High-temperature porcelain and preparation method thereof

A technology of high-temperature porcelain and kaolin, which is applied in the field of ceramic materials, can solve problems such as poor high-temperature deformation resistance, poor mechanical strength, formula improvement and design difficulties, and achieve the effects of improving mechanical strength, thermal stability and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The present invention also provides a method for preparing high-temperature porcelain described in the above technical solution, comprising the following steps:

[0059] a) mixing the material with water and ball milling to obtain mud;

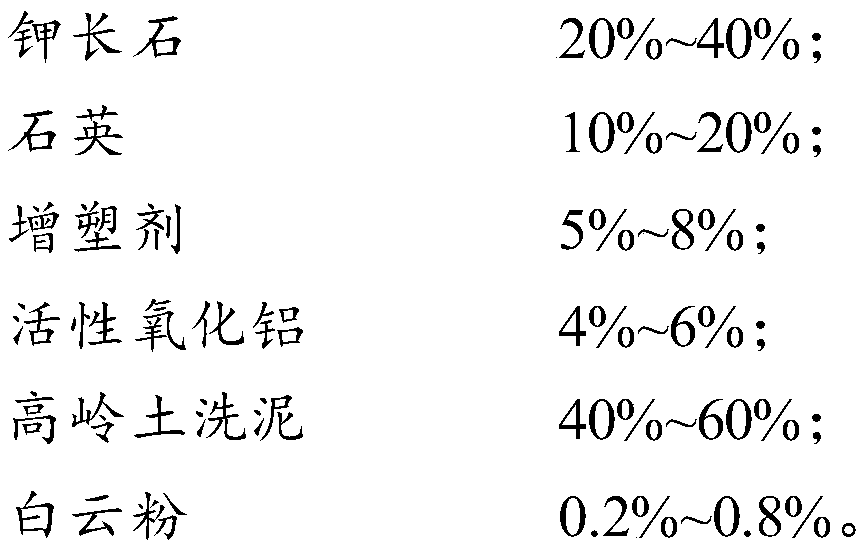

[0060] The materials include potassium feldspar, quartz, plasticizer, activated alumina, kaolin washing mud and dolomite;

[0061] b) refining and molding the mud to obtain a green body;

[0062] c) firing the green body to obtain high-temperature porcelain.

[0063] According to the present invention, the materials are first mixed with water and ball-milled to obtain mud.

[0064] Wherein, the materials include potassium feldspar, quartz, plasticizer, activated alumina, kaolin washing mud and dolomite; the types and dosages of each material are consistent with those described in the above technical scheme, and will not be described here one by one. repeat.

[0065] In the present invention, the mass ratio of the material to water i...

Embodiment 1

[0077] (1) Raw material formula:

[0078] Potassium feldspar 20%, quartz 20%, plasticizer 5%, activated alumina 4%, kaolin washing mud 50.8%, dolomite powder 0.2%.

[0079] (2) Preparation:

[0080] S1. Mixing and ball milling:

[0081] Pour the raw materials into the ball mill tank according to the above ratio, and add water in the ratio of material:water ratio=1:0.8; the ball milling medium uses high alumina ball stone, and add it according to the gradation of large:medium:small=1:2:1 , the volume of the ball stone added is 1 / 3 of the volume of the ball mill jar.

[0082] A 10Kg ball mill jar was used for ball milling, the raw material load was 6Kg, the ball milling speed was 61r / min, and the time was 18h.

[0083] After ball milling, discharge the mud, sieve (220 mesh national standard steel sieve), and remove iron.

[0084] S2. Practicing mud and molding:

[0085] The mud is squeezed into mud cakes through a mud press, and then made into mud bars through a mud trainer...

Embodiment 2

[0095] (1) Raw material formula:

[0096] Potassium feldspar 21%, quartz 20%, plasticizer 7%, activated alumina 5%, kaolin washing mud 46.5%, dolomite powder 0.5%.

[0097] (2) Preparation:

[0098] S1. Mixing and ball milling:

[0099] Pour the raw materials into the ball mill tank according to the above ratio, and add water in the ratio of material:water ratio=1:0.8; the ball milling medium uses high alumina ball stone, and add it according to the gradation of large:medium:small=1:2:1 , the volume of the ball stone added is 1 / 3 of the volume of the ball mill jar.

[0100] A 10Kg ball mill jar was used for ball milling, the raw material load was 6Kg, the ball milling speed was 61r / min, and the time was 18h.

[0101] After ball milling, discharge the mud, sieve (220 mesh national standard steel sieve), and remove iron.

[0102] S2. Practicing mud and molding:

[0103] The mud is squeezed into mud cakes through a mud press, and then made into mud bars through a mud trainer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com