Cloth dyeing method for increasing cloth dip dyeing speed

A speed and cloth dyeing technology, applied in the field of textile printing and dyeing, can solve the problems affecting the quality of cloth, inconsistent speed, easy to stain clothes, etc., to achieve the effect of strengthening the effect of dipping, fast rotation speed, and realization of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

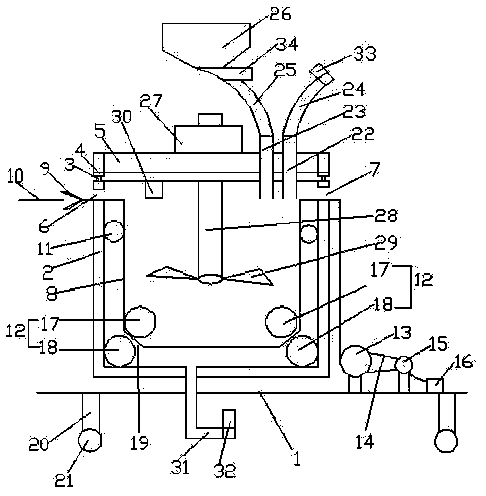

[0015] A cloth dyeing machine with adjustable dye concentration, a frame, a cloth dyeing vat, a driving motor and an intermittent drive mechanism, the cloth dyeing vat is arranged on the frame, and a stirring wing is arranged inside the dyeing vat, The driving motor is used to drive an intermittent driving mechanism, and the intermittent driving mechanism is used to provide intermittent driving force to realize the stirring blade has a rotating state and a static state within one rotation cycle.

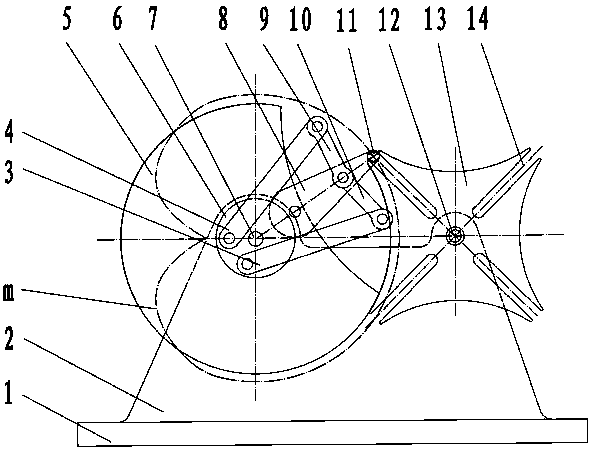

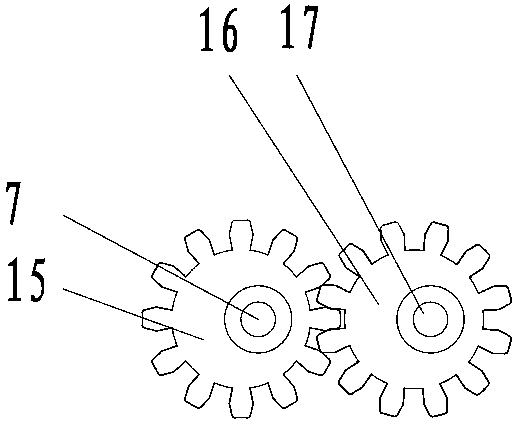

[0016] Such as figure 2 As shown, the intermittent drive mechanism includes a fixed plate 1, a support plate 2, a first long connecting rod 3, a second long connecting rod 4, a first engaging disc 5, a connecting rod fixing disc 6, a driving shaft 7, a rotating Arm 8, second short connecting rod 9, first short connecting rod 10, engaging pin shaft 11, driven shaft 12, second engaging disc 13 and bar-shaped engaging groove 14, the fixed plate 1 is fixedly arranged on On the frame, t...

Embodiment 2

[0019] A cloth dyeing machine with adjustable dye concentration, a frame, a cloth dyeing vat, a driving motor and an intermittent drive mechanism, the cloth dyeing vat is arranged on the frame, and a stirring wing is arranged inside the dyeing vat, The driving motor is used to drive an intermittent driving mechanism, and the intermittent driving mechanism is used to provide intermittent driving force to realize that the stirring blade has a rotating state and a static state within one rotation cycle.

[0020] Such as figure 2 As shown, the intermittent drive mechanism includes a fixed plate 1, a support plate 2, a first long connecting rod 3, a second long connecting rod 4, a first engaging disc 5, a connecting rod fixing disc 6, a driving shaft 7, a rotating Arm 8, second short connecting rod 9, first short connecting rod 10, engaging pin shaft 11, driven shaft 12, second engaging disc 13 and bar-shaped engaging groove 14, the fixed plate 1 is fixedly arranged on On the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com