Inorganic non-metal far-infrared graphite resistive film, and preparation method and application thereof

An inorganic non-metallic and graphite resistance technology, applied in the direction of ohmic resistance heating, electric heating devices, electrical components, etc., can solve the problems affecting the ecological environment and human health, poor adhesion and thermal stability, unsuitable for civilian use, etc., to achieve Excellent electrical comprehensive performance and far-infrared performance, improved stability, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Correspondingly, an embodiment of the present invention provides a method for preparing an inorganic non-metallic far-infrared graphite resistance film, comprising the following steps:

[0056] S01. take each component according to the formula of above-mentioned inorganic non-metallic far-infrared graphite resistance film;

[0057] S02. Heat and melt bismuth oxide, zinc oxide, antimony trioxide, boric acid, aluminum oxide, strontium carbonate, magnesium oxide, quartz sand, lithium carbonate, grind and sieve after cooling, add graphite powder, ultrafine mica powder, Far-infrared ceramic powder is mixed to obtain a base material mixture;

[0058] S03. In the substrate mixture, add an organic medium according to the weight ratio of the substrate mixture to the organic medium (1365-2355): (2320-4946), and mix to obtain a mixed slurry;

[0059] S04. Provide a substrate, print the mixed slurry on the substrate, perform drying and sintering treatment, and obtain an inorganic ...

Embodiment 1

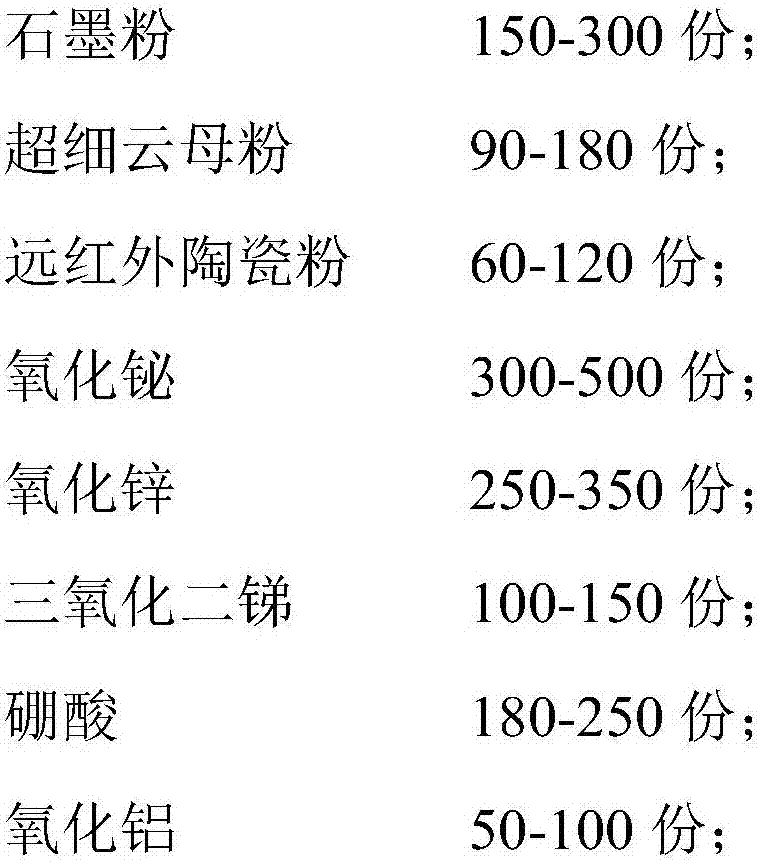

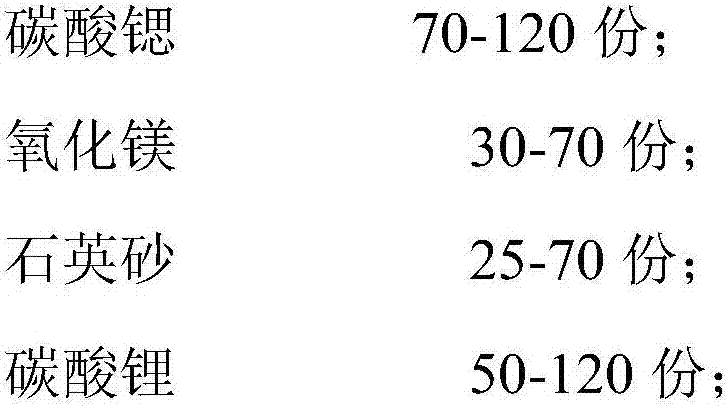

[0072] A kind of inorganic non-metallic far-infrared graphite resistance film (about 2000 grams), is made of base material and liquid medium, and described base material is made up of following raw material of following weight:

[0073]

[0074] The organic medium is a liquid organic medium composed of the following components in the following weight percentages:

[0075] Terpineol 85% by weight;

[0076] Ethylcellulose 9% by weight;

[0077] 6% by weight silane coupling agent,

[0078] The total weight is 3400g-4200g.

[0079] The preparation method of described inorganic non-metallic far-infrared graphite resistance film, comprises the following steps:

[0080] S11. take each component according to the formula of above-mentioned inorganic non-metallic far-infrared graphite resistance film;

[0081] S12. Stir bismuth oxide, zinc oxide, antimony trioxide, boric acid, aluminum oxide, strontium carbonate, magnesium oxide, quartz sand, and lithium carbonate in a mixer, and...

Embodiment 2

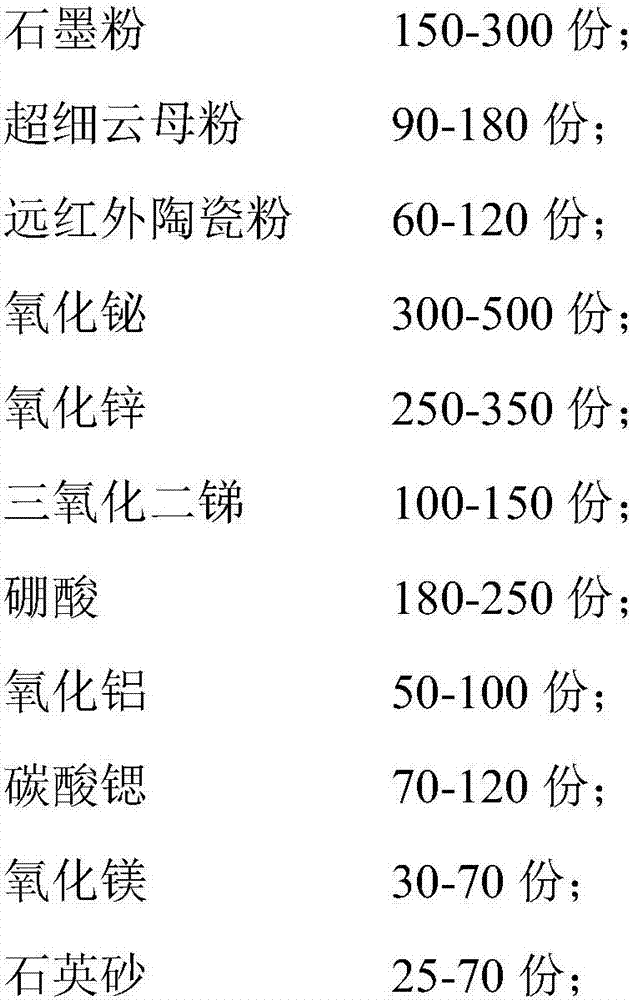

[0087] In embodiment 2, described base material is made up of following raw material of following weight:

[0088]

[0089] The organic medium is a liquid organic medium composed of the following components in the following weight percentages:

[0090] Terpineol 88% by weight;

[0091] Ethylcellulose 8% by weight;

[0092] 4% by weight silane coupling agent.

[0093] Others were all tested according to the conditions of Example 1, and the substantially identical results of Example 1 were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Gross weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com