Boron carbide reinforced foamed aluminum composite material and preparation method thereof

An aluminum composite material and reinforced foam technology, applied in the field of materials, can solve the problems of process equipment sealing, high pressure requirements, complex process, high production cost, etc., and achieve excellent vibration and noise reduction and energy absorption, High wear resistance and strong neutron radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

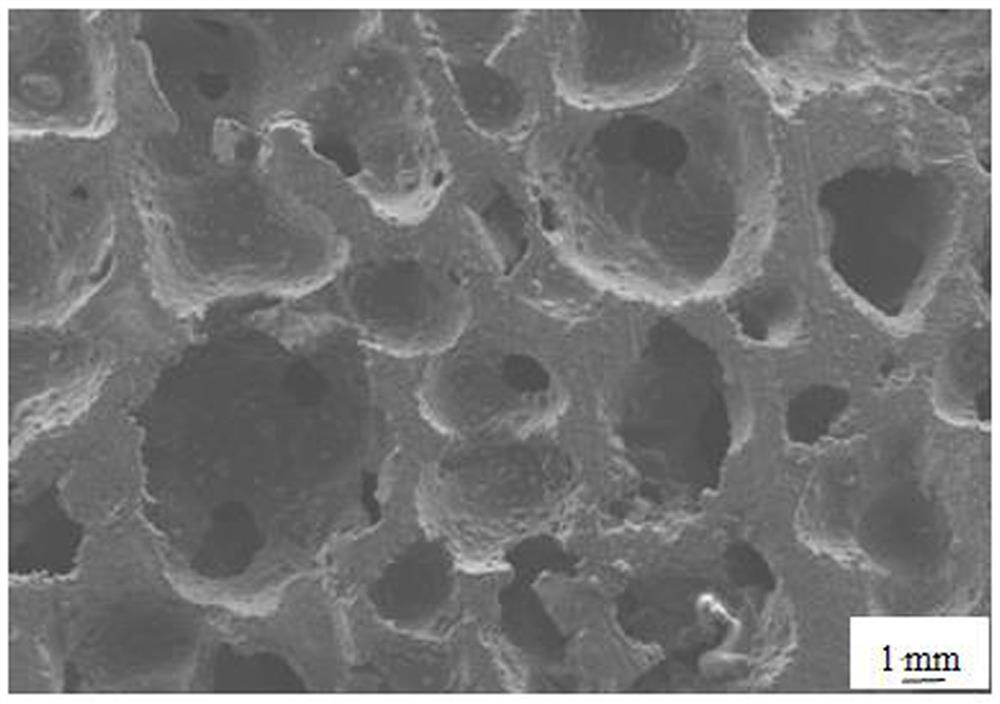

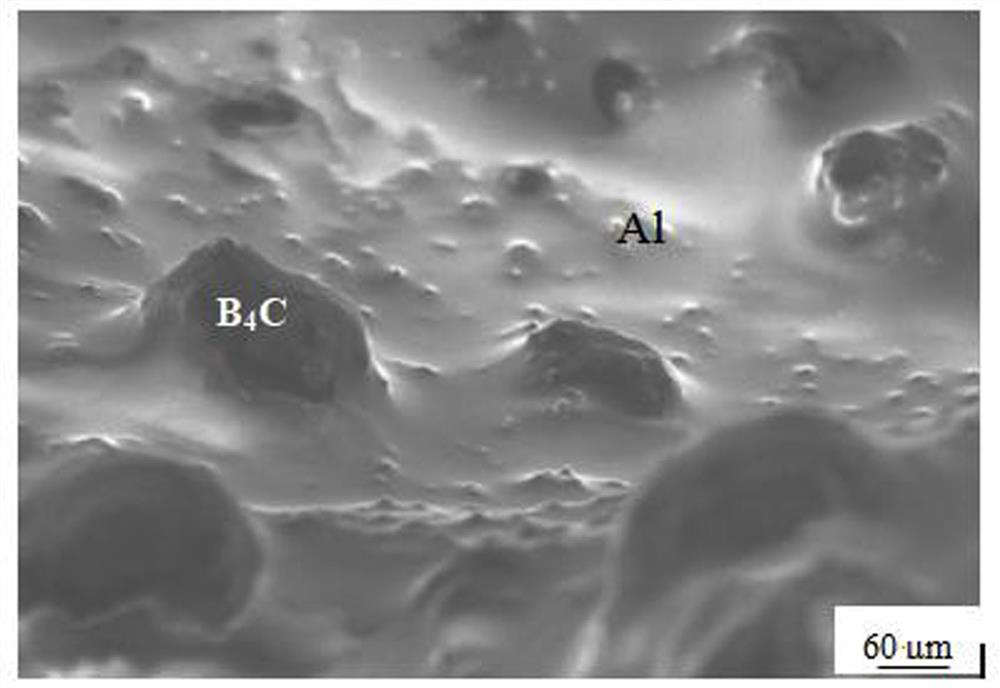

[0033] A preparation method of boron carbide reinforced aluminum foam composite material, comprising the following steps:

[0034] Step 1. Take B 4 The C powder, the 6061 aluminum alloy powder and the Ti powder are mechanically stirred and mixed uniformly to obtain a mixed powder.

[0035] Step 2: Weigh isocyanate, polyether polyol and dimethyl silicone oil, mix the above solvent with the mixed powder in step 1 and then mechanically stir to obtain a mixed slurry.

[0036] Step 3. Add the catalyst to the mixed slurry in Step 2. When the viscosity of the system increases and before the phenomenon of "climbing the pole" occurs, add deionized water, stir quickly, stop stirring, and let it stand at room temperature to complete the foaming, and let it stand for 24 minutes. hours, the preform preparation is complete.

[0037] Step 4. Put the preform into a debinding furnace for debinding and sintering to obtain a boron carbide reinforced aluminum foam composite material.

[0038] ...

Embodiment 1

[0054] A preparation method of a ceramic particle reinforced foamed aluminum composite material, the steps are as follows:

[0055] 1. Take the average particle size as 5μmB 4 12.2 g of C powder, 46.85 g of 6061 aluminum alloy powder with an average particle size of 38 μm, and 1.75 g of Ti powder with an average particle size of 5 μm were mixed uniformly by mechanical stirring to obtain a mixed powder.

[0056] 2. Weigh 17.1g of isocyanate PM200, 15.6g of polyether polyol R2305 and 0.09g of dimethicone, mix the above solvent with the mixed powder and mechanically stir for 300r / min×5min to obtain a mixed slurry.

[0057] 3. To the mixed slurry, add dibutyltin dilaurate T-12 and triethylenediamine A33 in a total of 0.09g, wherein T-12 is 0.0675g and A33 is 0.0225g. When the viscosity of the system increases, and before the phenomenon of "climbing the rod" occurs, add deionized water, stir rapidly at 700r / min×10s, stop stirring, and let it stand at room temperature to complete t...

Embodiment 2

[0061] A preparation method of a ceramic particle reinforced foamed aluminum composite material, the steps are as follows:

[0062] 1. Take the average particle size as 5μmB 4 8.6 g of C powder, 47.52 g of 6061 aluminum alloy powder with an average particle size of 38 μm, and 1.08 g of Ti powder with an average particle size of 5 μm were mixed uniformly by mechanical stirring to obtain a mixed powder.

[0063] 2. Weigh 16.1g of isocyanate PM200, 14.7g of polyether polyol R2305 and 0.087g of dimethicone, mix the above solvent with the mixed powder and mechanically stir for 300r / min×5min to obtain a mixed slurry.

[0064] 3. Add dibutyltin dilaurate T-12 and triethylenediamine A33 to the mixed slurry in a total of 0.087g, wherein T-12 is 0.06525g and A33 is 0.02175g. When the viscosity of the system increases, and before the phenomenon of "climbing the rod" occurs, add deionized water, stir rapidly at 700r / min×10s, stop stirring, and let it stand at room temperature to complete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com