Vertical paint dipping device of motor stator

A motor and stator technology, applied in electromechanical devices, manufacturing motor generators, electric components, etc., can solve problems such as long immersion time, thick paint film, cracking of insulating paint layer, etc., to improve the efficiency of immersion paint and the thickness of paint film Uniform, increased utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

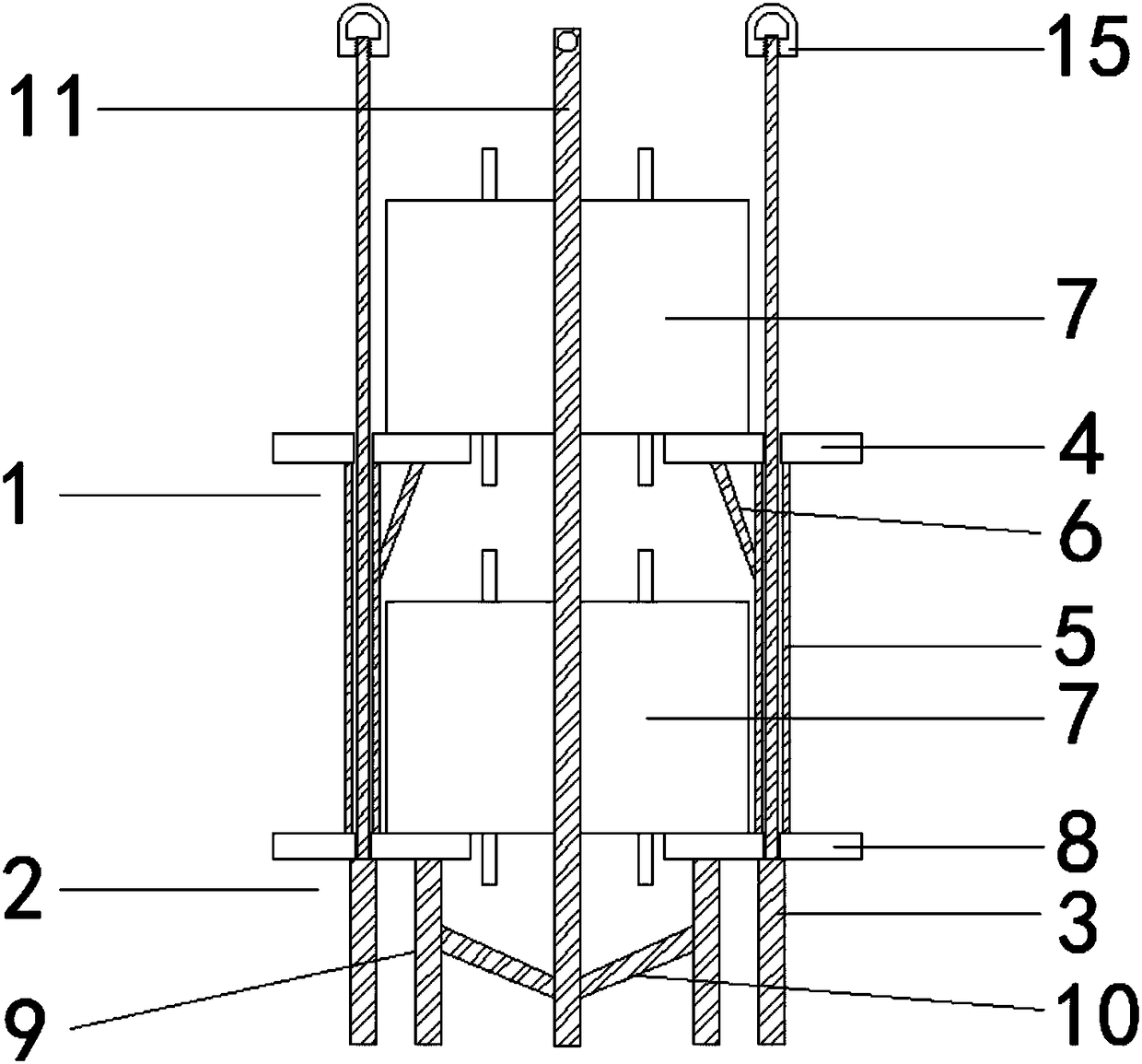

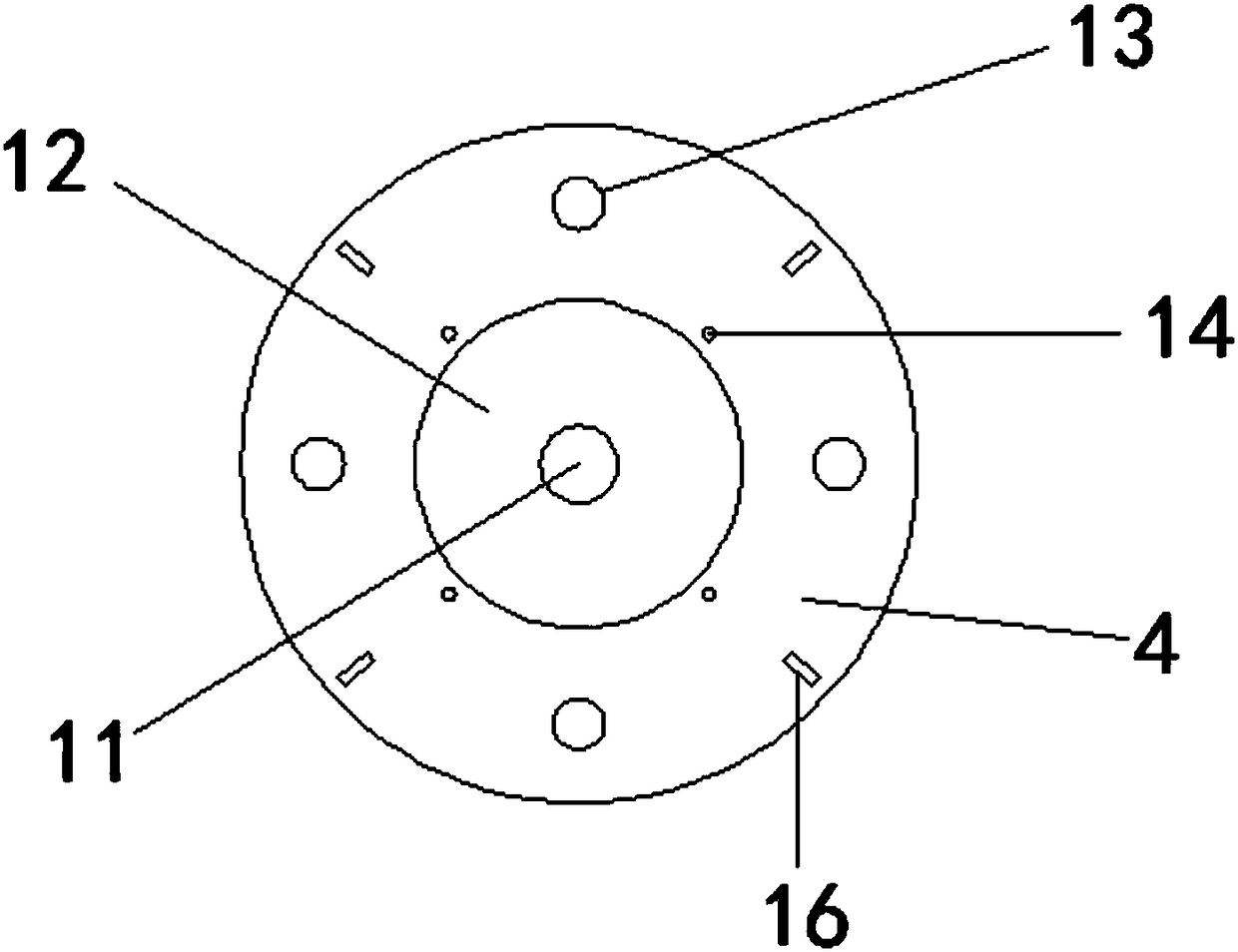

[0012] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0013] Such as figure 1 and figure 2 As shown, a vertical paint dipping device for a motor stator includes an upper load-bearing part 1, a lower load-bearing part 2 and a suspension rod 3; the upper load-bearing part 1, the lower load-bearing part 2 and the suspension rod 3 are all steel structures; The upper load-bearing part 1 is located on the lower load-bearing part, a space for placing the lower motor stator is formed between the upper load-bearing part and the lower load-bearing part, and a space for the motor stator is formed above the upper load-bearing part. The upper load-be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com