Separating and washing method of red mud by Bayer process

A technology of Bayer method red mud and washing method, which is applied in the field of process improvement, can solve problems such as difficulty in separation of red mud, limit the improvement of production efficiency, etc., and achieve the effect of ensuring production and increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

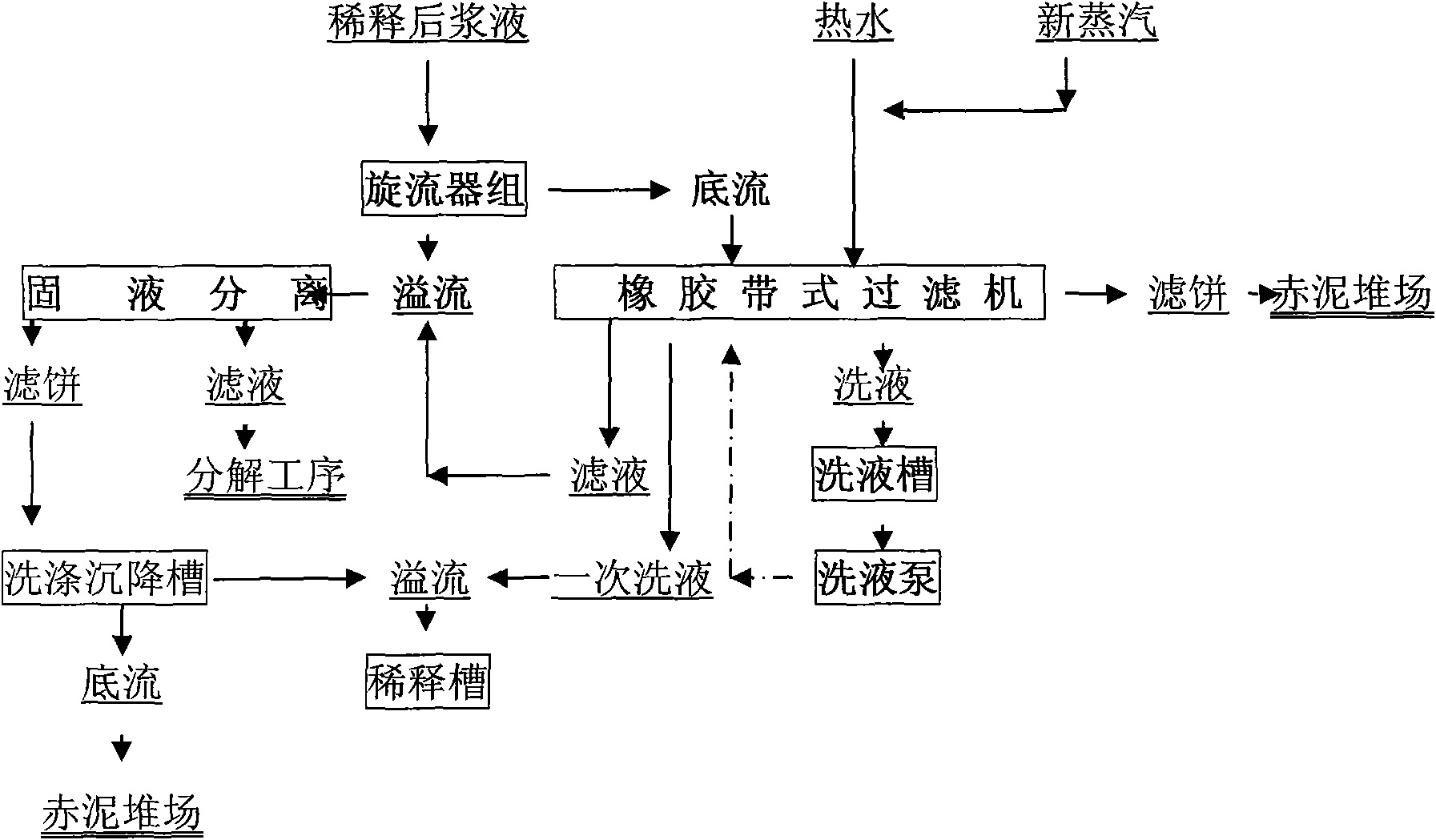

Image

Examples

Embodiment 1

[0016] The diluted slurry has a solid content of 10g / l, caustic Na 2 o K The concentration is 140g / l, pump the diluted slurry into the cyclone group, the solid content of the underflow is 90g / l, and the solid content of the overflow is 5g / l. The underflow of the cyclone enters the rubber belt filter for filtration and washing, the filtrate is mixed with the overflow of the cyclone, and the red mud filter cake is sent to the red mud stockpile; the overflow of the cyclone is pumped into the high-efficiency solid-liquid separator, and the filtrate is solid If the content is lower than 30-15mg / l, it is the sodium aluminate refining solution to decompose; the filter cake is washed in the washing settling tank, and then discharged to the red mud stockpile after washing.

Embodiment 2

[0018] After dilution, the solid content of the slurry is about 250g / l, and the caustic Na 2 o K The concentration is 250g / l, pump the diluted slurry into the cyclone group, the solid content of the underflow is 400g / l, and the solid content of the overflow is 50-200g / l. The underflow of the cyclone enters the rubber belt filter for filtration and washing, the filtrate is mixed with the overflow of the cyclone, and the red mud filter cake is sent to the red mud stockpile; the overflow of the cyclone is pumped into the high-efficiency solid-liquid separator, and the filtrate is solid If the content is lower than 30mg / l, it is the decomposing process of the sodium aluminate refining solution; the filter cake is washed in the washing and settling tank, and then discharged to the red mud stockpile after washing.

Embodiment 3

[0020] After dilution, the solid content of the slurry is about 80g / l, and the caustic Na 2 o K The concentration is 200g / l. Pump the diluted slurry into the cyclone group, the solid content of the underflow is 200g / l, and the solid content of the overflow is 100g / l. The underflow of the cyclone enters the rubber belt filter for filtration and washing, the filtrate is mixed with the overflow of the cyclone, and the red mud filter cake is sent to the red mud stockpile; the overflow of the cyclone is pumped into the high-efficiency solid-liquid separator, and the filtrate is solid If the content is lower than 30mg / l, it is the decomposing process of the sodium aluminate refining solution; the filter cake is washed in the washing and settling tank, and then discharged to the red mud stockpile after washing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com