Compact spinning lattice apron anti-blocking fiber removal system

A lattice ring and compact spinning technology, applied in the field of compact spinning lattice ring anti-blocking and fiber removal system, can solve problems such as rise and quality fluctuation, and achieve the effect of avoiding shutdown for cleaning, increasing energy consumption, and preventing clogging of mesh holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

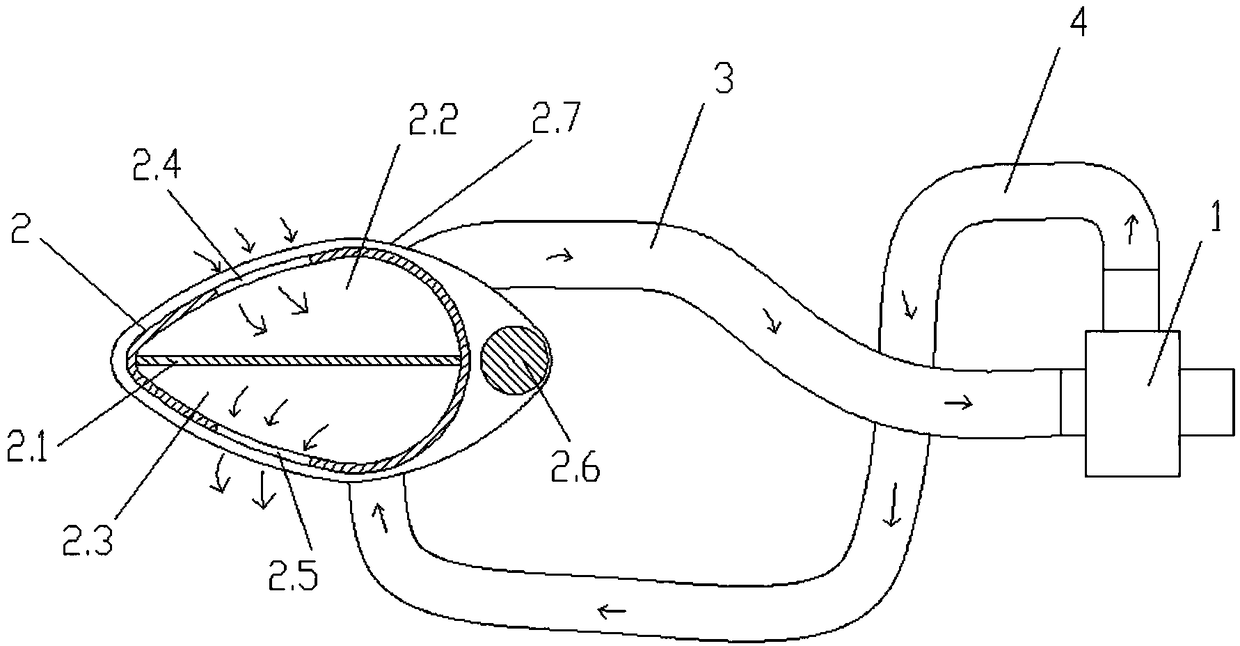

[0012] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0013] Such as figure 1 As shown, a compact spinning mesh circle anti-blocking defibrillation system includes a fan 1, an air duct 2, a suction hose 3 and an exhaust hose 4, and the air duct 2 is provided with an air duct partition 2.1, The air duct partition 2.1 divides the air duct 2 into an air suction chamber 2.2 and an air supply chamber 2.3; one end of the air suction hose 3 communicates with the air suction chamber 2.2, and the other end communicates with the fan 1 is communicated with the air inlet end; one end of the exhaust hose 4 is communicated with the air supply chamber 2.3, and the other end is communicated with the air outlet end of the fan 1; 2.2 A suction slot 2.4 in communication; the blower 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com