Glass fiber-reinforced plastic composite pipe and machining method thereof

A processing method and glass fiber reinforced plastic technology, which is applied in the direction of pipes, pipe components, rigid pipes, etc., can solve the problems of inability to apply high-pressure fluids, increased energy consumption for fluid transportation, and low pressure resistance of the pipe wall, and achieves good fusion bonding effect. The effect of improving the tolerance and meeting the conveying requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

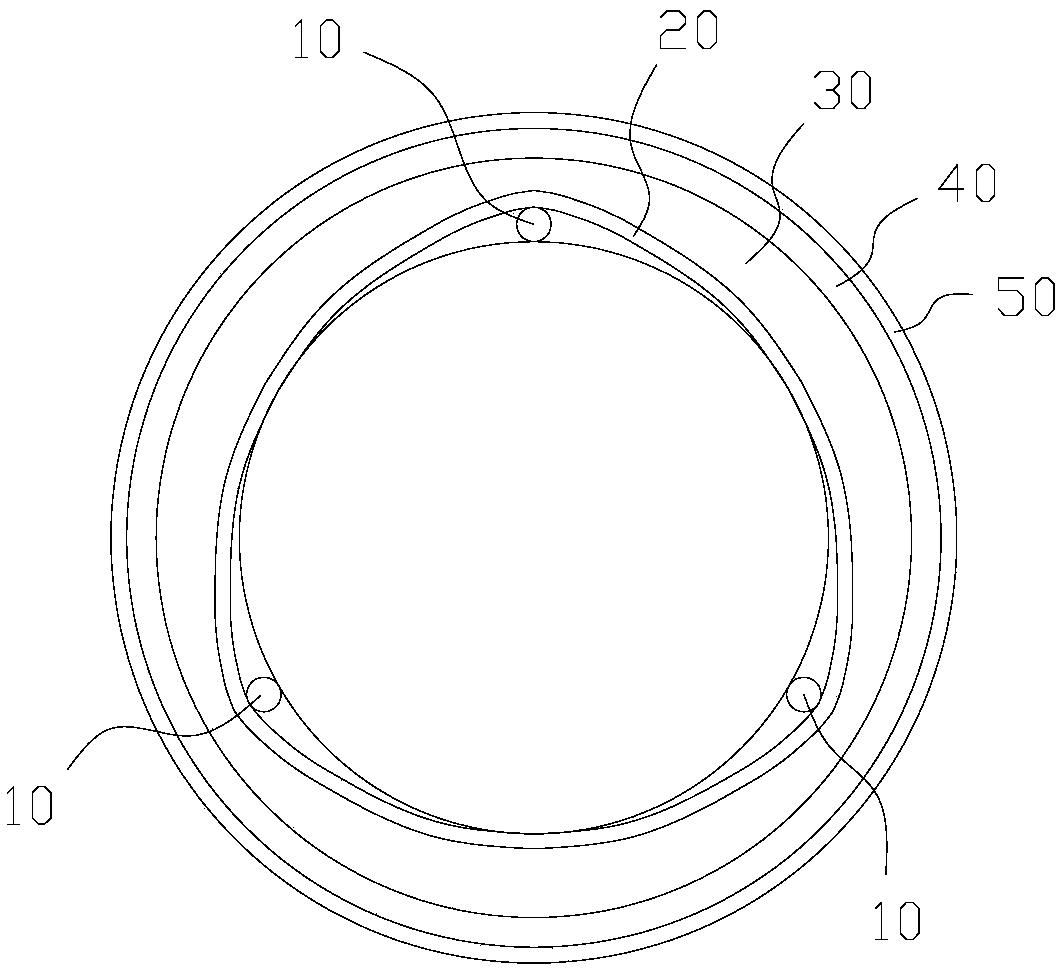

[0039] A method for processing a glass fiber reinforced plastic composite pipe, comprising the following steps:

[0040] (1) FRP is wound on the cylindrical inner mold to form an inner liner, and before winding, three first glass fiber tendons are evenly spaced along the circumferential direction of the cylindrical inner mold, and the first The length direction of the glass fiber reinforcement is consistent with the length direction of the cylindrical inner mold;

[0041] The ratio of the diameter of the first glass fiber reinforcement to the inner diameter of the FRP composite pipe to be formed is 1:15;

[0042] The winding thickness of the inner liner is 5mm;

[0043] (2) After the inner liner is cured, take off the cylindrical inner mold and put an outer mold on the outer side of the inner liner, the minimum distance between the outer mold and the inner liner is 5 mm;

[0044] pouring composite resin material into the cavity between the inner lining layer and the outer mo...

Embodiment 2

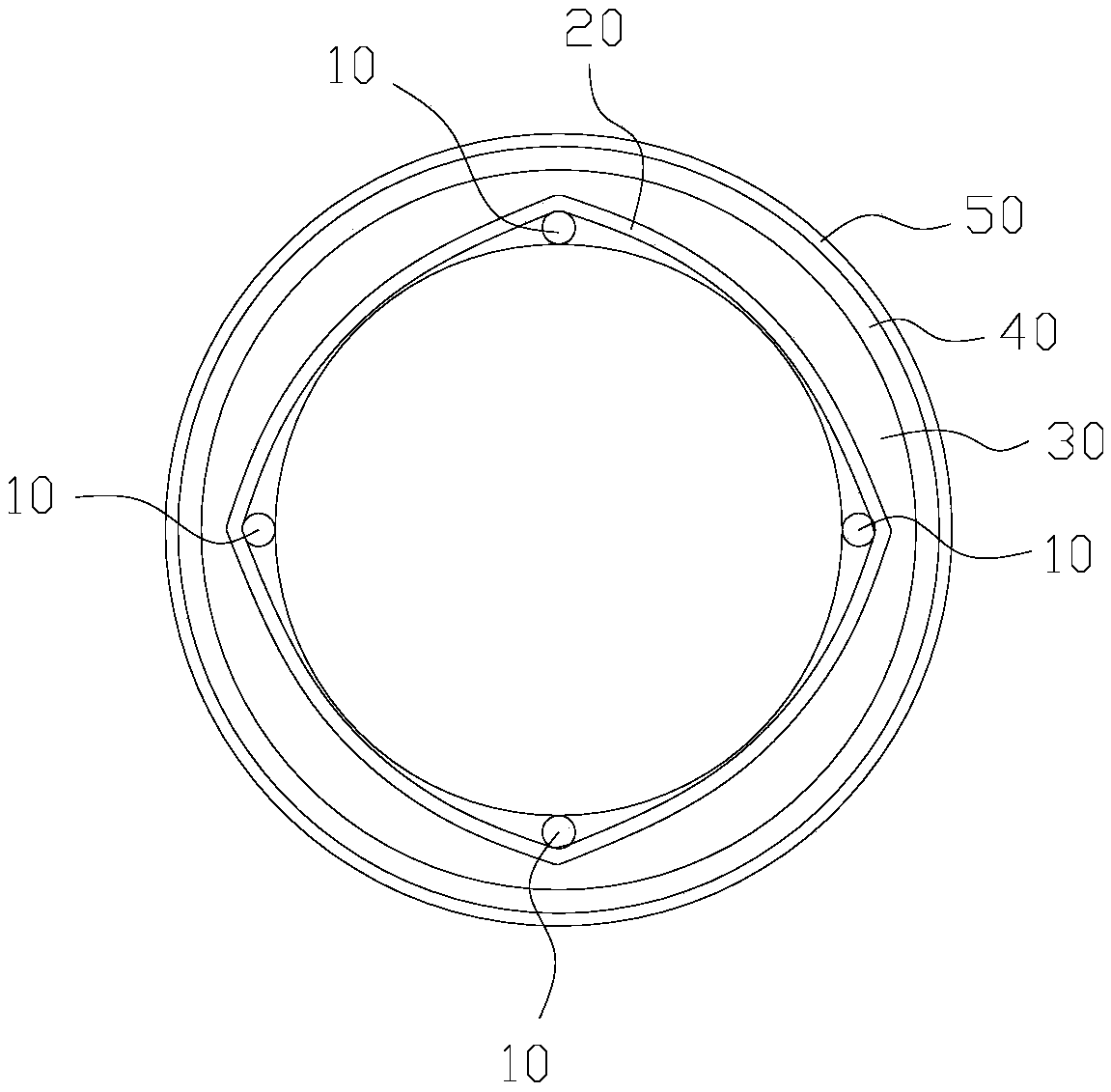

[0051] The processing method of the FRP composite pipe as provided in Example 1, the difference is that in step (1), four first glass fiber tendons are evenly spaced along the circumferential direction of the cylindrical inner mold; the rest remain unchanged, Processed by the processing method of Example 1 to obtain the FRP composite pipe.

[0052] The schematic diagram of the cross-section of the FRP composite pipe processed in this embodiment 2 is as follows figure 2 As shown, wherein, 10 is the first glass fiber reinforcement, 20 is the inner lining layer, 30 is the composite resin material layer, 40 is the second glass fiber reinforcement winding layer, and 50 is the outer protective layer.

Embodiment 3

[0054] The processing method of the FRP composite pipe as provided in Example 1, the difference is that in step (2), the composite resin material comprises the following raw materials by weight to make: 35 parts by weight of bisphenol A type epoxy resin, poly 5 parts by weight of amide, 5 parts by weight of polysulfide rubber, 2 parts by weight of silicon dioxide, 1 part by weight of talcum powder, 10 parts by weight of butyl acetate;

[0055] The rest remain unchanged, and the FRP composite pipe is obtained by processing according to the processing method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com