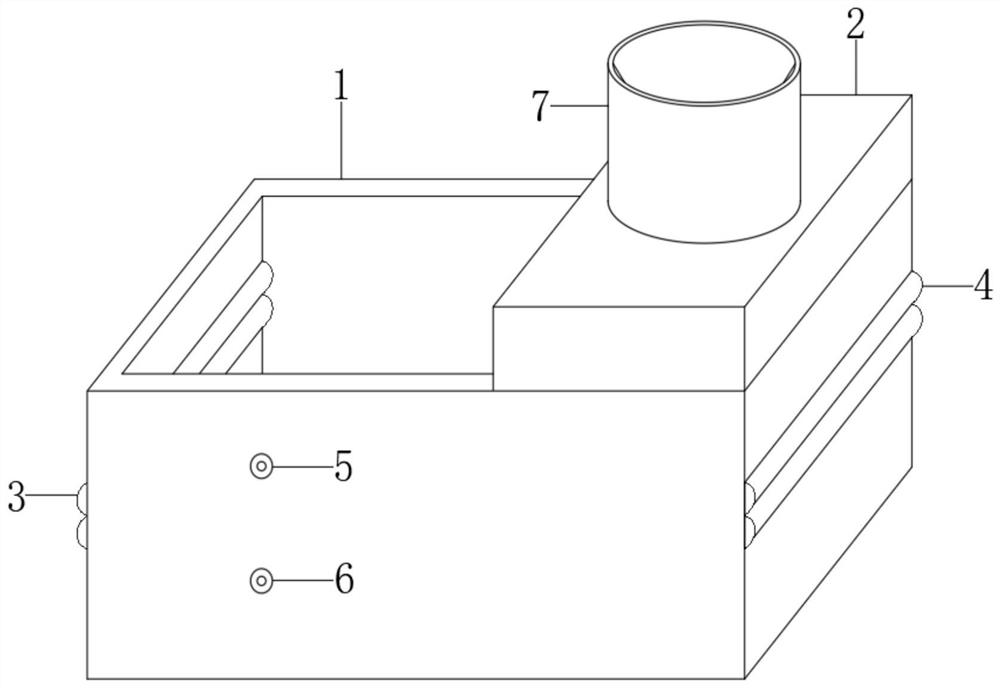

Dyeing equipment and dyeing process for regenerated polyester yarns

PendingCN113802296AIncrease flow rateSpeed up dippingTextile treatment machine arrangementsTextile treatment carriersPolyesterYarn

The invention belongs to the technical field of polyester yarn processing, and particularly relates to dyeing equipment and a dyeing process for regenerated polyester yarns. The dyeing equipment comprises a dyeing device, a feeding device, a material dissolving device and a controller; the dyeing device further comprises a cylinder body, a cylinder cover and a yarn cage assembly; The cylinder cover is hinged to the upper end of the cylinder body; the outer wall of the cylinder body is fixedly connected with a servo motor; the output end of the servo motor is fixedly connected with a hinged point of the cylinder cover and the cylinder body; and a feeding hole and a discharging hole are formed in the lower end of the cylinder body. A spiral plate is arranged and can be driven by a driving motor to rotate; on one hand, the flow speed of dye liquor is increased, so that the dip-dyeing speed of dye to yarn rolls is increased, and the dip-dyeing efficiency of the yarn rolls is improved; and on the other hand, dye particles in the dye liquor are stirred to be diffused upwards, so that the rising dye concentration is improved, the dip dyeing effect of the dye on the upper yarn rolls is enhanced, the color difference of the upper yarn rolls is reduced, and the product quality is improved.

Owner:王海波

Garment fabric dip-dyeing equipment based on garment production and processing

ActiveCN113005689AIncrease diversityImprove applicabilityMechanical cleaningPressure cleaningRemoving hairMechanical engineering

The invention discloses garment fabric dip-dyeing equipment based on garment production and processing. The equipment includes a dip-dyeing cavity and a support block, wherein a fabric inlet is detachably mounted on one side of the dip-dyeing cavity, a fabric outlet is detachably mounted on the other side of the dip-dyeing cavity, a triangle-like transmission shaft is clamped on one side of the middle of the dip-dyeing cavity, a fixing block is clamped to the other side of the middle of the dip dyeing cavity, a water inlet is detachably formed in the upper surface of the supporting block, a funnel is arranged in the water inlet, and a through rotating shaft is detachably installed at the bottom end of the funnel. By arranging a three-primary-color matching device, a stirring and fusing device and a rolling and hair removing device, the equipment can carry out specific color dip dyeing on fabric according to the user requirements through mutual cooperation of the three-primary-color matching device, the stirring and fusing device and the rolling and hair removing device, the diversified requirements of the current market are met, meanwhile, a hair removal measure is taken before the fabric is dip-dyed, so that the dip-dyeing effect of the equipment is ensured, and the working efficiency is also improved.

Owner:BEIJING GORNIA GARMENT FASHION

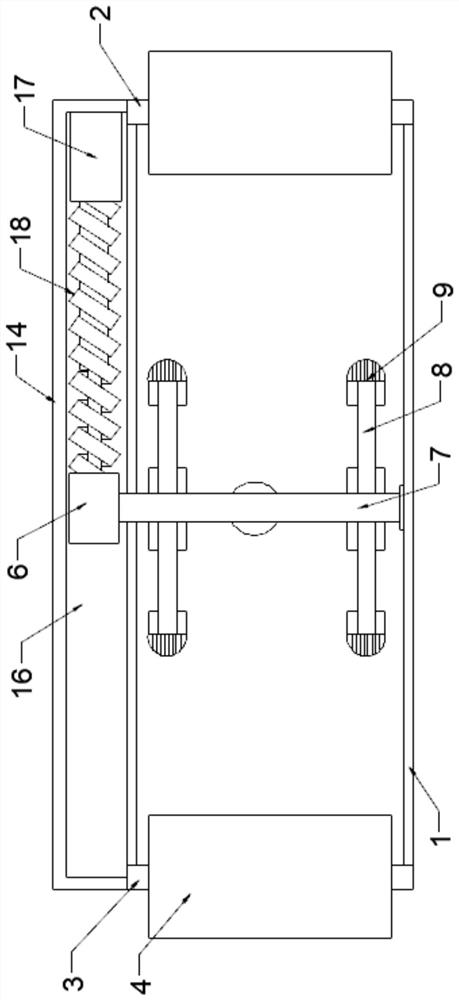

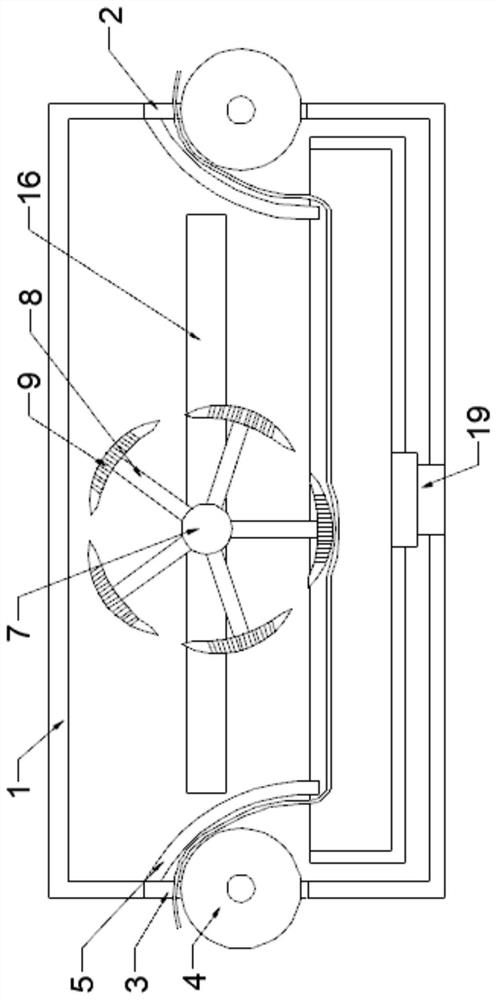

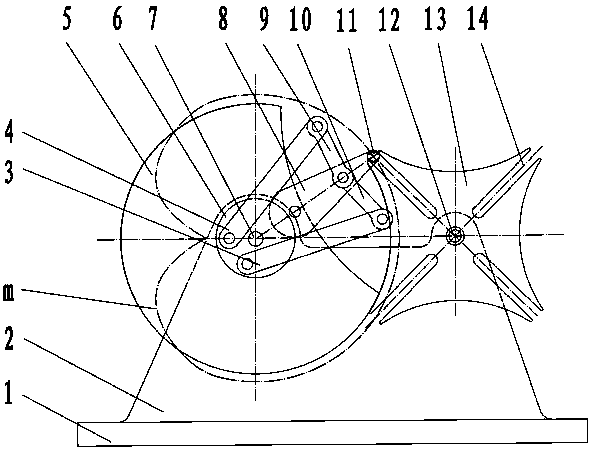

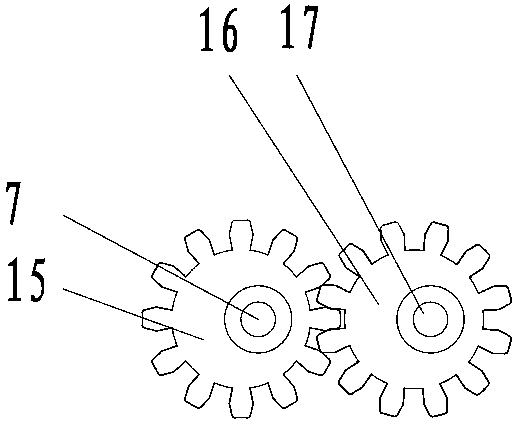

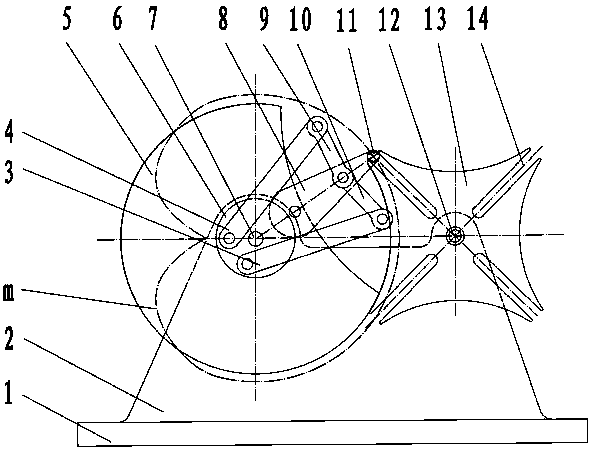

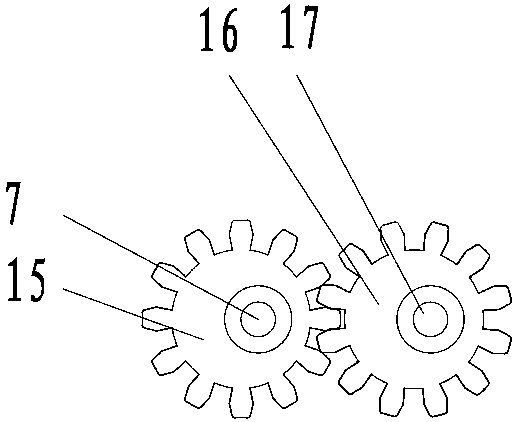

Cloth dyeing method for increasing cloth dip dyeing speed

InactiveCN108642749APromote infiltrationFully contactedTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentMechanical engineeringDyeing

The invention relates to a cloth dyeing method for increasing the cloth dip dyeing speed. The method is implemented through a dyeing machine. The dyeing machine comprises a rack, a cloth dyeing vat, adriving motor and an intermittent driving mechanism; the cloth dyeing vat is arranged on the rack, a stirring wing plate is arranged on the upper portion in the cloth dyeing vat, and the driving motor is used for driving the intermittent driving mechanism which is used for providing intermittent driving force so as to achieve the purpose that the stirring wing plate has the rotating state and thestationary state in a rotating period. When a clamping pin shaft on a rotating arm cooperates with strip-shaped clamping grooves, a second clamping disc is driven to rotate, and then the stirring wing plate is driven to rotate to make sufficient contact with cloth in the cloth dyeing vat; when the first clamping disc cooperates with a second arc-shaped groove, the second clamping disc is stationary; therefore, it is guaranteed that the stirring wing plate is stationary so that rotational inertia of dye is facilitated, and the dye can make more sufficient contact with the cloth.

Owner:张四通

Dye concentration-adjustable type cloth dyeing machine

InactiveCN108374256APromote infiltrationFully contactedLiquid/gas/vapor fabric treatmentEngineeringDrive motor

The invention relates a dye concentration-adjustable type cloth dyeing machine. The dye concentration-adjustable type cloth dyeing machine comprises a machine frame, a cloth dyeing cylinder, a drivingmotor and an intermittent driving mechanism, wherein the cloth dyeing cylinder is arranged on the machine frame; a stirring wing plate is arranged in the cloth dyeing cylinder; the driving motor is used for driving the intermittent driving mechanism; the intermittent driving mechanism is used for providing an intermittent driving force, so that the stirring wing plate can be set under the rotation state and standing state in a rotation cycle. The dye concentration-adjustable type cloth dyeing machine has the advantages that when a clamp pin shaft on the rotary arm is matched with a strip-shaped clamp groove, a second clamp disc is driven to rotate, so as to drive the stirring wing plate to rotate and fully touch the cloth in the cloth dyeing cylinder; when a first clamp disc is matched with a second arc-shaped groove, the second clamp dist is set under the standing state, so as to ensure the standing state of the stirring wing plate, thereby breaking the rotation inertia of dye, and realizing enough contact between the dye and the cloth.

Owner:张四通

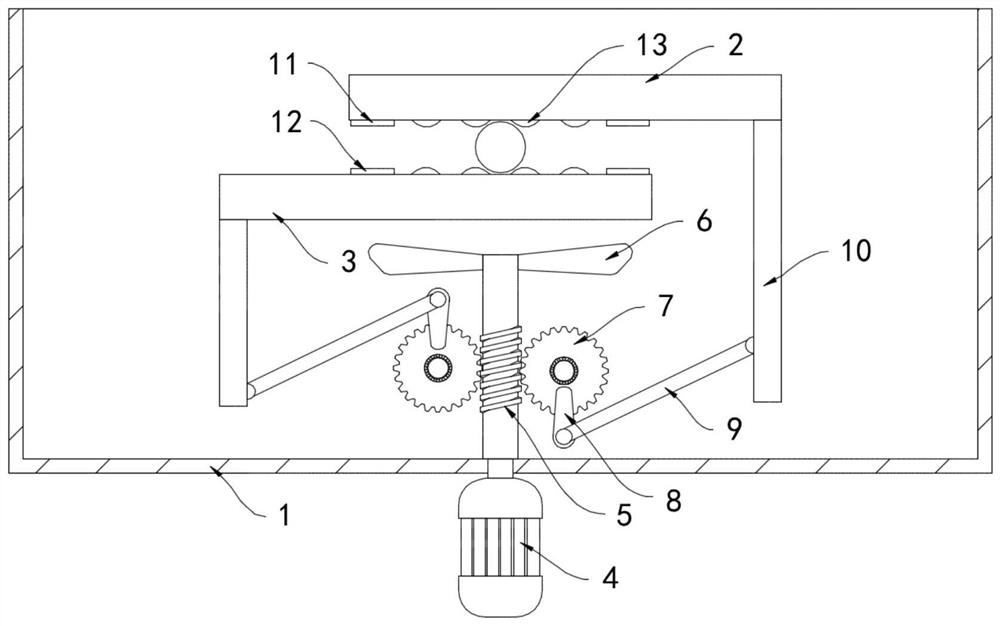

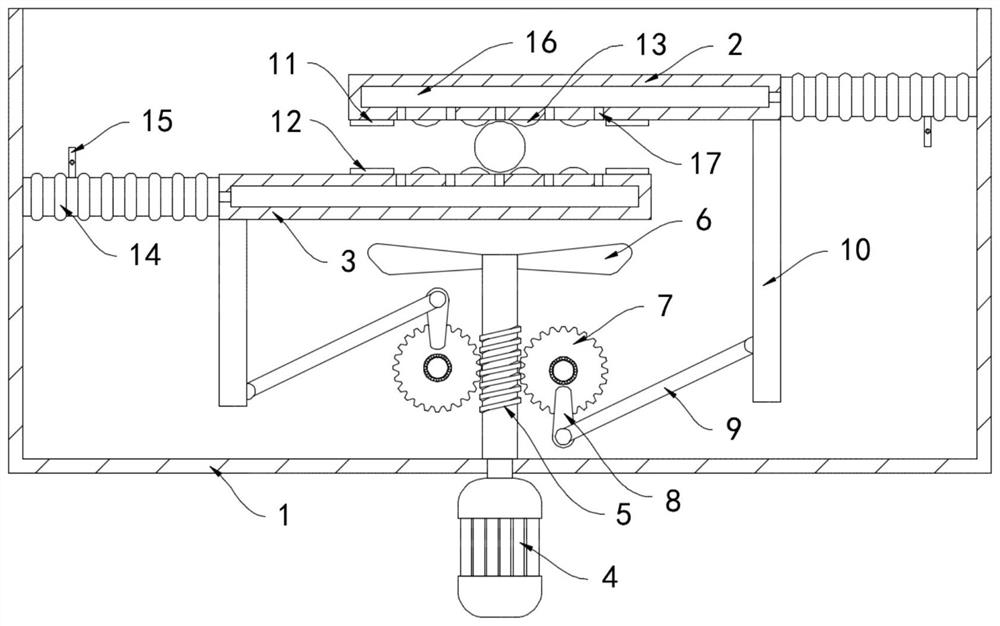

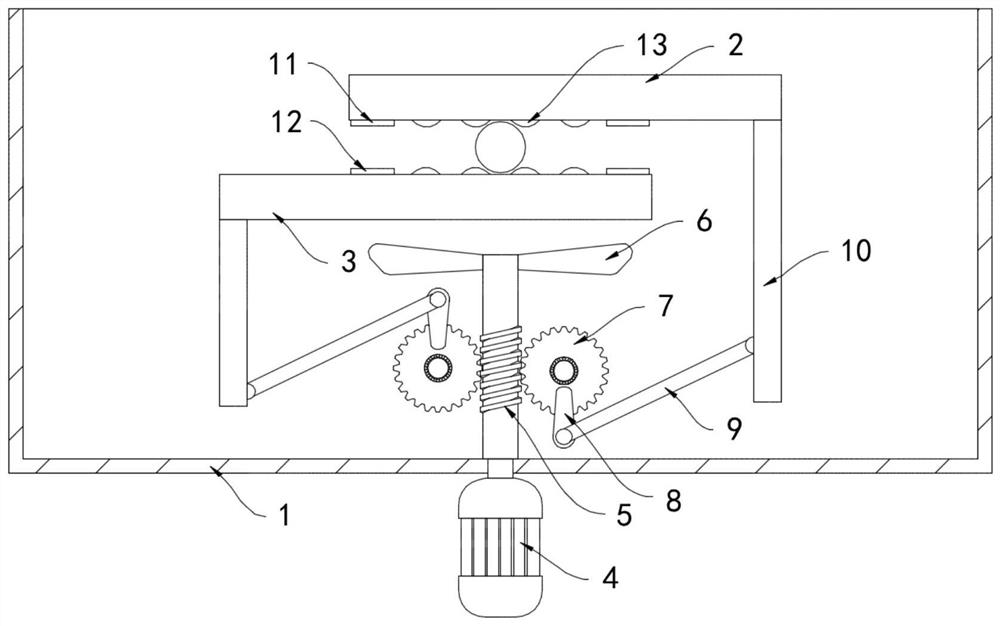

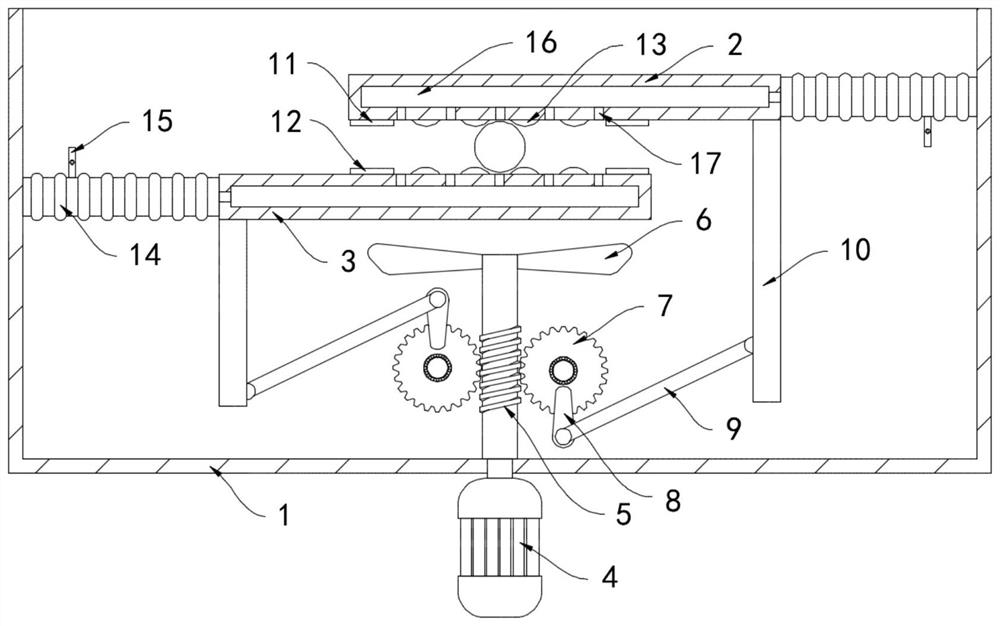

Dyeing device for rolling and rubbing type textile yarn

ActiveCN111850880AAchieve kneadingImprove permeabilityTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentElectric machineryTextile yarn

The invention belongs to the field of textile mechanical equipment, and particularly relates to a dyeing device for rolling and rubbing type textile yarn. The dyeing device comprises a dye liquor tank. A horizontally-arranged upper pressing plate and a horizontally-arranged lower pressing plate are slidingly connected to the inner side wall of the dye liquor tank, a motor is mounted at the bottomof the dye liquor tank, a worm is fixedly connected to an output shaft of the motor coaxially, the upper end of the worm stretches into the dye liquor tank and is coaxially provided with an impeller,two worm wheels are fixedly connected to the inner side wall of the dye liquor tank, the two worm wheels are located on the two sides of the worm and engaged with the worm, transmission rods are fixedly connected to the side walls of the two worm wheels, and the other ends of the two transmission rods are rotationally connected with connecting rods. The textile yarn can be rubbed, gas in yarn fibers is extruded out, seepage of dye liquor is accelerated, the dyeing efficiency is improved, meanwhile, when the yarn formed by combining multiple strands of single yarn is rolled and rubbed back andforth, the multiple strands of single yarn can be separated and then twisted, the dye liquor can conveniently evenly and fully seep for dyeing, and the product quality is improved.

Owner:盐城市海悦纺织有限公司

Red dyestuff with high color fastness to water

The invention discloses a red dyestuff with high color fastness to water. The red dyestuff is prepared from the following components in parts by weight: 20 to 25 parts of acid red, 5 to 10 parts of cycloaliphatic epoxy resin, 30 to 35 parts of urea, 5 to 7 parts of N-alkylbetaine and 1 part of auxiliary agent. The cycloaliphatic epoxy resin is used as a carrier; the cycloaliphatic epoxy resin is stably combined with carboxyl of the N-alkylbetaine and carboxyl of the acid red through an epoxy group of the cycloaliphatic epoxy resin; furthermore, the N-alkylbetaine has relatively low viscosity and a solvent system is formed by combining the N-alkylbetaine and the urea; protein fibers have a relatively good dip dyeing capability so that the color fastness of the dyestuff is improved.

Owner:吴文广

Black color paste for printing denim fabric

The invention discloses a black color paste for printing a denim fabric. The black color paste comprises the following components: 10-15 parts of carbon powder, 25-30 parts of alicyclic epoxy resin, 20-30 parts of urea, 1-3 parts of N-lauryl betaine, and 1 part of an auxiliary. The N-lauryl betaine is excellent in wettability and can fully wet the carbon powder; the carboxyl anion of the N-laurylbetaine is stably combined with the alicyclic epoxy resin, the alicyclic epoxy resin is combined with the N-lauryl betaine on the surface of the wetted carbon powder, equivalently, the alicyclic epoxyresin is sufficiently coated on the surface of the carbon powder, and the binding strength between the alicyclic epoxy resin and the carbon powder is improved; in addition, the viscosity of the N-lauryl betaine is relatively low, the N-lauryl betaine is combined with the urea to form a solvent system, and the solvent system has a better dip-dyeing property on the denim fabric, so that the adhesive force of a dye on the denim fabric is enhanced.

Owner:吴文广

Dyeing device for tumbling textile yarn

ActiveCN111850880BAchieve kneadingImprove permeabilityTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentFiberTextile yarn

Owner:盐城市海悦纺织有限公司

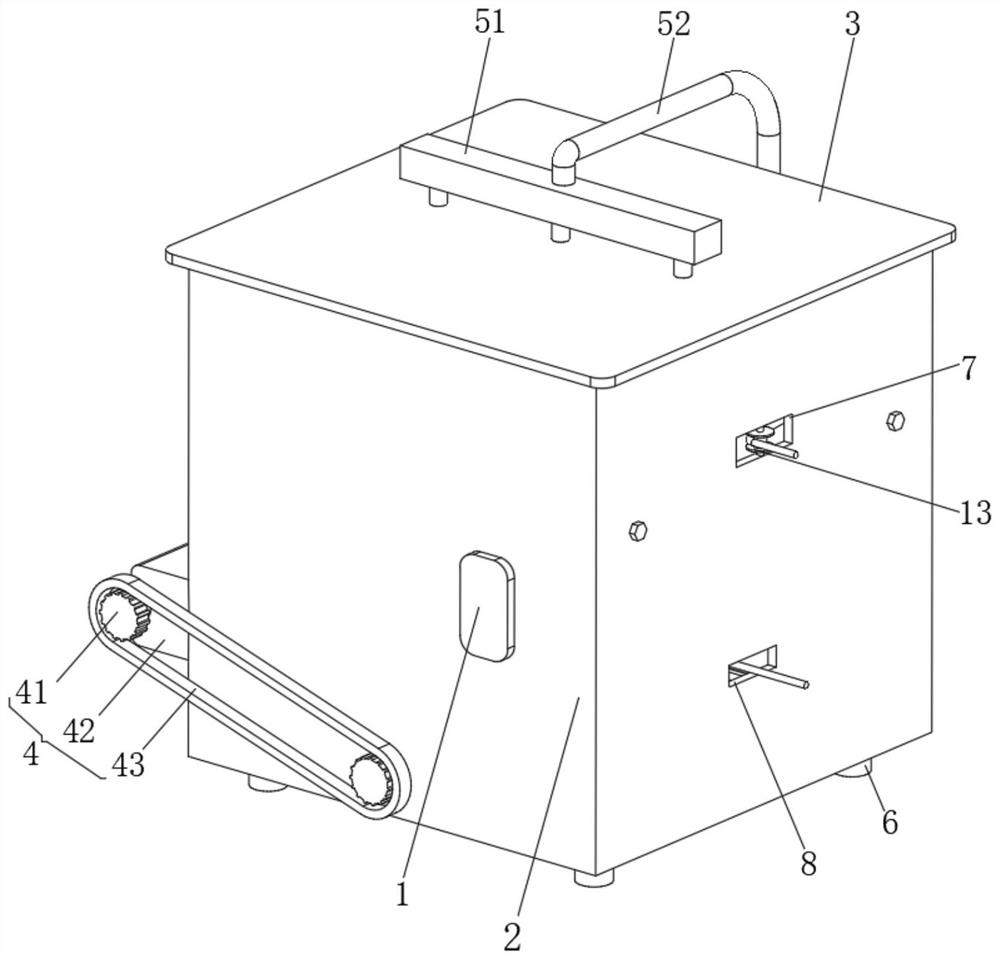

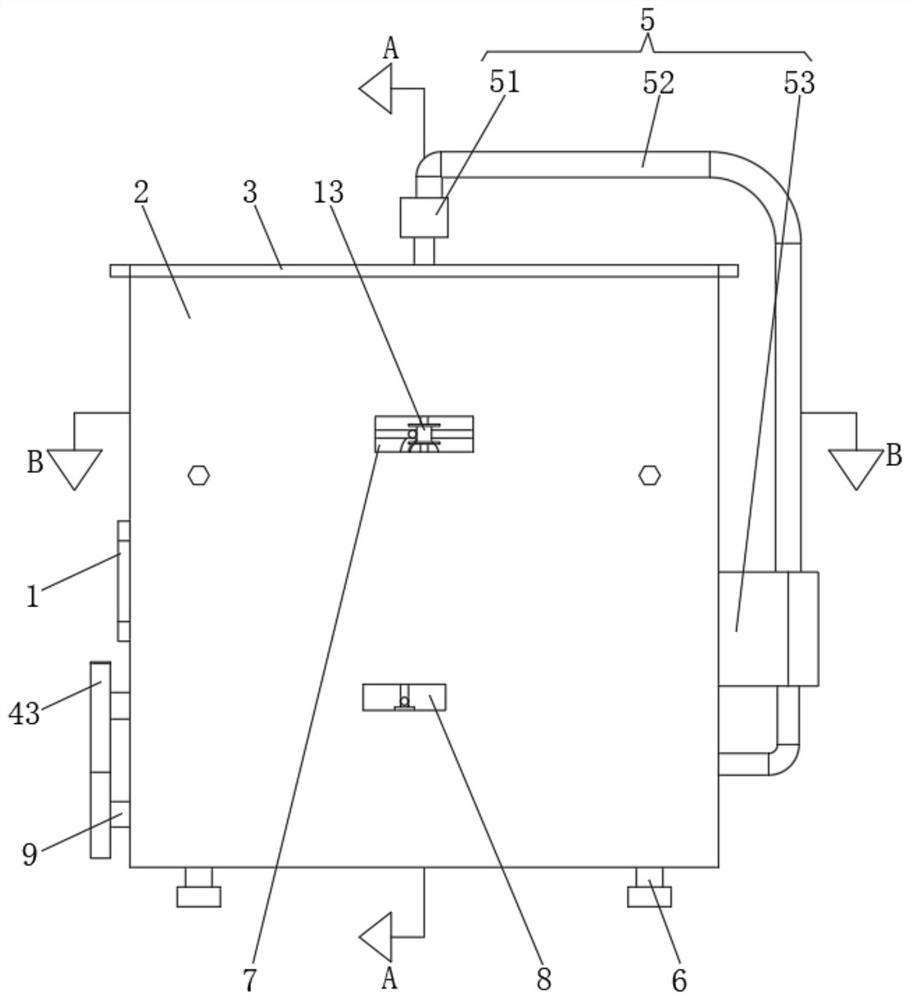

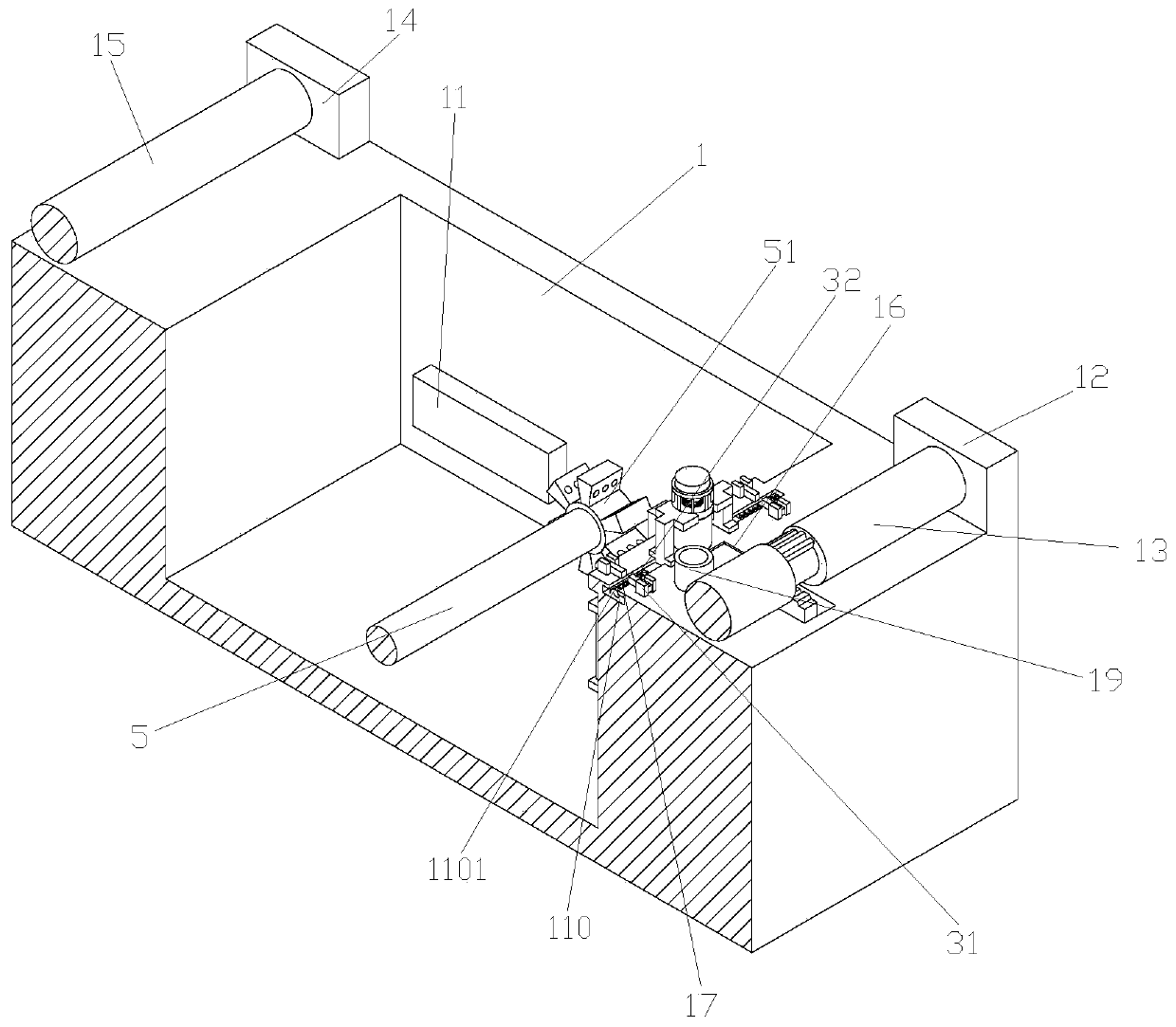

A kind of dipping tank for maintaining the concentration of dye solution

ActiveCN109023778BImprove the effect of dip dyeingIncrease concentrationTextile treatment machine arrangementsTextile treatment carriersPolymer scienceEngineering

The invention discloses a dipping box for maintaining the concentration of dye liquor, which comprises a dipping tank body, a first installation seat arranged on the top of the dipping pool body, a first cloth feeding shaft arranged on the first installation seat, a device The second mounting seat on the top of the dipping pool body and the second cloth feeding shaft arranged on the second mounting seat, the third cloth feeding shaft is arranged in the body of the dipping pool body, and the inner wall of the dipping pool body is provided with There is a heating block, which is characterized in that: the top of the body of the dipping pool is provided with a storage chamber, and a feeding device is provided in the storage chamber; the top of the storage chamber is provided with a feeding port, and the feeding port is provided with There is a first sealing film that can be opened and closed automatically.

Owner:SHAOXING UNIVERSITY

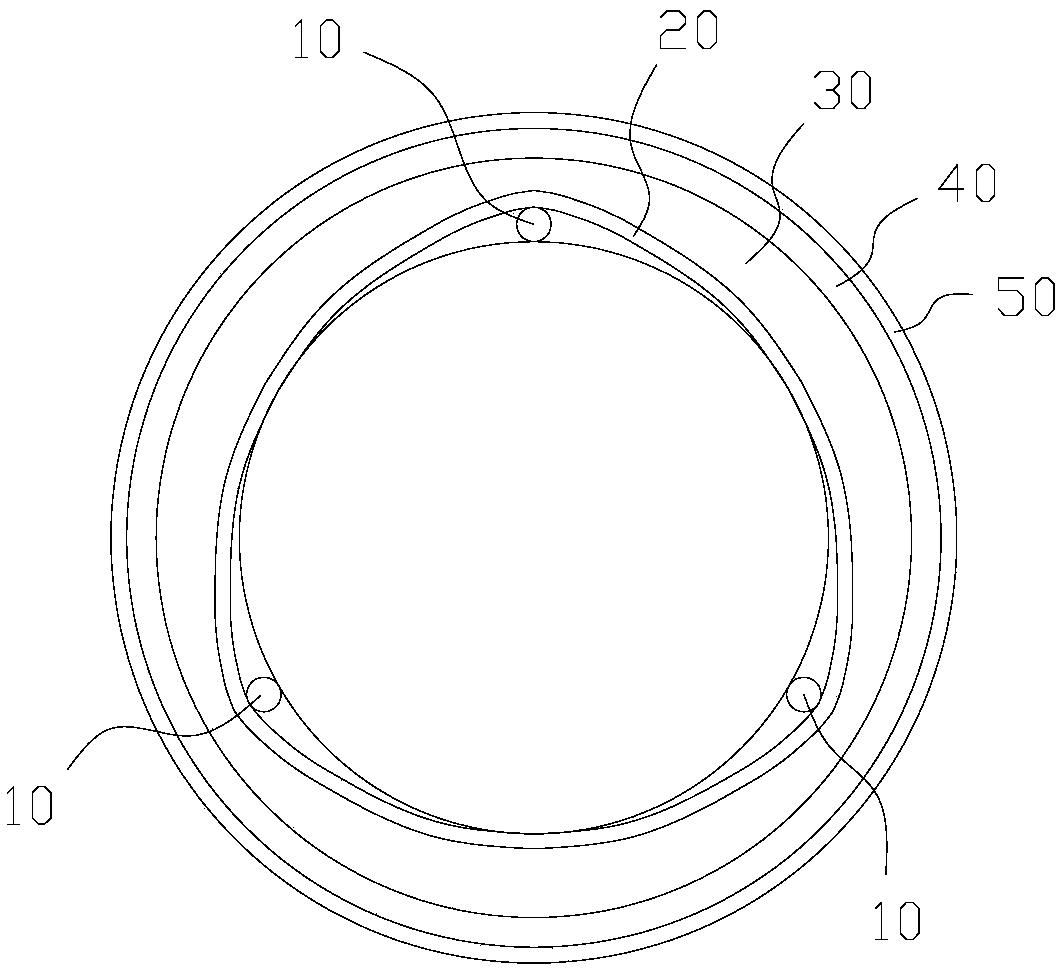

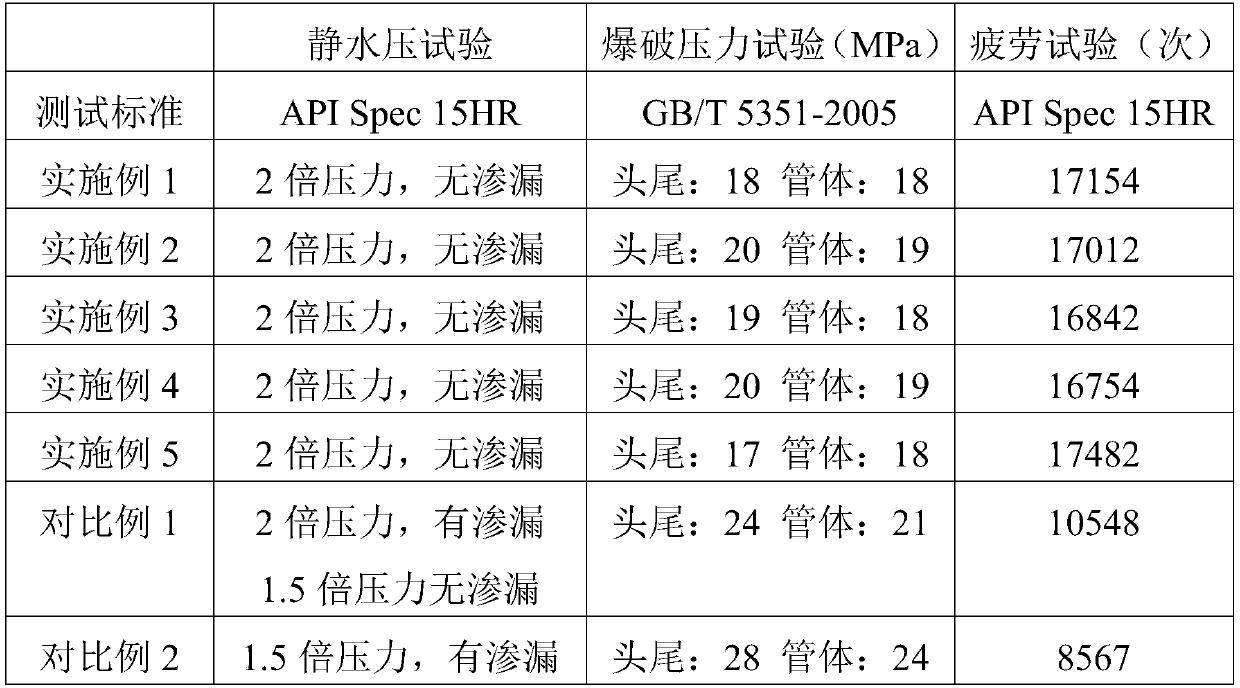

Glass fiber-reinforced plastic composite pipe and machining method thereof

InactiveCN109624352AAchieve structural improvementsImprove tolerancePipe elementsRigid pipesGlass fiberResin-Based Composite

The invention belongs to the technical field of composite pipe machining, and particularly relates to a glass fiber-reinforced plastic composite pipe and a machining method thereof. The machining method comprises the steps that (1) glass fiber-reinforced plastic is arranged on a cylindrical inner mould in a winding mode to form an inner liner layer, and first glass fiber rebars are arranged in thecircumferential direction of the cylindrical inner mould at intervals before winding arranging is carried out; (2) the cylindrical inner mould is removed after the inner liner layer is solidified, and an outer mould sleeves the inner liner layer, and composite resin materials are poured in a cavity between the inner liner layer and the outer mould to form a structural layer; (3) the outer mould is removed, second glass fiber rebars are arranged outside the structural layer in a winding mode, and the second glass fiber rebars are enabled to have prestressing force due to the applying of the tension in the process of winding the second glass fiber rebars; and (4) outer protecting materials are coated to obtain the glass fiber-reinforced plastic composite pipe. According to the machining method, the resistant capacity of the pipe wall of the glass fiber-reinforced plastic composite pipe to inner high pressure fluid is improved, and thus the conveying requirements of the high pressure fluid are met.

Owner:安徽鹏远金属制品股份有限公司

A processing technology of waterproof and stain-resistant down jacket

ActiveCN110367614BImprove waterproof performanceImproves stain resistanceLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsMachining processMechanical engineering

The invention discloses a processing technology for a waterproof and stain-resistant down jacket, which solves the problem that most of the down jackets processed by the traditional process have a slight waterproof function, and the stain-resistance performance is not good, and the traditional processing technology can cause the dyeing of the dye when the fabric is processed. The speed is slow and the efficiency is low, which leads to the slow speed of the entire processing process. At the same time, the traditional processing technology uses some high-performance fabrics to improve the waterproof and stain-resistant performance of the down jacket, and the cost is high, which also leads to the down jacket to a certain extent. the problem of higher cost. The waterproof and stain-resistant down jacket is prepared from the following materials: face cloth, color-separating paper, down gallbladder, inner cloth and down; the face cloth is composed of bottom cotton and surface dye, and the bottom cotton is woven by warp and weft. The warp is made of nylon with a fineness of 15D‑20D, and the warp density is 1000‑1005. The weft is made of spandex, and the weft density is 950‑955.

Owner:安徽西格玛服饰有限公司

Textile printing and dyeing method based on magnetization principle

InactiveCN111705460AImprove permeabilityImprove the effect of dip dyeingTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentTextile printerPolymer science

The invention belongs to the field of textile, in particular to a textile printing and dyeing method based on a magnetization principle. In the printing and dyeing process, a printing and dyeing device is further included, the printing and dyeing device comprises a shell internally containing dyeing liquid, conveying rollers are arranged on the two ends of the shell, cloth penetrating the whole shell is jointly conveyed on the conveying rollers, two permanent magnet plates with different magnetisms are fixedly connected to the inner top face and the inner bottom face of the shell correspondingly, two fixed plates which are horizontally mounted are arranged in the shell, multiple wires are fixedly embedded in the fixed plates, the two fixed plates are arranged on the upper end and the lowerend of the cloth correspondingly, the two ends of the fixed plates extend to the interior of the shell, sliding grooves matched with the fixed plates are formed in the inner side wall of the shell, aseal hopper is arranged, the seal hopper is arranged in the connecting position of the shell and the cloth outlet end, and is tightly attached to the cloth, in the process of conveying the cloth to the outside of the shell, remaining dye on the cloth is extruded into the shell, and waste of the dye can be effectively avoided.

Owner:谭秀娇

A high-efficiency printing and dyeing treatment system and process for textile fabrics

ActiveCN109023762BImprove dyeing effectIncrease profitTextile treatment machine arrangementsTextile treatment by spraying/projectingPolymer scienceEngineering

The invention relates to a high-efficiency textile fabric printing and dyeing treatment system and process. The process involves a dye box, wherein a first spray dyeing mechanism and a second spray dyeing mechanism are arranged in the dye box, and each of the first spray dyeing mechanism and second spray dyeing mechanism comprises a filtrate assembly fixed on the inner wall of the dye box, a squeezing and grinding assembly arranged in the corresponding filtrate assembly and a spray dyeing assembly arranged at the upper end of the corresponding filtrate assembly; a driving mechanism is arrangedbetween the first spray dyeing mechanism and the second spray dyeing mechanism and drives the two squeezing and grinding assemblies to rise and fall alternately, the filtrate assemblies extract a dyeliquor at the bottom of the dye box when the squeezing and grinding assemblies move upward, the dye liquor in the filtrate assemblies is squeezed to be filtered when the squeezing and grinding assemblies move downward so that the dye liquor is sprayed from a front spray dyeing assembly and a rear spray dyeing assembly to dye a fabric, and the squeezing and grinding assemblies move downward continuously after dye liquor squeezing and spray dyeing are completed to grind the coarse-particle dye remaining in the filtrate assemblies. The high-efficiency textile fabric printing and dyeing treatmentsystem and process solve the problems that the fabric dyeing mode is single, the dye liquor is stratified, the dyeing effect is poor, dyeing is nonuniform, and the dye utilization rate is low.

Owner:浙江盛邦化纤有限公司

Textile processing textile cloth fully soaked in bleaching and dyeing device

ActiveCN113249897BImproving the soaking effect of bleaching and dyeingImprove the effect of dip dyeingLiquid/gas/vapor removal by squeezingTextile treatment carriersWater flowProcess engineering

Owner:江苏红金顶织造有限公司

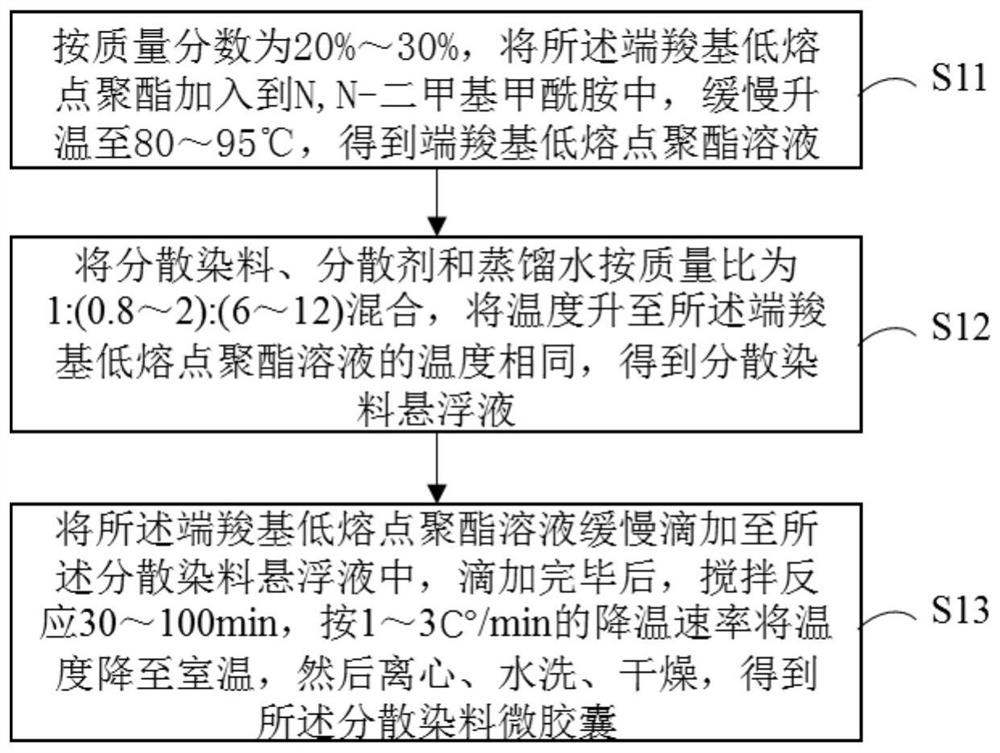

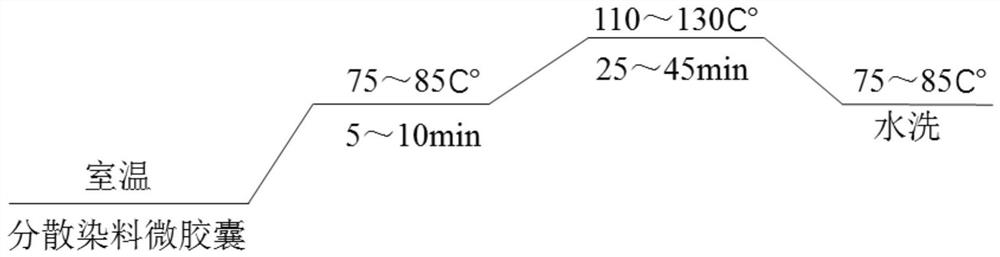

A kind of mattress fabric dyeing agent and dyeing method

ActiveCN111118920BSimple manufacturing methodLow costDyeing processMicroballoon preparationDisperse dyePolymer science

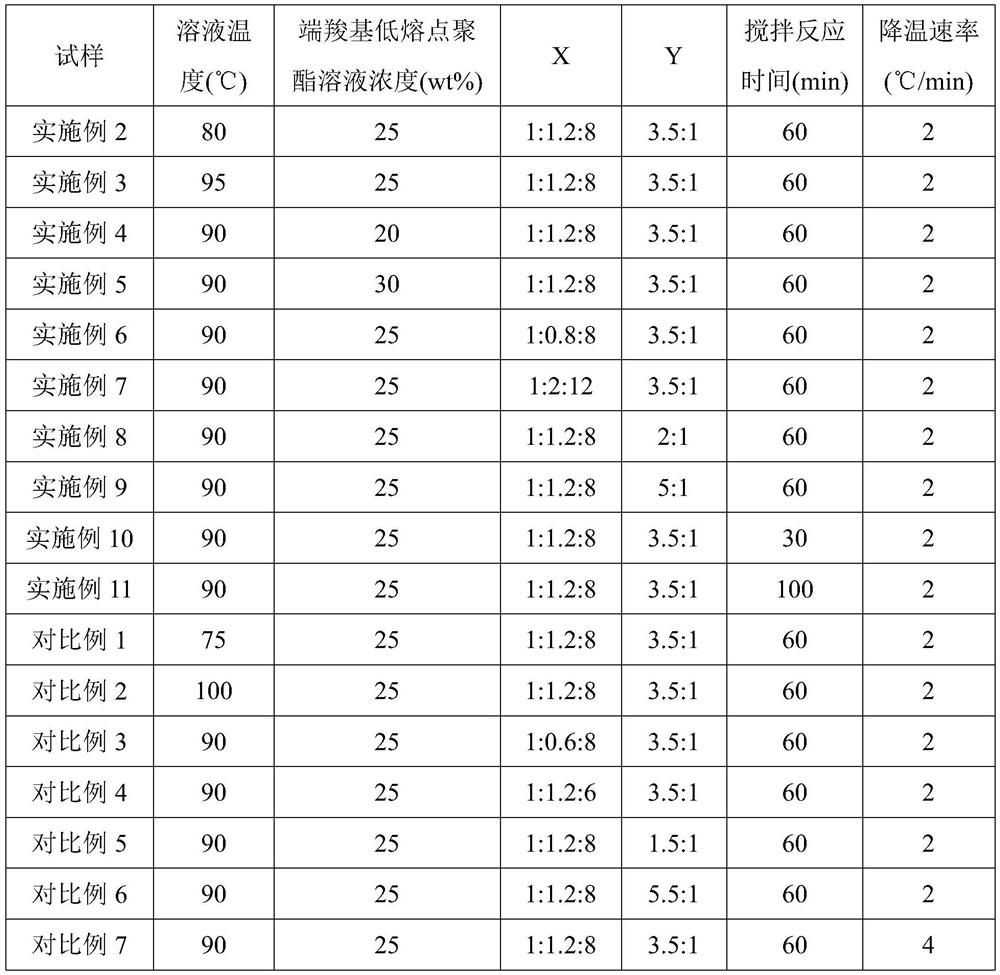

The invention provides a dyeing agent for mattress fabrics and a dyeing method. The dyeing agent is disperse dye microcapsules, the core material of the disperse dye microcapsules is disperse dyes, and the wall material is carboxyl-terminated low-melting polyester. The mass ratio of the carboxyl-terminated low-melting polyester to the disperse dye is 1:2-5. When dyeing, the prepared disperse dye microcapsules do not need to add additional PH buffer, and do not need to reduce cleaning, which significantly saves dyeing cost and time; The carboxyl-terminated low-melting polyester and the disperse dye are reconstituted into disperse dye microcapsules, and sedimentation occurs, thereby removing the dye in the dye liquor. The invention utilizes the low melting point characteristics of the carboxyl-terminated low melting point polyester and the good affinity with polyester fabrics, which significantly improves the dyeing rate of disperse dyes, and has the advantages of simple operation, low pollution and suitable for wide-scale popularization.

Owner:JIANGSU ZHONGHENG KELAIBI FURNITURE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com