Mass spectrometer and pole used for same

A mass spectrometer and pole technology, applied in the field of detection and analysis equipment, can solve the problems of lack of firm connection and fixation of the quadrupole, failure to obtain the pole, and reduced service life, etc., to achieve low secondary ion effect, low cost, and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] refer to figure 1 , In this embodiment, a pole for a mass spectrometer is provided. The pole rod for the mass spectrometer includes a pole body and a film layer, and the film layer is formed on the pole body by a vacuum coating process. In this embodiment, the film layer covers the entire outer peripheral surface of the pole body, and the two ends of the pole body are not covered with the film layer. Wherein, the "pole body" is equivalent to the pole in the prior art.

[0049] Vacuum coating technology is to use a certain method under vacuum conditions to coat a thin layer of material different from the base material on the solid surface, or to use the solid itself to generate a thin layer of material different from the base material. Different materials make the base material have many new physical and chemical properties, so vacuum coating technology is also called surface modification technology. The invention breaks through the improvement ideas of the prior art ...

Embodiment 2

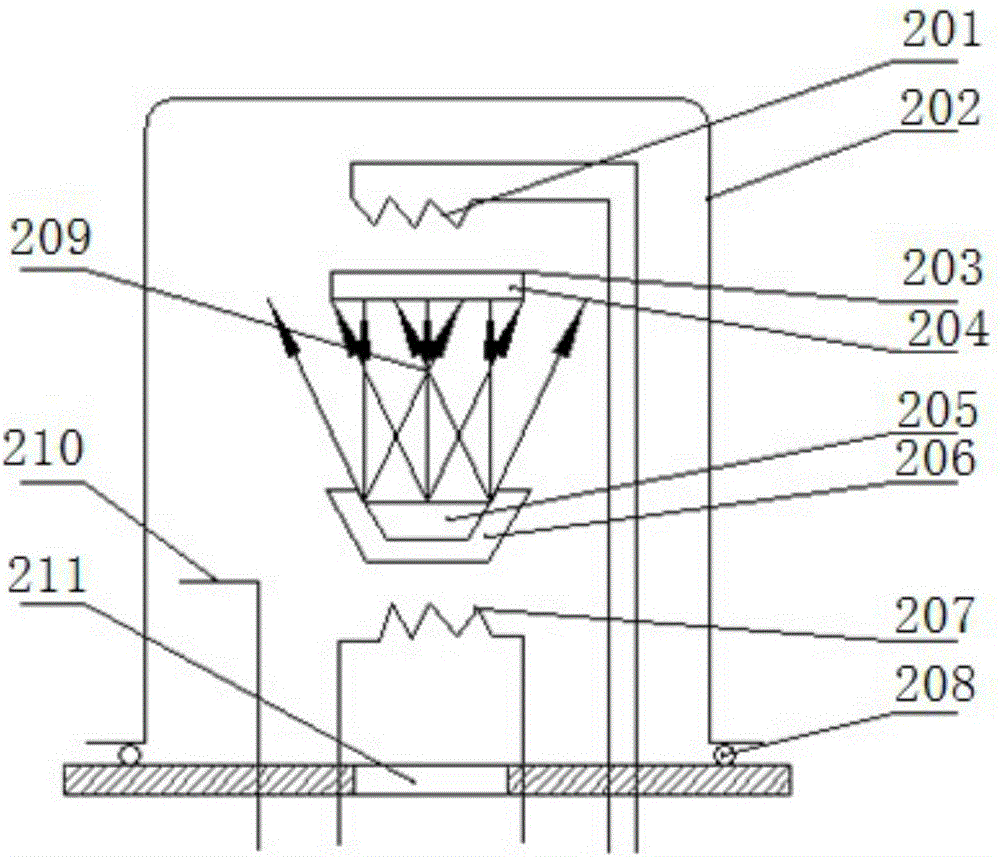

[0060] refer to image 3 The difference between this embodiment and Embodiment 1 is that the vacuum coating process is a vacuum evaporation coating process.

[0061] First, the rod body 204 is placed on the substrate frame 203, and the substrate frame 203 rotates at a constant speed during coating, and a substrate heating device 201 is arranged above the substrate frame 203, and the ceramic film material is placed in the evaporation boat 206, and the ceramic film material placed in the image 3 The position of the middle membrane material 205 shows that the coating chamber 202 is pumped to the working pressure, and the ceramic membrane material in the evaporation boat 206 is heated by the evaporation boat heating device 207, so that the evaporated atoms and molecules escape from the surface of the membrane material and directly reach the On the surface of the rod body 204 installed on the substrate frame 203 (the steam flow 209 is indicated by the arrow in the figure), due to...

Embodiment 3

[0064] refer to Figure 4 The difference between this embodiment and Embodiment 1 is that the vacuum coating process is a vacuum sputtering coating process, preferably a magnetron sputtering coating process.

[0065] Specifically, in the coating chamber 303, the rod body is placed on the substrate holder 301, the metal target and the ceramic target are installed on the target position 308, the metal target and the ceramic target are located under the substrate holder 301, and the heating device 302 is used to Heating metal / ceramic targets. Firstly, the ceramic target is facing the substrate frame 301, and the base distance of the target is adjusted to the set distance, and then the coating chamber 303 is pumped by the pumping system 304, and after reaching the background vacuum degree, the working gas is introduced by the pumping system 307 , after reaching the working pressure of 1.0-2.0Pa, turn on the heating power supply 305 and the negative high-voltage power supply 306, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com