Dyeing device for rolling and rubbing type textile yarn

A technology of textile yarn and dyeing device, which is applied in the direction of processing textile materials equipment configuration, textile and papermaking, textile processing machine accessories, etc., and can solve the problem of low dyeing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

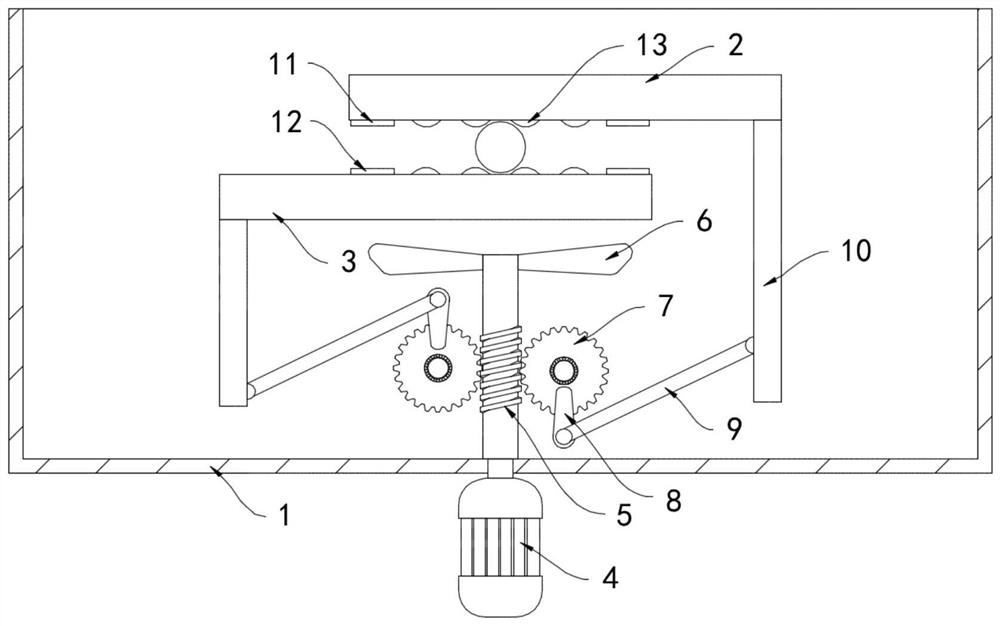

[0018] Such as figure 1 As shown, a tumbling type textile yarn dyeing device includes a dye liquor tank 1, an upper platen 2 and a lower platen 3 arranged horizontally are slidably connected to the inner wall of the dye liquor tank 1, and the lower surface of the upper platen 2 is fixed A permanent magnet piece 11 is connected, and the upper surface of the lower pressing plate 3 is fixedly connected with a magnet piece 12 that attracts the opposite poles of the permanent magnet piece 11. The side walls of the upper pressing plate 2 and the lower pressing plate 3 are provided with a plurality of Ribs 13 extending in the direction of the thread axis, the surface of the ribs 13 is arranged in an arc-shaped protrusion, when the upper pressing plate 2 and the lower pressing plate 3 are rolling and kneading the textile yarn, multiple ribs 13 repeatedly squeeze the textile yarn, Further improve the effect of exhaust dyeing on yarn.

[0019] A motor 4 is installed at the bottom of th...

Embodiment 2

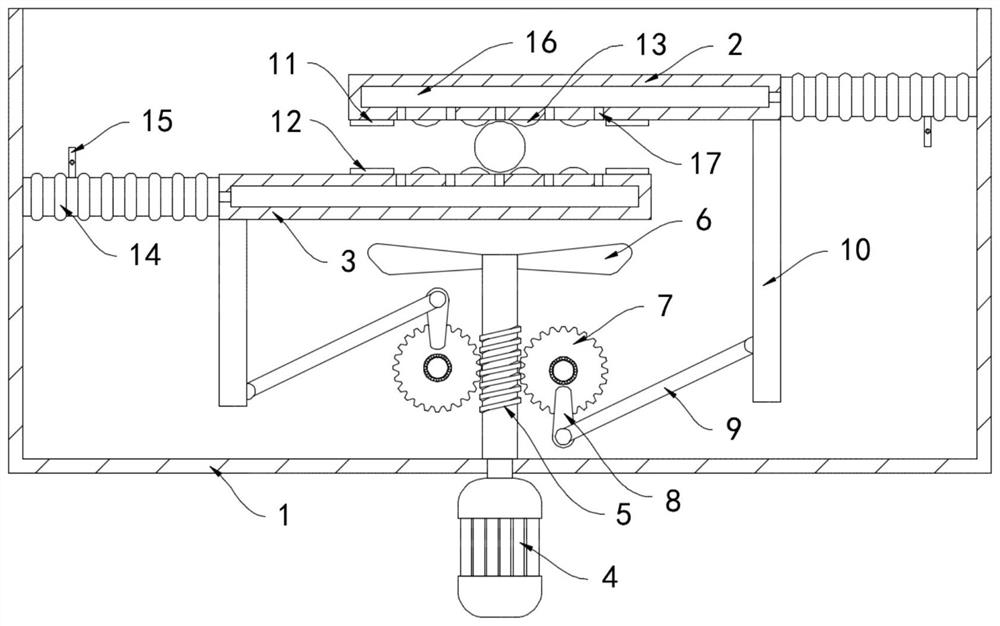

[0024] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the upper platen 2 and the lower platen 3 are fixedly connected to the inner side wall of the dyeing liquid tank 1 through the flexible liquid bag 14, and the side wall of the flexible liquid bag 14 is fixedly connected. There is a one-way liquid inlet pipe 15, and the one-way liquid inlet pipe 15 only allows the dye solution in the dye solution tank 1 to enter the telescopic liquid bag 14, and the upper platen 2 and the lower platen 3 are provided with drains communicating with the telescopic liquid bag 14. The side walls of the liquid chamber 16 and the two liquid discharge chambers 16 adjacent to each other are equally spaced with a plurality of liquid discharge holes 17 .

[0025] In this embodiment, the upper platen 2 and the lower platen 3 repeatedly stretch and squeeze the telescopic liquid bag 14, and the telescopic liquid bag 14 sucks the dye solution in the dye liquid t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com