Special clamping jaw installed on mechanical arm for casting shell mold and used for slurry dipping

A technology of mechanical arms and grippers, which is applied in the field of mechanization of the shell mold dipping process in the dewaxing casting industry. It can solve the problems of flexibility but insufficient strength, poor grasping flexibility, and low efficiency. Improve the efficiency of slurry dipping and the effect of grasping force control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following describes the implementation of the present invention in detail with the accompanying drawings and embodiments, so as to fully understand and implement the implementation process of how the present invention uses technical means to solve technical problems and achieve technical effects.

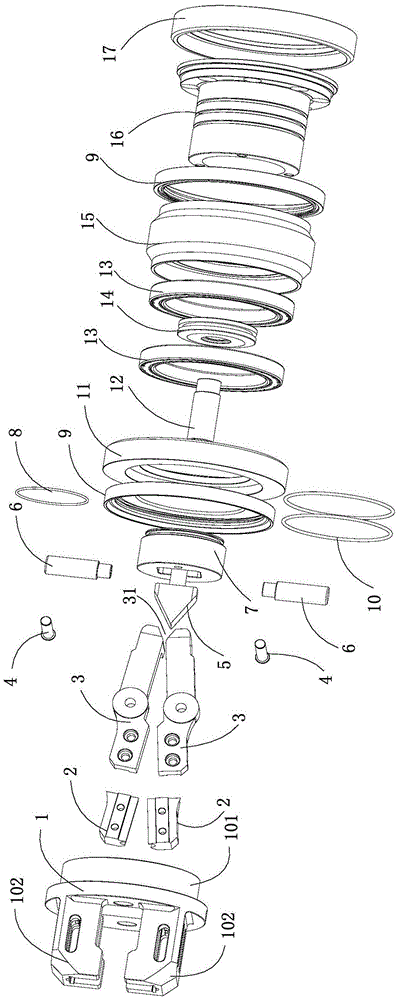

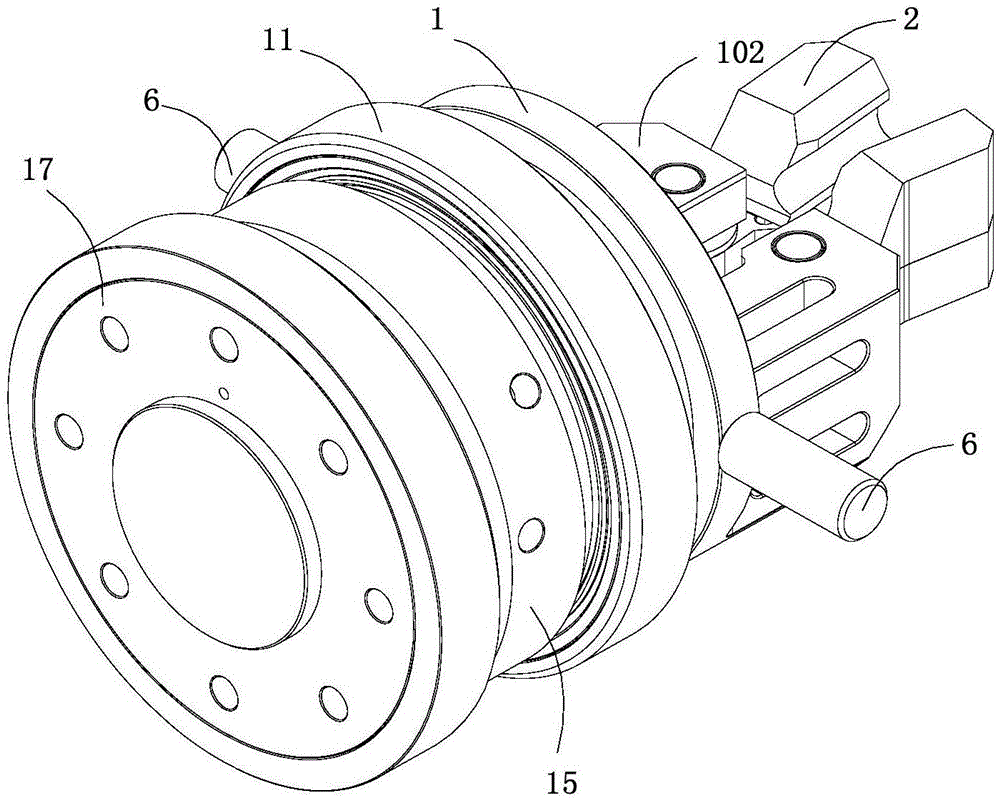

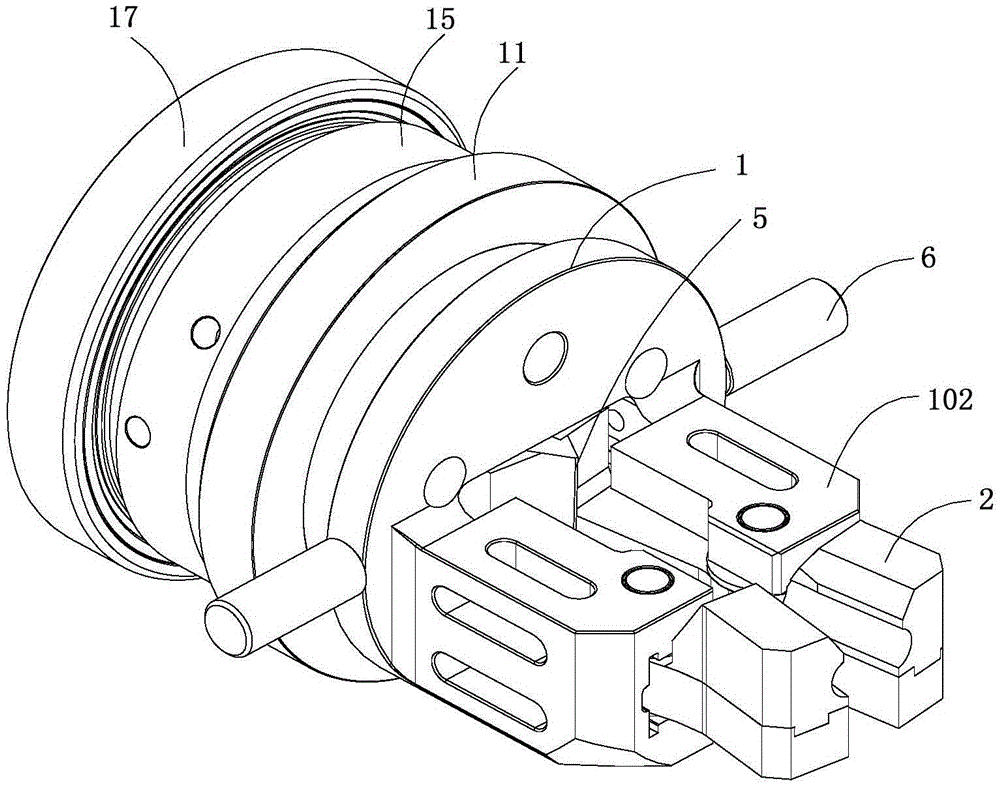

[0029] Please refer to Figure 1-7 , This embodiment provides a special clamping jaw for dipping a casting shell mold robot arm, including: a clamping part for clamping the workpiece; a holding part for lifting the clamping part to close the clamping part; In the driving part that pushes the holding part to rise, the driving part has a driving end; the clamping part is connected to the driving part and forms an accommodation space with the driving part; the holding part and the driving end are located in the accommodation space; the driving end is connected to the top The holding part is linked with the holding part. The driving part is connected with an external power sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com