A kind of far-infrared fiber used for physiotherapy travel pad and preparation method thereof

A technology of far-infrared fiber and solution, which is applied in the field of far-infrared fiber of physiotherapy travel mat and its preparation, can solve the problems of poor antibacterial effect and poor durability, and achieve the effect of long action time, good durability and alleviating human fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

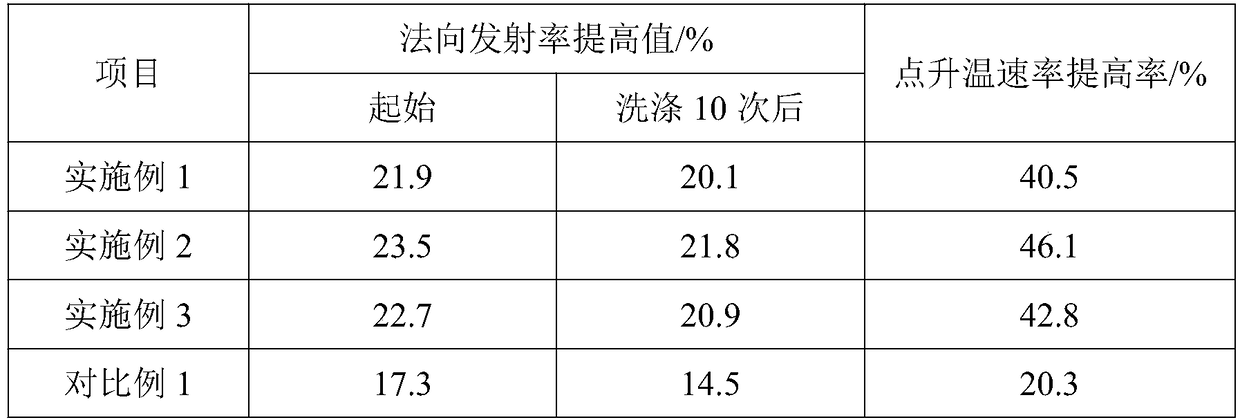

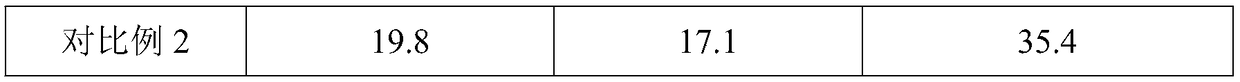

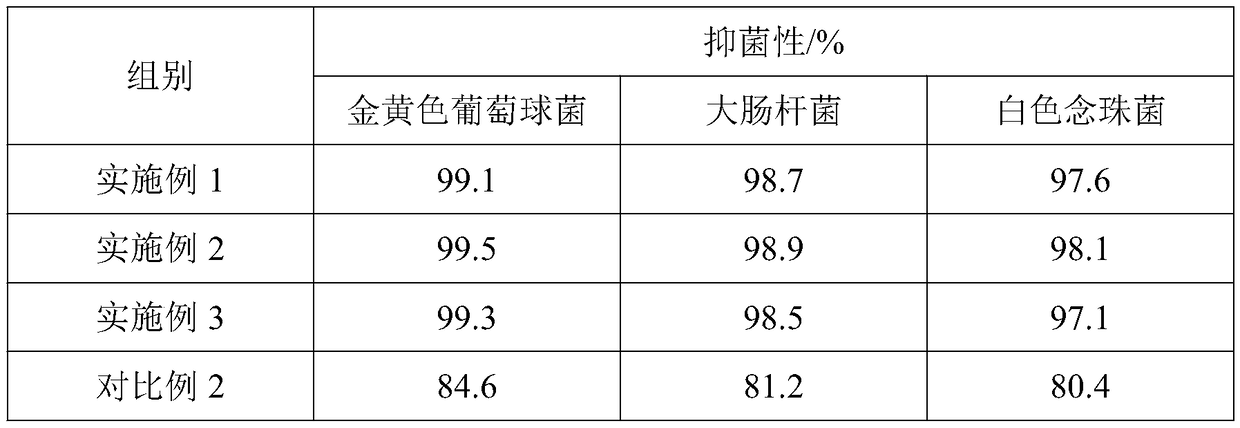

Examples

Embodiment 1

[0027] Embodiment 1 A kind of preparation of the far-infrared fiber that is used for physiotherapy travel mat

[0028] S1 Add 25g of chitosan to 250mL of 30% sodium hydroxide solution, heat to 100°C, stir for 2 hours, centrifuge and wash with water until the solution is neutral to obtain deacetylated chitosan;

[0029] S2 Add the deacetylated chitosan obtained in step S1 into 50mL of isopropanol, stir, gradually heat to 70°C, and then add 2,3-epoxypropyltrimethylammonium chloride solution with a mass concentration of 60% , wherein the mass ratio of deacetylated chitosan to 2,3-epoxypropyltrimethylammonium chloride solution is 1:3, stirred and reacted for 8h, added 150mL acetone to precipitate after the reaction, separated, washed, dried, Get hydroxypropyl trimethyl ammonium chloride chitosan;

[0030] S3 heats the sodium thiocyanate aqueous solution that mass concentration is 40% to 70 ℃, stirs and adds step S2 obtained hydroxypropyltrimethylammonium chloride chitosan and pol...

Embodiment 2

[0034] Embodiment 2 A kind of preparation of the far-infrared fiber that is used for physiotherapy travel mat

[0035] S1 Add 25g of chitosan to 250mL of 30% sodium hydroxide solution, heat to 115°C, stir for 2.5h, centrifuge and wash with water until the solution is neutral to obtain deacetylated chitosan;

[0036] S2 Add the deacetylated chitosan obtained in step S1 to 50mL of isopropanol, stir, gradually heat to 80°C, and then add 2,3-epoxypropyltrimethylammonium chloride solution with a mass concentration of 70% , wherein the mass ratio of deacetylated chitosan to 2,3-epoxypropyltrimethylammonium chloride solution is 1:4, stirring and reacting for 11h, adding 150mL acetone to precipitate after the reaction, separating, washing, drying, Get hydroxypropyl trimethyl ammonium chloride chitosan;

[0037] S3 heats the sodium thiocyanate aqueous solution that mass concentration is 50% to 80 ℃, stirs and adds step S2 obtained hydroxypropyltrimethylammonium chloride chitosan and p...

Embodiment 3

[0041] Embodiment 3 A kind of preparation of the far-infrared fiber that is used for physiotherapy travel mat

[0042] S1 Add 25g of chitosan to 250mL of 30% sodium hydroxide solution, heat to 130°C, stir for 3 hours, centrifuge and wash with water until the solution is neutral to obtain deacetylated chitosan;

[0043] S2 Add the deacetylated chitosan obtained in step S1 into 50mL of isopropanol, stir, gradually heat to 90°C, and then add 2,3-epoxypropyltrimethylammonium chloride solution with a mass concentration of 80% , wherein the mass ratio of deacetylated chitosan to 2,3-epoxypropyltrimethylammonium chloride solution is 1:5, stirred and reacted for 14h, added 150mL of acetone to precipitate after the reaction, separated, washed, dried, Get hydroxypropyl trimethyl ammonium chloride chitosan;

[0044] In S3, the sodium thiocyanate aqueous solution with a mass concentration of 60% is heated to 90°C, and the hydroxypropyltrimethylammonium chloride chitosan and polyacrylonit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com