Electrothermal element

A technology of electric heating body and electrode, which is applied in the direction of ohmic resistance heating parts, ohmic resistance electrodes, heating element materials, etc., which can solve the problems of low strength, easy damage, and inconspicuous far-infrared effect, etc., so as to prolong the service life and the scope of application The effect of large, increased strength and ability to resist shear forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, specifically illustrate the present invention:

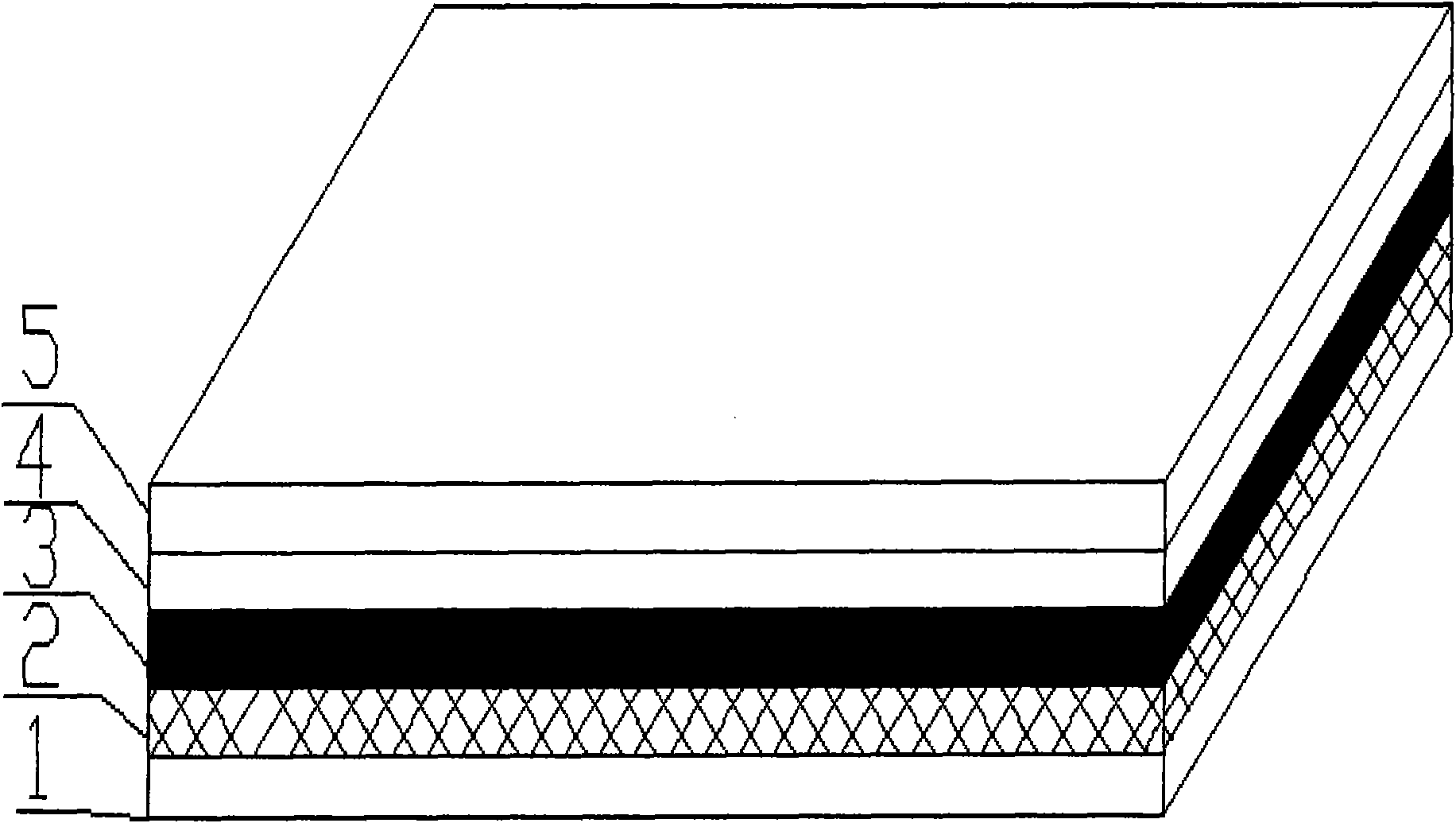

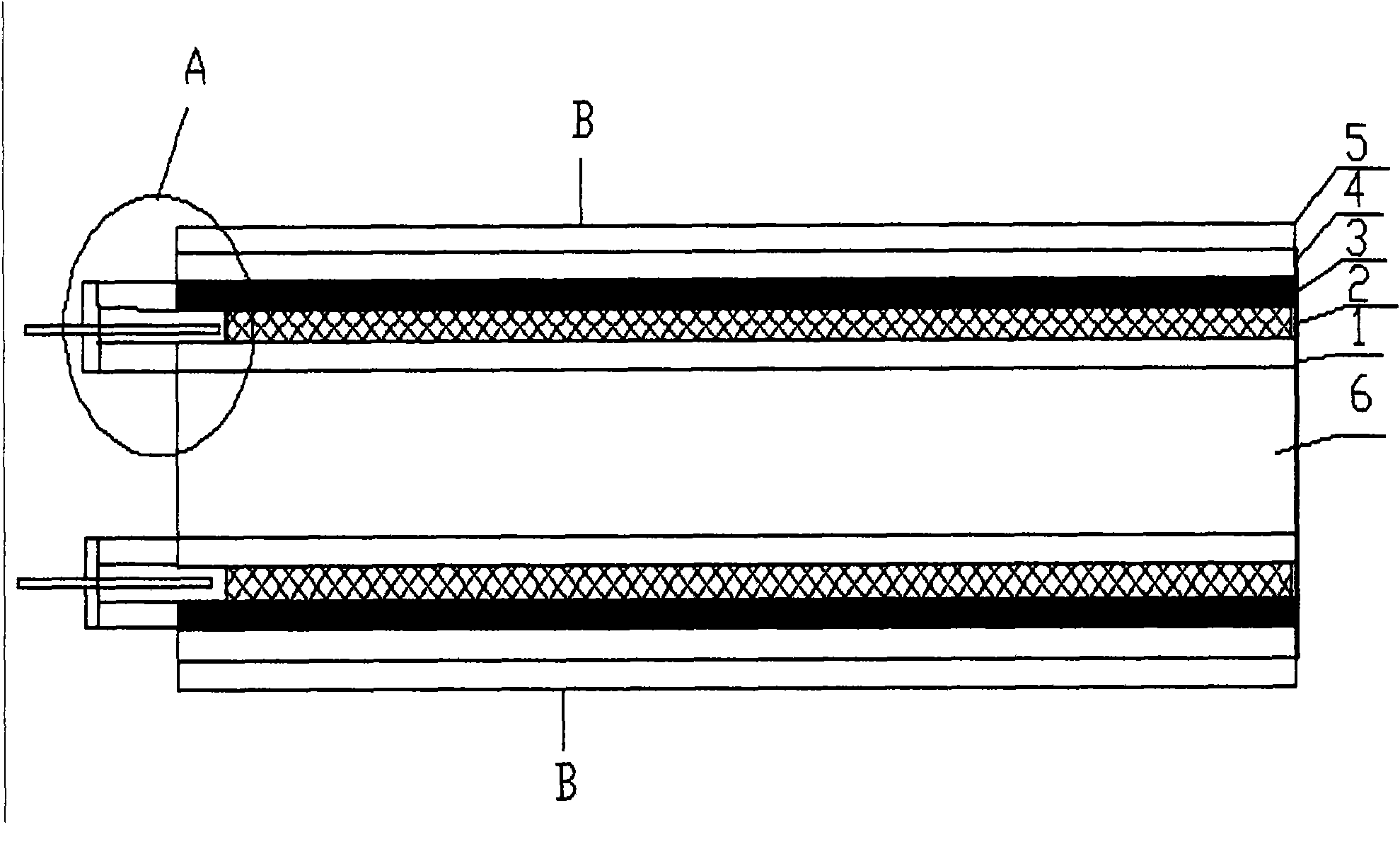

[0031] Such as figure 1 with figure 2 Shown are the plate and tube structures of a carbon fiber electric heating body of the present invention, including the bottom heat dissipation layer (1) and the carbon fiber layer (2) on the upper layer, heat insulation layer (4) and The casing (5), the electric heating body is in the shape of a tube or a plate, and of course it can also be in any other shape. If the carbon fiber electric heater is tubular, there will be a through hole (6) in the heat dissipation layer (1) at the bottom, which can allow water to pass through and heat the water through the heat dissipation layer (1). The heat dissipation layer (1) is made of quartz glass or ceramic cloth.

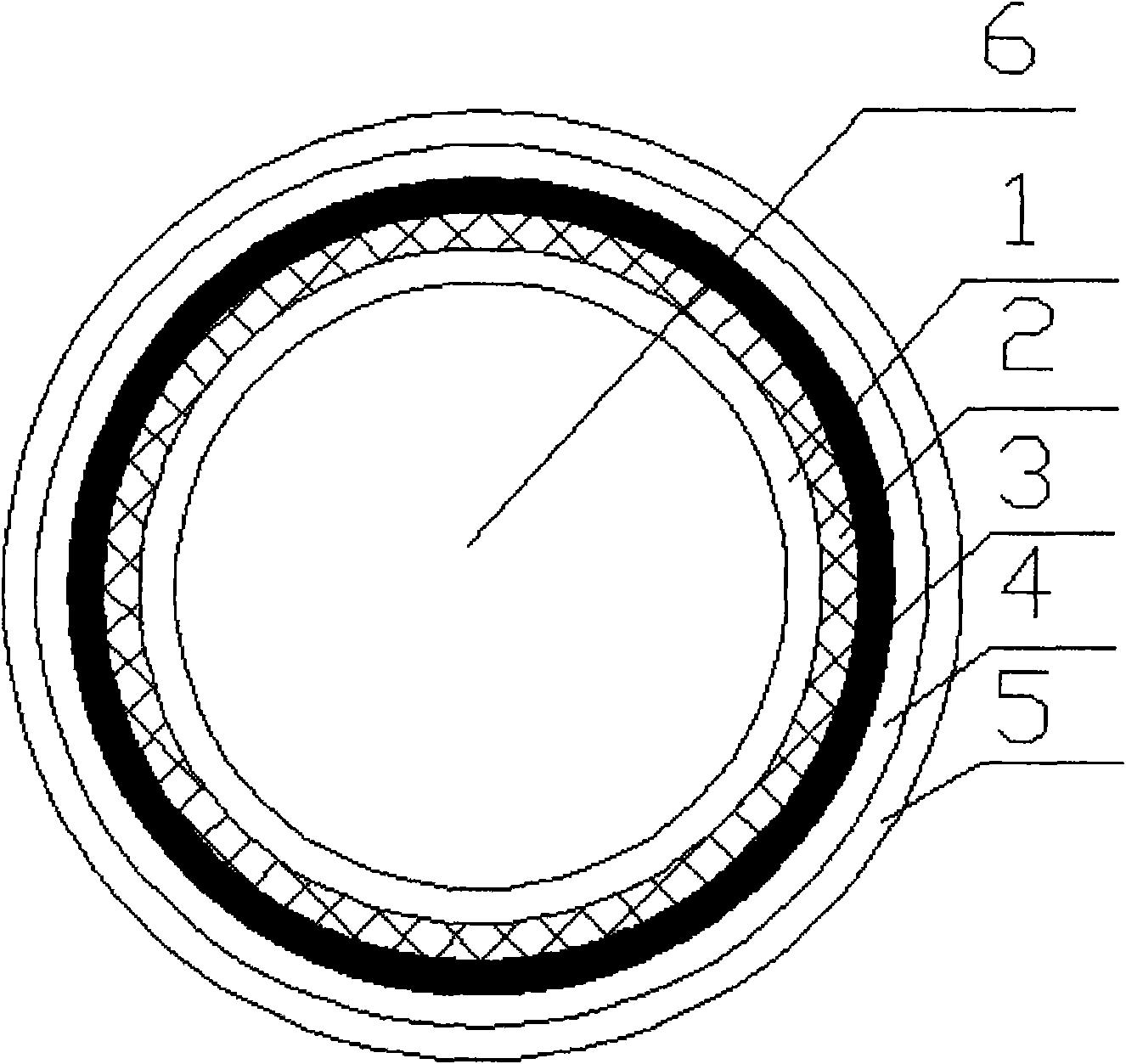

[0032] image 3 It is a B-B cross-sectional view of a tubular structure of a carbon fiber electric heating element in the present invention, and there is a solidified layer (3) b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com