Cold dyeing device and cold dyeing process

A technology of cold dyeing and equipment, which is applied in the field of cold dyeing equipment and cold dyeing technology, which can solve the problems of slow running speed of cloth, easy sedimentation, poor effect of cloth fiber dyeing, etc., and achieve the effect of improving the effect of dyeing and speeding up the flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

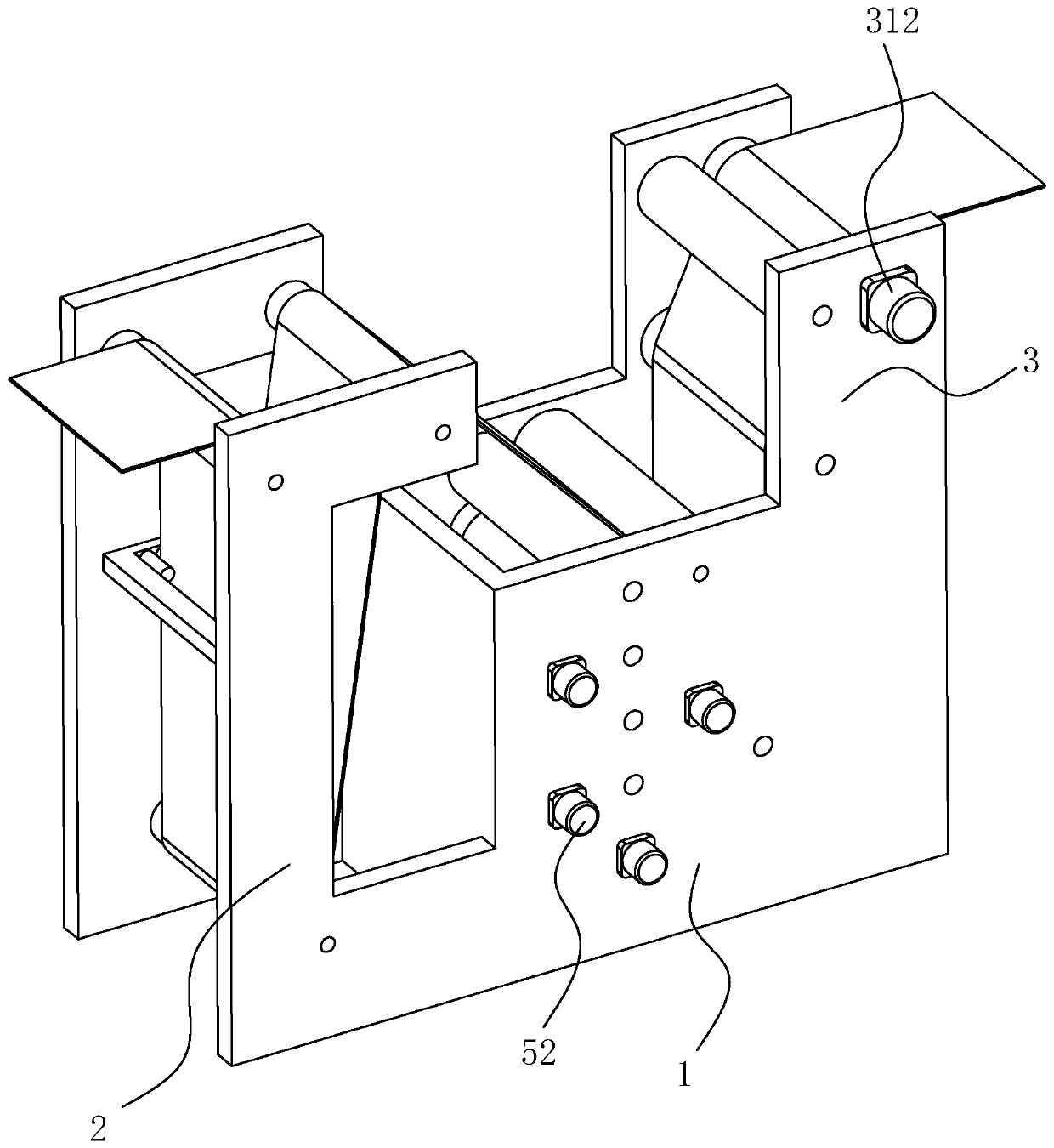

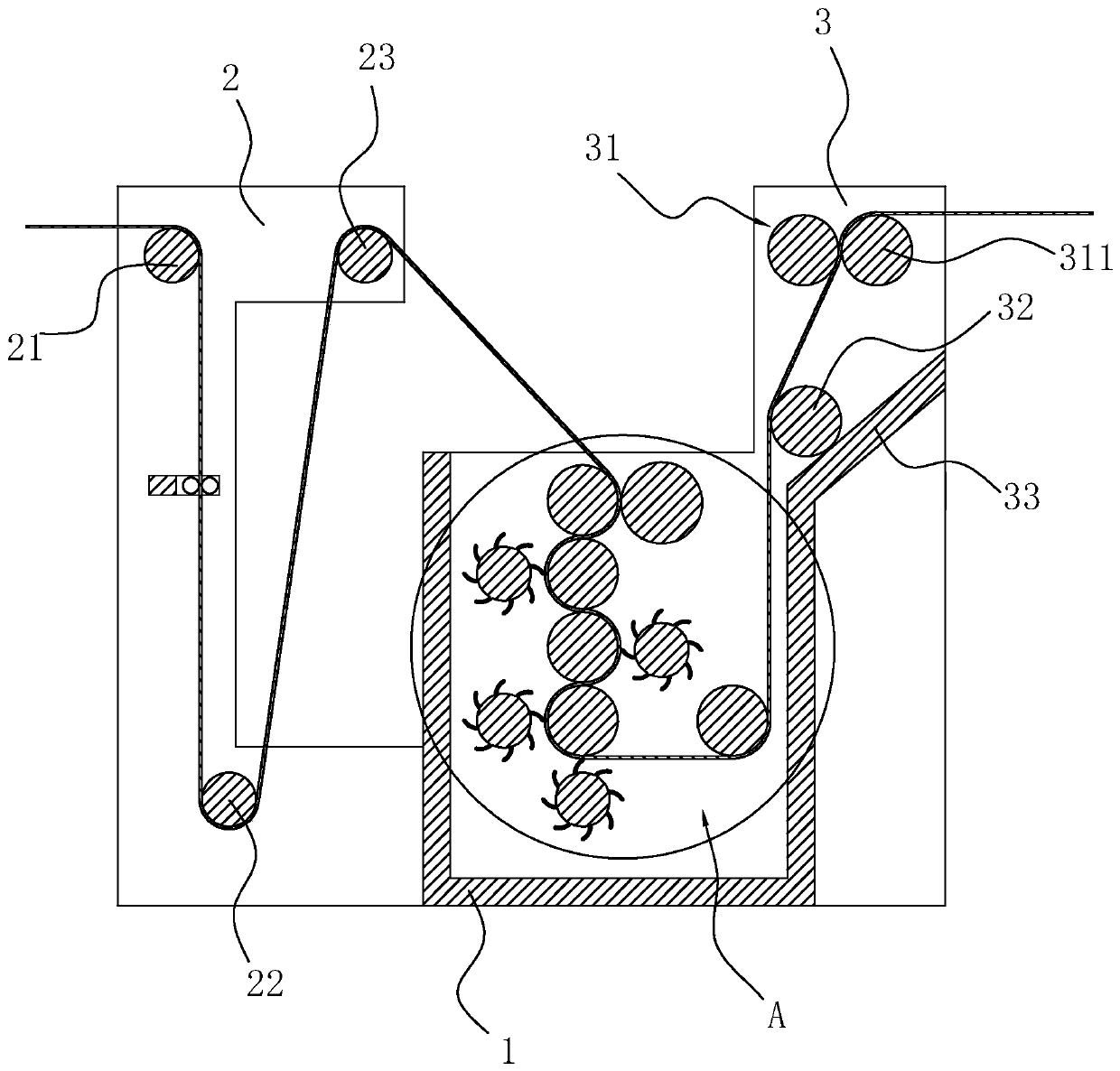

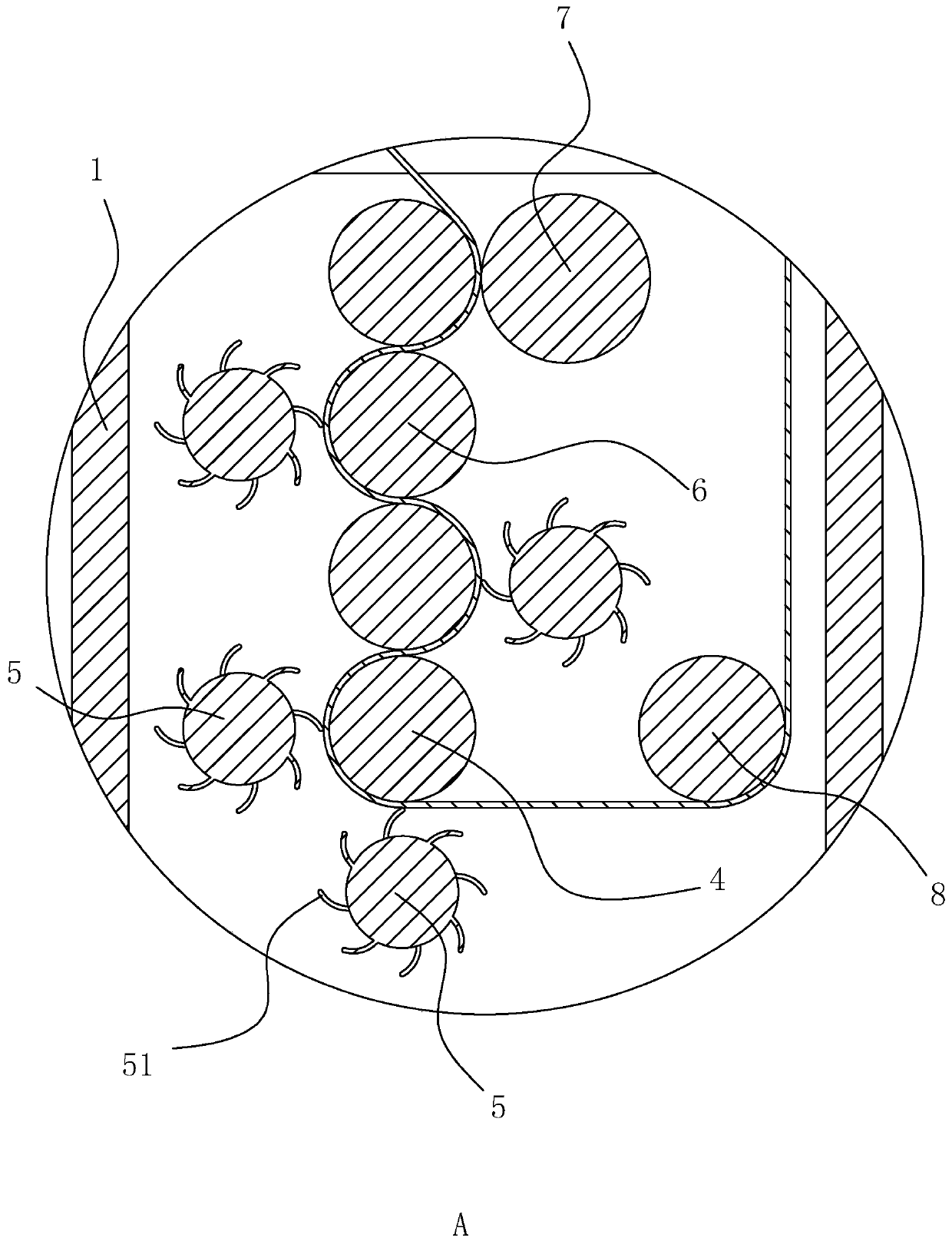

[0040]Embodiment 1: A kind of cold dyeing equipment, comprising a cold dyeing box 1, two feed racks 2 arranged on the feeding side of the cold dyeing box 1, and two output racks arranged on the side of the cold dyeing box 1 away from the feed rack 2 frame 3. The position near the top between the two feeding frames 2 is provided with a feed roller 21, and the two ends of the feed roller 21 are respectively rotatably connected to the two feed frames 2, and a guide roller 22 is arranged below the feed roller 21, and the guide roller The two ends of 22 are respectively rotatably connected on the two feeding racks 2, the axial direction of the feeding roller 21 is arranged horizontally and is parallel to the axial direction of the guide roller 22, and the side of the feeding roller 21 near the cold dyeing box 1 is provided with two Rotate the guide rollers 23 connected to the feed frame 2 respectively, the axis direction of the guide rollers 23 and the axis direction of the guide r...

Embodiment 2

[0048] Embodiment two: a kind of cold dyeing process, comprises the following steps:

[0049] a. Configure the dye: configure the dye according to the color to be dyed, put the configured dye into the cold dyeing box 1, so that the axes of the squeeze roller 7 on the liquid surface of the dye are flush with each other;

[0050] b. Dip dyeing: pass the cloth from the top of the feed roller 21 and then pull down the cloth so that the two sides of the cloth are respectively clamped between the two spreading rollers 93 on both sides of the cloth, then the cloth is passed around the bottom of the guide roller 22, and then The cloth is bypassed from the top of the guide roller 23, then the cloth is passed between the top winding roller 6 and the squeeze roller 7, and then the cloth passes between the top winding roller 6 and the middle winding roller 6 And the cloth and the winding roller 6 in the middle are in contact with each other near the feeding frame 2, and then the cloth i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com