Textile printing and dyeing method based on magnetization principle

A technology based on the principle of textile fabrics, applied in the field of textile fabric printing and dyeing based on the principle of magnetization, can solve the problems of low printing and dyeing quality, achieve the effects of improving the quality of exhaust dyeing, improving the effect of exhaust dyeing, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

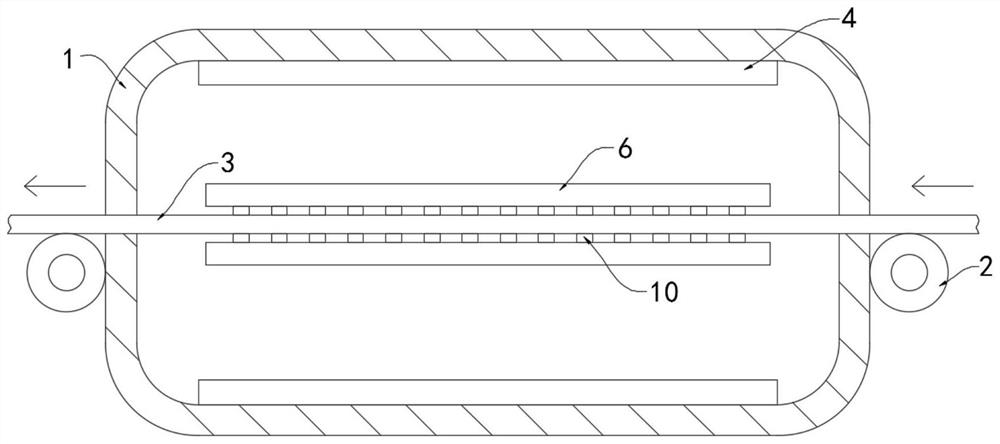

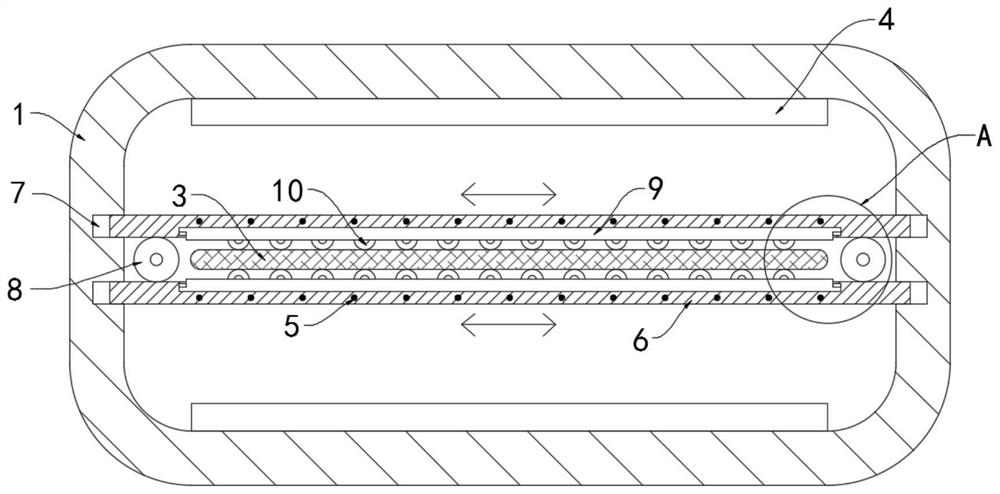

[0028] Such as Figure 1-3 As shown, a textile fabric printing and dyeing method based on the principle of magnetization, the specific printing and dyeing method is as follows:

[0029] S1. Place the fabric 3: pass the fabric 3 through the casing 1 and lay it flat on the two conveying rollers 2;

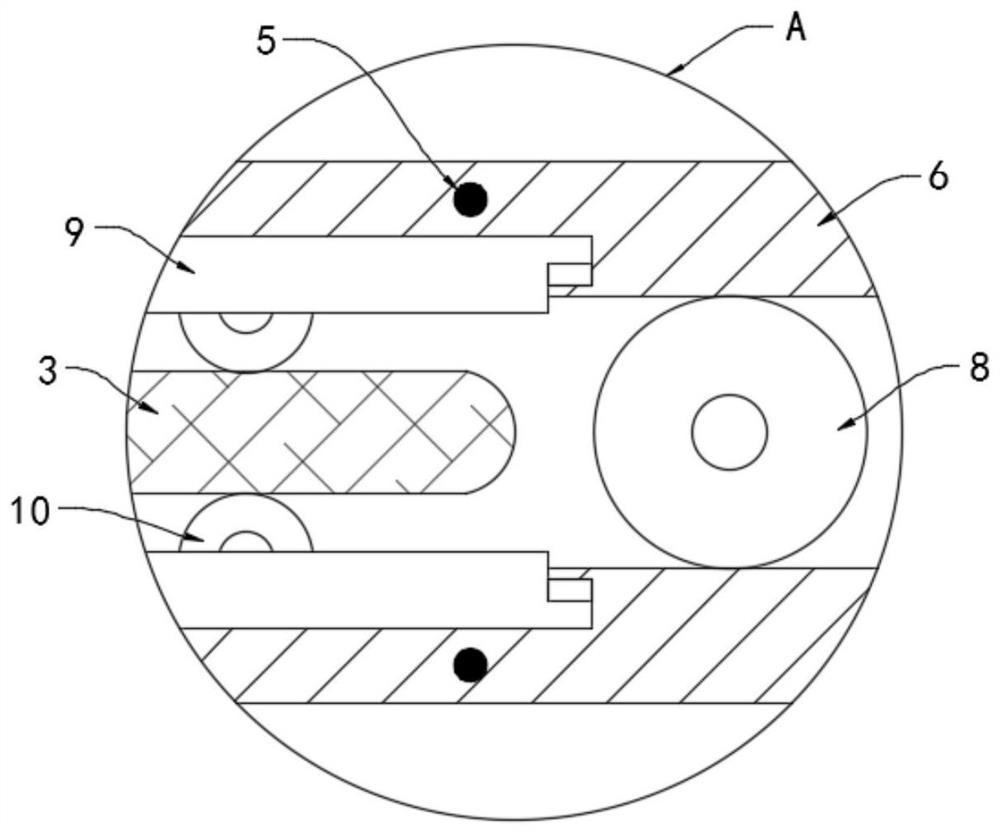

[0030] S2. Rolling the fabric 3: the back and forth rotation of the gear 8 will drive the fixed plate 6 to reciprocate on the fabric 3, thereby driving a plurality of rollers 10 to roll back and forth on the fabric 3, thereby promoting the absorption of the dye solution by the fabric 3;

[0031] S3, magnetized dye solution: the reciprocating movement of the fixed plate 6 drives the wire 5 to cut the magnetic induction line between the two permanent magnet plates 4 to generate current, and the energized extrusion plate 9 will generate magnetism, because the moving directions of the two fixed plates 6 are opposite , the magnetic poles of the two extruded plates 9 are always opposite, ...

Embodiment 2

[0046] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that a sealing bucket 11 is fixedly connected to the connection between the housing 1 and the outlet end of the cloth 3 (such as Figure 4 shown).

[0047] In this embodiment, the sealing bucket 11 is arranged inside the connection between the casing 1 and the outlet end of the cloth 3 and is arranged close to the cloth 3, so that the excess dye on the cloth 3 can be squeezed out when the cloth 3 is conveyed to the outside of the casing 1. Pressing it into the housing 1 can effectively avoid the waste of dye.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com