Method for rapidly detecting cellulose-ether anti-mold performance

A technology of cellulose ether and cellulase, applied in flow characteristics, measuring devices, instruments, etc., can solve the problems of test result error, long cycle, unfavorable large-scale production, etc., achieve high detection accuracy, ensure production efficiency and annual production The effect of short production and detection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

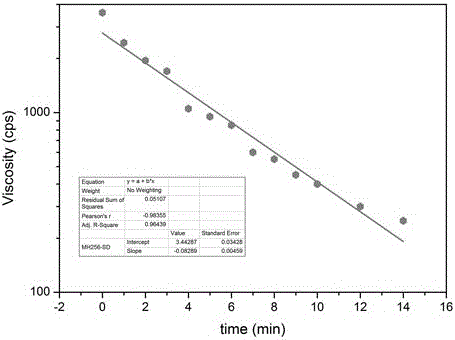

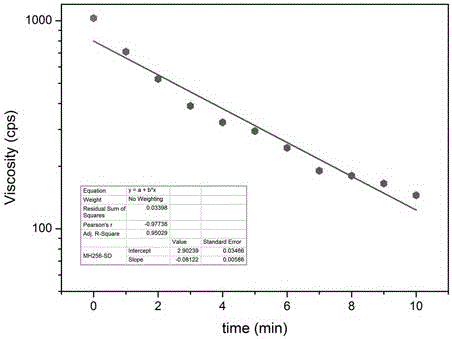

[0027] The method for rapid detection of mildew resistance of cellulose ether products in this embodiment 1 comprises the following steps:

[0028] (1) Preparation of cellulase solution:

[0029] Put 1.00 g of cellulase powder in 100 mL of distilled water, stir at a low speed for 3 minutes to fully suspend the cellulase, stop stirring and let it stand for at least 20 minutes, and wait until the supernatant is completely clarified before use. If the supernatant is still turbid, it can be separated with a centrifuge.

[0030] (2) Preparation of cellulose ether solution:

[0031] After the cellulose ether sample to be tested is dried, prepare 200mL of a 1-2% concentration solution with distilled water, keep the temperature in a constant temperature bath at 20ºC for 2 hours, and measure the initial viscosity V with a Brookfield RV viscometer at 20RPM after the cellulose ether is completely dissolved. 0 . If the initial viscosity is higher than 5000cps, prepare a 0.5% cellulose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com