Preparation method of metal material surface deformation layer transmission electron microscope sample

A technology for transmission electron microscope samples and metal materials, which is applied in the field of metal material transmission electron microscope sample preparation, can solve the problems of low cost and difficulty in preparing metal material surface deformation layer transmission electron microscope samples by electrochemical double-spraying method, and achieves low cost and excellent preparation process. Ease of use and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

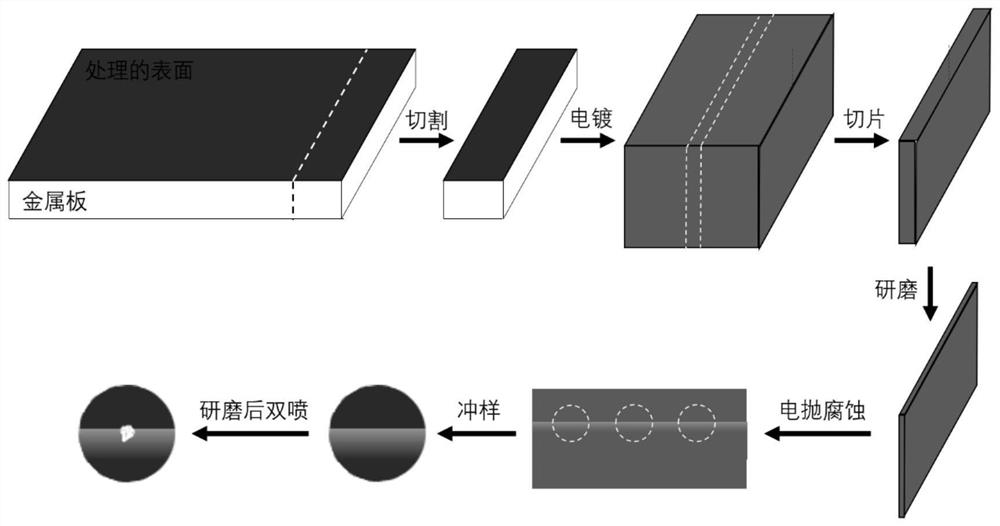

[0023] (1) From the pure copper plate after surface treatment, cut 10x10mm squares by wire cutting, and carry out alkali cleaning and pickling activation treatment;

[0024] (2) Place the activated square sample in the electroplating pool to electroplate the outer cladding layer. The electroplating solution formula is CuSO4 aqueous solution, the Cu2+ concentration is about 80g / ml, and the pH value is about 4; the pure copper plate is used as the anode plate , Constant current control, current density 35mA / cm2, electroplating at room temperature, electromagnetic stirring.

[0025] (3) Cutting and grinding: wire electric discharge cutting is adopted, perpendicular to the treatment surface, and the thickness is 1mm. Sandpaper was used to mechanically grind to a thickness of 60 μm.

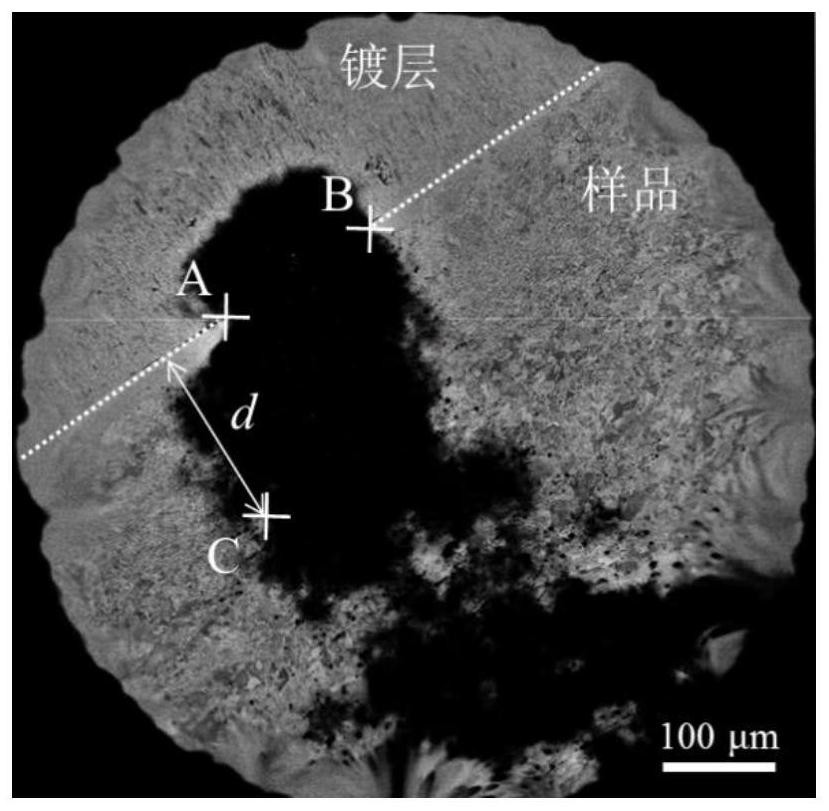

[0026] (4) Electrochemical polishing and corrosion of the electroplating interface: Use pointed stainless steel tweezers to hold the ground thin slice sample, connect the tweezers to the positive pol...

Embodiment 2

[0032] (1) From the surface-treated copper-aluminum alloy (Cu-11w.t.%Al) plate, cut 8x8mm squares by wire cutting, and carry out alkali cleaning and pickling activation treatment;

[0033] (2) the square sample after the activation is placed in the electroplating pool, and the outer cladding layer is electroplated; the electroplating solution formula is CuSO4 aqueous solution, Cu2 + concentration is about 60g / ml, and the pH value is about 3; the pure copper plate is used as the anode plate, Constant current control, current density 25mA / cm2, electroplating at room temperature, electromagnetic stirring;

[0034] (3) Cutting and grinding: use electric discharge wire cutting, perpendicular to the surface to be treated, thin slices with a thickness of 1 mm, and use sandpaper to mechanically grind to a thickness of 80 μm;

[0035] (4) Electrochemical polishing and corrosion of the electroplating interface: use pointed stainless steel tweezers to hold the ground thin slice sample, c...

Embodiment 3

[0041] (1) From the IF steel plate after surface treatment, cut 5x5mm squares by wire cutting, and carry out alkali cleaning and pickling activation treatment;

[0042] (2) the square sample after the activation is placed in the electroplating pool, and the outer cladding layer is electroplated; the electroplating solution formula is CuSO4 aqueous solution, Cu2 + concentration is about 50g / ml, and the pH value is about 3; the pure copper plate is used as the anode plate, Constant current control, current density 30mA / cm2, electroplating at room temperature, electromagnetic stirring;

[0043] (3) Cutting and grinding: use electric discharge wire cutting, perpendicular to the surface to be treated, thin slices with a thickness of 1 mm, use sandpaper, and mechanically grind to a thickness of 100 μm;

[0044] (4) Electrochemical polishing and corrosion of the electroplating interface: use pointed stainless steel tweezers to hold the ground thin slice sample, connect the tweezers t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com