Anti-pilling sportwear fabric and preparation method thereof

A technology for sportswear and anti-pilling, which is applied in the processing of textile material equipment configuration, fabric surface trimming, and textile material treatment, etc. Fabric surface and other problems to achieve the effect of keeping the skin fresh, environmentally friendly, and good moisture-wicking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

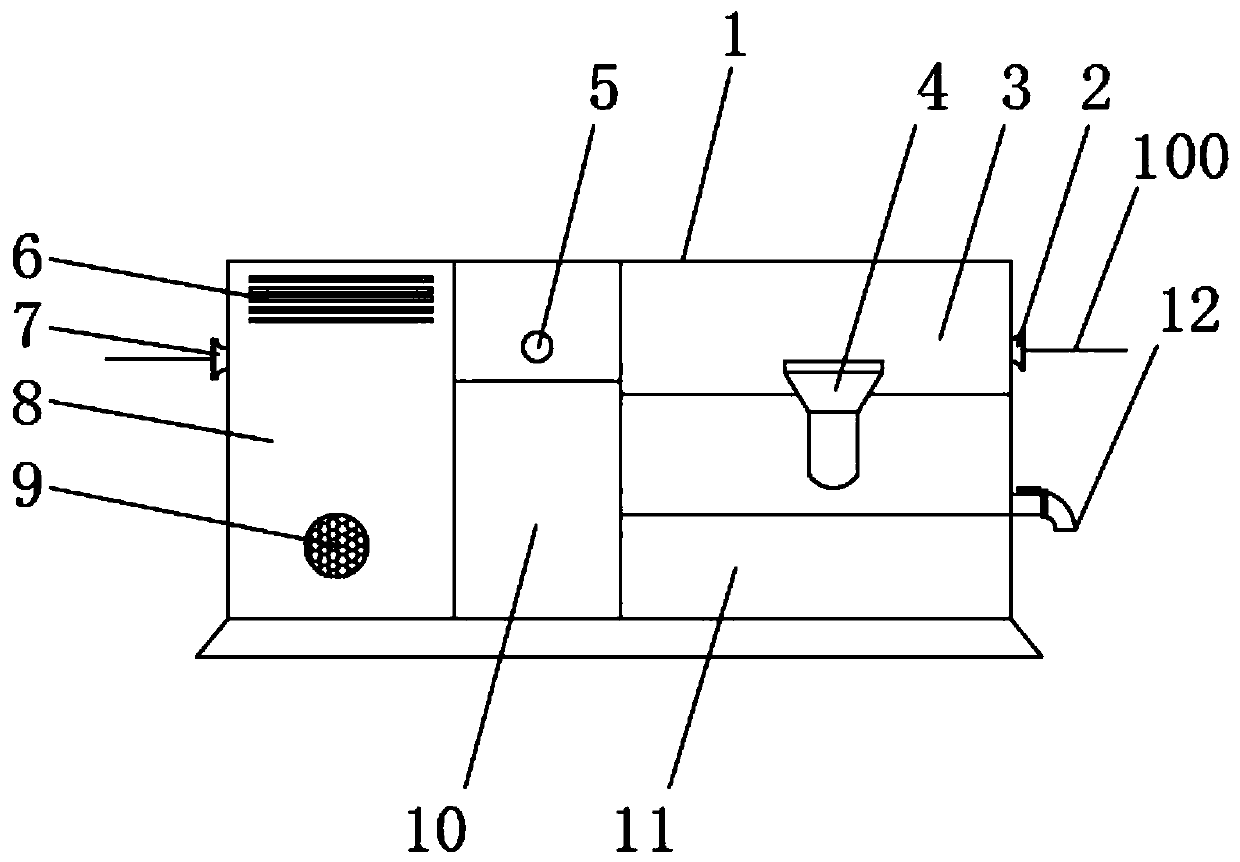

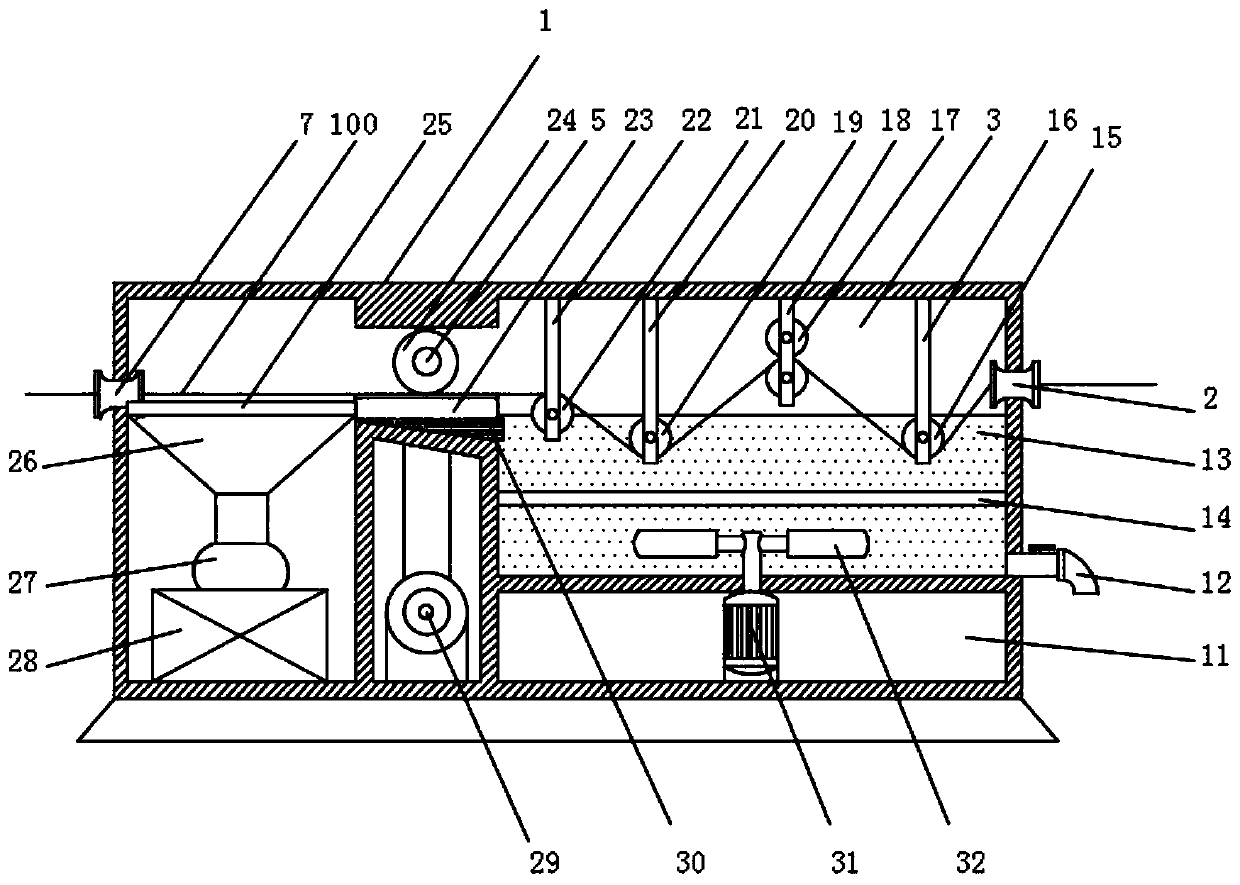

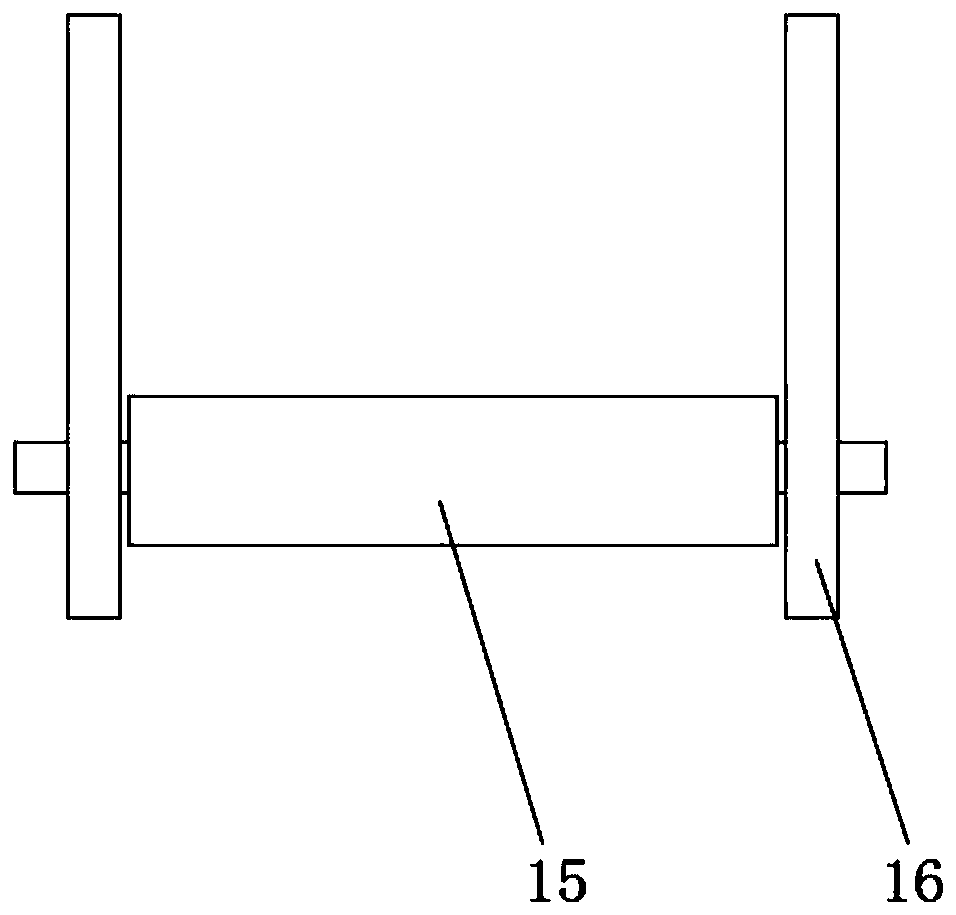

[0059] see Figure 1-7 Shown, present embodiment is a kind of preparation method of anti-pilling sportswear fabric, comprises the following steps:

[0060] Step 1: Weaving: Weigh 55 parts of polyester fiber and 25 parts of modal fiber, mix them evenly and weave them into gray cloth with a water jet loom;

[0061] Step 2: Sizing and oiling treatment: Sizing and oiling the gray cloth;

[0062] Step 3: Desizing and refining treatment: use a low bath ratio high-pressure jet overflow machine to desizing and refining the gray cloth;

[0063] Step 4: Alkali weight reduction treatment: After desizing and refining, the gray cloth is subjected to alkali weight reduction treatment;

[0064] Step 5: Post-setting drying treatment: first soak the gray cloth in 2-5% sodium dodecylsulfonate solution for 5-10 minutes, then perform 100°C water padding, and then dry at 170-190°C Dry setting to obtain the fabric to be padded;

[0065] Step 6: Prepare anti-pilling finishing agent;

[0066] S1...

Embodiment 2

[0080] see Figure 1-7 Shown, present embodiment is a kind of preparation method of anti-pilling sportswear fabric, comprises the following steps:

[0081] Step 1: Weaving: Weigh 65 parts of polyester fiber and 35 parts of modal fiber, mix them evenly and weave them into gray cloth with a water jet loom;

[0082] Step 2: Sizing and oiling treatment: Sizing and oiling the gray cloth;

[0083]Step 3: Desizing and refining treatment: use a low bath ratio high-pressure jet overflow machine to desizing and refining the gray cloth;

[0084] Step 4: Alkali weight reduction treatment: After desizing and refining, the gray cloth is subjected to alkali weight reduction treatment;

[0085] Step 5: Post-setting drying treatment: first soak the gray cloth in 2-5% sodium dodecylsulfonate solution for 5-10 minutes, then perform 100°C water padding, and then dry at 170-190°C Dry setting to obtain the fabric to be padded;

[0086] Step 6: Prepare anti-pilling finishing agent;

[0087] S1,...

Embodiment 3

[0101] see Figure 1-7 Shown, present embodiment is a kind of preparation method of anti-pilling sportswear fabric, comprises the following steps:

[0102] Step 1: Weaving: Weigh 75 parts of polyester fiber and 45 parts of modal fiber, mix them evenly, and weave them into gray cloth with a water jet loom;

[0103] Step 2: Sizing and oiling treatment: Sizing and oiling the gray cloth;

[0104] Step 3: Desizing and refining treatment: use a low bath ratio high-pressure jet overflow machine to desizing and refining the gray cloth;

[0105] Step 4: Alkali weight reduction treatment: After desizing and refining, the gray cloth is subjected to alkali weight reduction treatment;

[0106] Step 5: Post-setting drying treatment: first soak the gray cloth in 2-5% sodium dodecylsulfonate solution for 5-10 minutes, then perform 100°C water padding, and then dry at 170-190°C Dry setting to obtain the fabric to be padded;

[0107] Step 6: Prepare anti-pilling finishing agent;

[0108] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com