Patents

Literature

32results about How to "Guaranteed production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

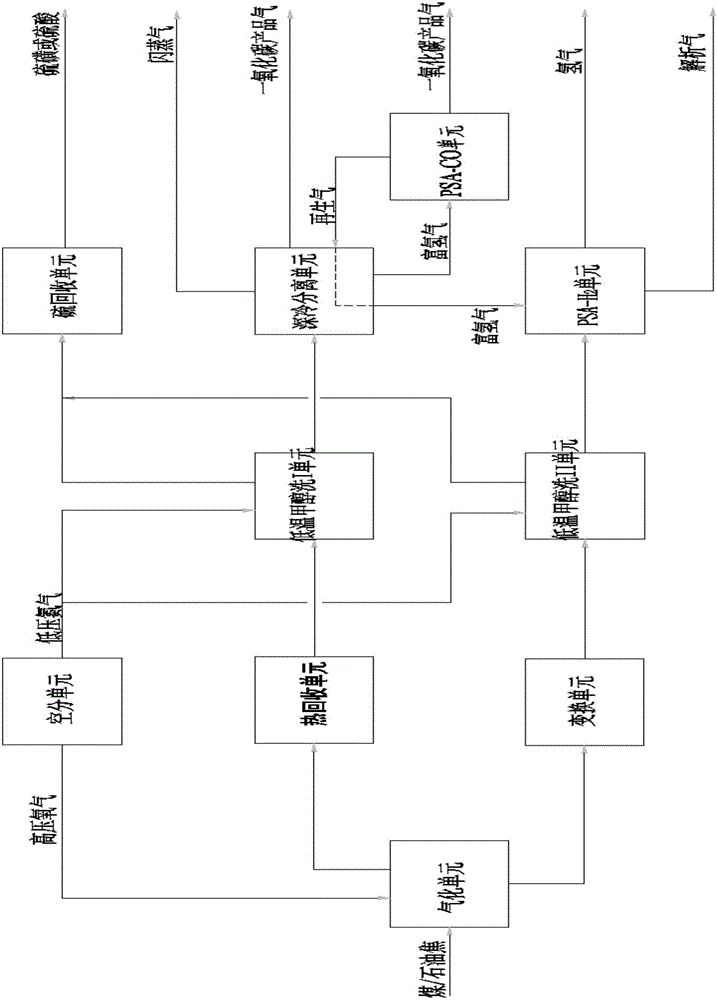

Method for simultaneously preparing pure hydrogen and pure carbon monoxide by gasification without desorbed gas circulation

ActiveCN105948046AFlexible scale adjustmentHigh recovery rateHydrogen separation by selective and reversible uptakeGas treatmentSyngasPhysical chemistry

The invention discloses a method for simultaneously preparing pure hydrogen and pure carbon monoxide by gasification without desorbed gas circulation. The crude synthetic gas prepared by the gasification unit is divided into two parts, one part is used for preparing pure carbon monoxide, and the other part is preparing pure hydrogen. The process of preparing pure carbon monoxide is divided into two parts: one part is used for preparing pure carbon monoxide with the crude synthetic gas prepared by gasification by a heat recovery unit, a low temperature methanol washing I unit, and a cryogenic separation unit; and the other part is used for preparing pure carbon monoxide by the hydrogen rich gas from the outlet of the cold box of the cryogenic separation unit sending into a PSA-CO unit. The feedstock of preparing hydrogen is divided into two parts: one part is the converted gas which is purified by a conversion unit and a low temperature methanol washing II unit with the crude synthetic gas prepared by gasification and contains carbon monoxide -1% (mol), and the other part is the hydrogen rich gas from a resurgent TSA device of the cryogenic separation unit, and the two parts of the gas are mixed and sent into the PSA-H2 unit to prepare pure hydrogen. The method has high recovery rates of carbon monoxide and hydrogen, has no desorbed gas circulation and no resurgent gas introduced by environment, has small investment and low energy consumption, and can adjust product gas scale of hydrogen and carbon monoxide flexibly.

Owner:HUALU ENG & TECH

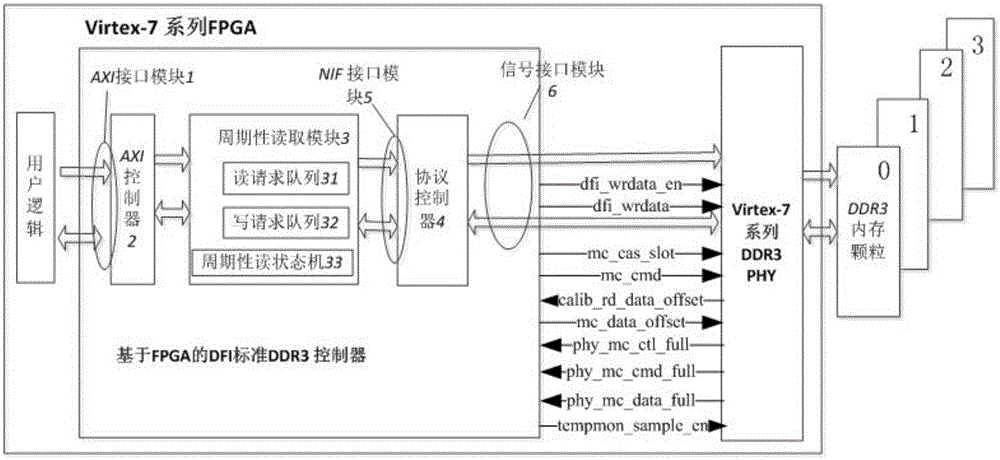

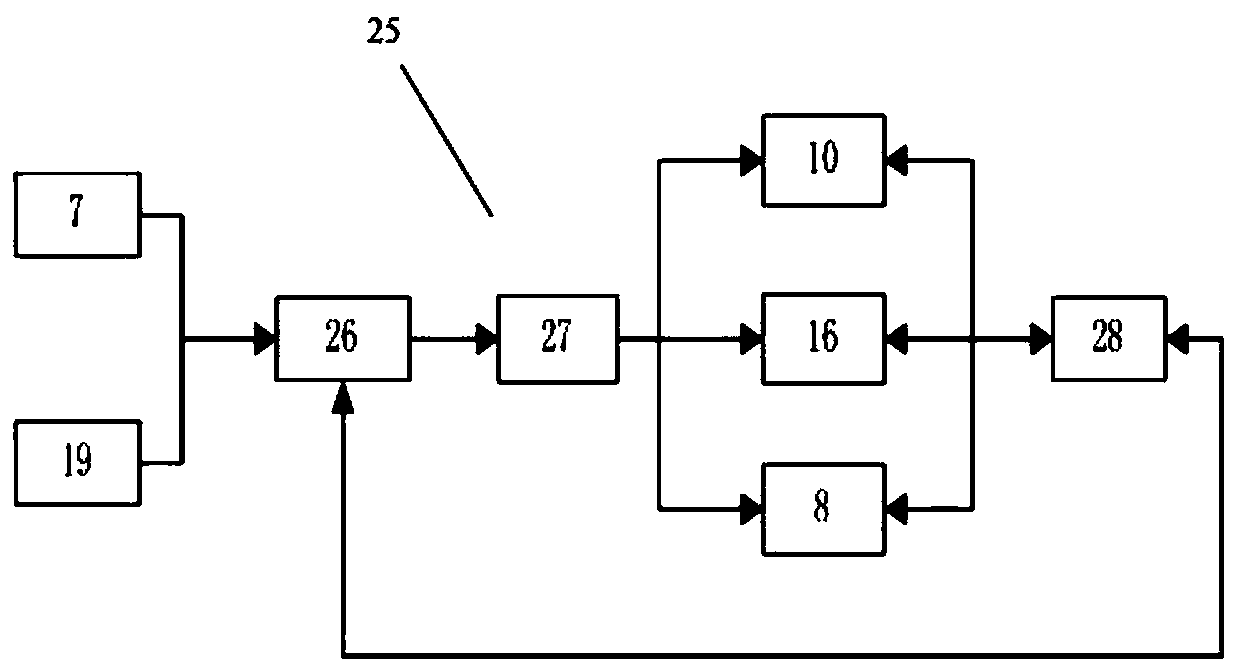

DFI standard DDR3 controller based on FPGA

ActiveCN105159853AGuaranteed productionNo disruptive transmissionElectric digital data processingComputer hardwarePhysical layer

The present invention discloses a DFI standard DDR3 controller based on an FPGA. The DFI standard DDR3 controller comprises an AXI interface module, an AXI controller, a periodic read module, a protocol controller and a signal interface module which are electrically connected successively. The AXI interface module is used for receiving a user logic sent by the FPGA and sending the user logic to the AXI controller, and also used for receiving DDR3 memory data forwarded by the AXI controller and sending the memory data to the FPGA; the AXI controller is used for transforming the user logic into data in the form of an AXI protocol, and sending the data in the form of the AXI protocol to the periodic read module, and also used for receiving the DDR3 memory data sent by the periodic read module and sending the DDR3 memory data to the AXI interface module; and the periodic read module is used for providing periodic data strobe data DQS for dynamic calibration of a DDR3 physical layer, and also used for sending the data in an AXI form to the protocol controller periodically, and sending the DDR3 memory data to the AXI controller periodically.

Owner:武汉凌久微电子有限公司

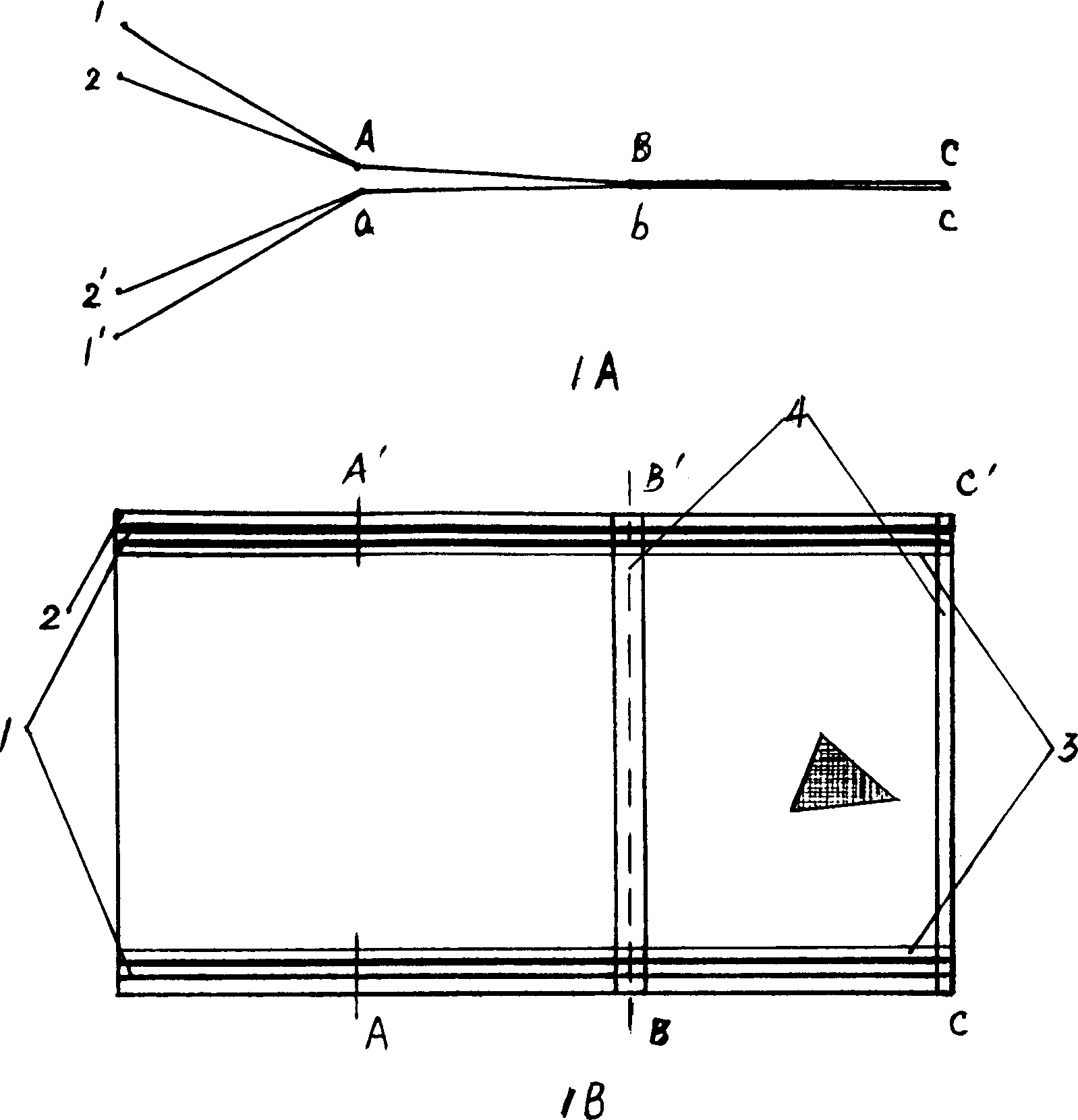

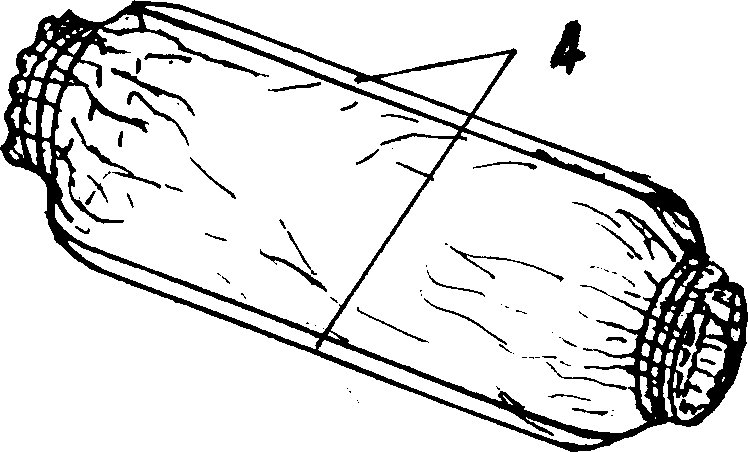

Technology for making oversleeve

The present invention relates to a new production process of sleeve protector, and is characterized by that the rib cuff elastic ring of each of two ends of said sleeve protector is a circular ring synthesized by two symmetrical notched rubber bands, and the number of the rib cuff elastic rings can be one or several bands, and said sleeve is a cylinder synthesized by two symmetric notched plane face fabrics, and the internal side of said sleeve protector has two but-welded seams and four folded selvages, and the rubber band and face fabrics can be adhered and fixed together by adopting the processes of collosed coating and plastic welding, so that the original traditional manual circumferential movement can be changed into the invented mechanical linear movement so as to raise its production efficiency.

Owner:上海蓝岛卫生用品有限公司

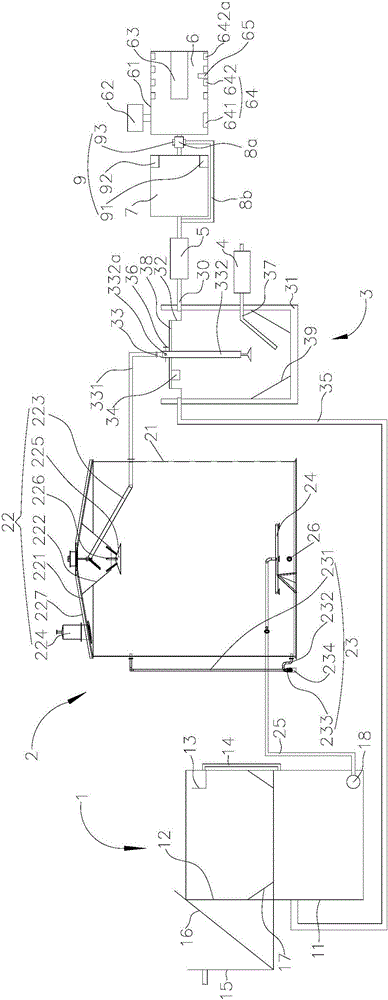

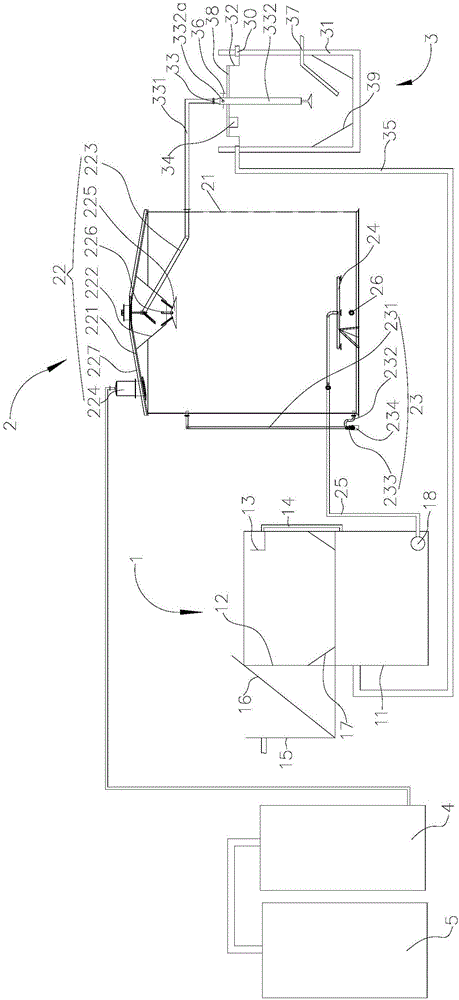

High-concentration colored sewage treatment system and method

InactiveCN105884140AIncrease acidityImprove processing efficiencyTreatment using aerobic processesWater/sewage treatment by irradiationActivated sludgeHigh concentration

The invention discloses a high-concentration colored sewage treatment system and method. The system comprises a hydrolytic acidification device, an anaerobic reactor, a sludge treatment device, an activated sludge reactor, a biological aerated filter and a photocatalytic oxidation reactor; a second overflowing weir is communicated with a hydrolytic acidification pool through a reflux pipe, and a water inlet pipe is provided with a jet hole and an adjusting valve. The treatment method comprises the step that hydrolytic acidification, anaerobic fermentation, sludge treatment, aeration treatment and photocatalytic oxidation treatment are sequentially conducted on sewage. According to the high-concentration colored sewage treatment system and method, by arranging the jet hole on the sludge treatment device to adjust the dissolved oxygen content of the reaction liquid level, it is guaranteed that nitrite is generated through reacting, generated nitrite flows back into the hydrolytic acidification pool, and therefore the phenomenon that the acidity of the acidized sewage is overhigh is avoided; in addition, the reacted sludge is treated through the activated sludge reactor, the reacted sludge and sewage are treated through the activated sludge reactor, the biological aerated filter and the photocatalytic oxidation reactor separately, and therefore the sewage treatment efficiency and degradation efficiency are improved.

Owner:WUHAN DONGCHUAN WATER ENVIRONMENT TECH CO LTD

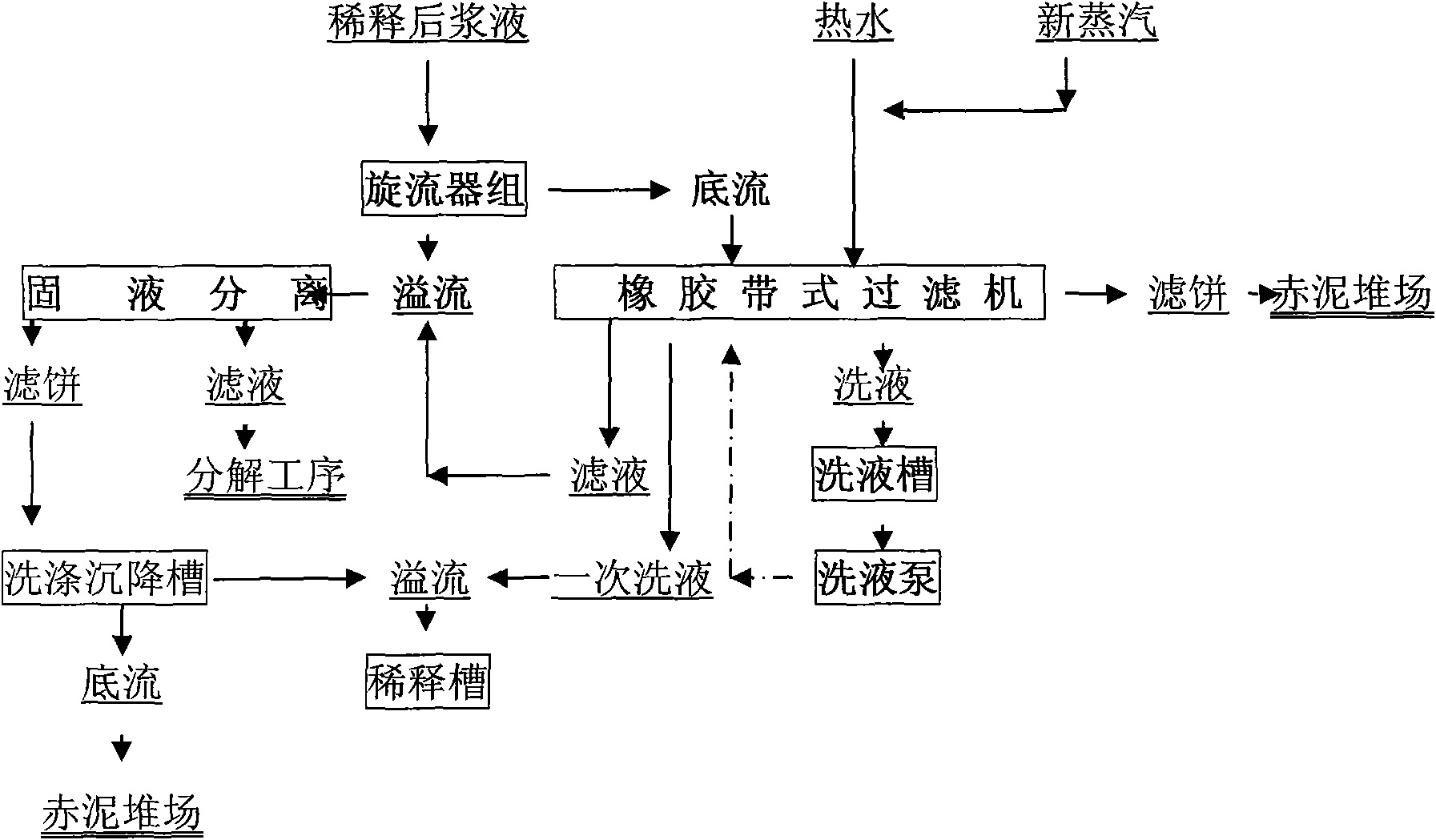

Separating and washing method of red mud by Bayer process

InactiveCN101570340AIncrease concentrationGuaranteed productionFiltration circuitsAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSolid phasesDecomposition

A separating and washing method of red mud by Bayer process relates to a process improvement in the production process of aluminum oxide. The method is characterized in that the red mud in the Bayer process firstly passes through a swirler for preliminary separation, then the bottom flow of the swirler is filtered by adopting a rubber belt filter, the red mud is washed; the solid-liquid separation is carried out on the overflow of the swirler, the separated liquid phase is sodium sodium aluminate refining liquid which enters the decomposition process; the separated solid phase is a red mud filter cake which enters a settling tank for washing, and the red mud after washing is discharged to a red mud yard. The method realizes the filtration and the separation of the red mud in the Bayer process, has the capability of mandatory separation of the red mud in the Bayer process, is applicable to a variety of working conditions, can greatly improve the concentration of the sodium aluminate solution and can ensure the high-efficient operation of the aluminum oxide production in the Bayer process.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Steel pipeline anticorrosive material and preparation method of steel pipeline anticorrosive material

ActiveCN102850857AHigh temperature indentation hardnessGuaranteed productionAnti-corrosive paintsSteel qualityPolypropylene

The invention discloses a steel pipeline anticorrosive material and a preparation method of the steel pipeline anticorrosive material. The steel pipeline anticorrosive material comprises the following ingredients in proportion by weight: 44 to 54 parts of polypropylene, 3 to 12 parts of high-density polyethylene powder, 0.3 to 2.4 parts of anti-aging agents, 0.06 to 1.2 parts of antioxidant, 0.06 to 1.2 parts of lubricating agents, 0.06 to 0.6 parts of degradation inhibitors and 0.06 to 0.6 parts of initiators, wherein all ingredients are uniformly mixed in a highly mixed pot and are then extruded out through a reactive double-screw-rod extruding machine with the length-diameter ratio being 52:1, the extruded ingredients are subjected to strip pulling, air cooling and grain cutting, the temperature is set to be 180 DEG C to 220 DEG C, and the rotation speed of screw rods is set to be 180 to 400 turns per minute. Compared with the anticorrosive material in the market, the steel pipeline anticorrosive material has the advantages that the processing applicability is wide, high Vicat, high hardness and good low-temperature toughness are realized, and long service life at high temperature and requirements on the anticorrosive material when passing through specific districts such as water, sand and stone soil and oceans are met.

Owner:四川仁智新材料科技有限责任公司

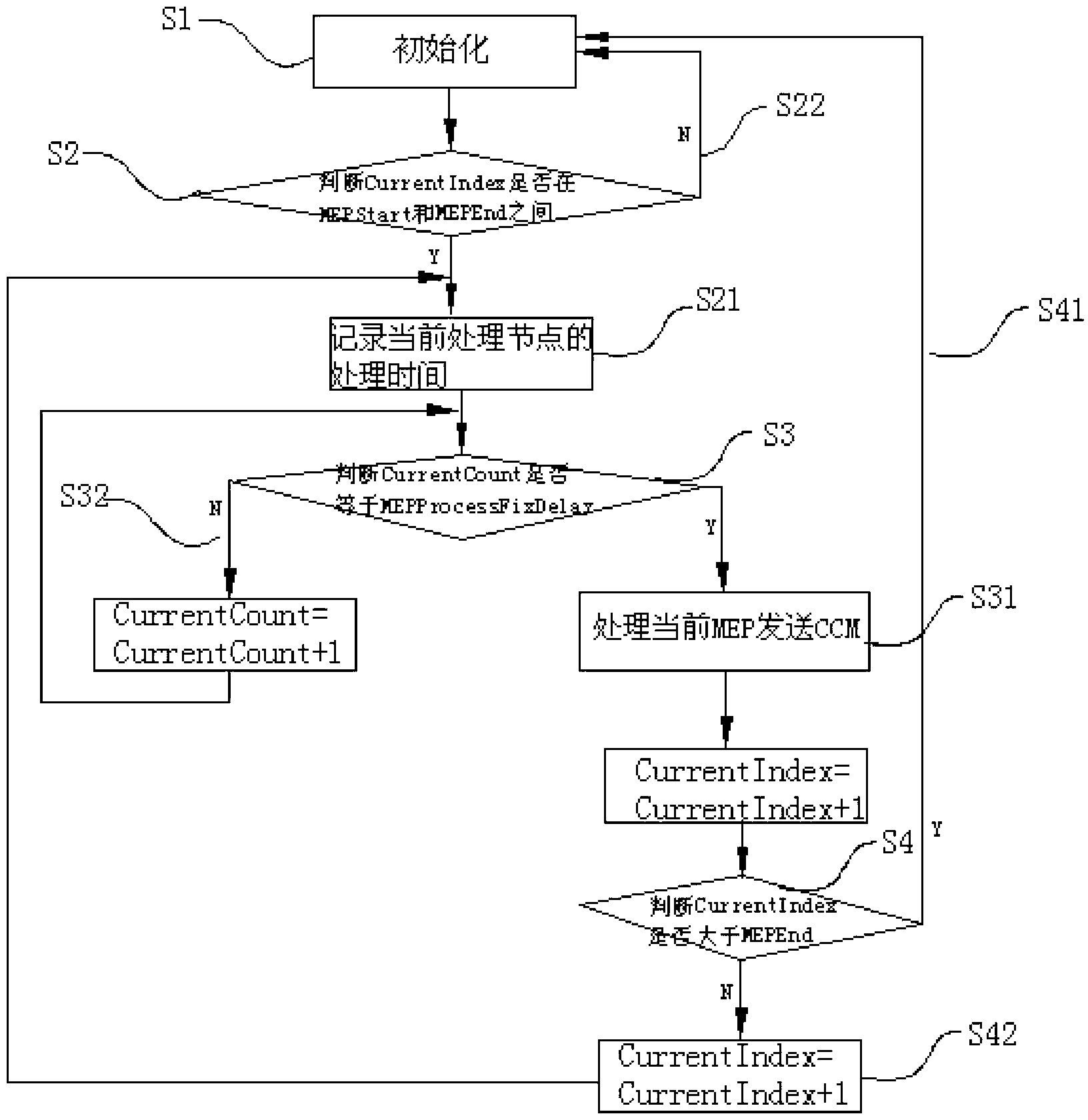

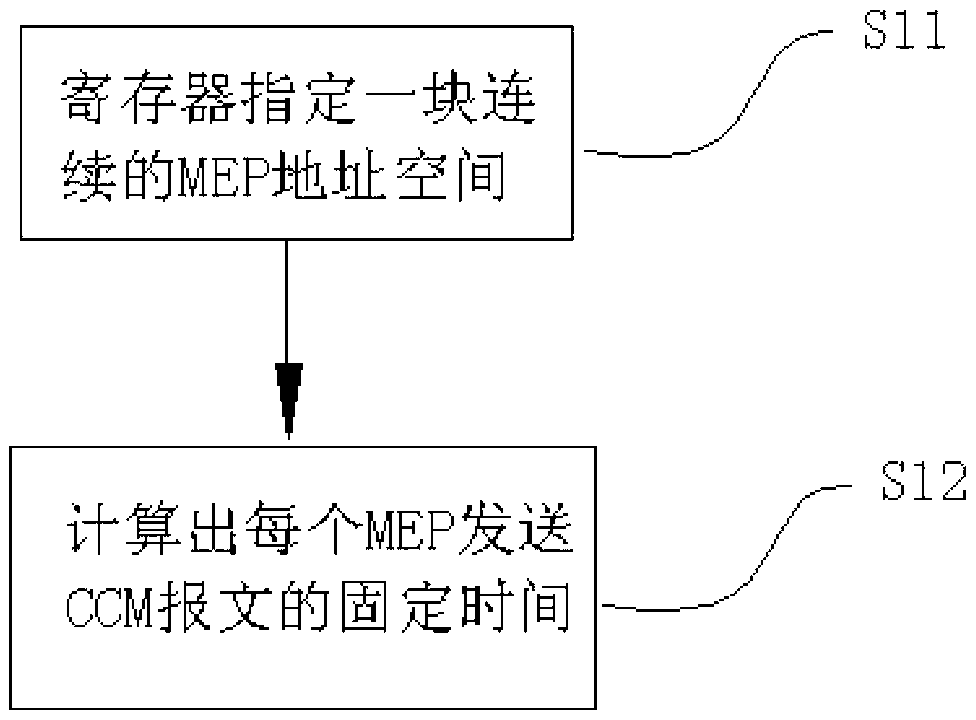

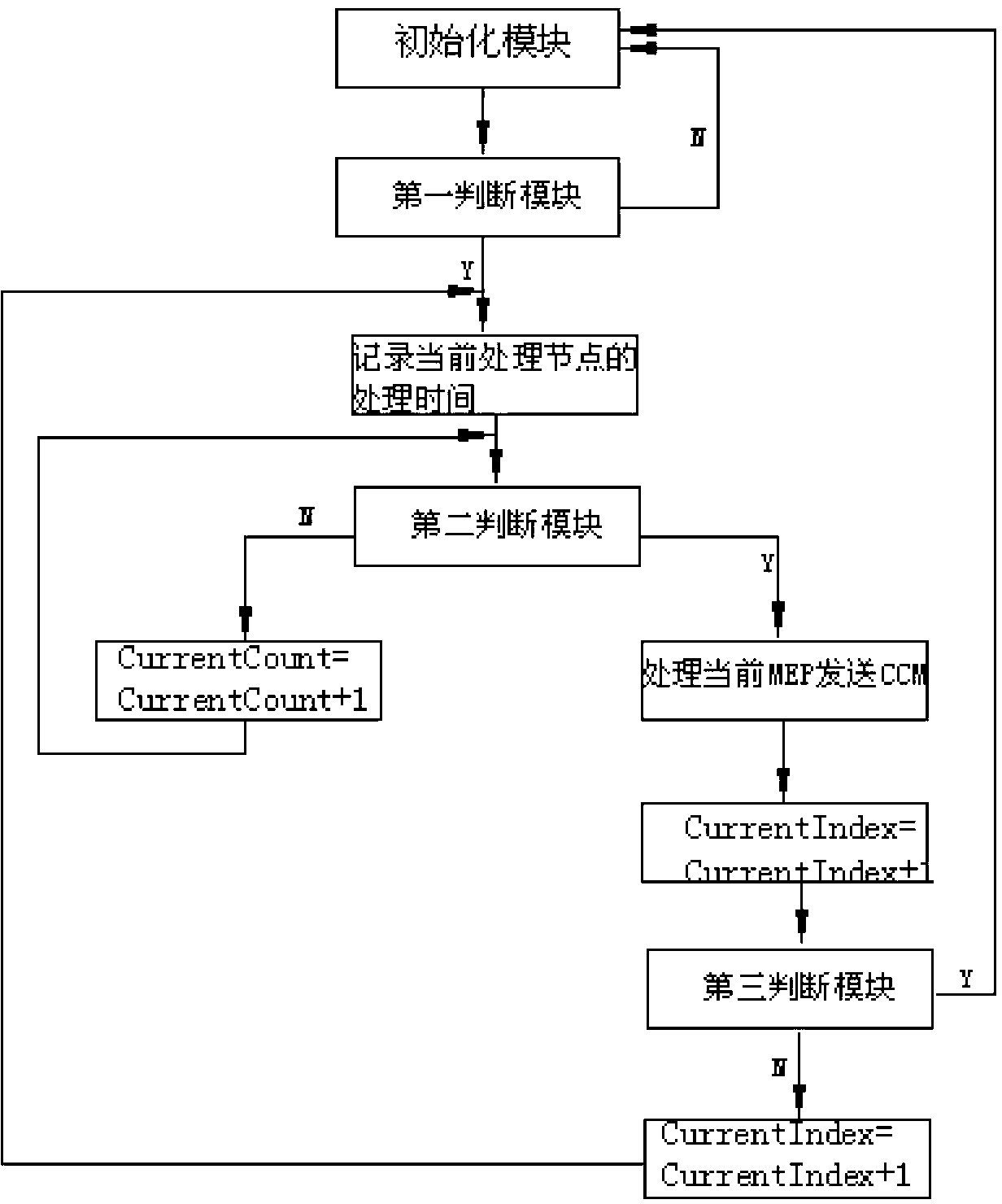

Method and device for enabling switch chip to generate OAM (Operation Administration and Management) messages at constant speed

ActiveCN103312633AGuaranteed productionEnsure that each MEP entry is correctly generatedData switching networksTraffic capacityProcessor register

The invention discloses a method and a device for enabling a switch chip to generate OAM (Operation Administration and Management) messages at a constant speed, which belong to the field of network communication. Different CCM (Continuity Check Messages) sending frequencies are supported by multiple timer intervals. A register is used for configuring the adjustable delay time of MEP (Maintenance Endpoint) tables and adjusting the regular CCM sending time of each MEP. All the MEPs on the current time shaft can be processed at just one Interval, and the processing time dots of all the MEPs are evenly scattered on the dots of the Interval / (MEP End-MEP Start+1), so that the CCM sending frequency is set as the Interval, and the processing time of all the MEPs is evenly scattered. The method and the device can ensure that CCMs are generated by each MEP at a correct frequency, messages needing to be transmitted by the network are transmitted at a constant speed to an utmost extent, and the impact on the flow of network equipment is reduced.

Owner:SUZHOU CENTEC COMM CO LTD

Semicontinuous fermentation method for producing gamma-aminobutyric acid by lactic acid bacteria

InactiveCN102108370AGuaranteed productionReduce dosageMicroorganism based processesFermentationSolventOxygen

The invention discloses a semicontinuous fermentation method for producing gamma-aminobutyric acid by lactic acid bacteria, which comprises the following steps: inoculating lactic acid bacteria onto an Man, Rogosa and Sharpe gelatin (MRSG) culture medium; and fermenting in a mode of segmental substrate addition, segmental temperature control and segmental oxygen control to obtain gamma-aminobutyric acid, wherein the solvent of the MRSG culture medium is water, and the solute comprises the following materials at concentration: 7 to 12g / L glucose, 20 to 30g / L peptone, 30 to 40g / L beef extract, 0.05 to 1g / L manganese sulfate, 0.01 to 0.05g / L vitamin B, and 2 to 5g / L sodium glutamate. When the method provided by the invention is adopted, the yield of the gamma-aminobutyric acid can reach 13.1to 38.7g / L.

Owner:山东水晶生物科技股份有限公司

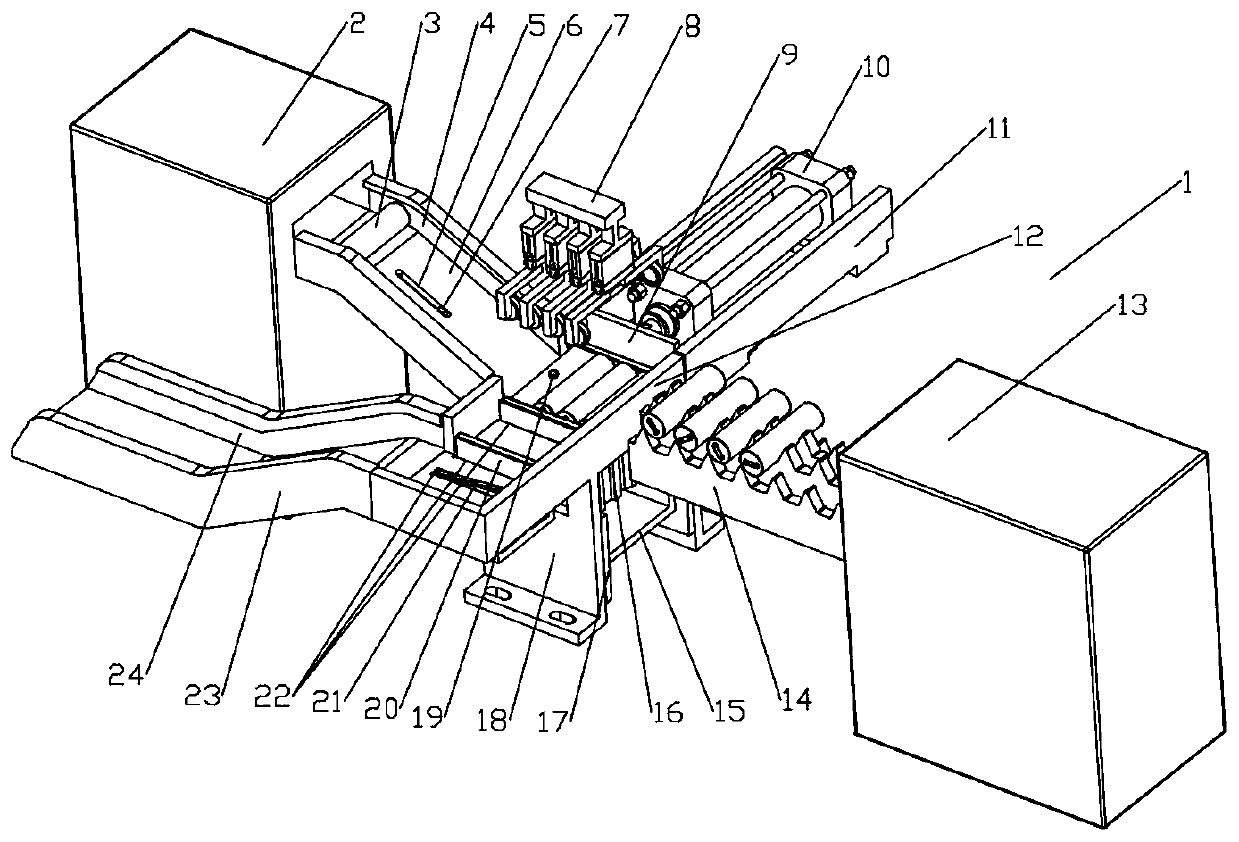

Full-automatic edge-cutting, notching and cutting-off all-in-one machine

ActiveCN105108799AAvoid paper jamsGuaranteed productionMetal working apparatusCardboardProduction line

The invention discloses a full-automatic edge-cutting, notching and cutting-off all-in-one machine. The machine is installed on a corrugated paper board production line and comprises a cutting-off part and a waste discharging part which are installed on a machine frame. The cutting-off part comprises a rubber mat roll transversely installed on the machine frame and a cutting-off cutter shaft located above the rubber mat roll. The whole cutting-off cutter shaft is a cylindrical cutter shaft, and a plurality of cutting-off assemblies are installed on the outer surface of the cutter shaft and provided with blades and independent driving air cylinders used for driving the blades of the cutting-off assemblies to stretch and retract. The cutting-off cutter shaft and the rubber mat roll are driven by a servo motor through a transmission gear. The waste discharging part is installed behind the cutting-off part and mainly composed of a sun gear assembly, a conveying assembly, a paper board beating assembly and a paper pressing assembly. The edge-cutting, notching and cutting-off functions can be achieved by one cutting-off assembly, the working mode is flexible, the notching order exchanging speed is increased to 200 m / min from 130 m / min, and the waste discharging speed is increased to 200 m / min from 150 m / min.

Owner:QINGDAO KAITUO NC EQUIP

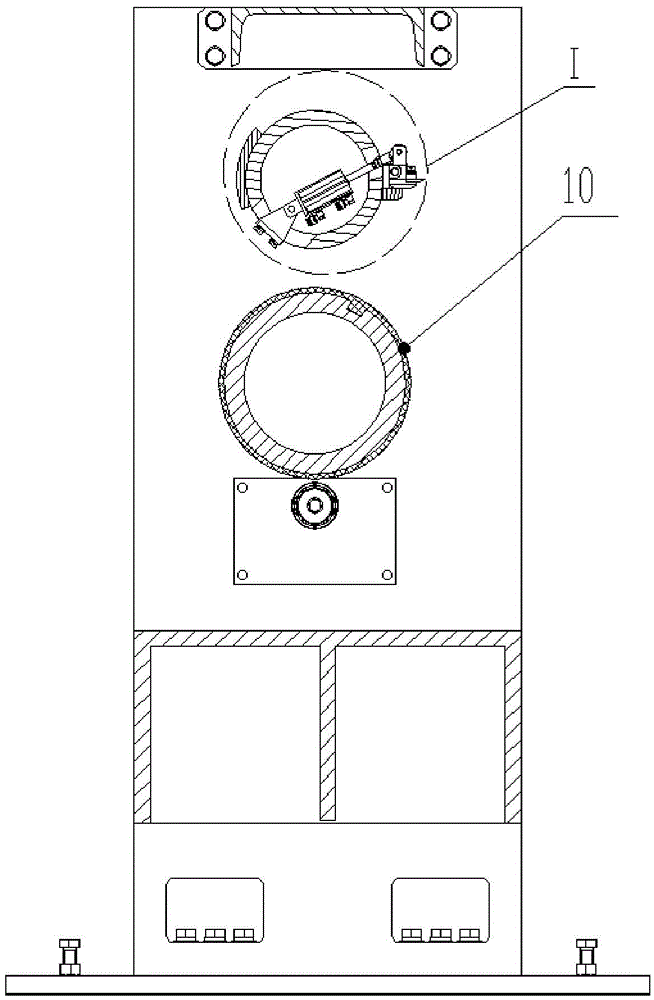

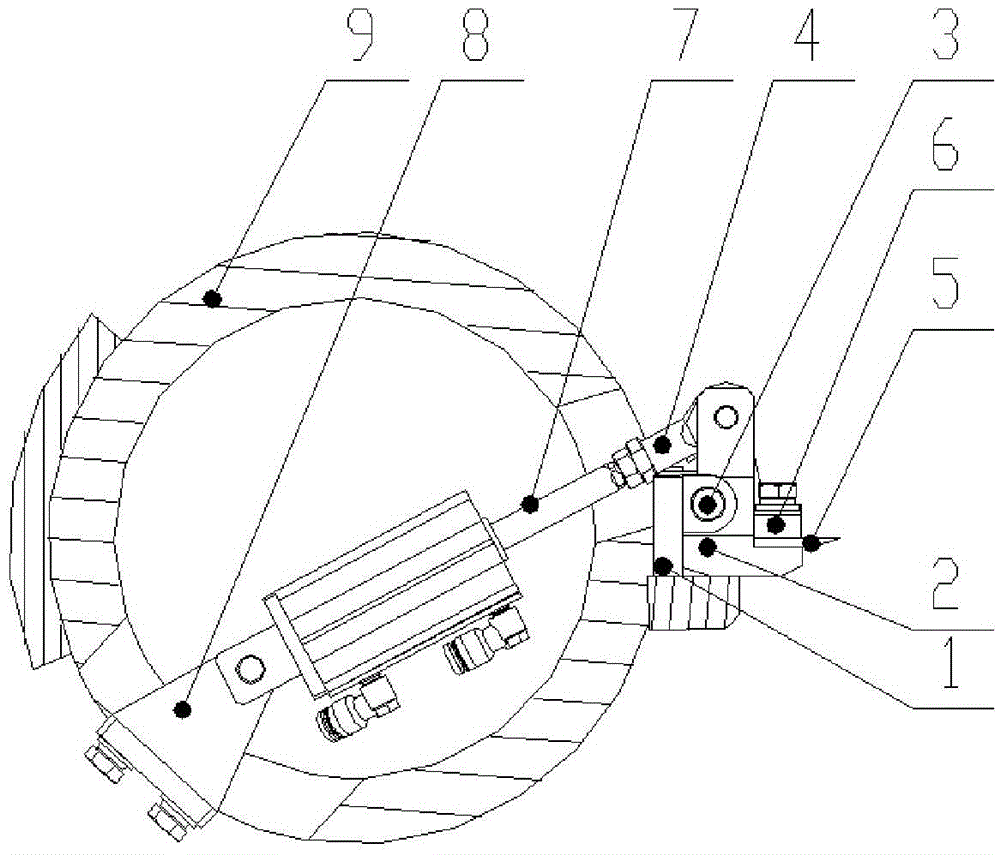

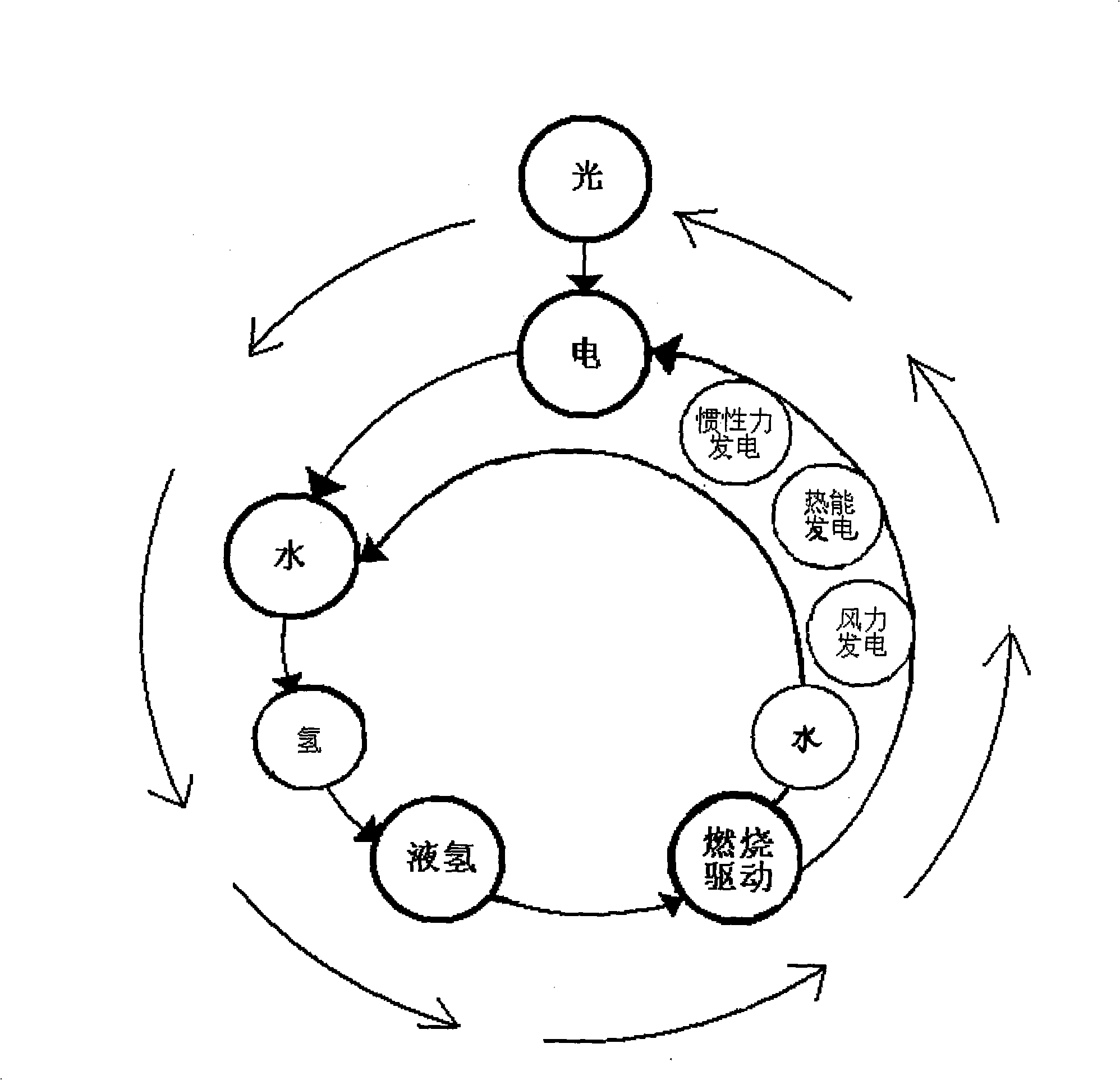

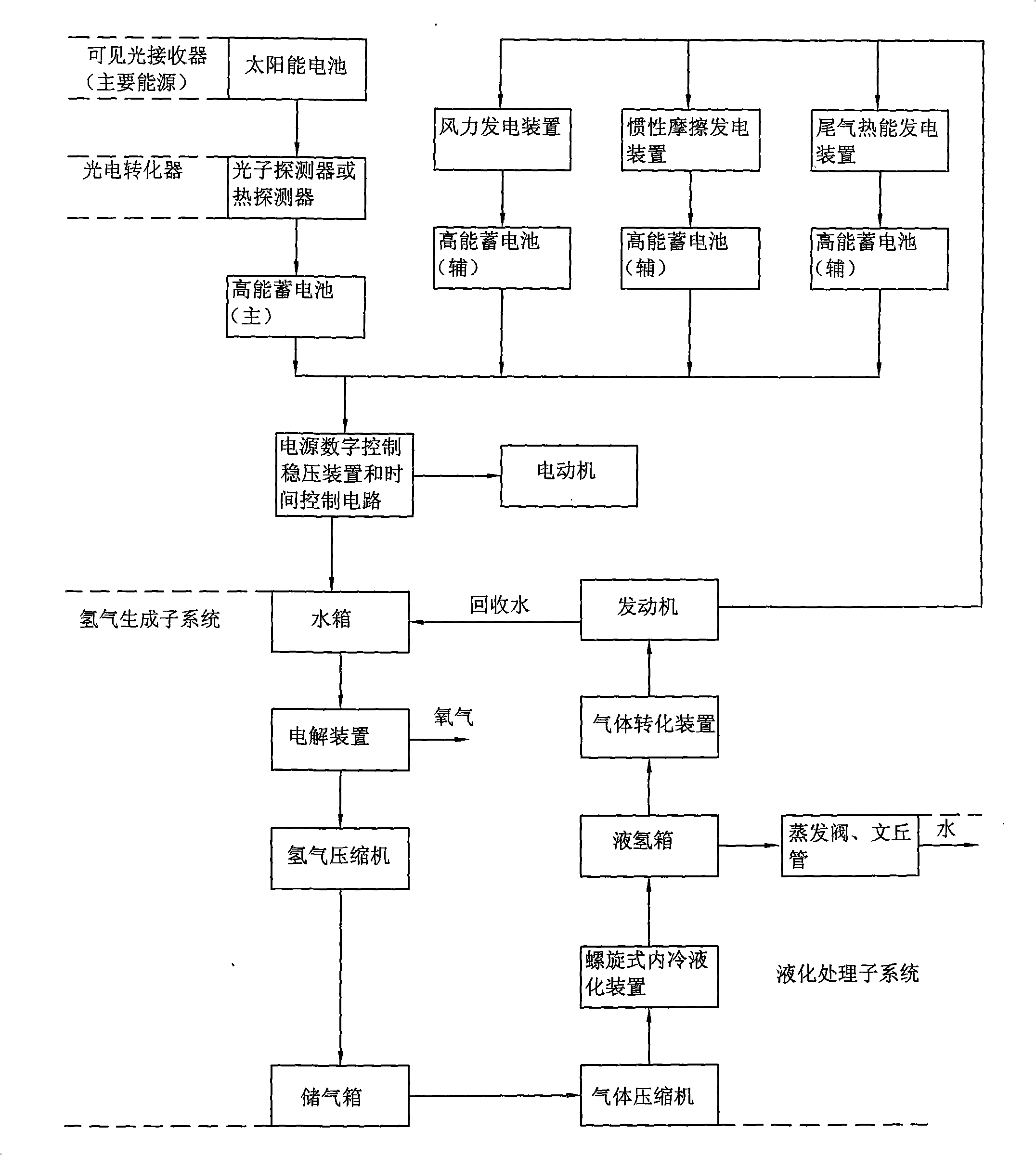

Accumulating continuous conversion automatic energy supply automobile power system

InactiveCN101348070AStrong follow-up kinetic energy guaranteeReduce loadGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingInfraredThermal energy

The invention discloses an automatic energy supply automobile power system for integrating odds and ends into integral and continuously converting. The system takes light energy and hydrogen as main power supply, and employs inertia power generation, wind power generation and thermal power generation as auxiliary power source, uses a visible light receiver to receive the visible light in the wavelength coverage of infrared ray and ultraviolet ray, uses a photoelectric converter to convert light energy to power energy, uses a high-energy storage battery to store the power energy, uses an electrolysis device to convert water to combustible gas, i.e., the hydrogen, uses a gas compressor and a liquefaction device to convert the hydrogen to liquid hydrogen, uses a gas reforming device to secondarily convert the liquid hydrogen to combustible gas, and uses a comprehensive recovery subsystem to continuously provide water, thermal energy and wind energy. The circulatory energy supply system for continuously converting hydrogen energy not only saves energy, but also realizes zero pollution emission and full-automatic energy supply in the driving process of automobiles.

Owner:刘开宁

Mass spectrometer and pole used for same

ActiveCN106611694ALow costHigh dimensional accuracyStability-of-path spectrometersParticle separator tube detailsMaterial typeSurface roughness

The invention relates to a detection analysis device, and particularly to a mass spectrometer and a pole used for the same. The pole comprises a pole body and a film layer; and the film layer is formed on a pole body by adopting a vacuum film plating technology. The vacuum film plating technology has lower cost than the existing complex processing technology. By carrying out film plating processing on the surface of the pole body, the manufacturing deficiency of the pole body can be made up, the pole dimension precision can be improved, the pole is enabled to meet the processing precision requirements such as the cylindricity and the surface roughness, and the pole is enabled to have the characteristics such as good conductivity, good corrosion resistance, good thermal stability, relatively low vacuum air release, relatively low secondary ion effect, difficult surface particle release and pollution resistance. Furthermore, the mass spectrometer using the pole can generate an ideal electric field; and the service lifetime of the pole is prolonged while the detection work is finished; the requirement on the material type of the pole body is reduced, and materials at low cost can be selected. The mass spectrometer comprises the pole, is low in cost, can guarantee generation of the ideal electric field and is long in service lifetime.

Owner:NORTHEASTERN UNIV

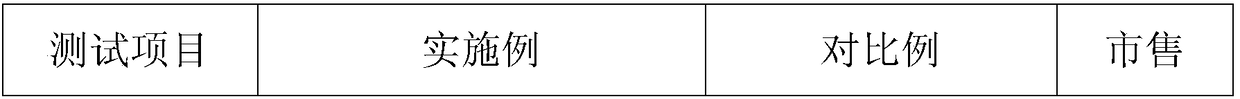

Amorphous-nanocrystalline Fe-based composite soft magnetic alloy and preparation method thereof

ActiveCN108447641AMagneticReasonable formulaInductances/transformers/magnets manufactureMagnetic materialsCompound aMischmetal

The invention discloses an amorphous-nanocrystalline Fe-based composite soft magnetic alloy and a preparation method thereof. The amorphous-nanocrystalline Fe-based composite soft magnetic alloy is formed by compounding a Fe-based soft magnetic alloy A and a Fe-based soft magnetic alloy B, wherein the Fe-based soft magnetic alloy A is prepared from the following raw materials of Al, Si, B, Fe andunavoidable impurities; the Fe-based soft magnetic alloy B is prepared from the following raw materials of Al, Si, Ni, Co, Cr, Ti, Mo, Sm, B, composite rare-earth metal, Fe and unavoidable impurities;and the preparation method comprises the following steps of (S1) preparing powder of the Fe-based soft magnetic alloy A; (S2) preparing the powder of the Fe-based soft magnetic alloy B; (S3) preparing the powder of a Fe-based composite soft magnet; and (S4) smelting and rapidly quenching the powder of the Fe-based composite soft magnet to obtain the amorphous-nanocrystalline Fe-based composite soft magnetic alloy. The composite soft magnetic alloy disclosed by the invention is reasonable in formula, low in coercivity, simple in preparation method and suitable for industrial production.

Owner:ZHEJIANG HENGJI YONGXIN NEW MATERIALS CO LTD

Coke furnace riser pipe root sealing method

ActiveCN104194804AImprove bindingGuaranteed tightnessCoke oven safety devicesDistillation gas withdrawalTemperature controlSludge

The invention relates to a coke furnace riser pipe root sealing method which comprises the following steps: 1) preparing lower-layer mixed sludge from concentrate powder, water glass and clay fireclay; 2) preparing an upper-layer coating mixture from clay fireclay, concentrate powder, clay brick fragments (the particle size is at most 3mm), water glass and phosphoric acid; 3) constructing after the thermal expansion of the coke furnace body finishes, and cleaning the slit of the riser pipe root; 4) constructing the lower-layer mixture; and 5) constructing the upper-layer coating mixture. Compared with the prior art, the sealing material has favorable binding property with the riser pipe and refractory brick, thereby ensuring the sealing effect; the method has the advantages of high strength, favorable cracking resistance and long maintenance period, ensures the production and lowers the labor intensity; the surface strength is high, thereby reducing the damage caused by external force; and the method basically prevents the riser pipe root from leakage, enhances the temperature control accuracy of the coke furnace, and improves the working environment.

Owner:CHINA THIRD METALLURGICAL GRP

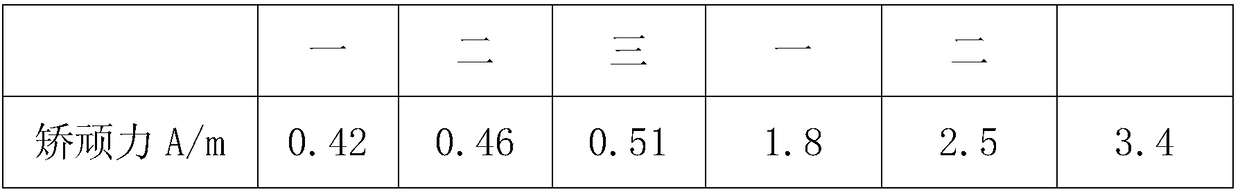

Northern greenhouse planting method for organic green tea

InactiveCN108739031AImprove permeabilityImprove fertilizer efficiencyCultivating equipmentsTemperature controlShoot

The invention discloses a northern greenhouse planting method for organic green tea, and relates to the technical field of green tea planting. The method comprises the following steps: (1) greenhouseconstruction; (2) soil improvement; (3) tea tree planting, wherein the spacing between hills is 35 cm; and (4) environment temperature control. The growing environment of tea trees is controlled by using greenhouses, once growth repair period is carried out at an interval of 3 months, the tea trees are promoted to generate more tender shoots by simulating the southern environment at grain rain solar term in the fourth month (the temperature inside the greenhouse in daytime is controlled to be 20 to 25 DEG C, the night temperature is controlled to be 10 to 12 DEG C, and the air relative air humidity inside the greenhouse is 80% to 85%), so that the yield of tea leaves is greatly improved, simultaneously, repeated picking can be carried out in one year, a certain greenhouse can be in a picking period within one year by controlling the difference of the growth conditions in different greenhouses, the generation of new tea in one year is guaranteed, and the yield of the tea leaves and thesupply of new tea are greatly improved.

Owner:蚌埠农兴达现代农业有限公司

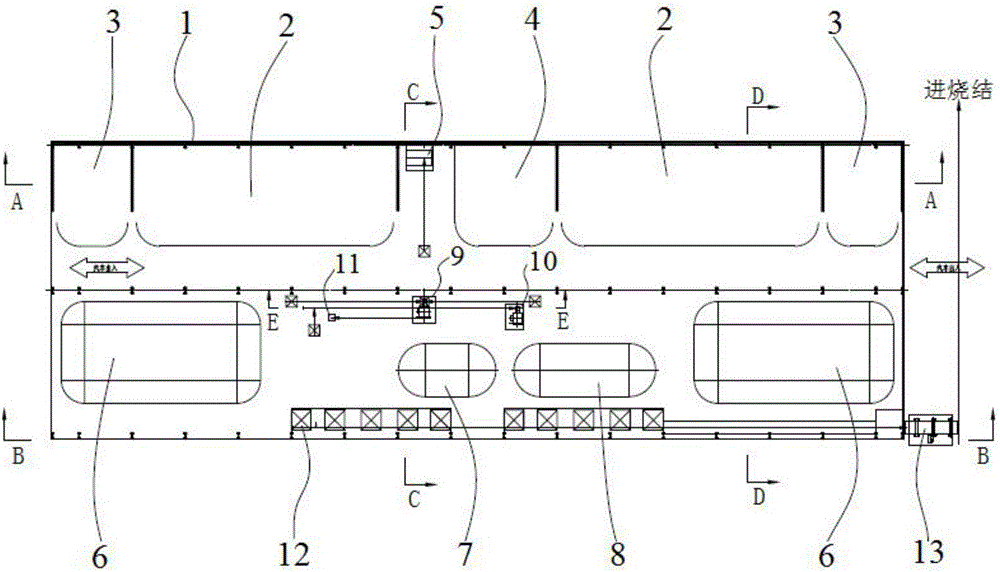

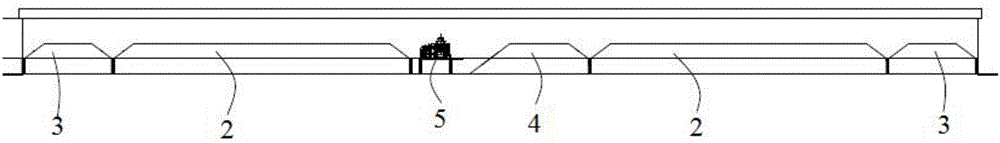

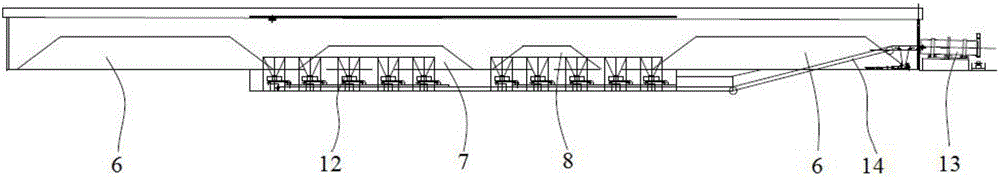

Nickel laterite ore raw material storehouse and nickel laterite ore raw material preparation system

The invention relates to a nickel laterite ore raw material storehouse which comprises a storehouse body. The space in the storehouse body is divided into a storage area and a burdening area. The storage area comprises a nickel laterite ore bin, a quicklime bin and a reduction agent bin, and is provided with a raw material inlet for delivering corresponding raw materials to the raw material bins. The burdening area comprises a drying section and a burdening section. Nickel laterite ore and quicklime are stacked in the drying section so that the nickel laterite ore can be subjected to dewatering and drying. The burdening section receives the raw materials from the drying section and the reduction agent bin so as to prepare sintering raw materials. The burdening area is provided with a prepared material outlet communicating with the burdening section. According to the nickel laterite ore raw material storehouse, preparation, burdening and other operations of the raw materials are carried out in the sealed storehouse and not affected by wind or rain, and normal and stable operation of the production work is ensured; and material loss is avoided, and the production work has no raising dust pollution or noise pollution or sewage pollution to the external environment. The nickel laterite ore is wholly subjected to dewatering and drying with the quicklime, and energy consumption is reduced for subsequent sintering and smelting.

Owner:WISDRI ENG & RES INC LTD

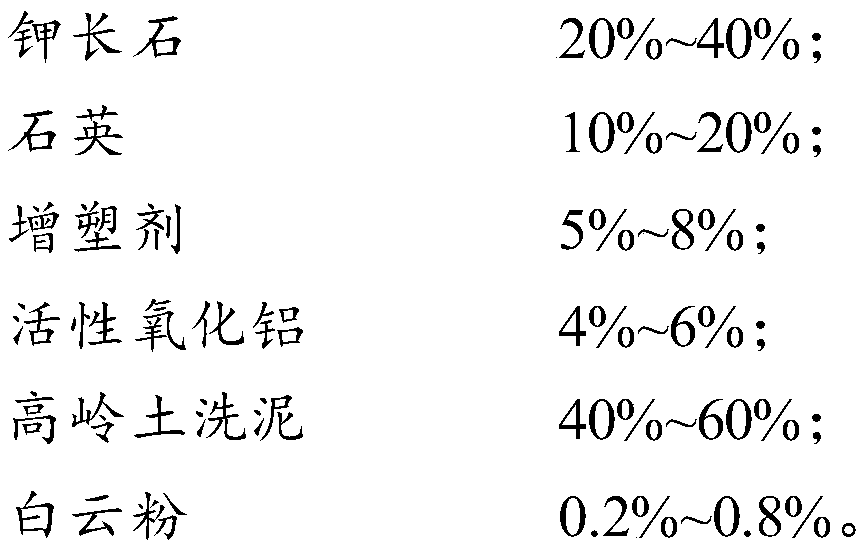

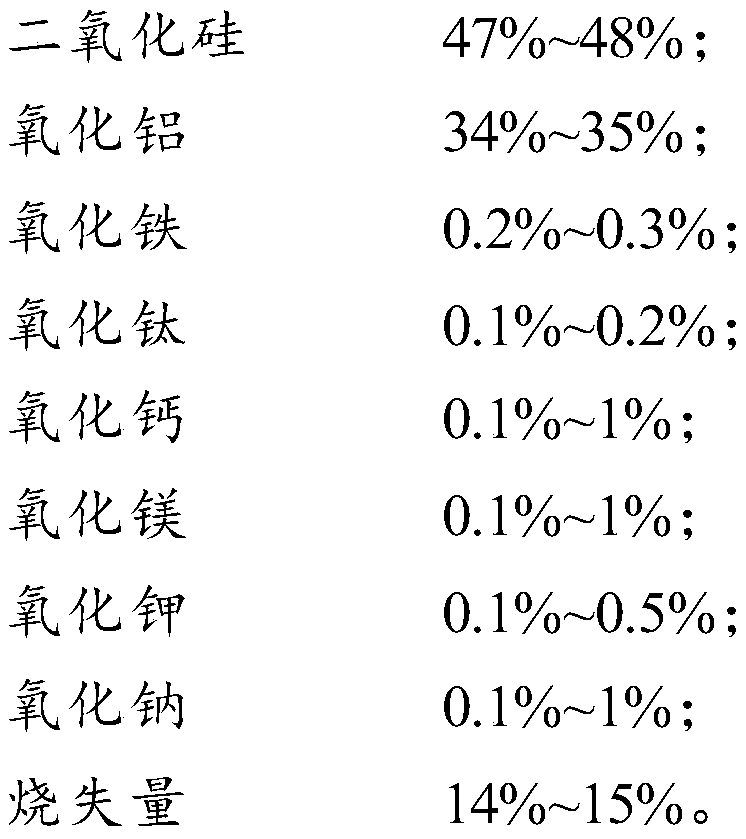

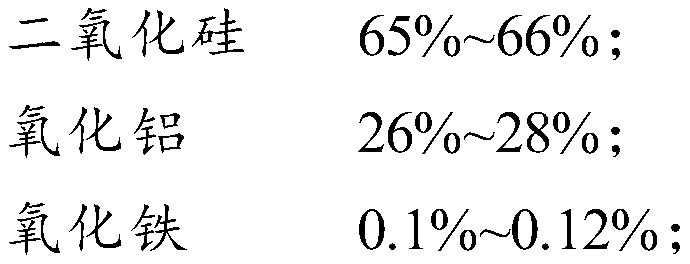

High-temperature porcelain and preparation method thereof

The invention provides a high-temperature porcelain and a preparation method thereof. The high-temperature porcelain is prepared from, by mass, 20-40% of potassium feldspar, 10-20% of quartz, 5-8% ofa plasticizer, 4-6% of activated alumina, 40-60% of kaolin washing mud, 0.2-0.8% of dolomite powder. The activated alumina and dolomite powder are introduced into the potash feldspar, quartz and kaolin washing mud system, and are mixed according to a specific ratio, and then are mixed with the plasticizer, so that the system can be promoted to generate a large amount of mullite crystals in the reaction process; the microcrystalline structure of the activated alumina plays a role in whisker toughening in a porcelain body sintering reaction, so the thermal stability and the mechanical strength of the formed porcelain can be improved; and the dolomite powder can accelerate the high-temperature sintering reaction to generate sufficient liquid phase filling and ensure the generation of enough glass phase without influencing reactions of the activated alumina with other components, so the light transmittance of the finished porcelain is improved on the basis of ensuring the thermal stabilityand the mechanical strength.

Owner:上海信传信息技术有限公司

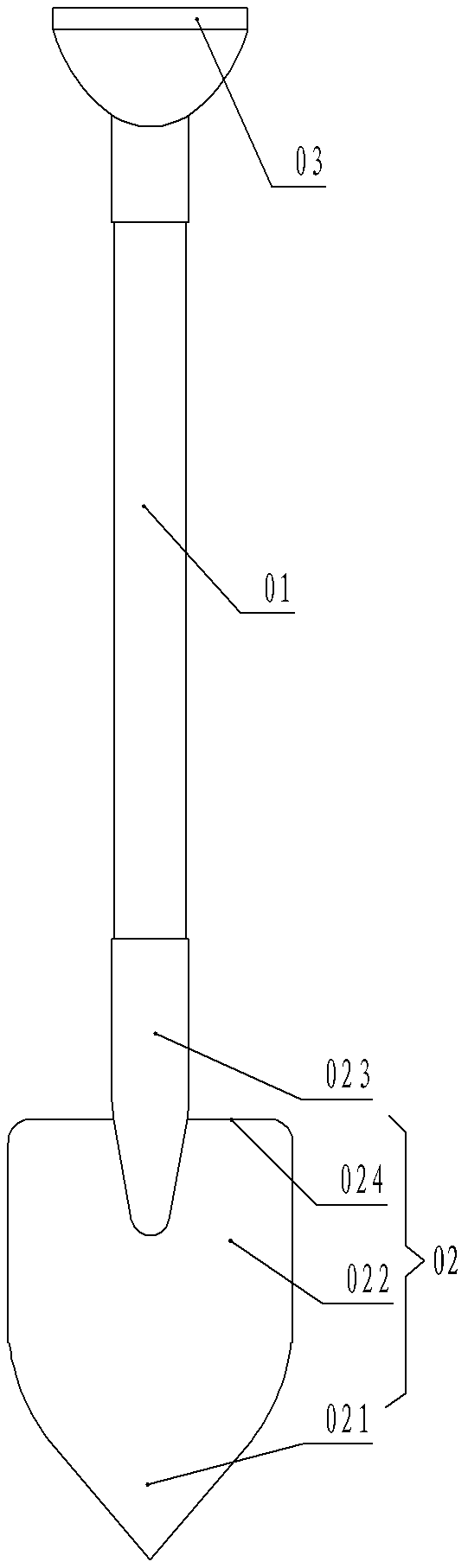

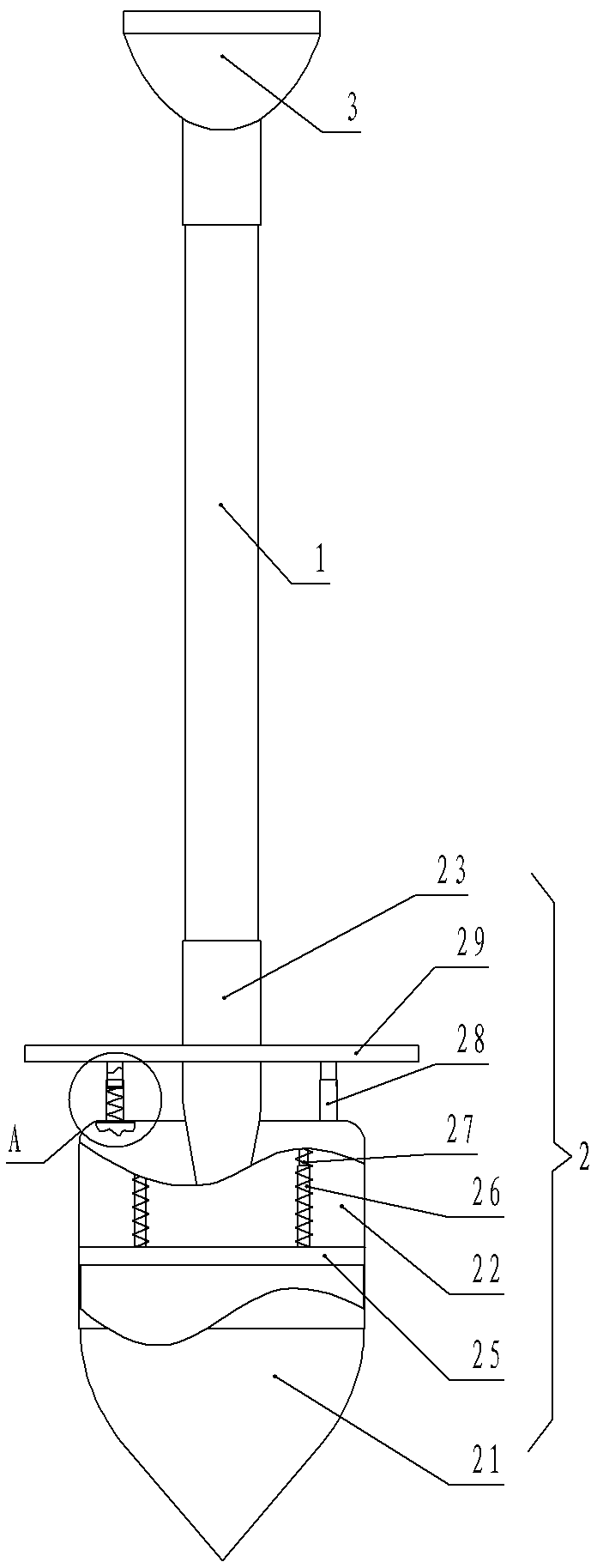

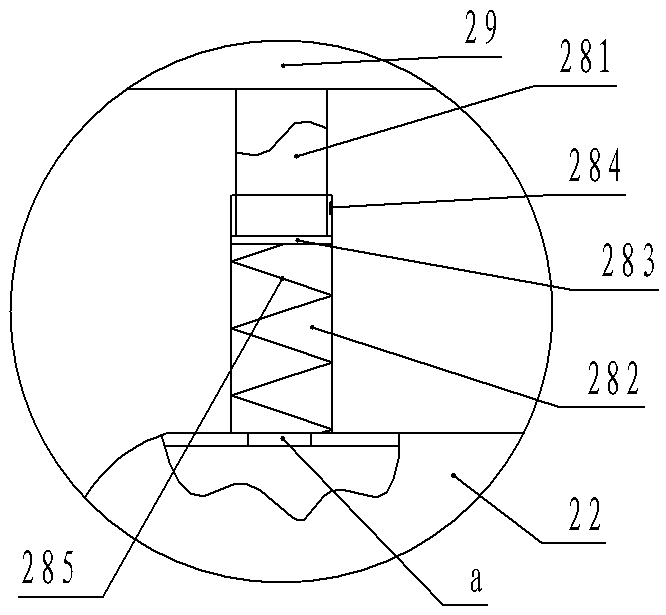

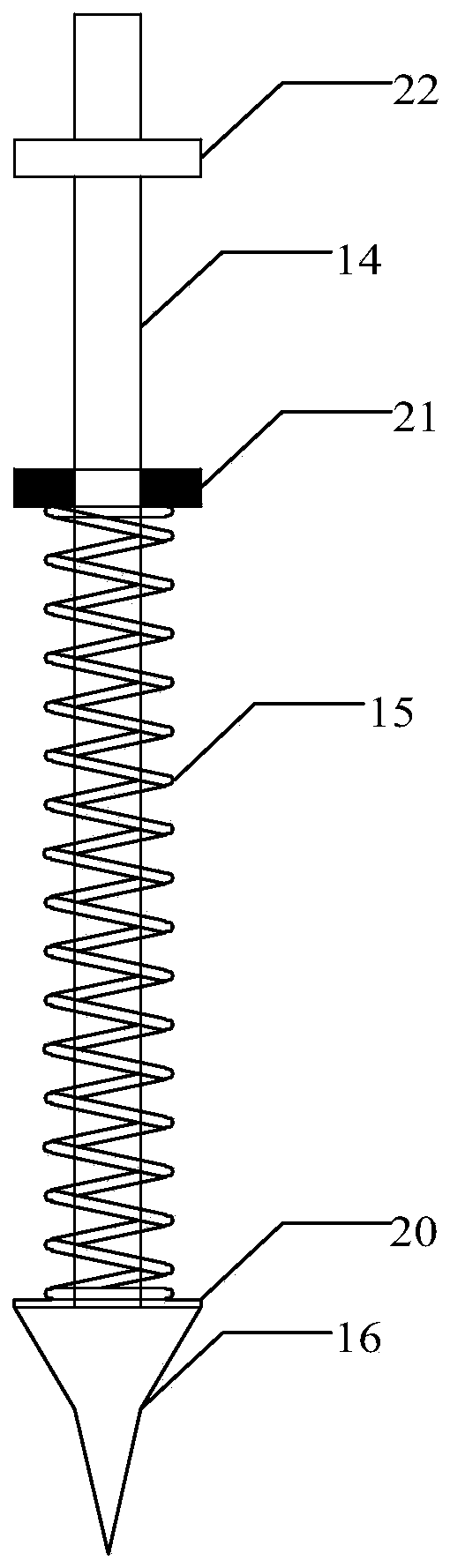

Agricultural shovel

InactiveCN107683641AReduce labor intensityImprove work efficiencySpadesShovelsAgricultural scienceAgricultural engineering

The invention discloses an agricultural shovel and belongs to the technical field of agricultural tool manufacturing. The agricultural shovel comprises a shovel head, one end of the shovel head is provided with a tip portion extending outwards and the other end of the same is provided with a barrel connecting portion in sleeved connection with a shovel handle, a shovel plate portion is arranged between the tip portion and the barrel connecting portion, a cavity is formed in the shovel plate portion, and the inside of the cavity is divided into a rod cavity and a rodless cavity through a pistonplate; the inner end of the tip portion is penetratingly mounted in the rod cavity and is in abutted connection with the piston plate, and springs are arranged in the rodless cavity; a pressing plateis mounted outside the barrel connecting portion in a sleeved manner, an inflator is arranged between the pressing plate on the outer side of the barrel connecting portion and the shovel plate portion, a rod cavity air inlet is arranged in a wall body of the shovel plate portion, and an air outlet of the inflator is communicated with the rodless cavity air inlet. By the agricultural shovel, the problem that existing agricultural shovels are high in labor intensity and low in working efficiency can be solved.

Owner:鹿寨县众生园中药材种植专业合作社

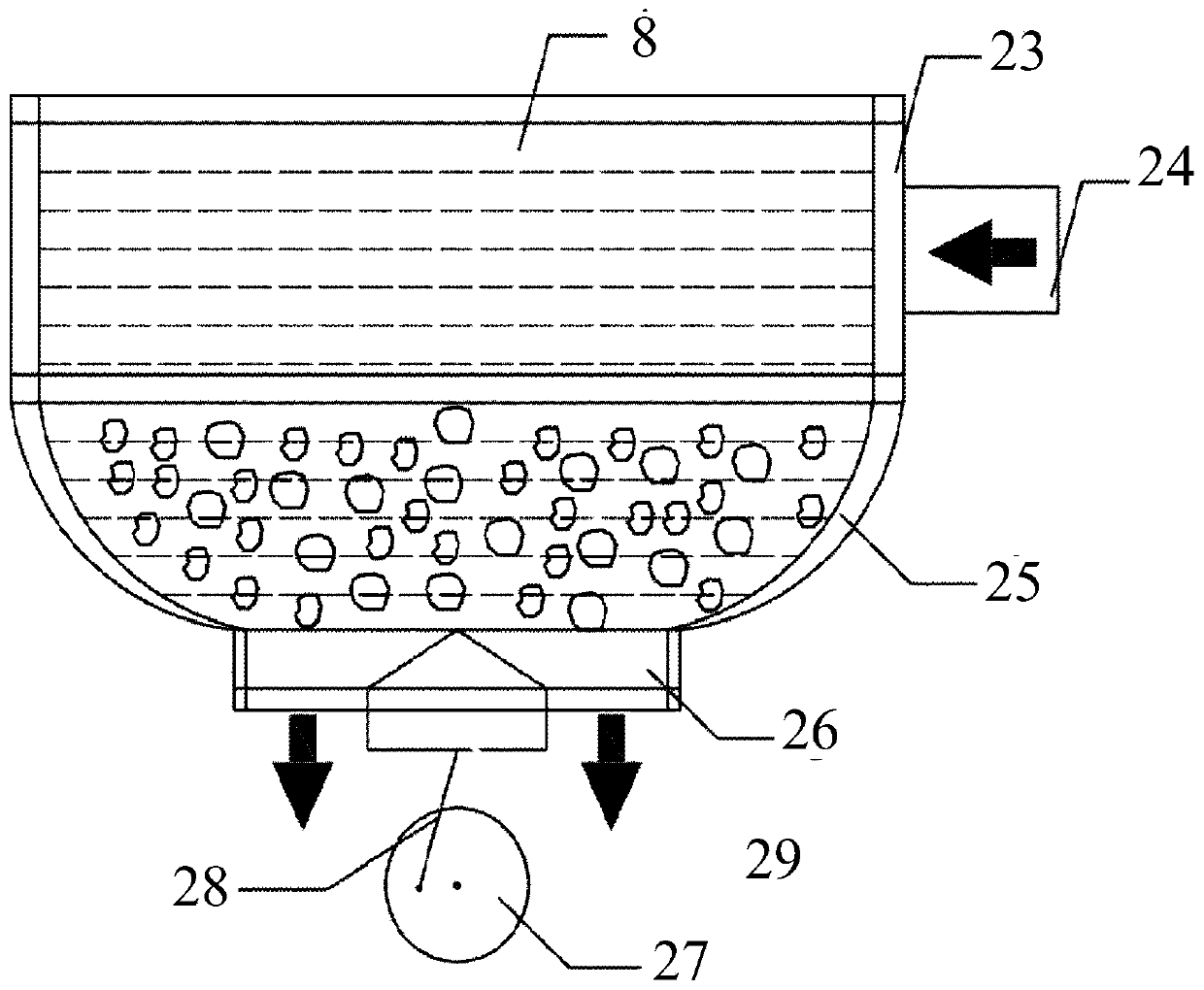

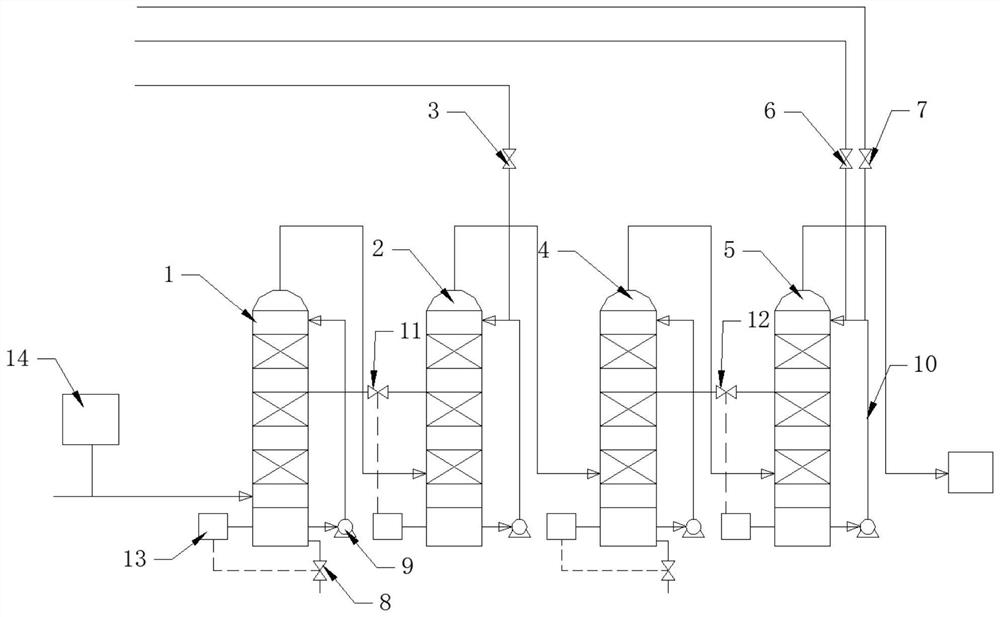

Energy self-sufficiency high concentrated sewage treating system and method

ActiveCN105906043AGuaranteed productionIncrease acidityWater treatment parameter controlSludge treatment by oxidationEngineeringAnaerobic reactor

The invention discloses an energy self-sufficiency high concentrated sewage treating system and method. The system comprises a hydrolytic acidification device, an anaerobic reactor, a sludge treating device, a desulfurizing tower and a marsh gas power generation device. The sludge treating device comprises a second sedimentation basin, a second overflow weir, a water inlet pipe and an oxygen dissolving instrument. The second overflow weir is communicated with the hydrolytic acidification pool through a backflow pipe, and the water inlet is provided with a jet flow hole and an adjusting valve. The method comprises the steps of hydrolytic acidification, anaerobic fermentation, sludge treatment and desulfuration power generation in sequence. Due to the fact that the sludge treating device is provided with the jet flow hole to adjust the oxygen dissolving content of the reaction liquid surface, it is ensured that reaction produces nitrite, the formed nitrite backflows to the hydrolytic acidification pool, acidity of acidized sewage is prevented from being too high, and overall sewage treating efficiency is improved; meanwhile, the marsh gas power generation device is adopted, so that marsh gas produced in the anaerobic reaction stage is used for power generation, the requirements of sewage treatment for energy consumption are met, and energy consumption can be lowered.

Owner:WUHAN HUIZHONG DACHUAN AUTOMATIC CONTROL EQUIP CO LTD

Quick falling and collecting device of cylindrical cells after being covered with films

ActiveCN110654653AImprove equipment utilizationGuaranteed productionPackagingConveyor partsPhysicsElectrical control

A quick falling and collecting device of cylindrical cells after being covered with films can solve the technical problems that a film covering machine is low in equipment utilization rate, and then production efficiency of products is influenced in the prior art. The quick falling and collecting device of the cylindrical cells after being covered with the films comprises a quick falling device machinery transmission system, and further comprise an electrical control system and a cylindrical cell recycle device. The quick falling and collecting device of the cylindrical cells after being covered with the films is used for quickly collecting and temporarily storing the applicable targets which are the cylindrical cells after being accumulated on all stations of a variety of cylindrical cellproduction lines. The quick falling and collecting device of the cylindrical cells after being covered with the films timely collects the fallen cylindrical cells which are accumulated after film covering, prevents normal output of the devices in the current procedure from being influenced by fault or low efficiency of devices in the next procedure, meanwhile alleviates the problem that underfeeding or device fault in the current procedure causes insufficient feed and wait to the next procedure, and then the materials are temporarily stored, and can make great contributions to improvement ofcomprehensive equipment utilization rate and production efficiency.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

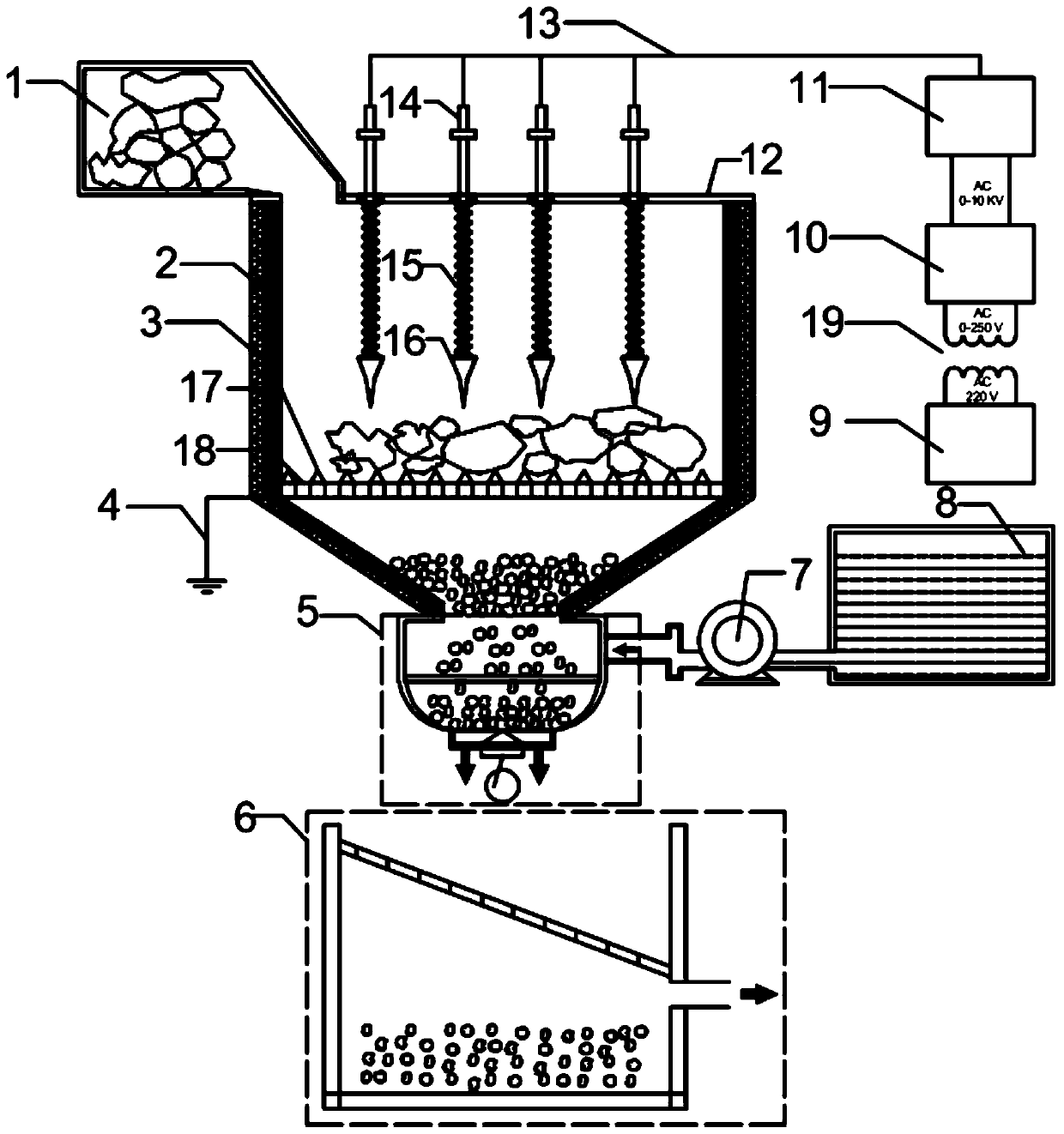

High-voltage pulse pretreatment method for reinforcing cassiterite crushing and sorting

ActiveCN110193418AImprove sorting indexPromote productionGrain treatmentsPretreatment methodEngineering

The invention provides a high-voltage pulse pretreatment method for reinforcing cassiterite crushing and sorting, a high-voltage pulse device is adopted, and the high-voltage pulse pretreatment methodcomprises the following steps that (1), a water pump is started, water continuously enters a pulsating insulation cylinder body, and is discharged from a water outlet of a product collector; (2), cassiterite ore is conveyed into a pulse insulating cylinder body through a ore feeding bin and is accumulated on a screen, and the top of the cassiterite ore is in contact with a high-voltage electrode;(3), a power supply is turned on, and discharging is carried out between the high-voltage electrode and a high-voltage negative electrode to enable the cassiterite ore to be broken; (4), through therotation of an eccentric wheel, the lifting of the water flow acts on the ore on the screen, and a small particle part moves downwards; and (5), the crushed cassiterite ore enters the product collector. The method can be used for improving the useful mineral content of crushed products, the monomer dissociation degree of the crushed products is improved, the energy consumption in the subsequent processing process is reduced, and the enterprise cost is reduced.

Owner:NORTHEASTERN UNIV

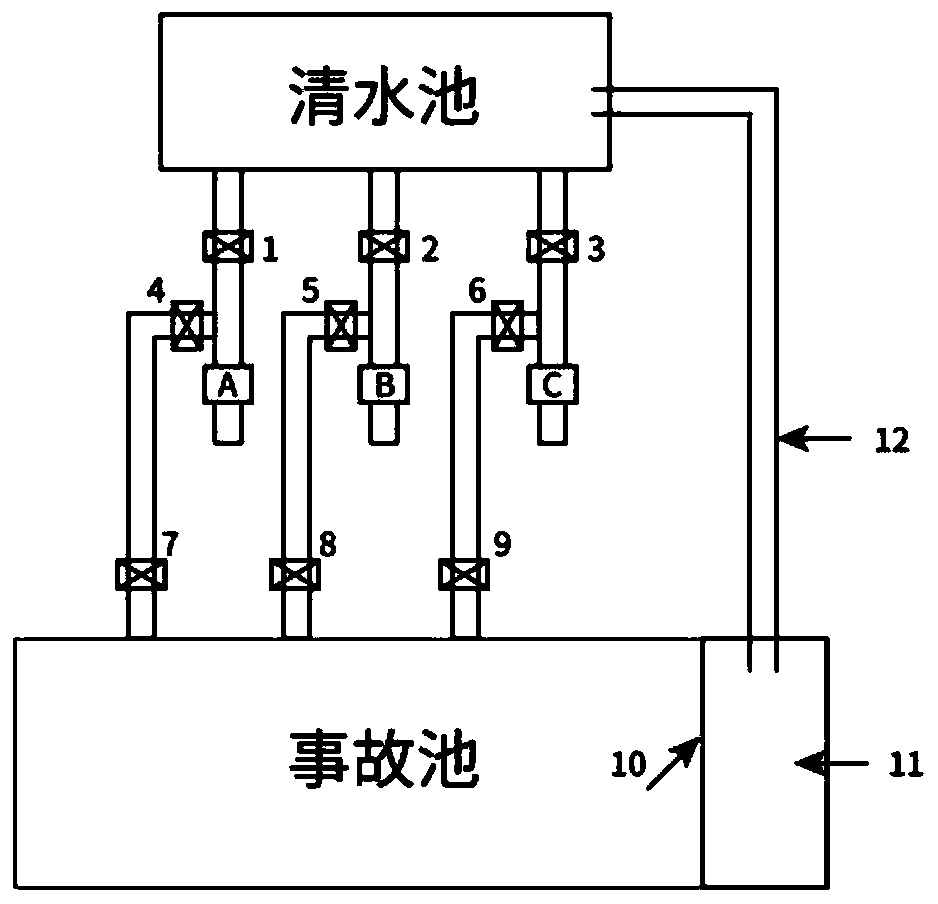

Cross use system between material pools, and control method thereof

InactiveCN110745925AGuaranteed productionWater for production needsWater/sewage treatment by flocculation/precipitationProcess engineeringWater tanks

The invention discloses a cross use system between material pools. The system is characterized in that the system comprises a clear water pool and an accident pool; the clear water tank is connected with a water circulating pump through a first pipeline, and the first pipeline is provided with a first valve; a preliminary sedimentation tank is arranged on the accident tank and is connected with the clear water pool through a second pipeline; and the first pipeline is connected with a third pipeline, the third pipeline is communicated to the accident pool, and i the third pipeline is provided with a second valve. The cross use system between the material pools solves the problem that water cannot be normally supplied when accumulated ores in the clear water pool are cleaned, and ensures production operation.

Owner:YUNNAN DAHONGSHAN PIPELINE

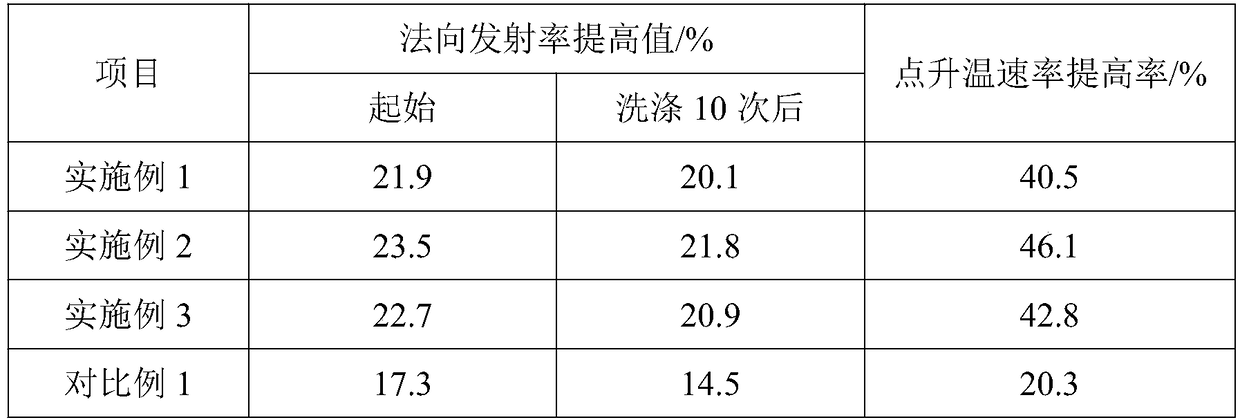

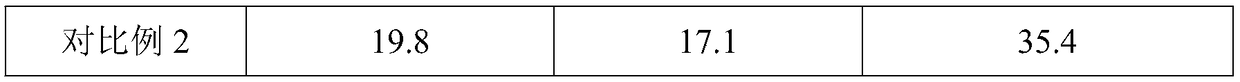

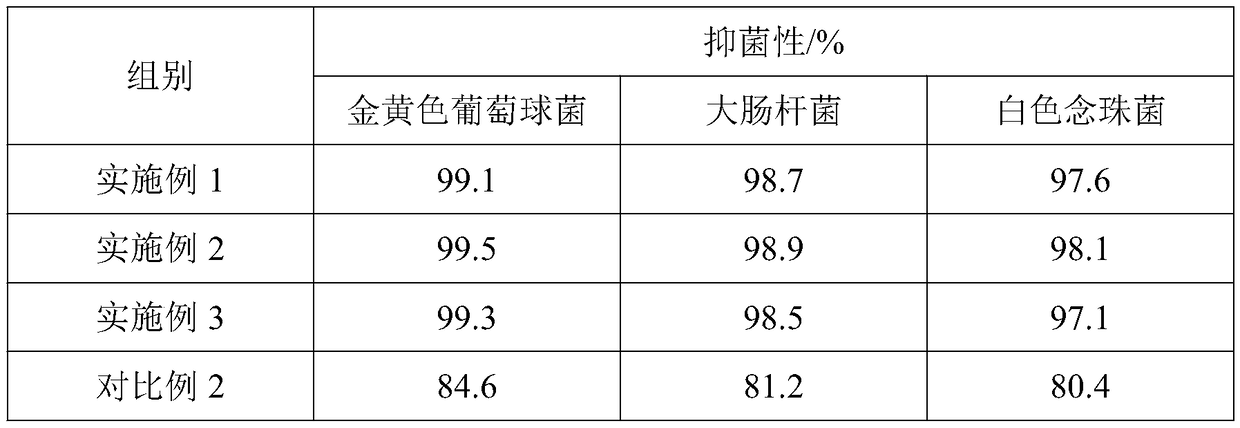

A kind of far-infrared fiber used for physiotherapy travel pad and preparation method thereof

ActiveCN107502993BEnhanced Far Infrared PerformanceImprove antibacterial propertiesConjugated synthetic polymer artificial filamentsArtifical filament manufactureWound healingFiber

The invention belongs to the field of fiber materials, in particular to a far-infrared fiber for a physiotherapy travel mat and a preparation method of the far-infrared fiber. The preparation method of the far-infrared fiber for the physiotherapy travel mat comprises the following steps: S1 deacetylation of chitosan; S2 preparation of quaternary ammonium salt modified chitosan; S3 preparation of a spinning stock solution; S4 preparation of a nanometer powder dispersion; S5 preparation of a spinnable solution; S6 wet spinning. The far infrared fiber prepared with the method has better far infrared performance, antibacterial property, washing resistance and high durability, is comfortable, insulated, environmentally friendly and safe, and has effects of refreshing the mind, diminishing inflammation, promoting wound healing and effectively relieving human fatigue.

Owner:广东富琳健康产业有限公司

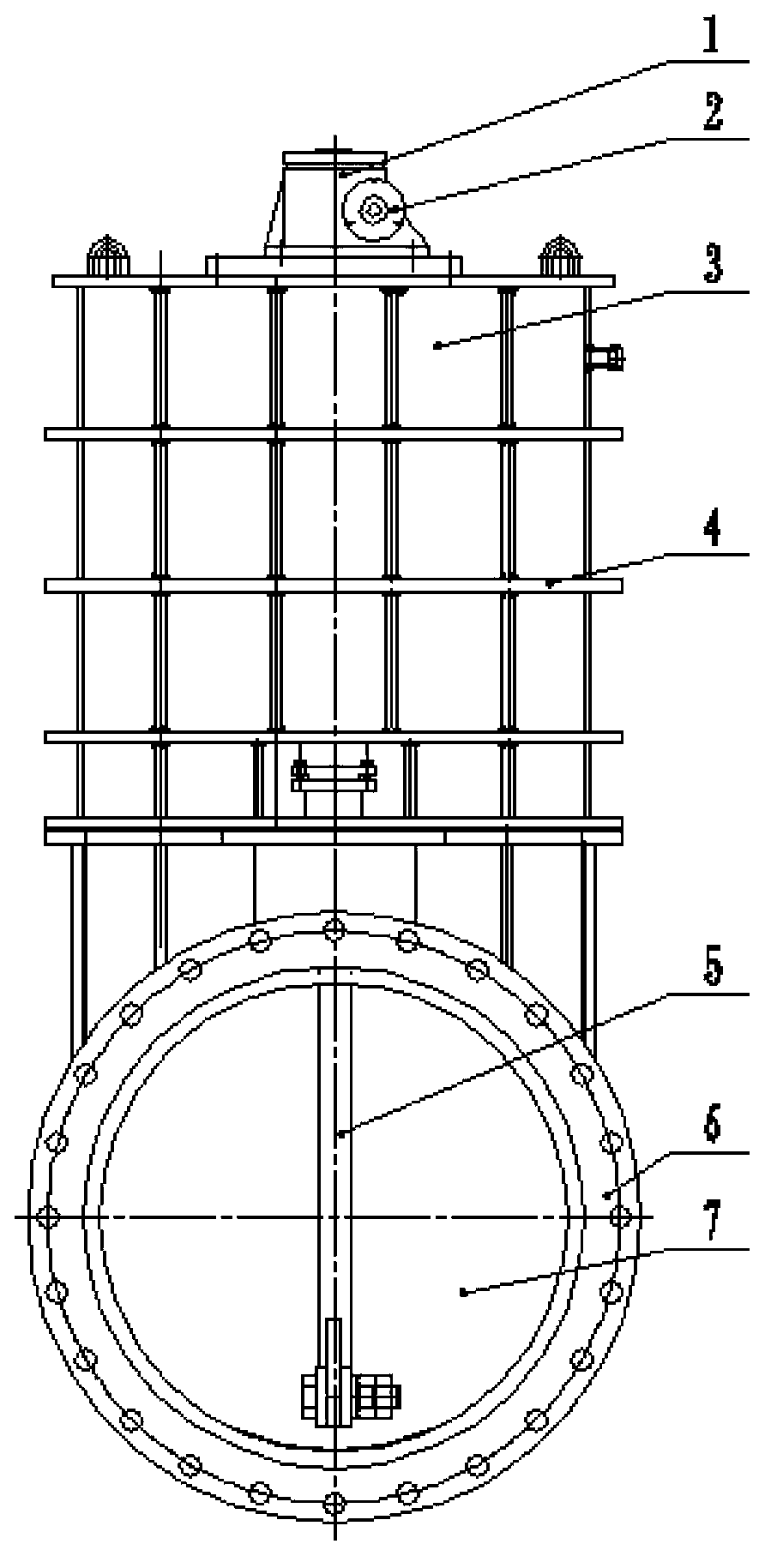

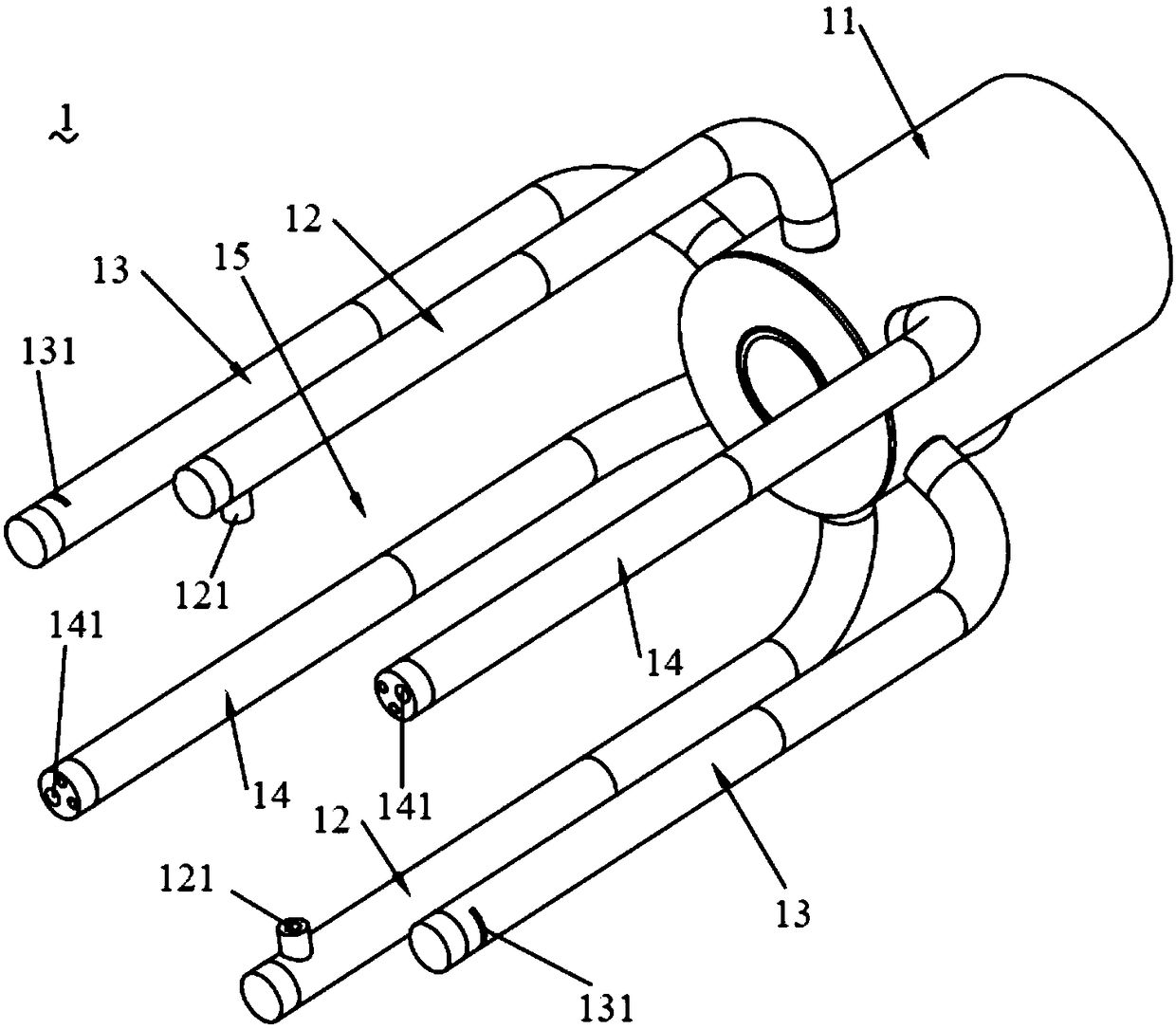

High-power gate valve

The invention relates to a high-power gate valve which comprises an upper box body, a lower box body, a gate plate and a screw rod, wherein a pipeline through hole is formed in the lower box body; the lower box body and the upper box body are vertically and fixedly mounted through a flange; a gate slot which is longitudinally communicated through a same shaft is formed in the upper box body and the lower box body; the gate plate is mounted in the gate slot in longitudinal gliding guide manner; the lower end of the screw rod is longitudinally mounted on one side of the gate plate; the upper end of the screw rod stretches out of the upper box body and is connected with a valve rod; a hydraulic assistance device is mounted at the top end of the screw rod; a rotary control knob is mounted on the hydraulic assistance device and used for selecting to use the hydraulic assistance device or lock the device. The high-power gate valve is scientific and reasonable in design, simple in structure, lower in cost, easy to operate and long in service life, the transmission power of the gate valve can be improved, time and labor are saved, and the working efficiency is improved.

Owner:TIANJIN HONGXINRUN HYDRAULIC MACHINERY SCI & TECH CO LTD

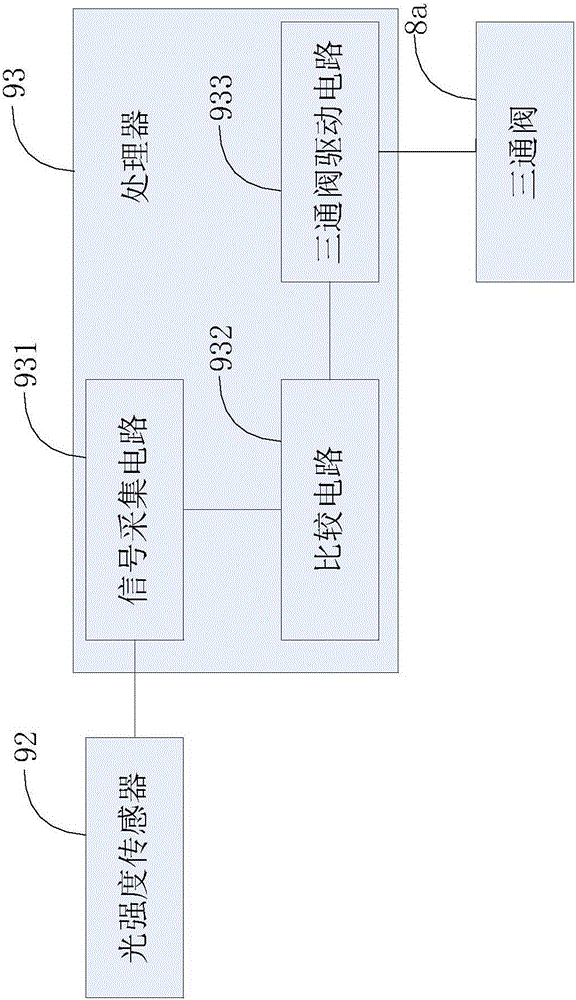

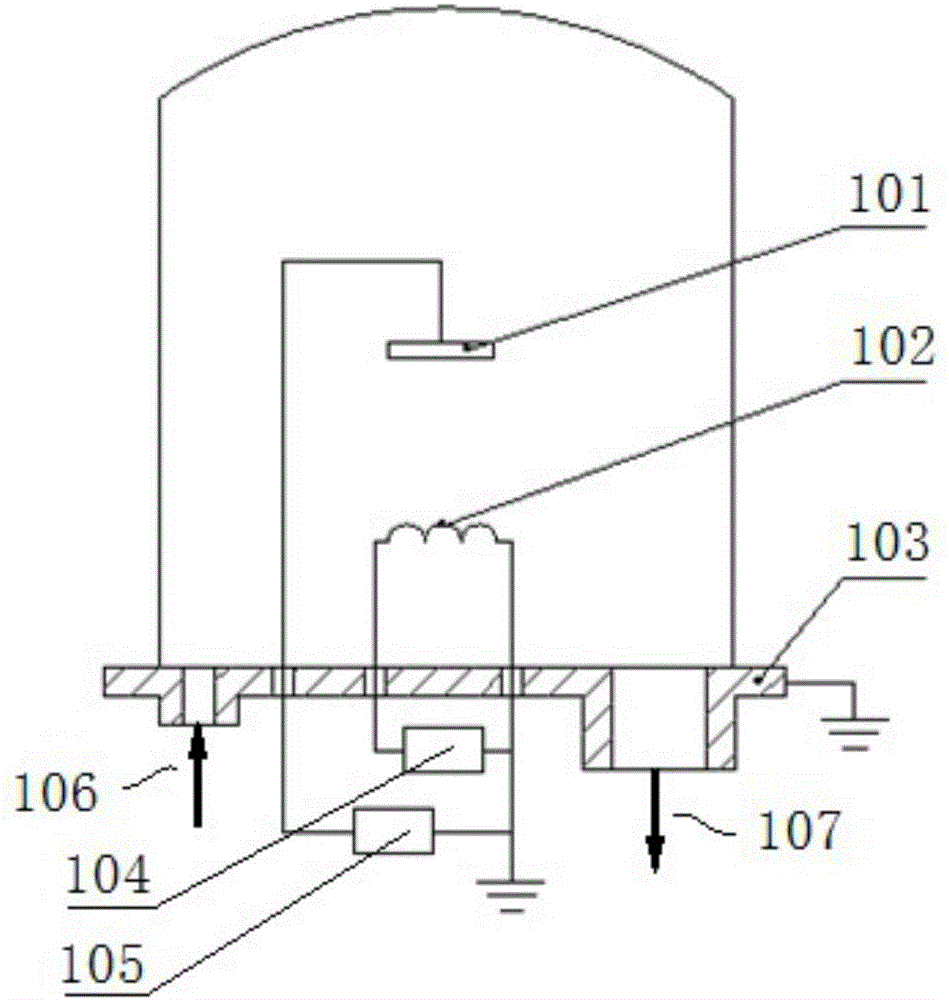

Temperature control system for smelter

InactiveCN104019675AGuaranteed productionAccurately grasp the temperatureControl devices for furnacesSignal amplifierEngineering

The invention discloses a temperature control system for a smelter. The temperature control system comprises a temperature sensor, a signal amplifier, an A / D (analogue / digital) conversion circuit, a main control CPU (central processing unit), a D / A (digital / analogue) conversion circuit, a driving circuit and an air blower; the temperature sensor is arranged in the smelter, and is connected with the signal amplifier; the signal amplifier, the A / D conversion circuit, the main control CPU, the D / A conversion circuit, the driving circuit and the air blower are sequentially connected. The temperature control system has the advantages that temperature in the smelter can be accurately mastered, and subtle temperature changes can be adjusted, so that the production stability and the quality of a product are ensured.

Owner:镇江新晔网络科技有限公司

Combustion gas gun device, combustor and boiler

PendingCN108895449ASolve for uniformitySolve the problem of concentrationGaseous fuel burnerInjection portCombustor

The invention discloses a combustion gas gun device, which comprises a gas distributor and at least two gas guns, wherein the gas distributor comprises a fuel gas channel; an injection port connectedwith the flue gas channel is formed on each gas gun; the at least two gas guns are arranged on the gas distributor and formed space; and injection directions of the injection ports of the at least twogas guns are towards at least two combinations of the inside, the lateral side, and the front of the space, so as to enable the gas gun device to inject flue gas towards at least two directions of the inside, the side, and the front of the space. The combustion gas gun device solves the problem of uneven and concentrated flame injection, and also solves the problem that the central gas volume cannot be ensured due to the inner injection port.

Owner:SHANGHAI NUOTE FEIBO COMBUSTION EQUIP CO LTD

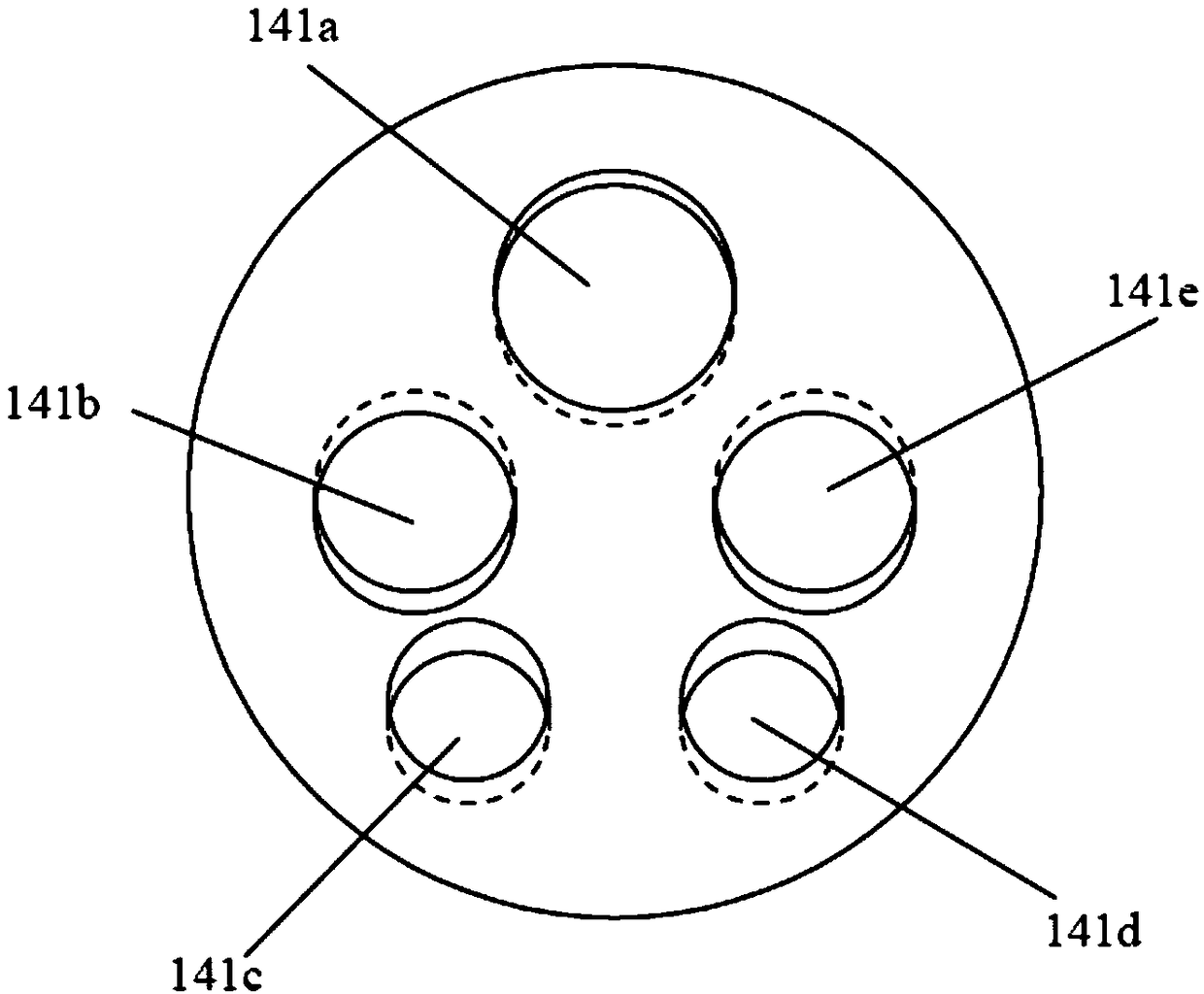

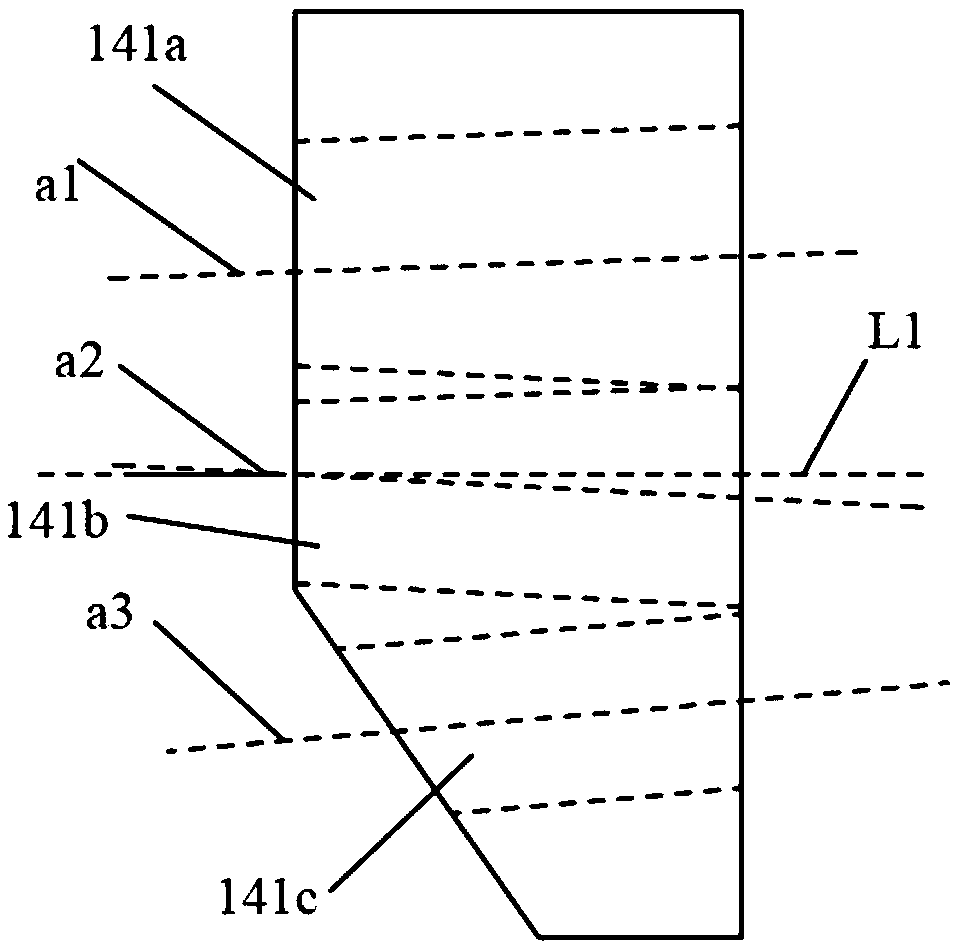

Four-tower normal-temperature nitrogen oxide removal process and four-tower normal-temperature nitrogen oxide removal device

PendingCN113209792AAchieve the effect of reasonable utilizationReduce trip factorDispersed particle separationNitrogen oxidesChemical reaction

The invention discloses a four-tower normal-temperature nitrogen oxide removal process and a four-tower normal-temperature nitrogen oxide removal device, belongs to the technical field of tail gas treatment, and solves the problem of high operation cost caused by low effective utilization rate of chemicals in an existing workshop tail gas treatment process. The four-tower normal-temperature nitrogen oxide removal device comprises a primary oxidation tower; an inlet of the primary oxidation tower is connected with a tail gas passing pipe; the primary oxidation tower is further connected with a deep oxidation tower, the deep oxidation tower is connected with an oxidizing agent adding valve, the deep oxidation tower is connected with a primary reduction tower, the primary reduction tower is connected with a deep reduction tower, and the deep reduction tower is connected with a reducing agent adding valve and a liquid caustic soda adding valve. And the bottoms of the primary oxidation tower and the primary reduction tower are connected with a comprehensive regulation tank through discharge valves. According to the invention, the absorption, oxidation and reduction of the chemical reaction are accurately controlled, and the economic cost is maximally controlled.

Owner:四川省创飞格环保技术有限公司

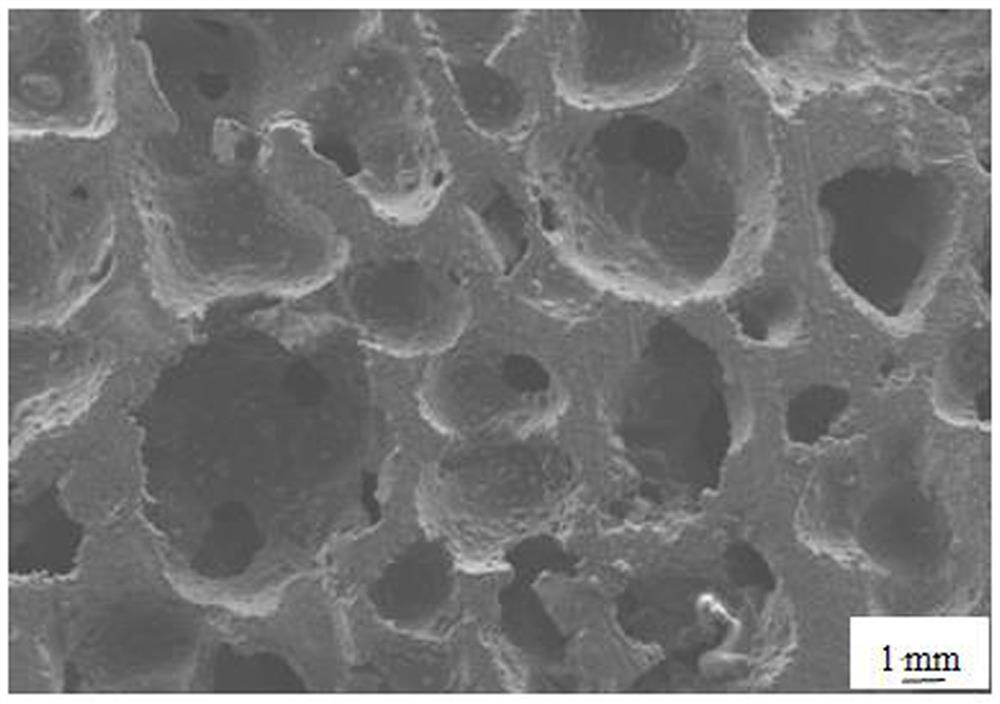

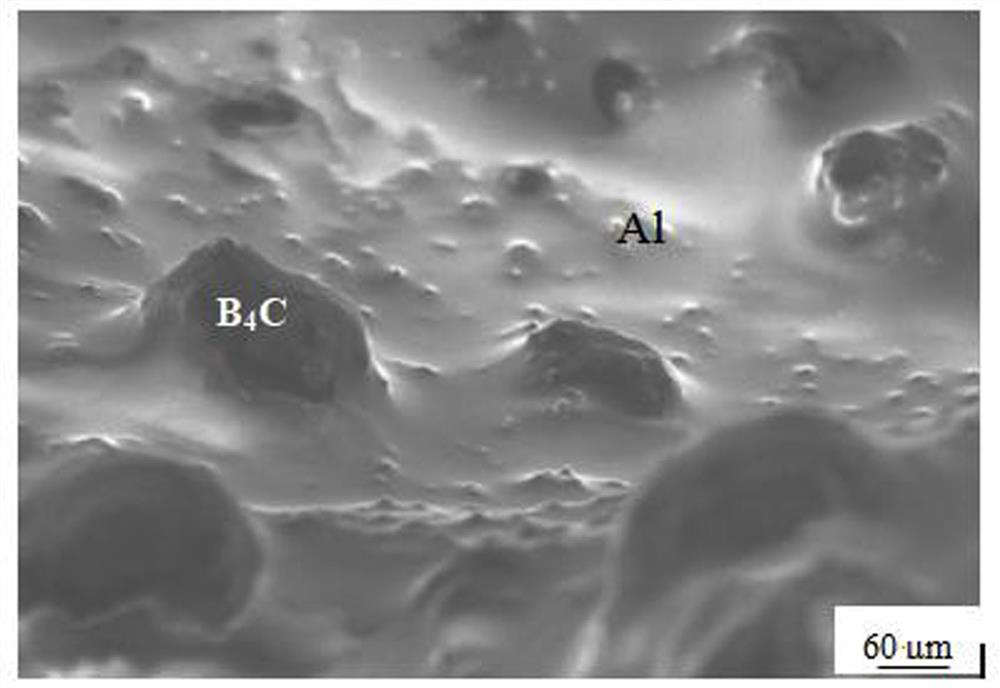

Boron carbide reinforced foamed aluminum composite material and preparation method thereof

PendingCN114669743AGuaranteed productionGood vibration and noise reductionTransportation and packagingMetal-working apparatusEnergy absorptionLow density

The invention belongs to the technical field of materials, and relates to a boron carbide reinforced foamed aluminum composite material and a preparation method thereof. The composite material specifically comprises an aluminum alloy matrix, boron carbide reinforced particles and an open-cell foam structure. Wherein the aluminum alloy powder accounts for 77.1-88.9% of the solid phase mass of the composite material, the B4C powder accounts for 10-20% of the solid phase mass of the composite material, and the Ti powder accounts for 1.1-2.9% of the solid phase mass of the composite material; b4C and molten aluminum alloy are subjected to an in-situ synthesis reaction to generate Al3BC and AlB2 phases, meanwhile, polyurethane is decomposed to release gas, and a communicated open pore structure is generated in the composite material. The composite material integrates the advantages of an in-situ reinforced phase and a network interpenetrating open pore structure of the aluminum and the B4C ceramic particles, has the characteristics of low density, energy absorption and vibration reduction and the like, and meanwhile, the added boron carbide particles and the in-situ reinforced phase enable the composite material to have higher hardness and strength, so that the composite material plays a greater application potential in the field of energy absorption and vibration reduction.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

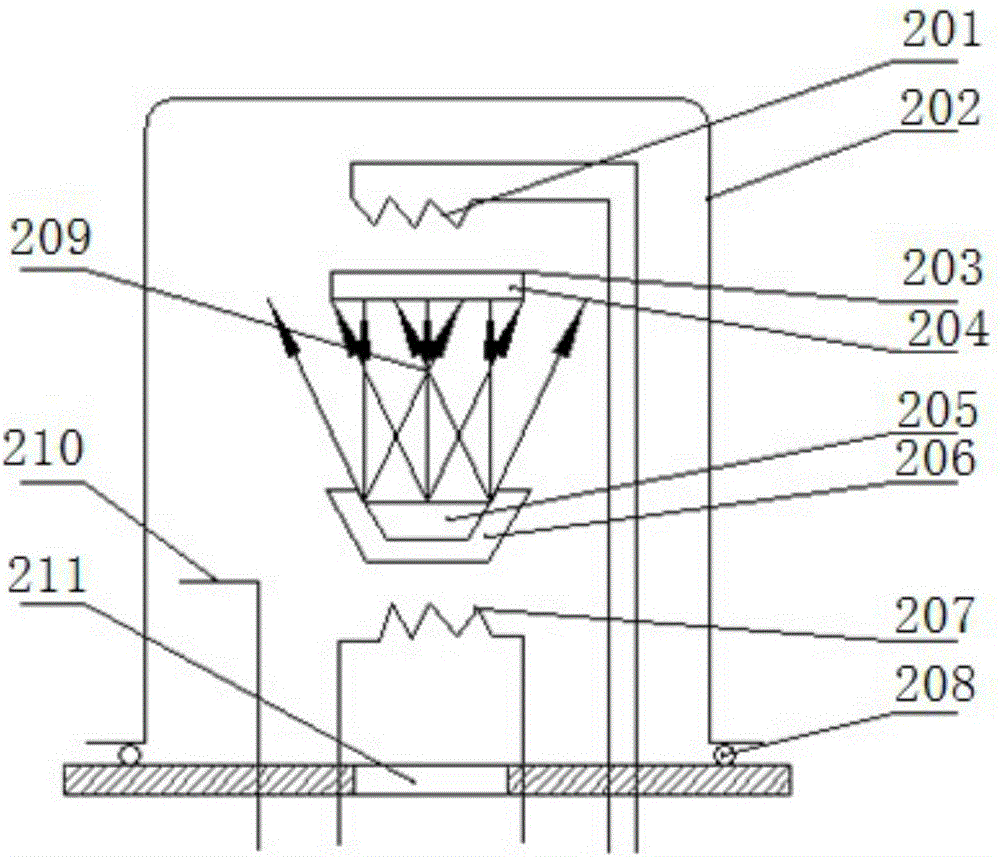

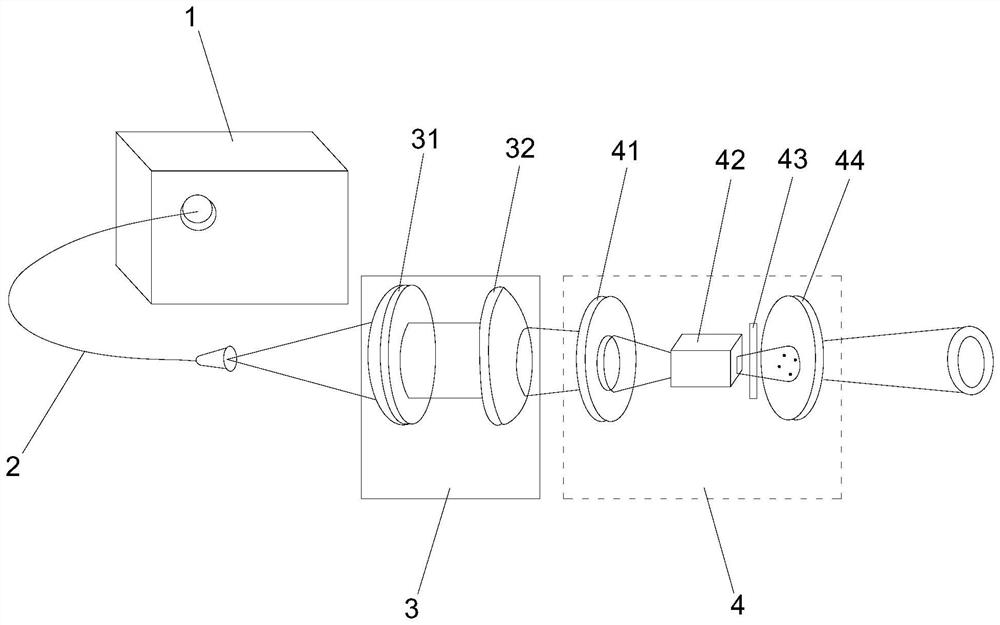

Single-frequency high-order vortex laser direct generation device

PendingCN113872031AGuaranteed normal inputGuaranteed productionOptical resonator shape and constructionResonant cavityLight spot

The invention discloses a single-frequency high-order vortex laser direct generation device, which comprises a pumping source, a pumping light coupling element and a laser resonant cavity, and is characterized in that the laser resonant cavity is composed of a resonant cavity input mirror, a laser crystal, a filter element and an output point defect mirror; the pumping source is used for providing pumping laser; the pump light coupling element is used for focusing the laser generated by the pump source on the resonant cavity input mirror; the resonant cavity input mirror is used for receiving the light beam from the pump light coupling element and outputting the light beam to the laser crystal. The laser crystal obtains single-frequency laser through the filtering element and outputs the single-frequency laser to the output point defect mirror; and the output point defect mirror is used for generating high-order vortex laser output. By forming a concave-flat laser resonant cavity structure, the quality of output light spots is good, the length of the resonant cavity can be adjusted to a very short size, less longitudinal mode output is ensured, the output point defect mirror can ensure generation of high-order vortex laser, and single-frequency laser output can be ensured by inserting an etalon (filter element) into the laser resonant cavity.

Owner:广东镭泰激光智能装备有限公司

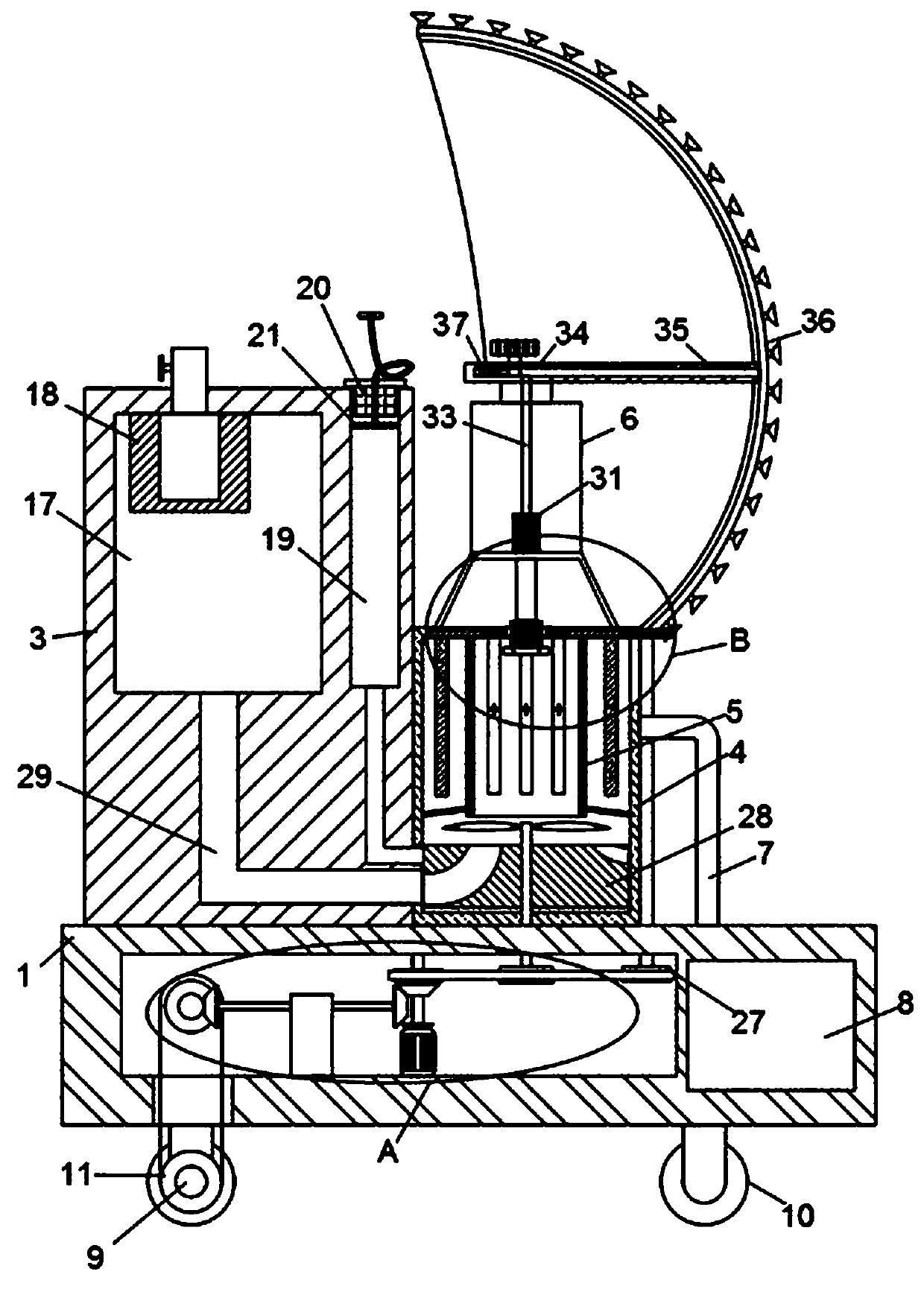

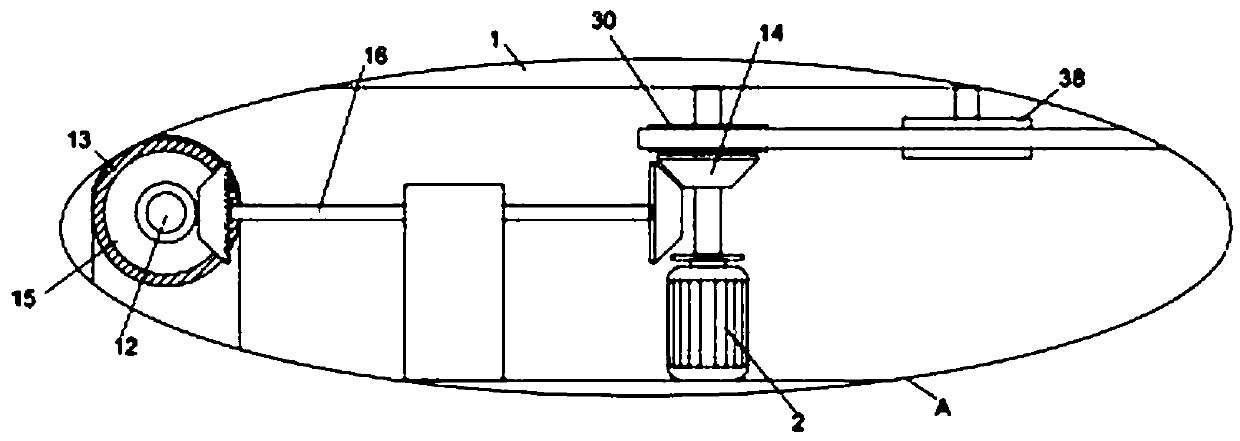

Intelligent acidic electrolyzed oxidizing water cloud atomization disinfection device

InactiveCN111453819AGuaranteed productionReduce infection rateScale removal and water softeningMultistage water/sewage treatmentElectric machineTap water

The invention discloses an intelligent acidic electrolyzed oxidizing water cloud atomization disinfection device. The device comprises a moving base, wherein the moving base is provided with a drivingmotor, the output end of the driving motor is connected with a moving mechanism, the top of the moving base is provided with a storage box and a reaction box, the storage box is provided with a storage mechanism, the reaction box is provided with a quantitative conveying mechanism, a supporting ring is arranged at the top of an electrolytic cell, and a high-pressure conveying mechanism is arranged in the supporting ring. According to the invention, tap water is softened, a quantifying disc is rotated through the motor, and a flowing-in channel on the quantifying disc communicates with outputthrough holes at different positions in a timing manner, so softened water and a sodium chloride solution are quantitatively supplemented into the electrolytic cell, and the device is guaranteed to continuously generate acidic electrolyzed oxidizing water; the acidic electrolyzed oxidizing water is pumped out of vaporific spray heads on an arc-shaped plate through a high-pressure water pump to achieve spray disinfection, and moving wheels move under the driving of the motor; and since automatic moving disinfection is conducted through the device, the infection probability of users is reduced.

Owner:李仲秋

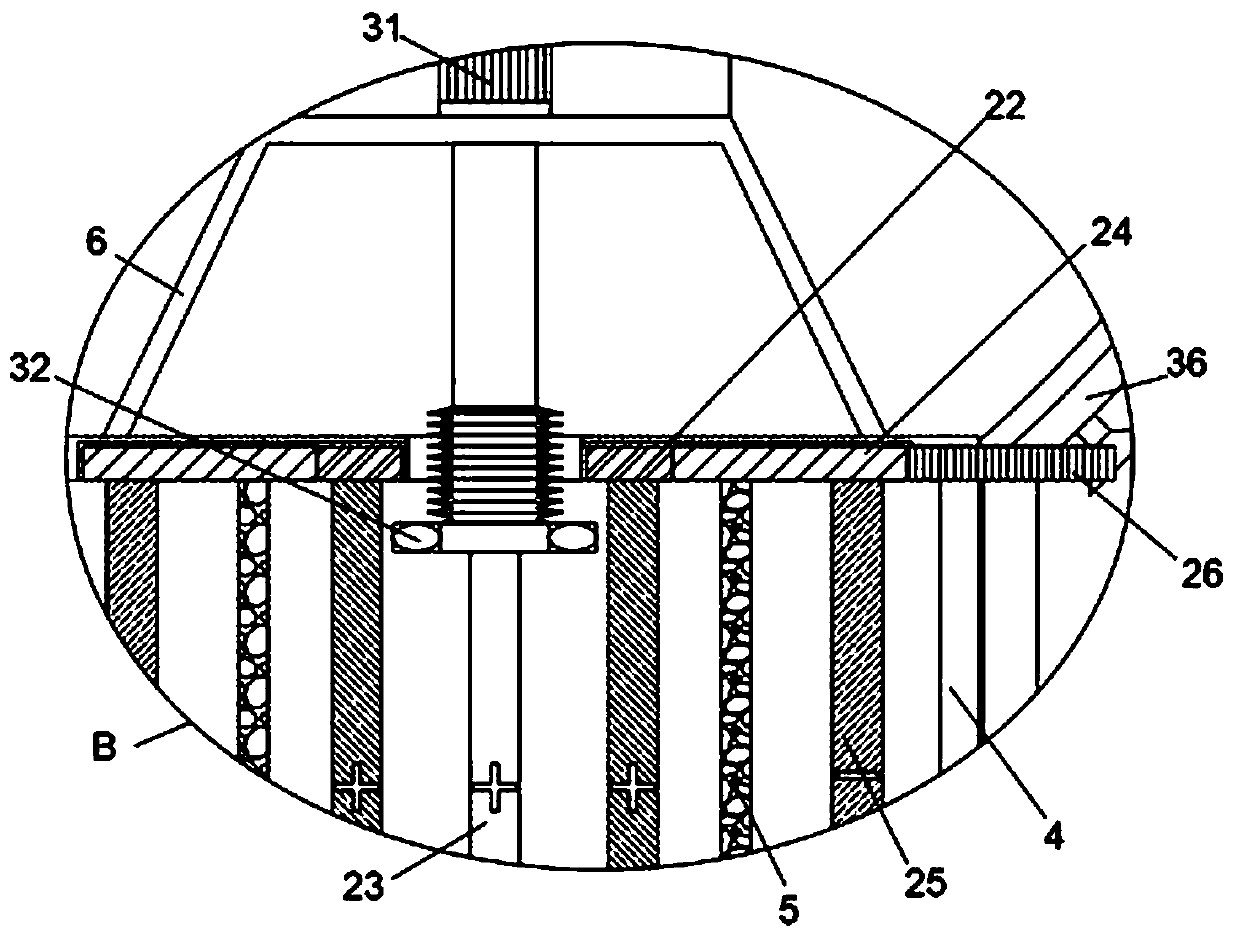

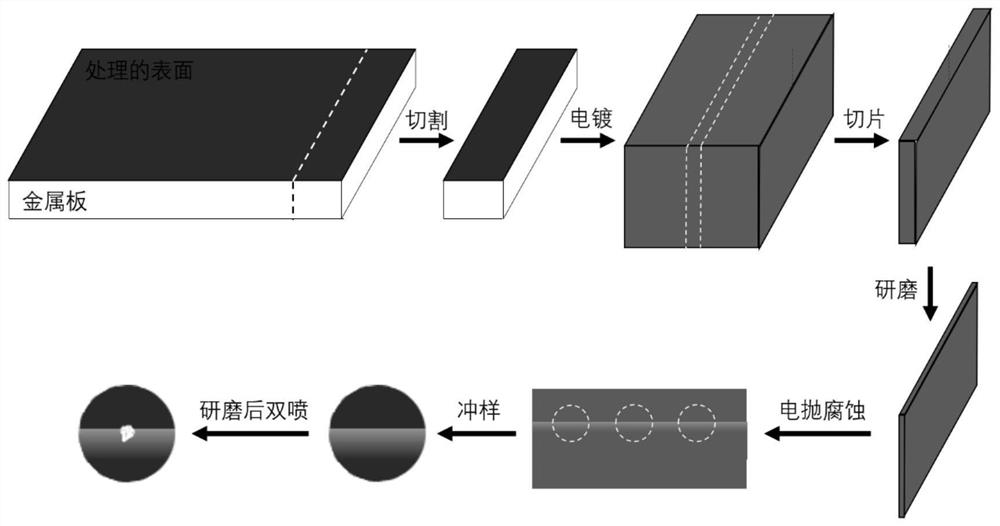

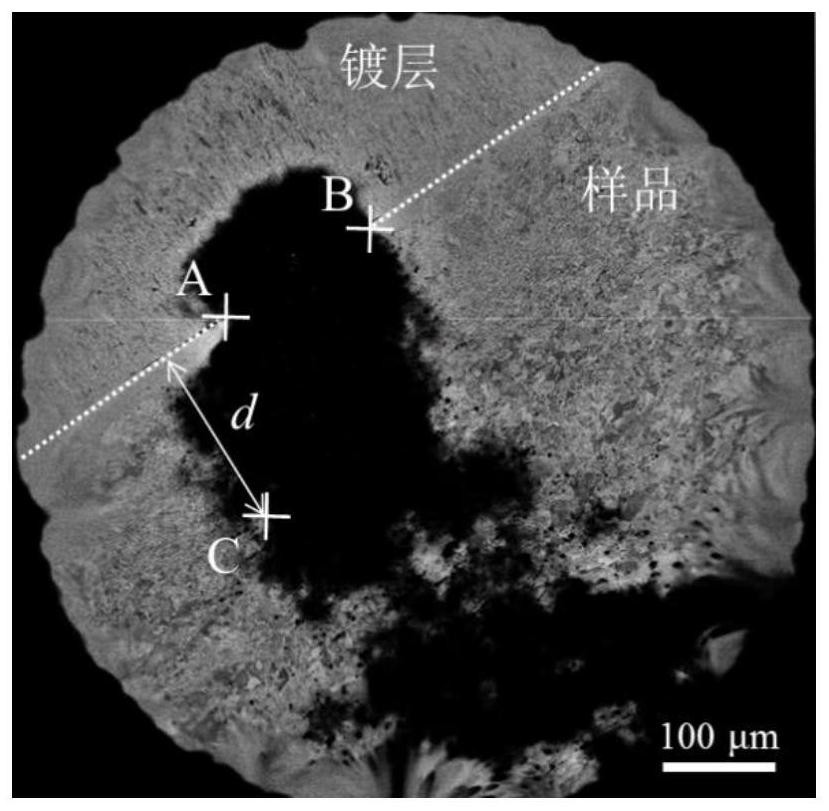

Preparation method of metal material surface deformation layer transmission electron microscope sample

ActiveCN111982643ASolve the problem that it is difficult to prepare transmission electron microscope samples of deformed layers on the surface of metal materialsGuaranteed productionPreparing sample for investigationMetallic materialsElectron microscope

The invention provides a preparation method of a metal material surface deformation layer transmission electron microscope sample. The specific preparation process comprises eight preparation steps ofmaterial preparation, outer coating layer electroplating, mechanical cutting and grinding, electropolishing of a corrosion bonding interface, marking of a sample punching position, sample punching, mechanical grinding and electrochemical double spraying, the method is used for preparing a metal material surface deformation layer transmission electron microscope sample, and the position of a transmission sample thin area can be effectively controlled. The method provided by the invention is simple and feasible in preparation process, high in efficiency and low in cost, solves the problem thata metal material surface deformation layer transmission electron microscope sample is difficult to prepare by an electrochemical double-spraying method, and effectively ensures that a double-sprayingthin area is generated in material surface deformation.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com