Production line of electrical equipment electric heating dipping and ultraviolet curing operation

A technology of electrical equipment and assembly line, which is applied in the direction of electrical components, manufacturing of motor generators, coil manufacturing, etc. It can solve the problems of cumbersome positioning and control of dipping equipment, many installation stations, and complicated design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

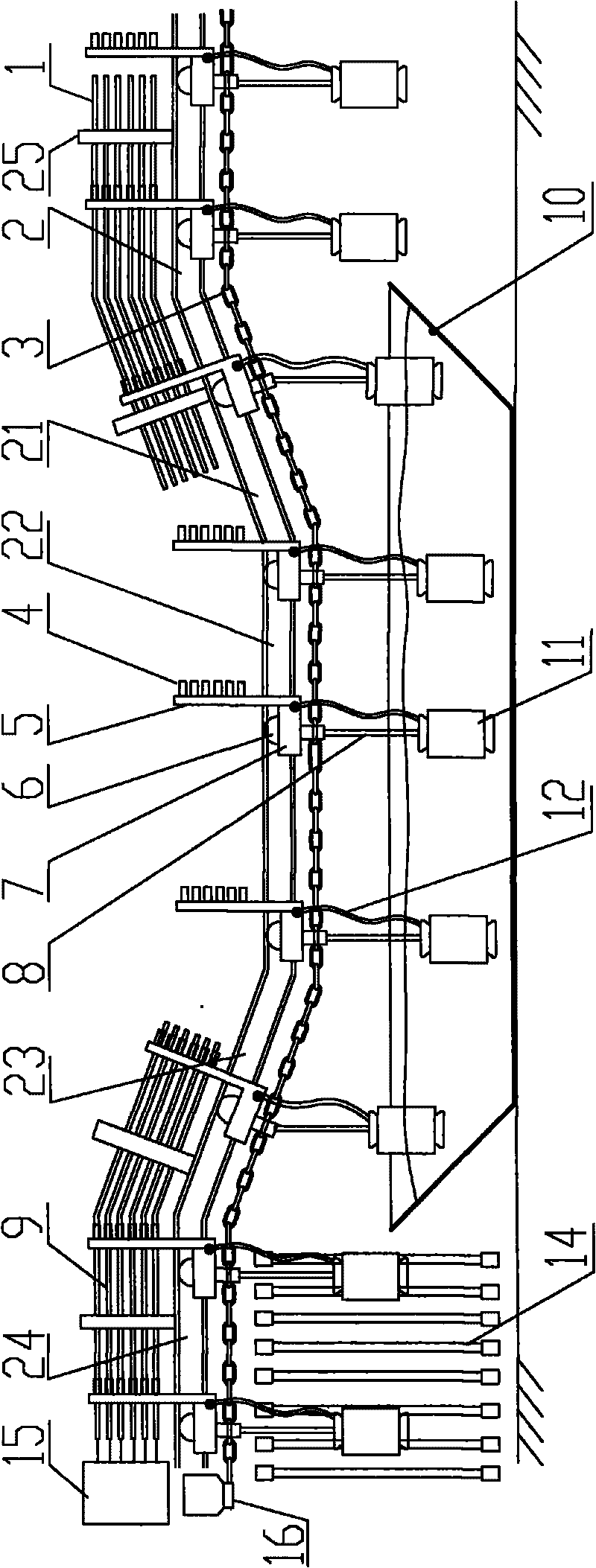

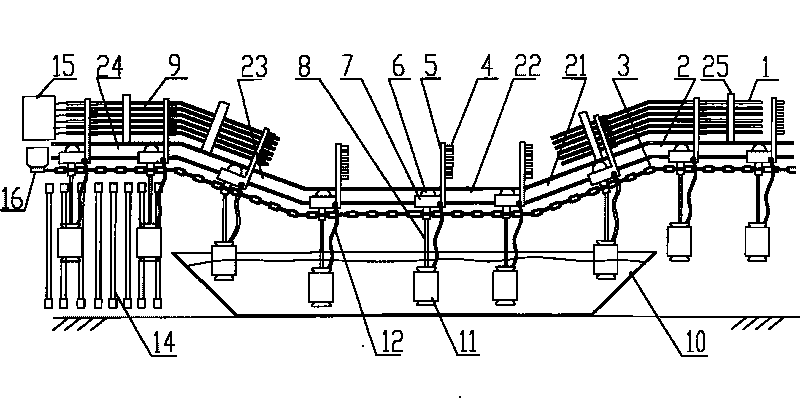

[0020] Such as figure 1 As shown, the assembly line of electric heating dipping and ultraviolet curing operation of electrical equipment of the present invention includes an external power supply 15, a paint dipping tank 10 and an ultraviolet curing lamp 14, and also includes a guide rail, a traction motor 16, a conveyor chain 3, several hanging devices, two Segment conductors 1 and 9;

[0021] Described guide rail comprises two sections of parallel sections 2 and 24 and dipping paint section 22, and described dipping paint section 22 is lower than described parallel section 2 and 24, and between described parallel section 2 and 24 and dipping paint section 22 passes through respectively Segment 21 and ascending segment 23 transition;

[0022] The hanging device includes a roller 6 and a roller bracket 7, and a brush holder 5 and an electric brush 4 that are installed on the roller bracket 7 and travel synchronously. The roller 6 is arranged on the roller bracket 7 through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com