System and method for detecting filter material counting efficiency based on monodispersed aerosol

A quasi-monodisperse, detection system technology, applied in the direction of measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of low measurable concentration, difficult to meet the precision requirements of diluters, and high maintenance costs. Achieve high detection accuracy and facilitate large-scale promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

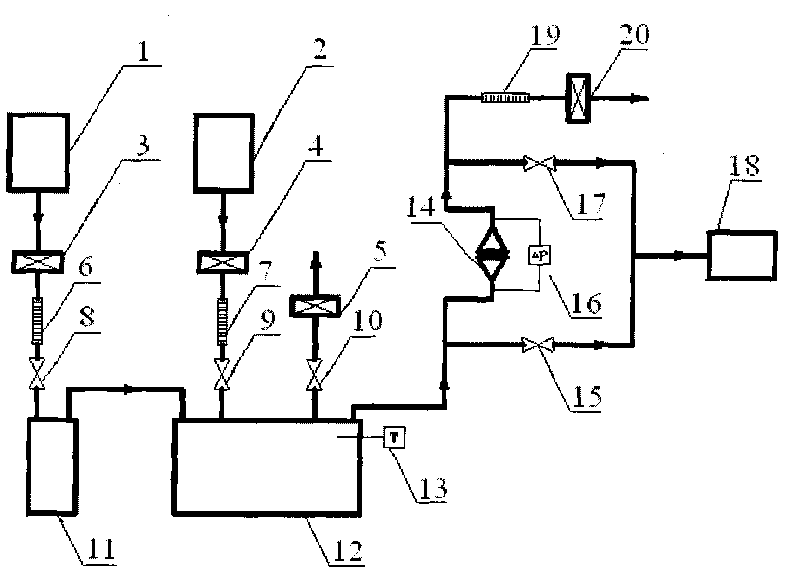

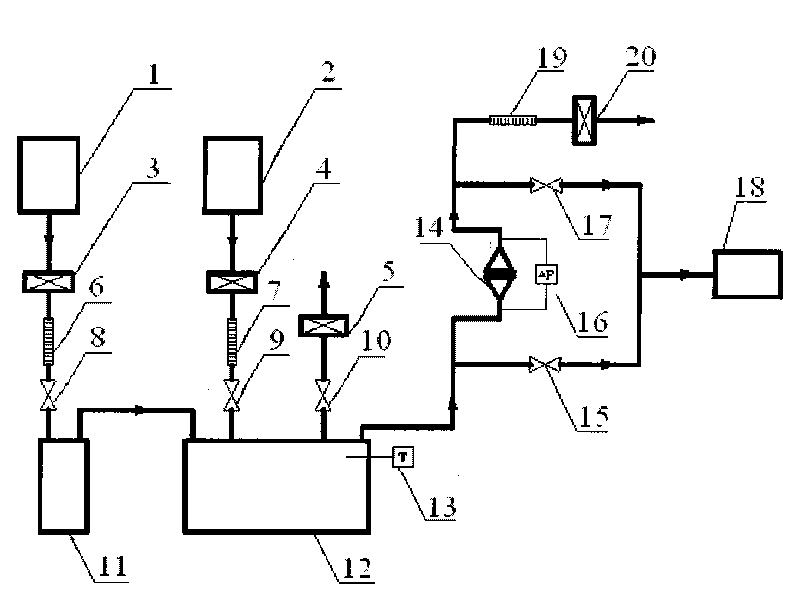

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] As shown in the accompanying drawings, the structure of an embodiment of the detection system of the present invention includes a quasi-monodisperse aerosol generator 11 and a mixing box 12 arranged side by side, and the top of the quasi-monodisperse aerosol generator 11 and the mixing box 12 passes through the pipeline In communication, the top of the quasi-monodisperse aerosol generator 11 is also communicated with the first valve 8, the aerosol generating flowmeter 6, the first filter 3 and the first high-pressure gas source 1 through pipelines in sequence.

[0022] The top of the mixing box 12 communicates with the second valve 9, the dilution flow meter 7, the second filter 4 and the second high-pressure gas source 2 through pipelines, and the top of the mixing box 12 also communicates with the third valve 10 and the third filter t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com