Splicing component and vacuum glass manufactured by adopting splicing component

A technology of vacuum glass and components, which is applied in the field of vacuum glass manufacturing structure, and can solve the problems of fragile products, poor appearance and inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

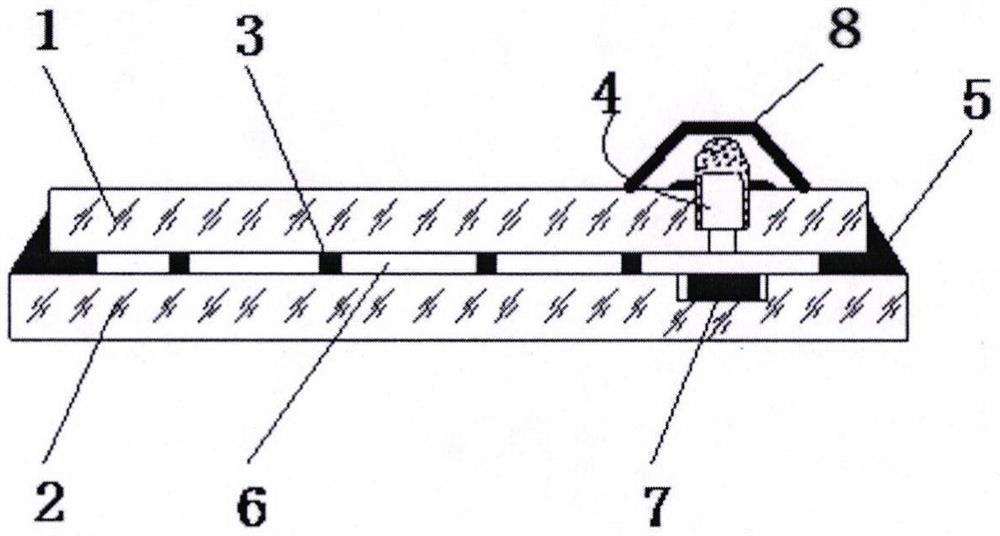

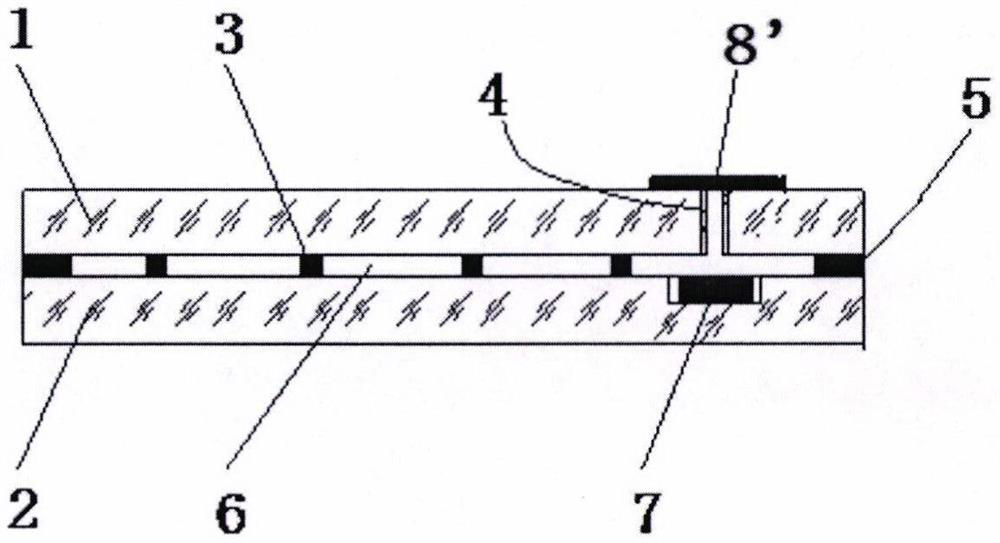

[0026] Embodiments of the present invention will be described below with reference to the accompanying drawings.

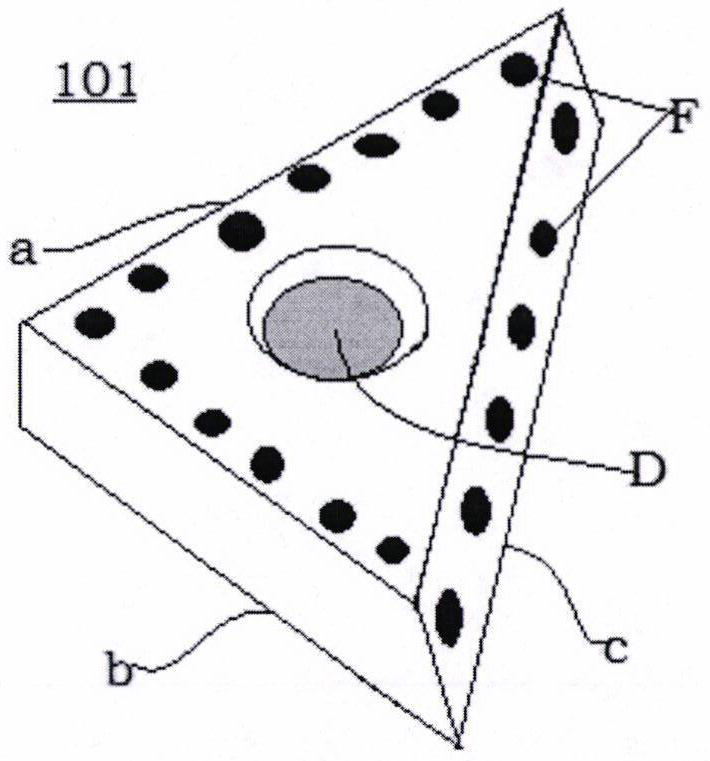

[0027] see figure 2 , the partial splicing part 101 of the vacuum glass according to an embodiment of the present invention is a right-angled triangular glass sheet, shown in the figure is an isosceles triangle with a base angle of 45°, and a pit D (or Blind hole) for the placement of the getter 7. The splicing part 101 can be regarded as a truncated angle cut from the upper glass of the vacuum glass 10 . The splicing part 101 is used as a sealing sheet, and its isosceles triangle geometric shape can also be replaced by a quadrilateral, a circle or other shapes. The waist length of the waist triangle is preferably 2 cm, for example, and can be applied to the production of vacuum glass of various sizes. The figure shows that the pit circle D used to accommodate the getter is a circular blind hole, and any other suitable form of pit can be used to replace it, ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com