Patents

Literature

58results about How to "No need to increase energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal-cycle continuous pyrolysis-gasification comprehensive device for coal gangues

ActiveCN103205278ASignificant environmental benefitsGood economic valueIndirect and direct heating destructive distillationGas purification with selectively adsorptive solidsExhaust fumesProcess engineering

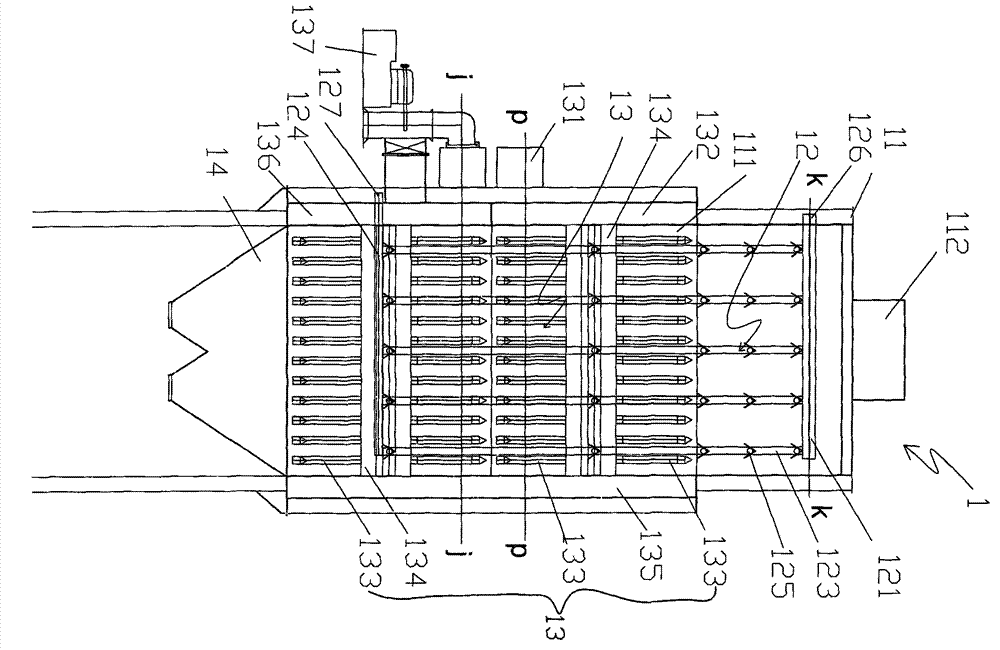

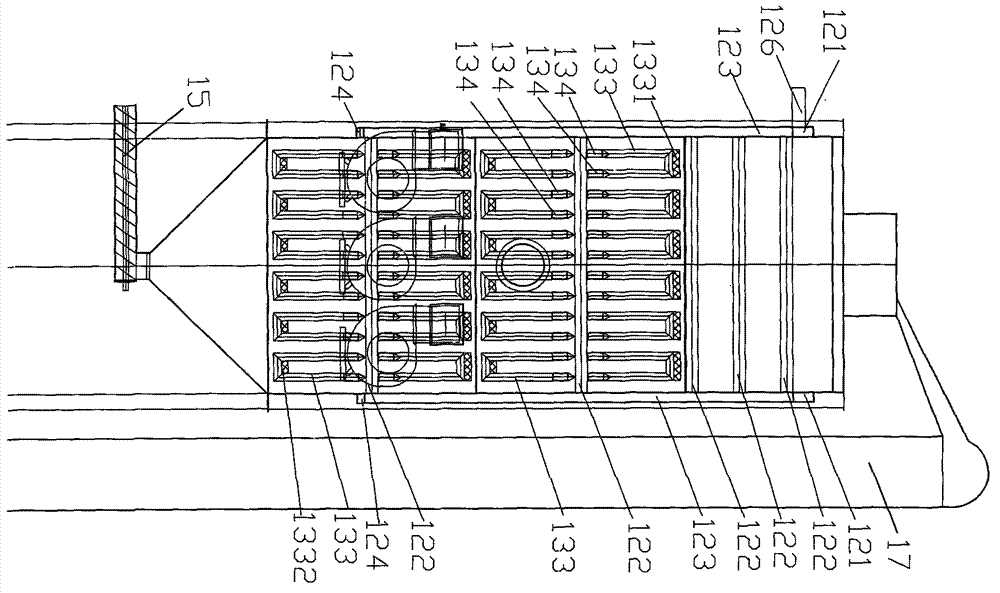

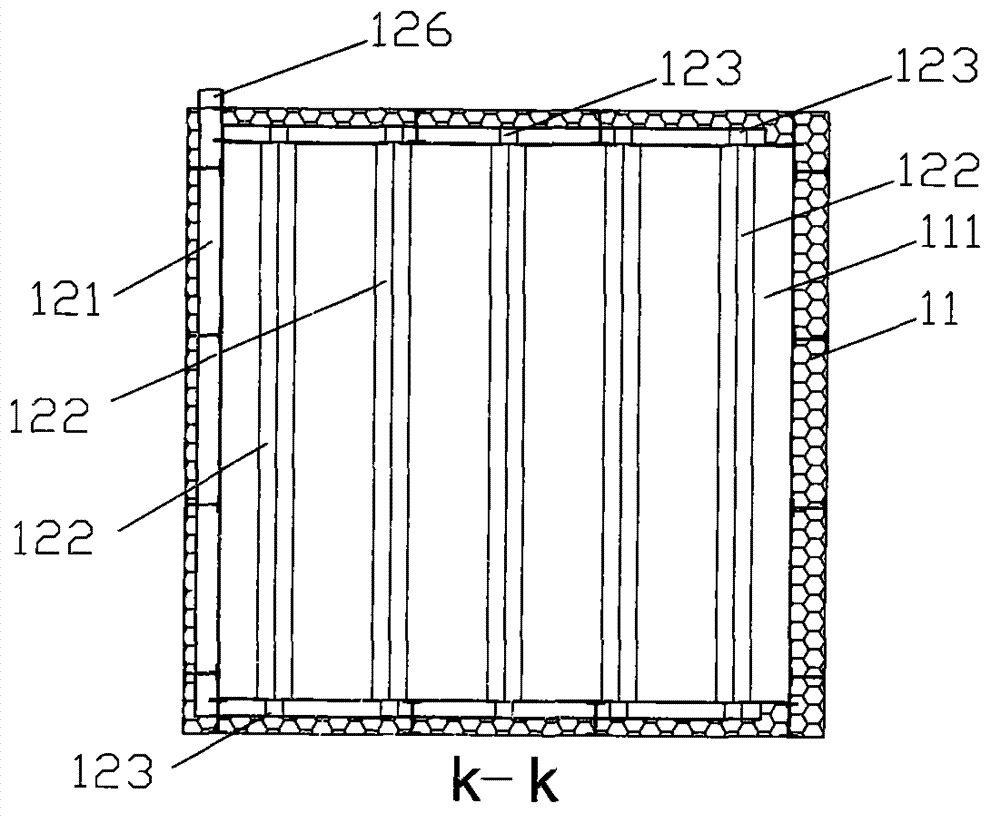

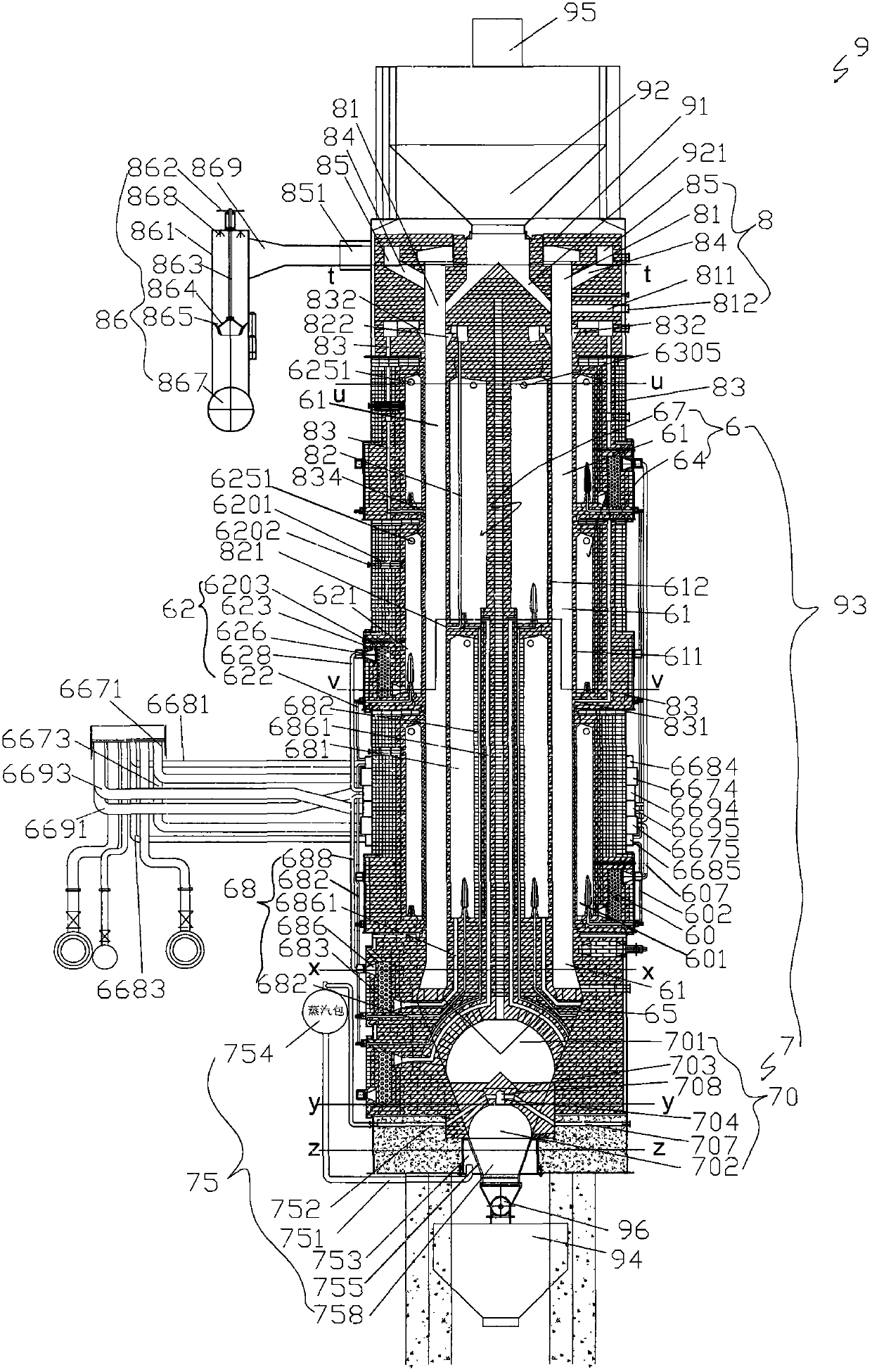

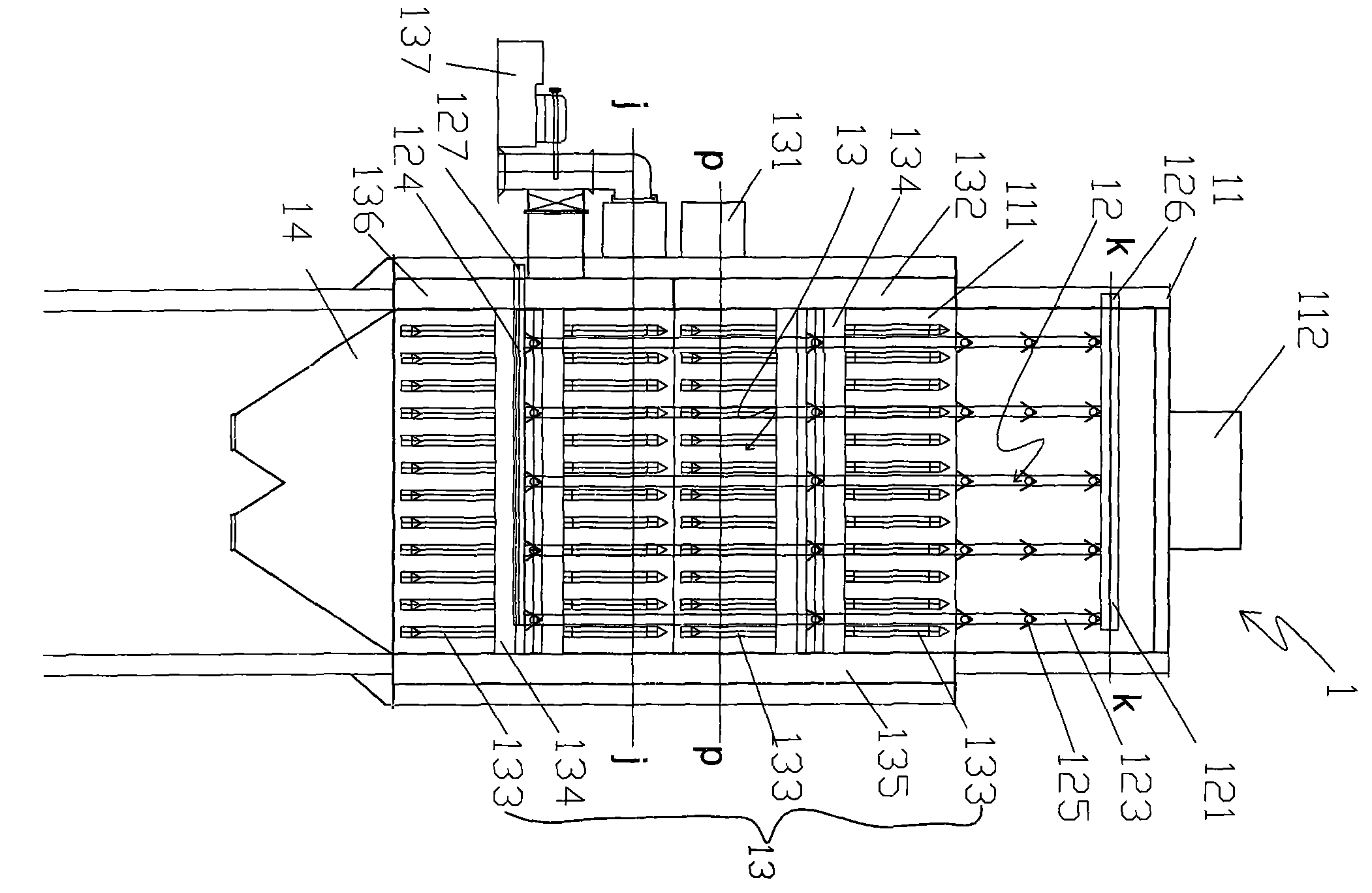

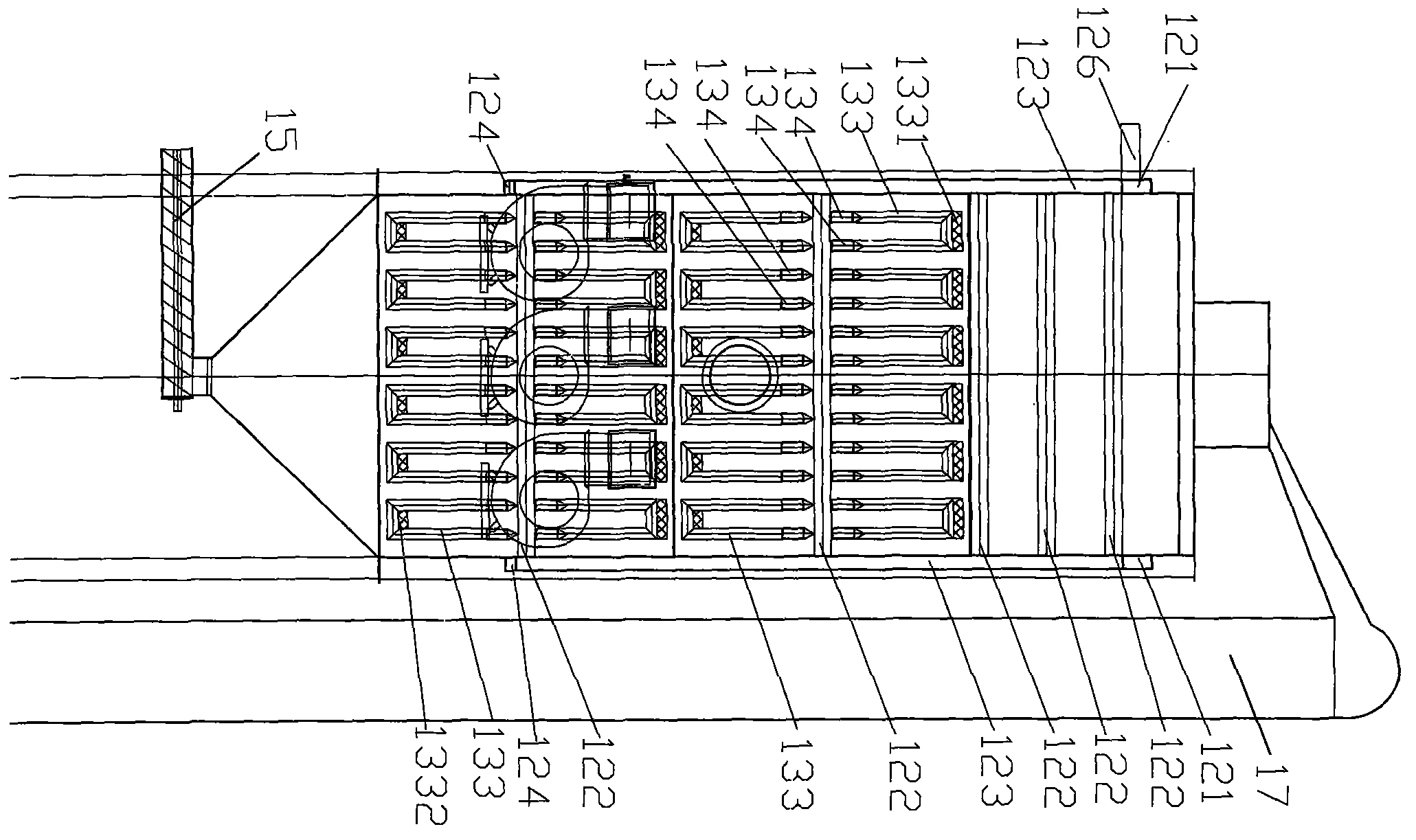

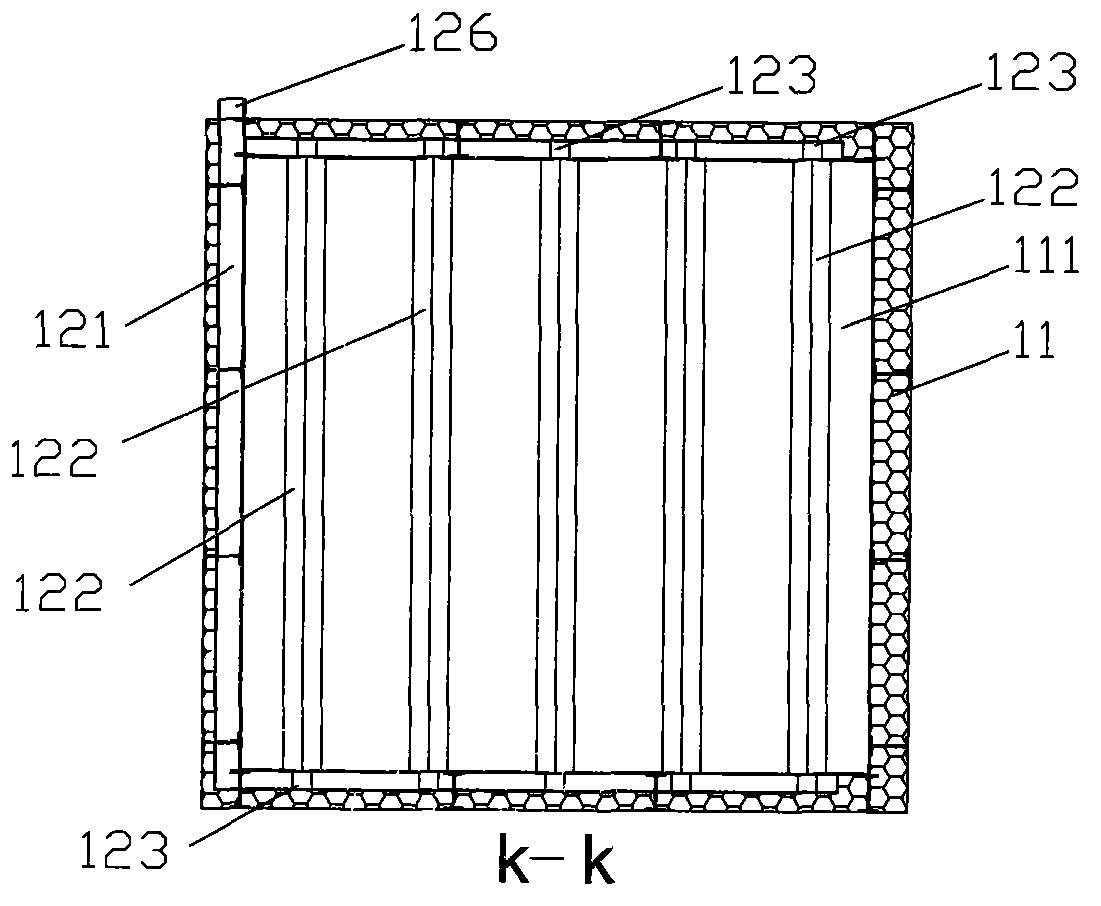

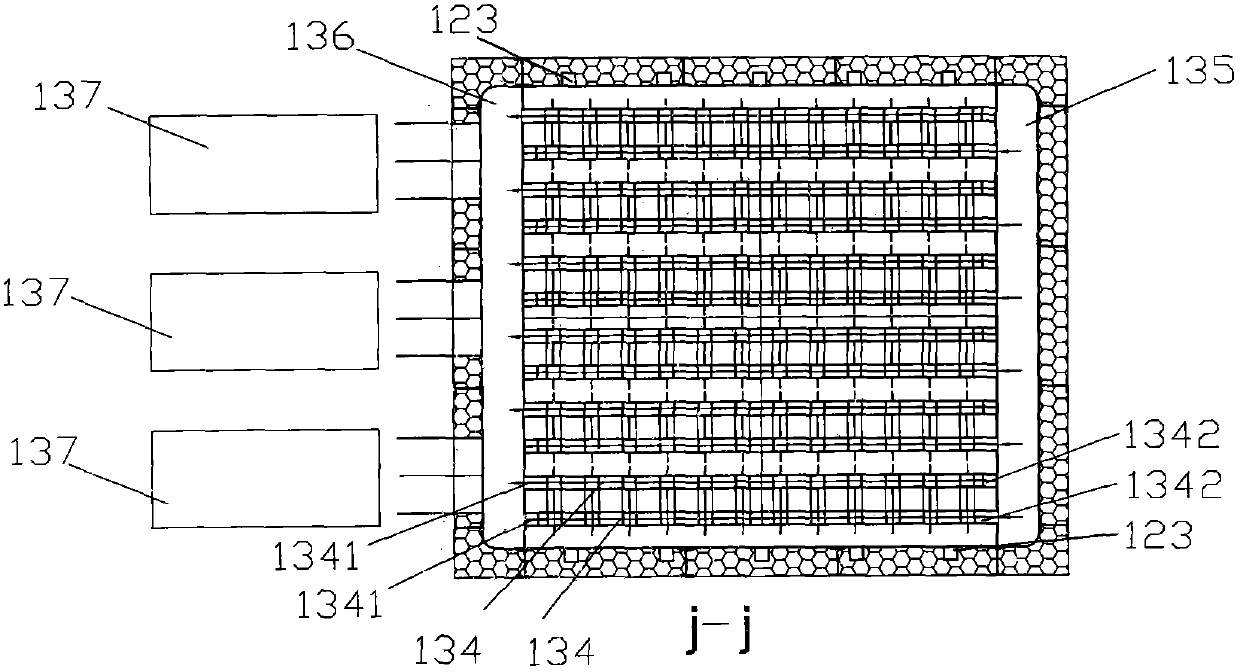

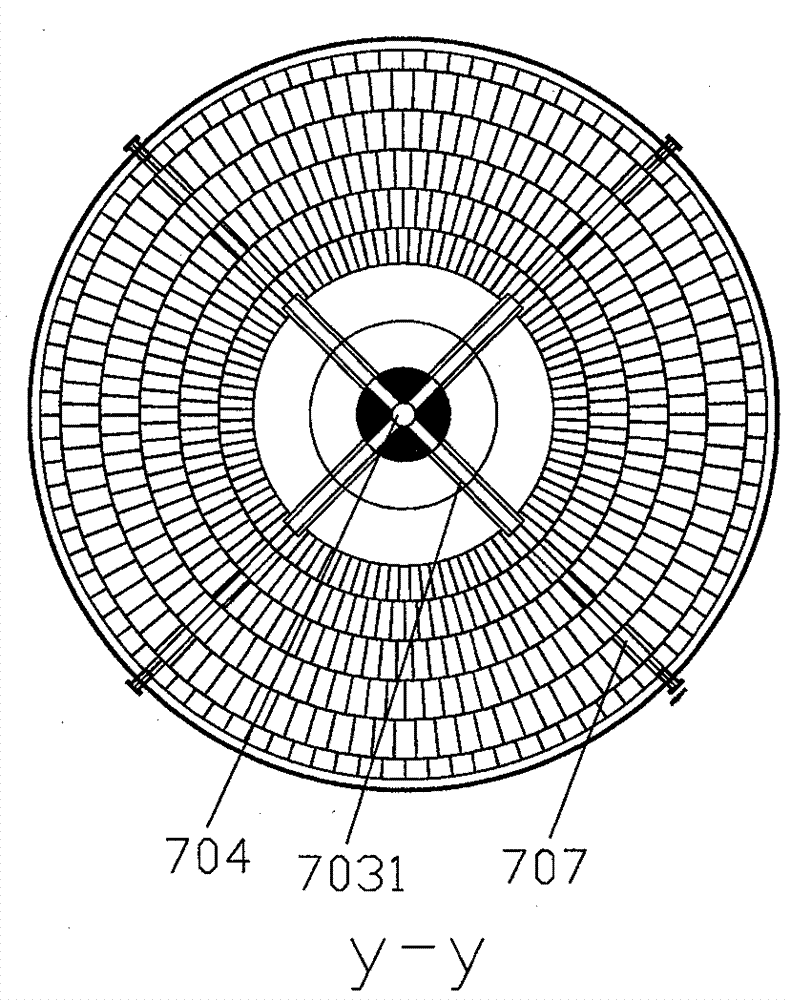

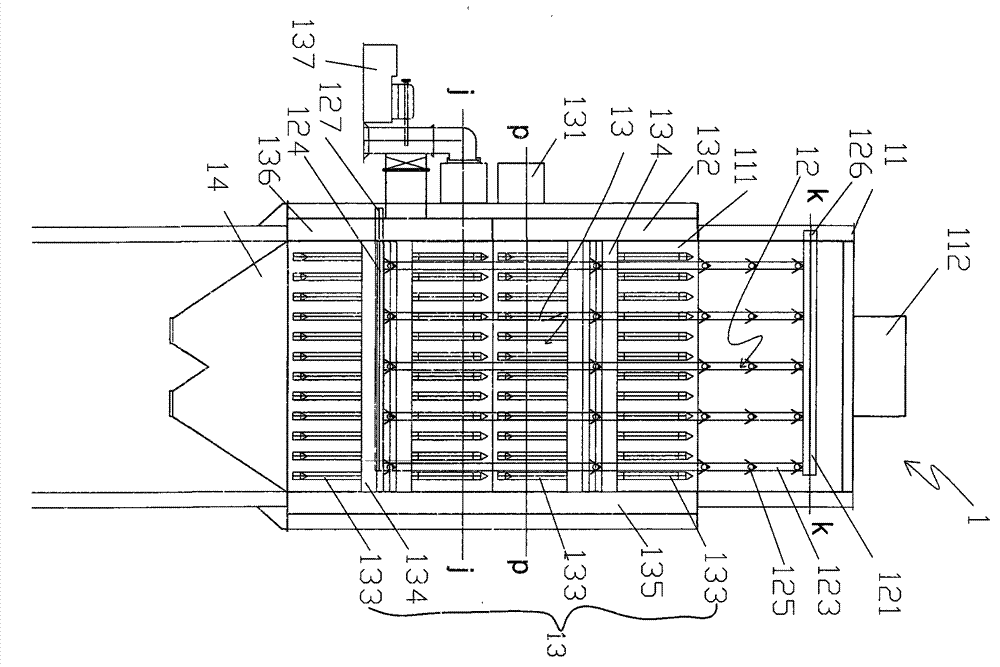

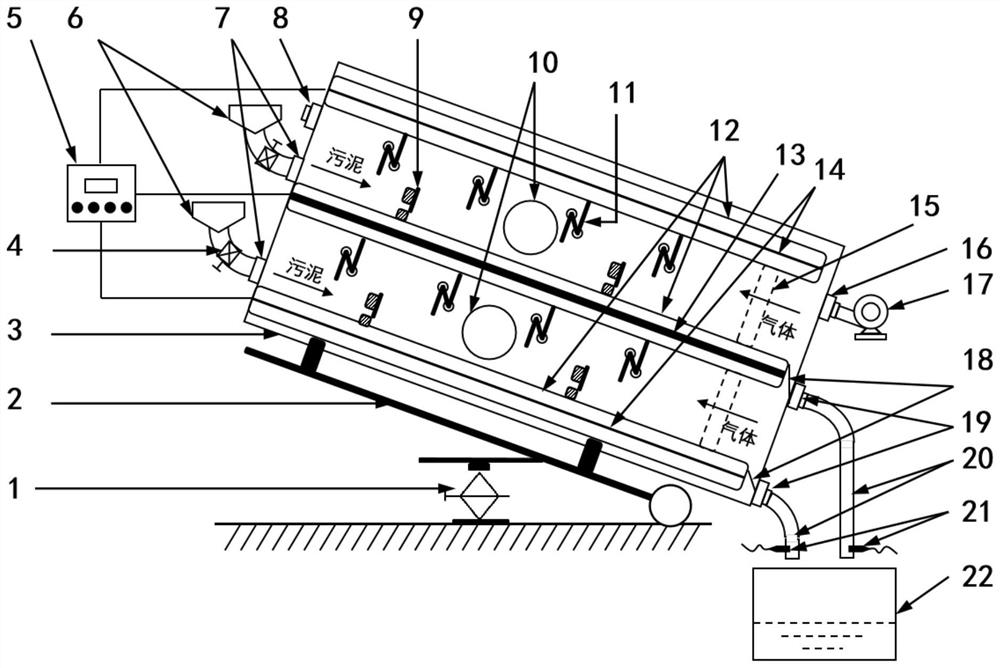

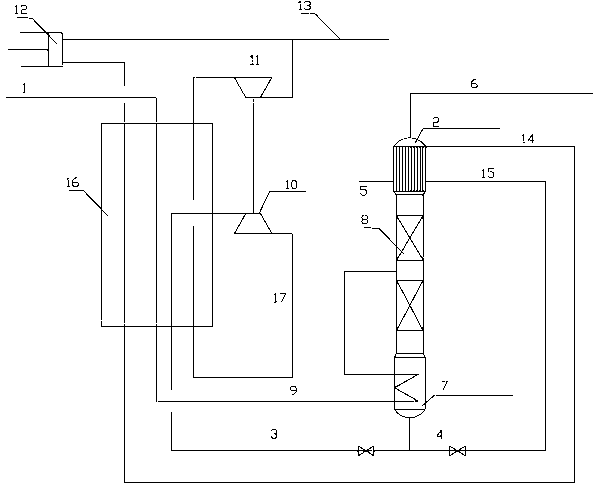

The invention provides a thermal-cycle continuous pyrolysis-gasification comprehensive device for coal gangues. The thermal-cycle continuous pyrolysis-gasification comprehensive device for coal gangues comprises a coal gangue pyrolysis-gasification furnace, a raw coke oven gas condensing device, a raw coke oven gas recycling and purifying device, a furnace coal gangue heat waste gas humidifying and dehydrating device and tail gas water-spraying purifier, wherein a raw coke oven gas guide-out device of the coal gangue pyrolysis-gasification furnace is communicated with the raw coke oven gas condensing device; and the raw coke oven gas condensing device is communicated with the raw coke oven gas recycling and purifying device. The purified raw coke oven gas is combusted; the combusted waste gas is fed to the furnace coal gangue heat waste gas humidifying and dehydrating device; and the dehydrated waste gas is exhausted through the tail gas water-spraying purifier. Besides, the combusted waste gas is fed to an active coke regenerator of the raw coke oven gas recycling and purifying device; and the waste gas regenerated by the active coke regenerator is fed to a waste gas heat exchange dehydrator or the tail gas water-spraying purifier. The thermal-cycle continuous pyrolysis-gasification comprehensive device for the coal gangues is prominent in environmental protection benefit by utilizing the pyrolysis-gasification of the coal gangues and not consuming extra energy resources, and is considerable in economic value.

Owner:SHANXI XINLI ENERGY TECH

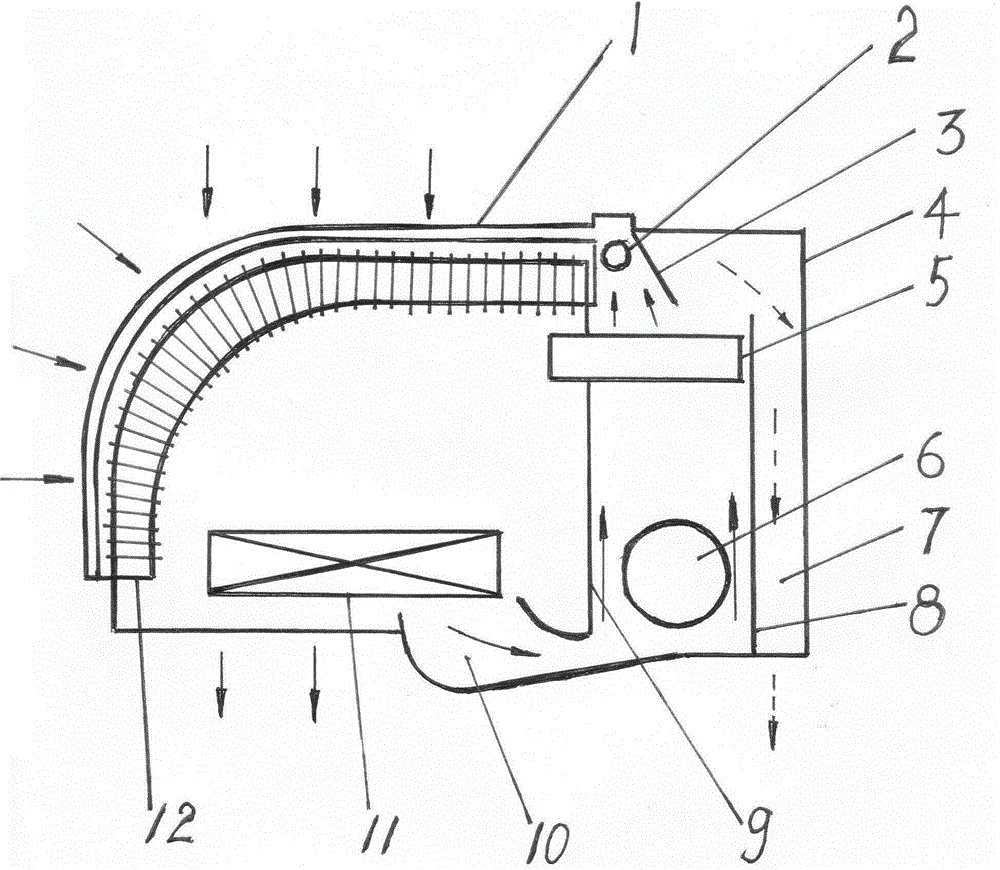

Refrigerating and heating pump type frostless air conditioner outdoor unit

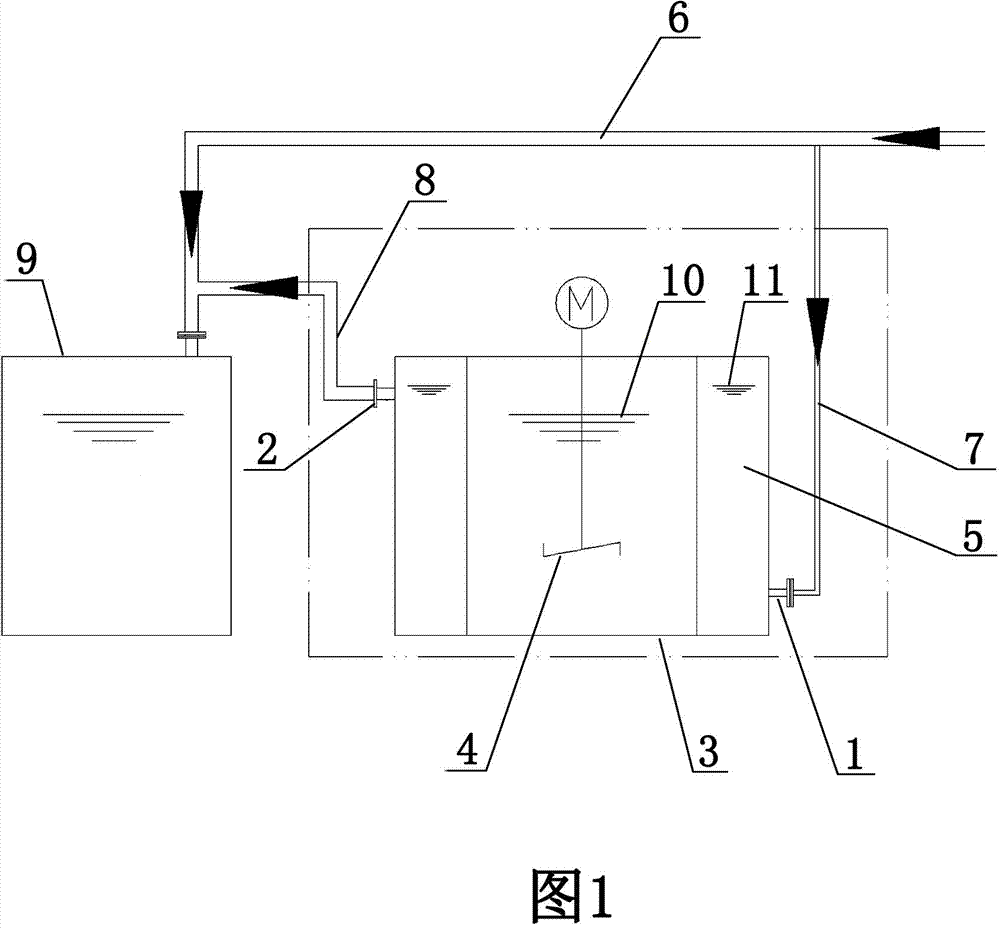

InactiveCN106568134AImprove heating energy efficiencyReduce frequencyCorrosion preventionRefrigeration componentsFrequency conversionEvaporation

The invention discloses a refrigerating and heating pump type frostless air conditioner outdoor unit. The refrigerating and heating pump type frostless air conditioner outdoor unit comprises an outdoor unit shell, an evaporator, a draught fan, a middle partition plate, a compressor and frequency conversion electric control module space, a frequency conversion electric control box and a compressor. The refrigerating and heating pump type frostless air conditioner outdoor unit is characterized in that an induced air flue is arranged at an air outlet of the draught fan, and the induced air flue penetrates the middle partition plate and communicates with the compressor and frequency conversion electric control module space; a wind collecting hood is arranged at the position, corresponding to the compressor and frequency conversion electric control module space, of the outdoor unit shelland connected with a heating air supply air pipe; outflow air of the draught fan enters the compressor and frequency conversion electric control module space through the induced air flue, flows through the compressor and the frequency conversion electric control box, and then enters the wind collecting hood to be conveyed by the heating air supply air pipe to the evaporator to flow out from the air inlet side. The refrigerating and heating pump type frostless air conditioner outdoor unit has the beneficial effects that frostless heating is achieved, heat dissipation and cooling are conducted on a compressor frequency conversion electric control module, the evaporation heating amount is large, and the energy efficiency of an air conditioner is large.

Owner:孙海潮

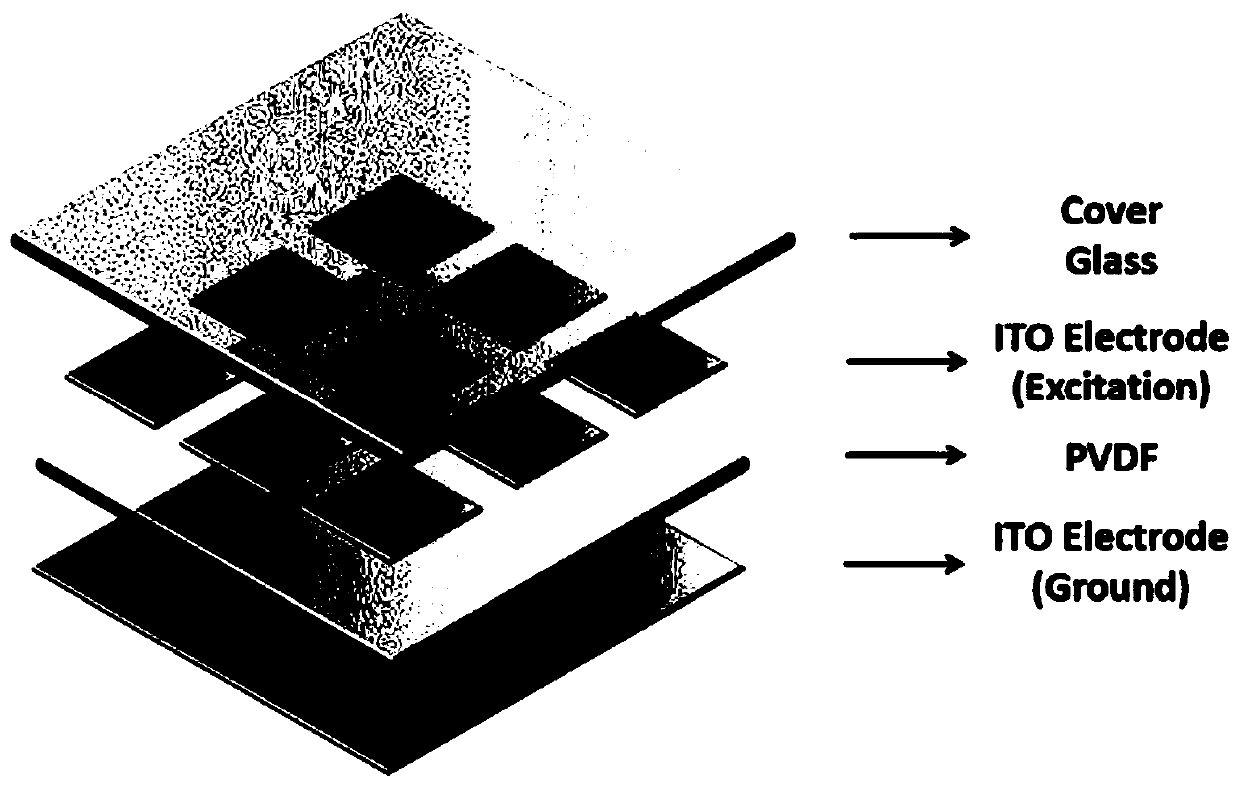

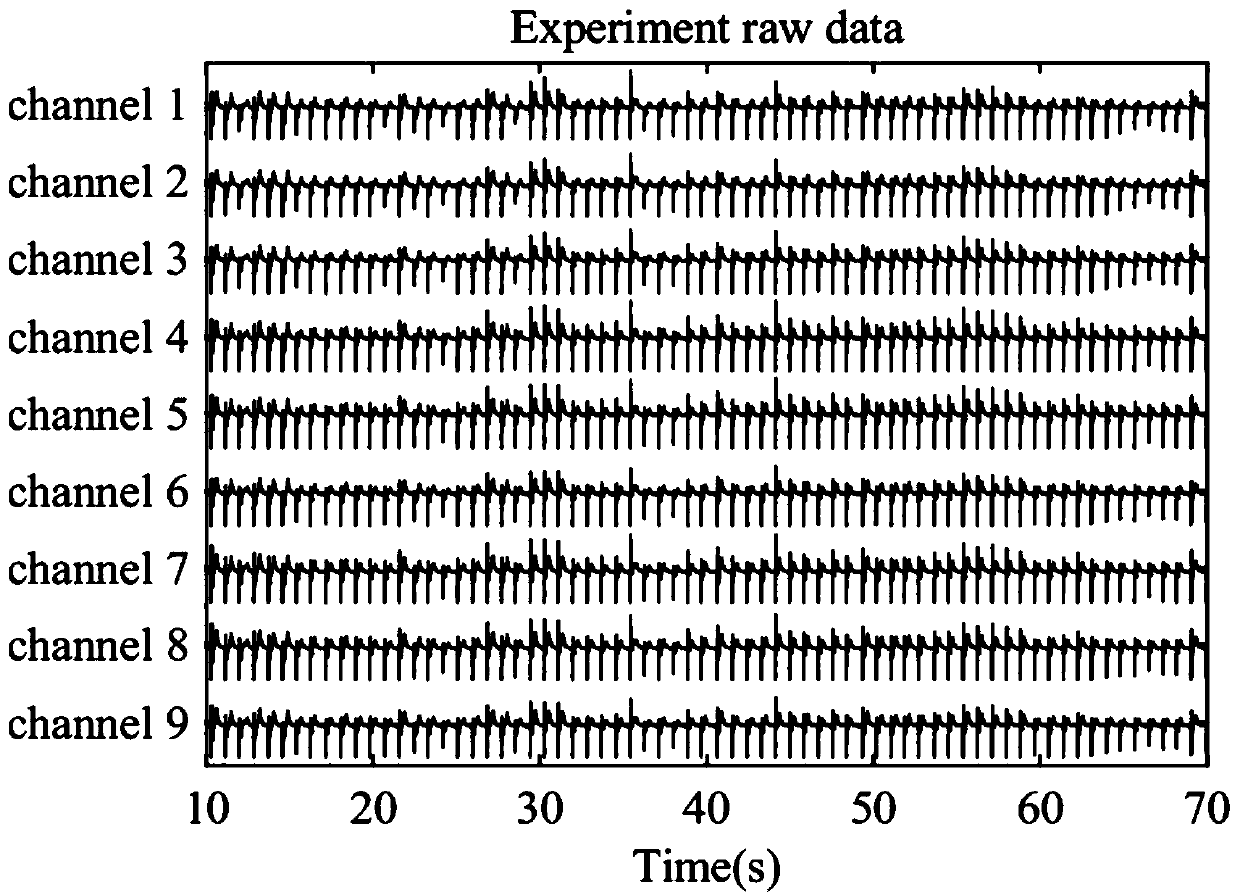

Method for realizing piezoelectric pressure detection touch screen piezoelectric response uniformity by using neural network

ActiveCN110044522ANo need to increase energy consumptionAvoid matching problemsForce measurement using piezo-electric devicesNeural architecturesVoltage responseElectrode array

Owner:苏州二向箔科技有限公司

Polystyrene fiber adsorption material with surface grafted with beta-cyclodextrin, and preparation and application thereof

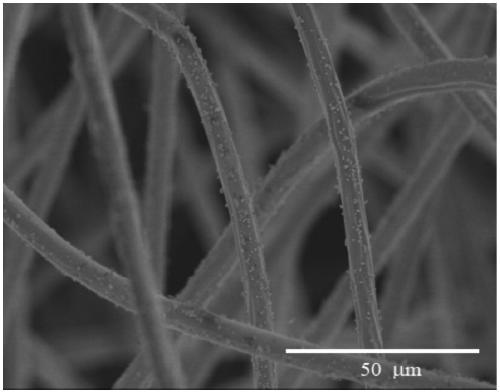

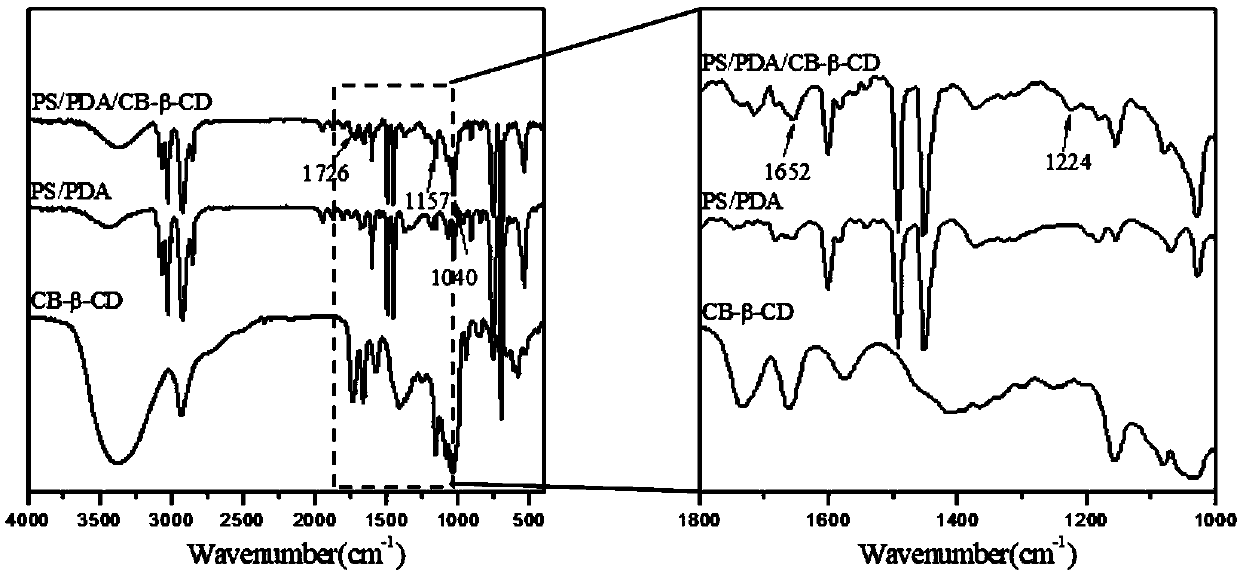

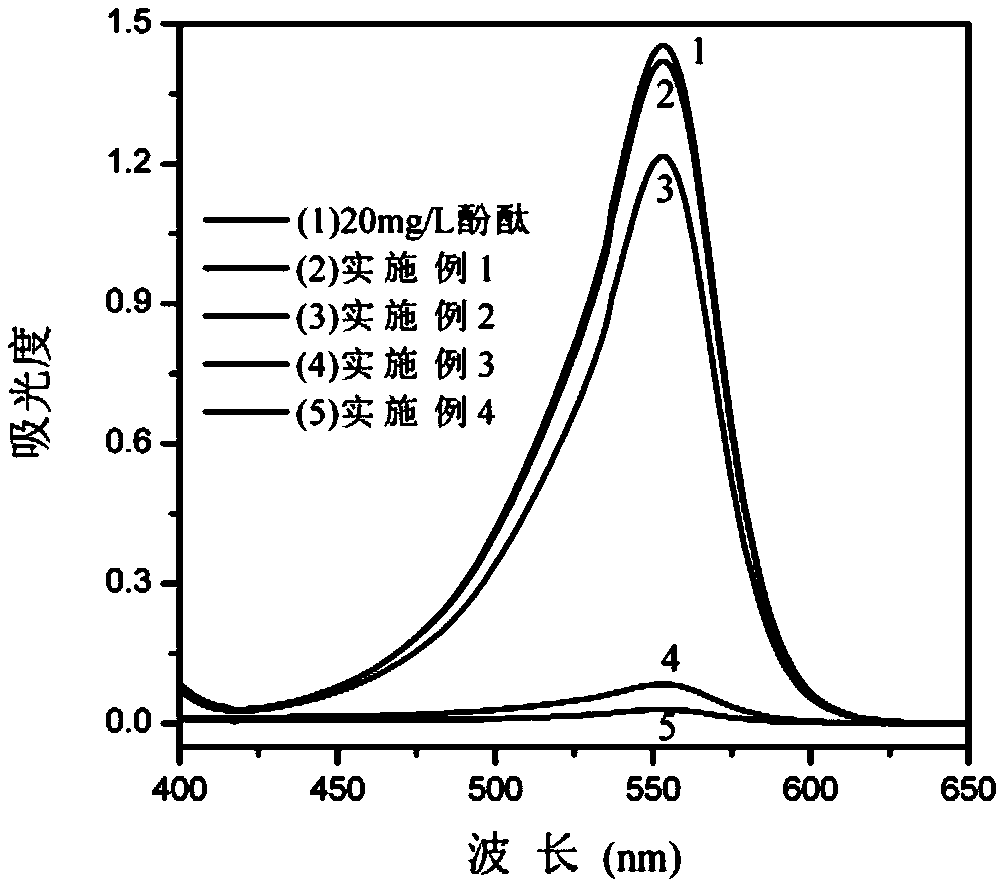

ActiveCN109529790ALow costGood environmental compatibilityOther chemical processesWater contaminantsElectrospinningPhenolphthalein

The invention relates to a polystyrene fiber adsorption material with surface grafted with beta-cyclodextrin, and preparation and application thereof, belonging to the field of environmental novel functional adsorption materials. The material uses polystyrene fiber as a carrier; the surface of the polystyrene fiber is a layer of polydopamine nanoparticles; and the beta-cyclodextrin is grafted ontodopamine nanoparticles through amido bonds. With the method provided by the invention, a polystyrene fiber material is firstly prepared through electrospinning, and dopamine generates in-situ self-polymerization on the surface of the polystyrene fiber material, so the surface of the polystyrene fiber material is rich in a large amount of active amino groups; meanwhile, chemical crosslinking is generated between carboxylated beta-cyclodextrin and polydopamine on the surface of the polystyrene fiber material; and through formation of the amido bonds, the beta-cyclodextrin is bonded onto an electrospun polystyrene fiber material. The beta-cyclodextrin in the material is located on the surface of polystyrene fiber, and the cavity structure of the beta-cyclodextrin remains intact, so the adsorption performance of the material to phenolphthalein is effectively improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

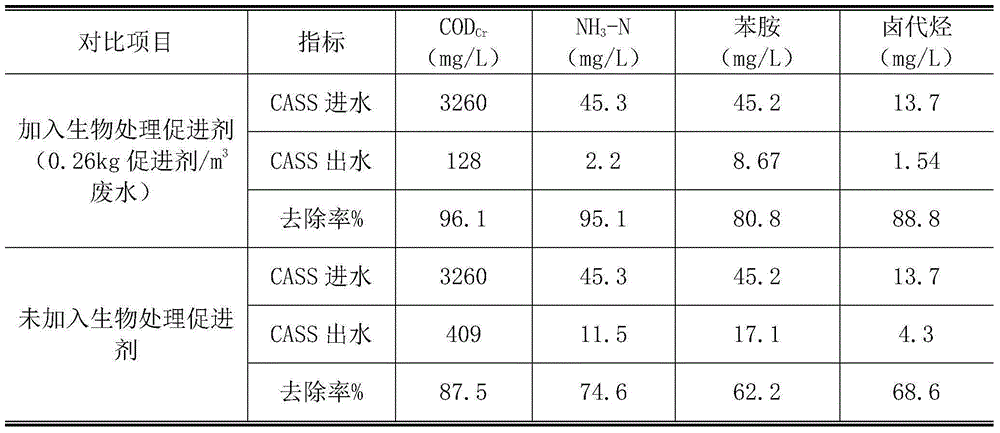

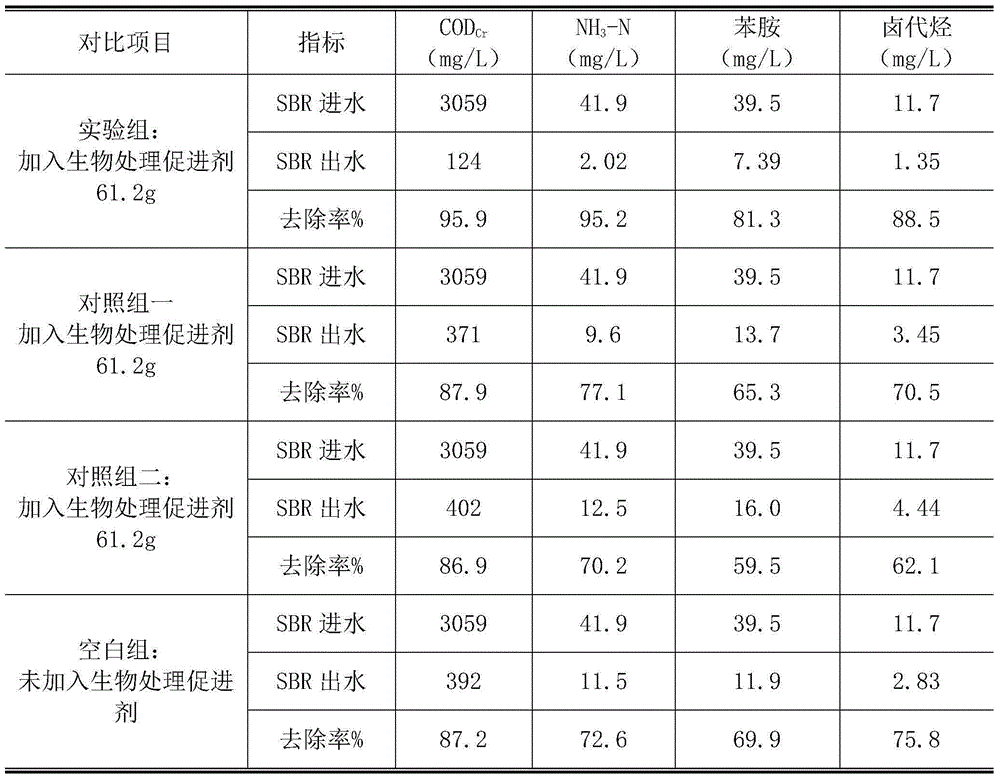

Medical intermediate biological waste water treatment accelerant and preparing method and application thereof

ActiveCN105152357APromote growthPromote growth and reproductionBiological water/sewage treatmentWater qualityVitamin B12

The invention discloses a medical intermediate biological waste water treatment accelerant and a preparing method and application thereof and belongs to the field of waste water treatment. The accelerant is prepared by matching glucose, ammonium phosphate, ethyl alcohol, phenol, calcium chloride, zinc chloride, magnesium sulfate, ferrous sulfate, vitamin B1 and vitamin B12. The accelerant can promote growth of microorganism, start a cometabolism action of the microorganism and improve the toxicity resistance of the microorganism to the medical intermediate by adding the accelerant into a medical intermediate waste water disposal system, thus effectively stably treating the medical intermediate waste water; the accelerant is wide in raw material resource, simple to prepare, convenient to use and suitable for the water quality of the medical intermediate waste water, and has a broad application prospect.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Automatic pressure relief type transformer substation for intelligent power monitoring system and using method of transformer substation

InactiveCN112531523AReduce riskIncrease cooling and pressure relief capacitySubstation/switching arrangement cooling/ventilationTransformerControl engineering

,The invention relates to the field of transformer substations, in particular to an automatic pressure relief type transformer substation for an intelligent power monitoring system and a using methodof the transformer substation. The transformer substation comprises a box body and a heat dissipation mechanism for dissipating high heat in the box body, a pressure relief pipe is arranged on the topwall of the box body an opening and closing mechanism used for controlling the circulation amount of the pressure relief pipe is arranged at the end, located in the box body, of the pressure relief pipe, a temperature and pressure regulation and control mechanism used for sensing the temperature in the box body is arranged in the box body, the temperature and pressure regulation and control mechanism is in transmission connection with the opening and closing mechanism, and the temperature and pressure regulation and control mechanism is in transmission connection with the heat dissipation mechanism. According to the automatic pressure relief type transformer substation for the intelligent power monitoring system and the using method of the transformer substation, the pressure relief pipeautomatically relieves pressure in the box body, high-temperature and high-pressure airflow is cooled through water liquid, and therefore the pressure and the temperature in the box body are reduced,the danger of the box body is reduced, the cooling and pressure relief capacity in the box body is improved through the heat dissipation mechanism, and the strength of the side wall of the box body isimproved without increasing energy consumption.

Owner:钱南林

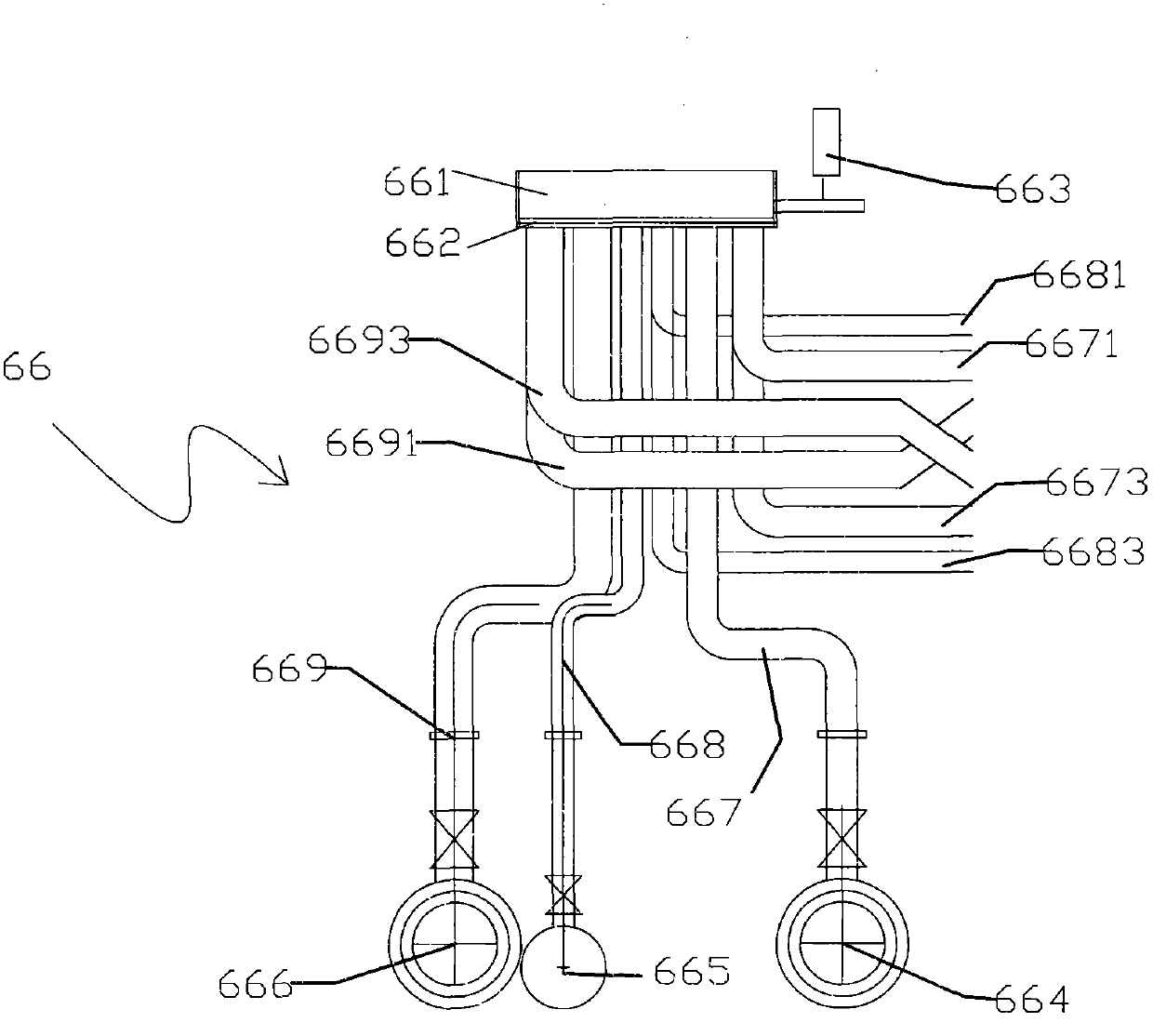

Method for active coke regeneration through hot exhaust gas obtained by purification and combustion of coke oven raw gas in coal gangue pyrolysis gasification

ActiveCN103224814AEasy to reuseNo need to increase energy consumptionCombustible gas coke oven heatingGas purification with selectively adsorptive solidsExhaust gasCoal gangue

The invention discloses a method for active coke regeneration through hot exhaust gas obtained by purification and combustion of coke oven raw gas in coal gangue pyrolysis gasification. The method includes the steps of: (1) providing a heat source for coal gangue pyrolysis gasification by heat storage and exchange and alternate combustion of purified coal gas; (2) letting carbon in a coal gangue pyrolysis solid product encounter superheated steam to undergo a water gas reaction so as to generate water gas; (3) exporting coke oven raw gas; and (4) purifying and combusting the exported coke oven raw gas, and evaporating purification adsorbed saturated active coke by the combusted hot exhaust gas to regenerate unsaturated active coke. According to the method provided in the invention, afterheat of the hot exhaust gas generated by purification and combustion of recycled coke oven raw gas in coal gangue pyrolysis gasification is employed to evaporate saturated active coke for regeneration, no extra energy consumption is needed, heating equipment is saved, and the economic value of cyclic utilization can be obtained.

Owner:SHANXI XINLI ENERGY TECH

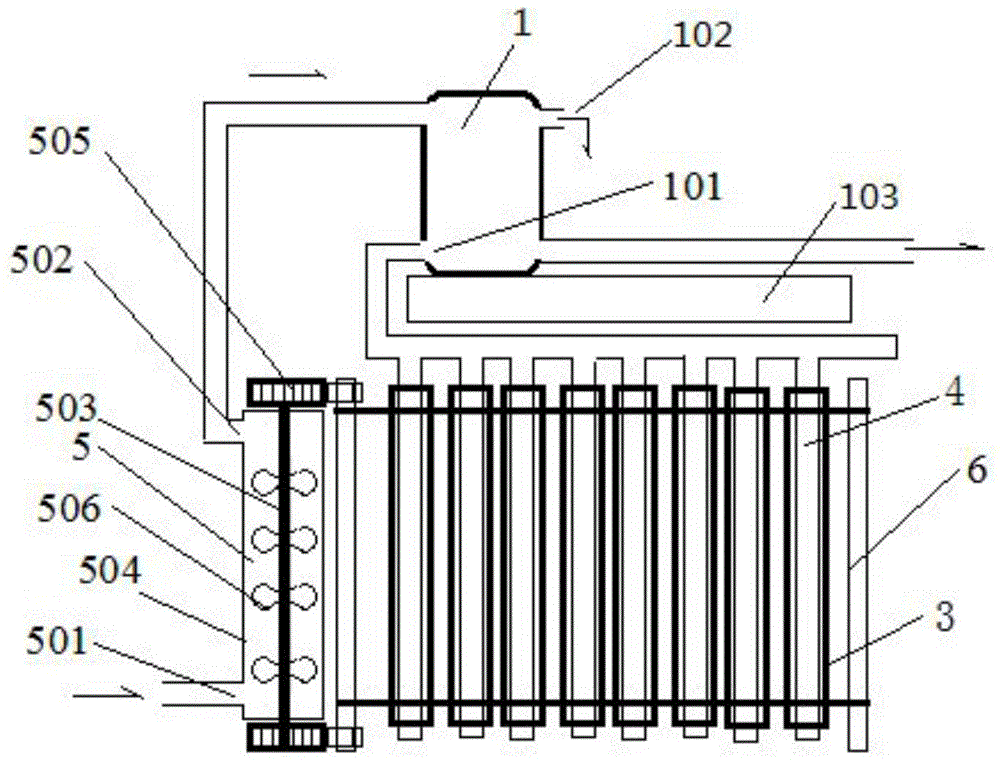

Solar water heater with self cleaning device

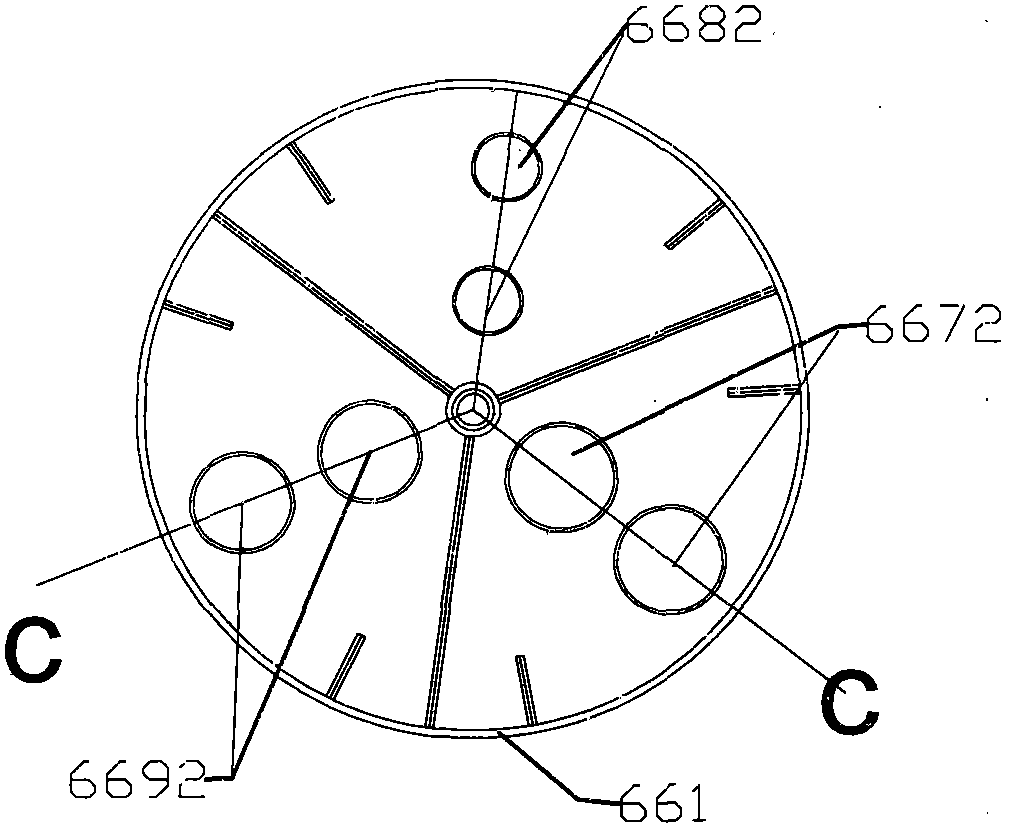

PendingCN104596136ANo need to increase energy consumptionSimple structureSolar heating energySolar heat devicesImpellerLine tubing

The invention relates to a solar water heater, and provides a solar water heater with a self cleaning device. The solar water heater comprises a water tank and a heat absorber connected with the water tank, wherein the heat absorber comprises a transparent outer pipe and a heat collecting inner pipe, the heat collecting inner pipe is arranged in the transparent outer pipe, and the heat collecting inner pipe is connected with a circulation water opening of the water tank through a pipeline. The solar water heater is characterized by also comprising a hydraulic pump and a cleaning device, the hydraulic pump comprises a tubular casing, a rotating shaft and an impeller fixedly arranged on the rotating shaft, an inlet of the hydraulic pump is connected with the water inlet pipe, an outlet of the hydraulic pump is connected with a water inlet of the water tank, a rotating shaft of the hydraulic pump passes through the two ends of the casing, a sealing element is arranged between the rotating shaft and the casing, the rotating shaft is connected with the cleaning device through an active transmission mechanism, and the cleaning device transversely spans across the two sides of the heat absorber. The solar water heater has the advantages that the heat absorber of the solar water heater can be cleaned without increasing the new energy consumption, the structure is simple, the preparing cost is low, and the popularization and the application are convenient.

Owner:ZIBO BOXU RENEWABLE ENERGY TECH

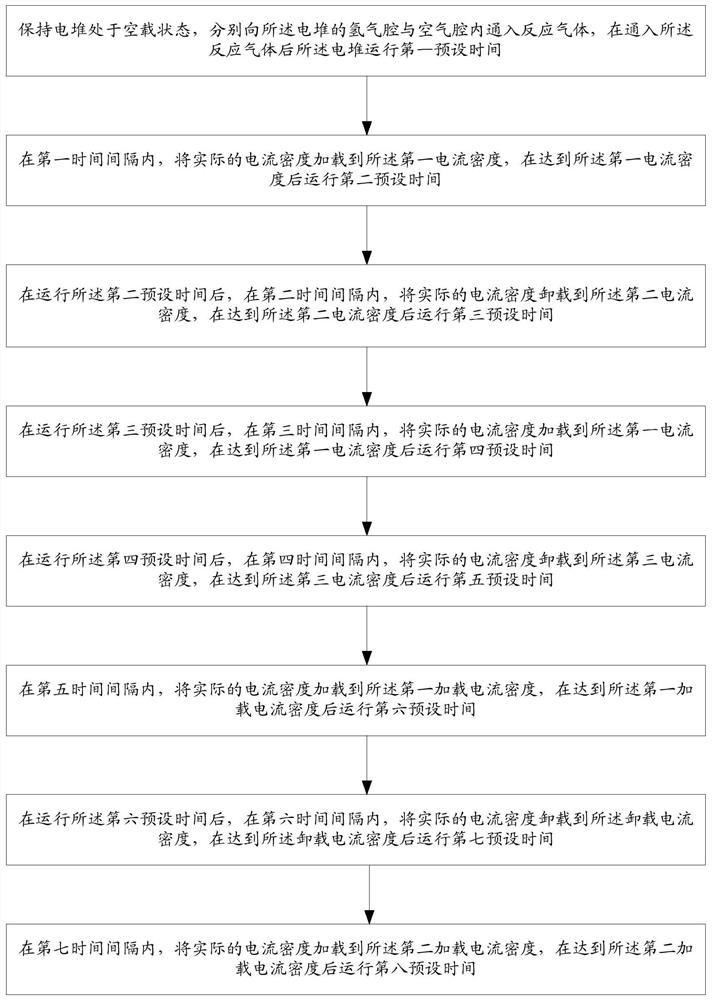

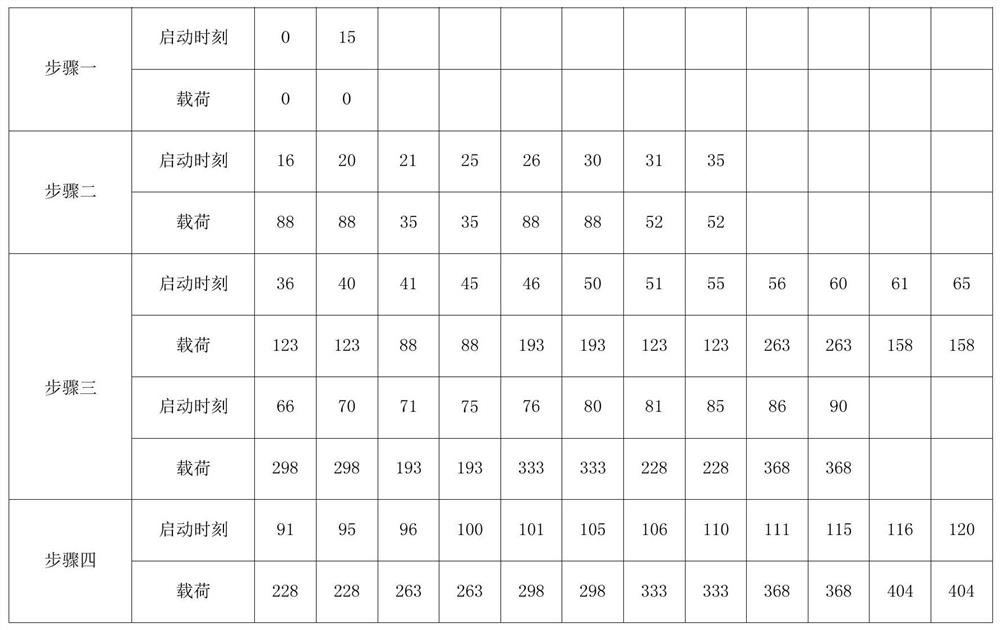

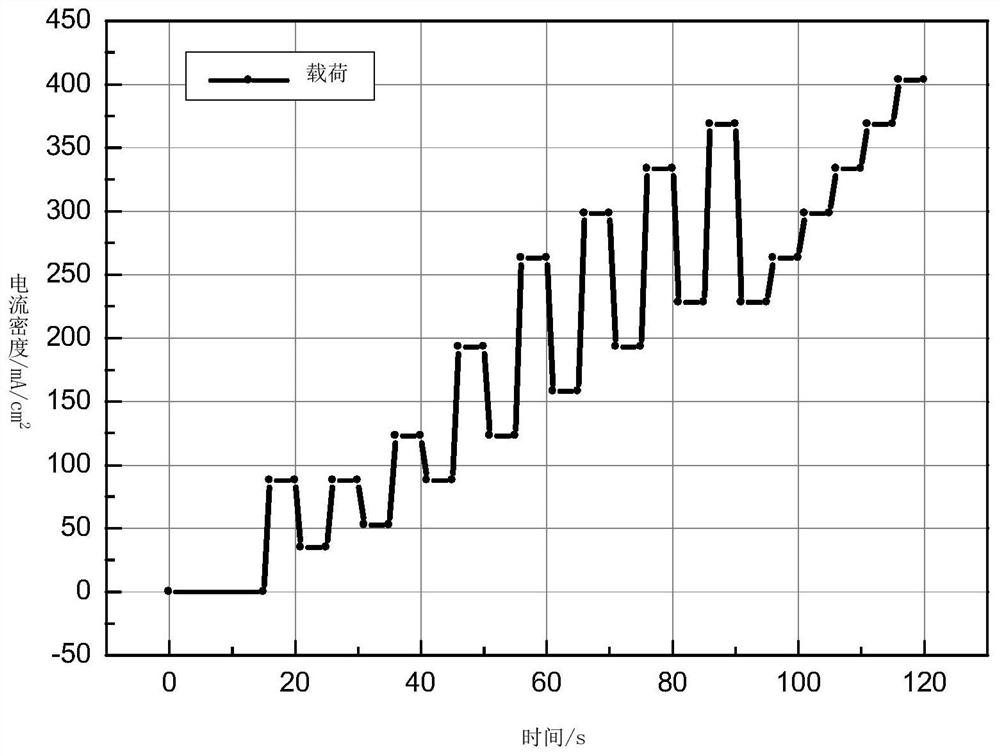

Low-temperature starting method of fuel cell stack

The invention discloses a low-temperature starting method of a fuel cell stack. The low-temperature starting method comprises the following specific steps of respectively introducing a reaction gas into a hydrogen cavity and an air cavity of the stack; running a first preset discharge step to enable a reaction region to be filled with the reaction gas, and starting a sensitive period through the stack; operating a second preset discharging step for multiple times to achieve the purpose of quickly preheating the stack; and operating the third preset discharging step for multiple times to finishthe normal starting process of the stack. According to the low-temperature starting method of the fuel cell stack, the current density of the discharge current is effectively controlled for multipletimes, the waste heat of the stack is utilized to the maximum extent at stages under the condition that the single stack is not reversed in polarity, the proportion of external output energy is adjusted, an additional auxiliary heating device is not added, energy consumption does not need to be increased, and the normal starting of a fuel cell in a low-temperature state is achieved.

Owner:国鸿氢能科技(嘉兴)股份有限公司

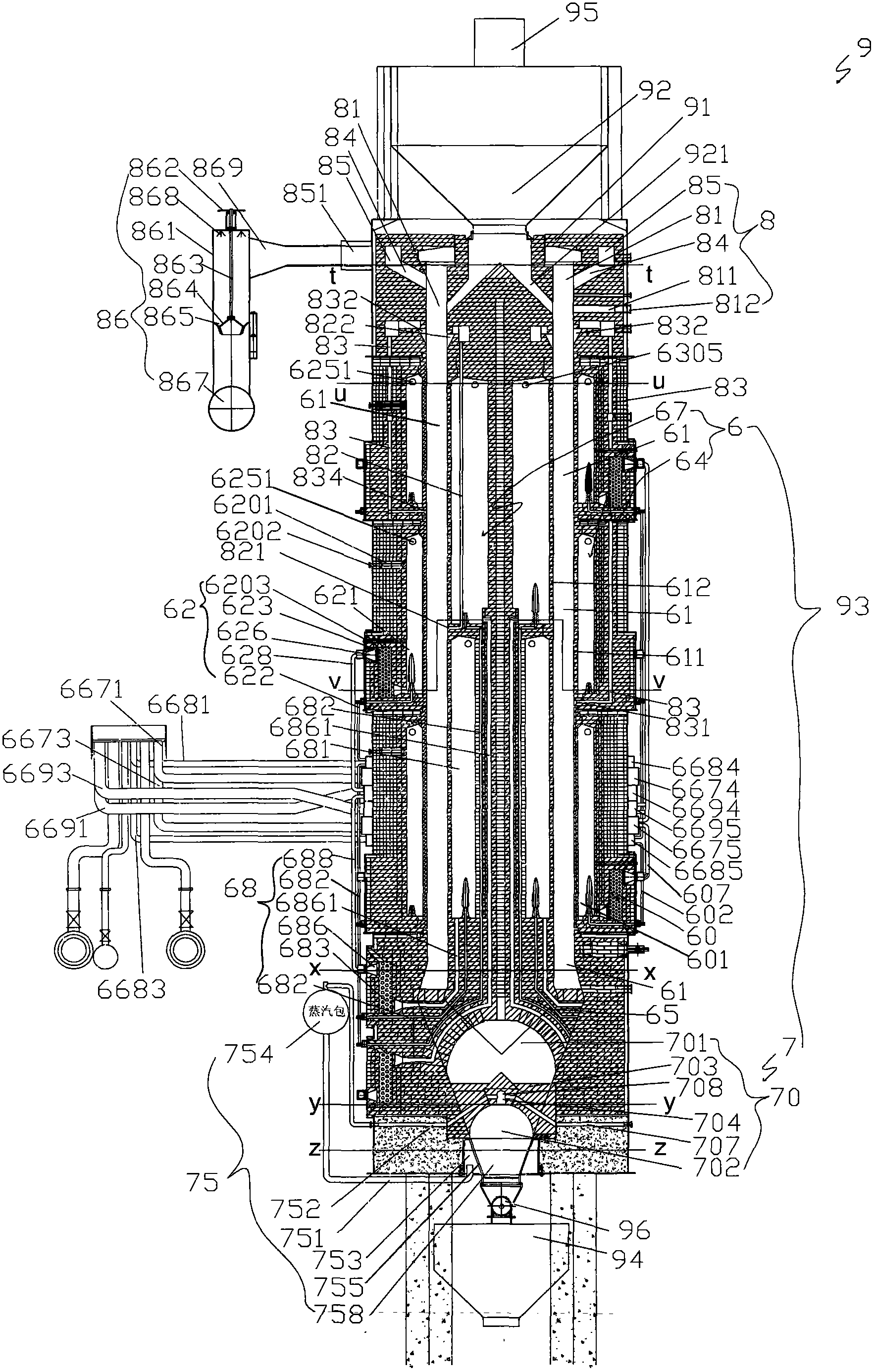

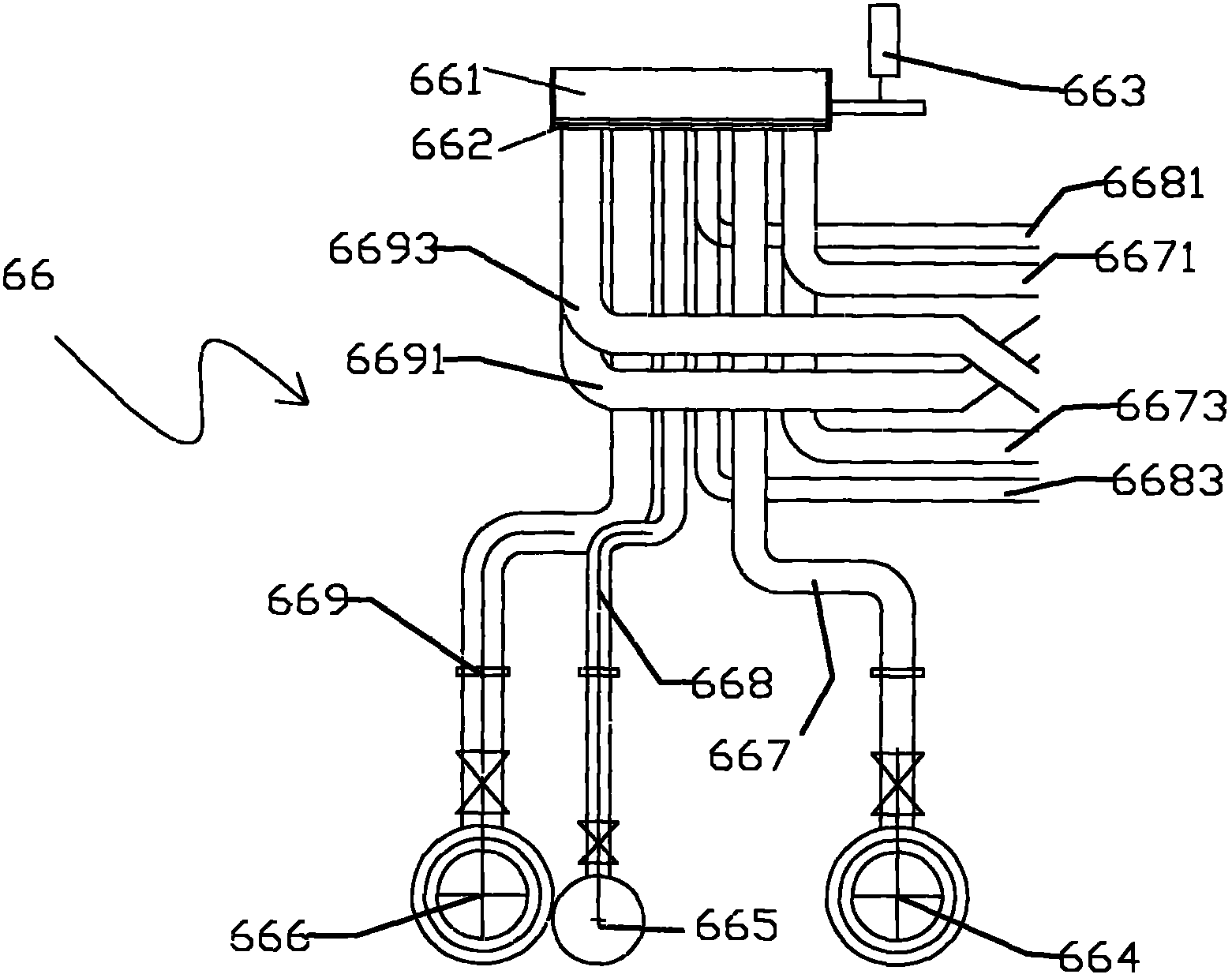

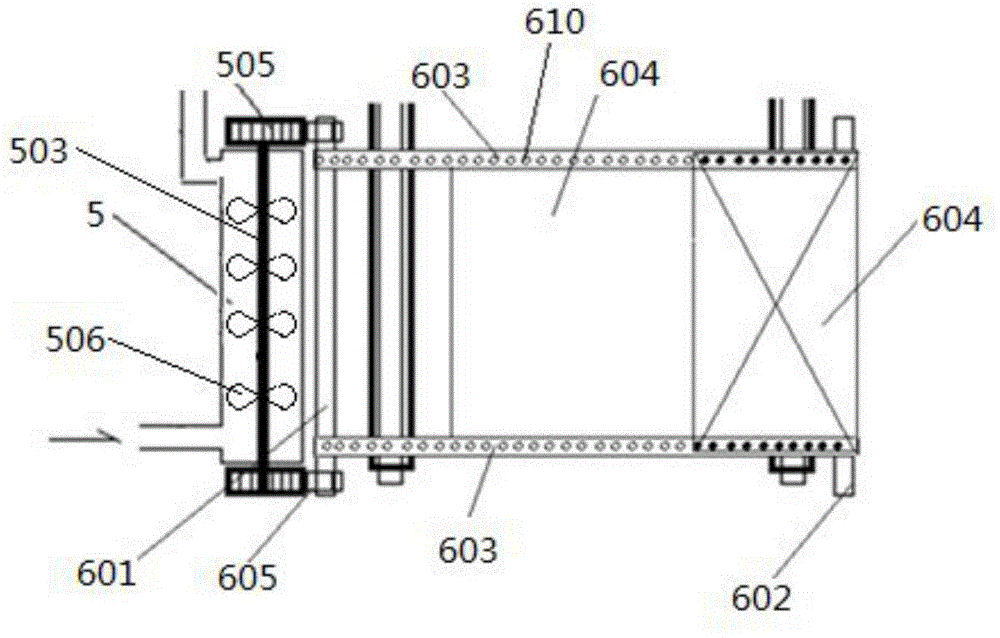

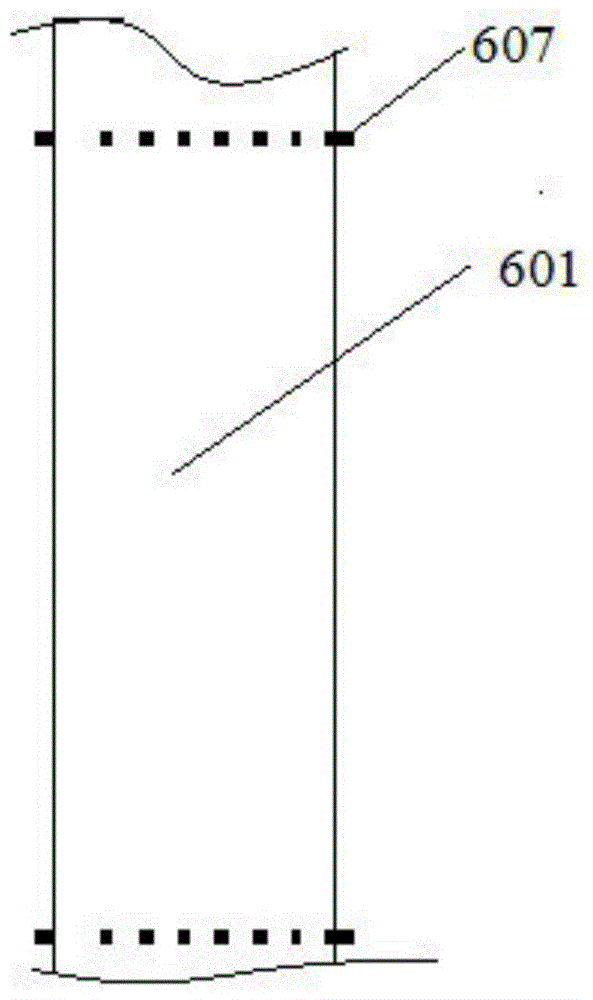

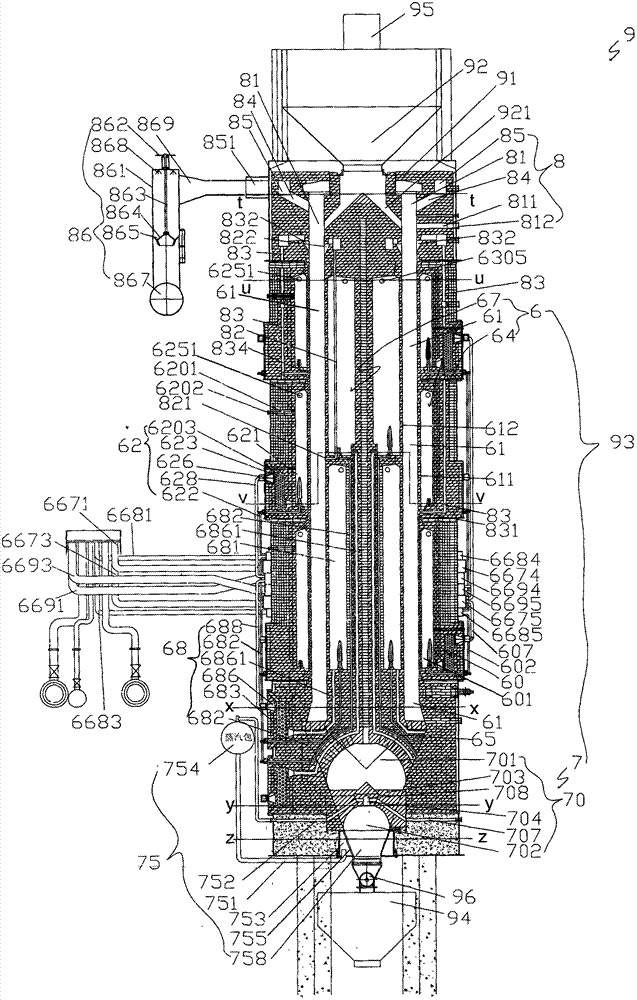

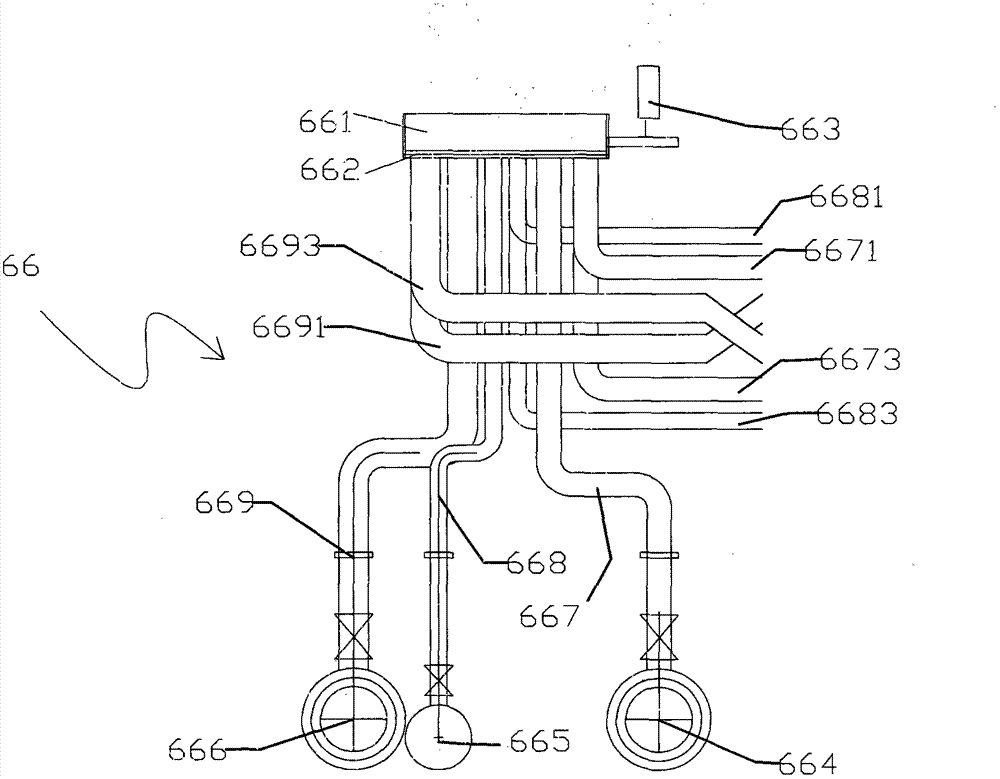

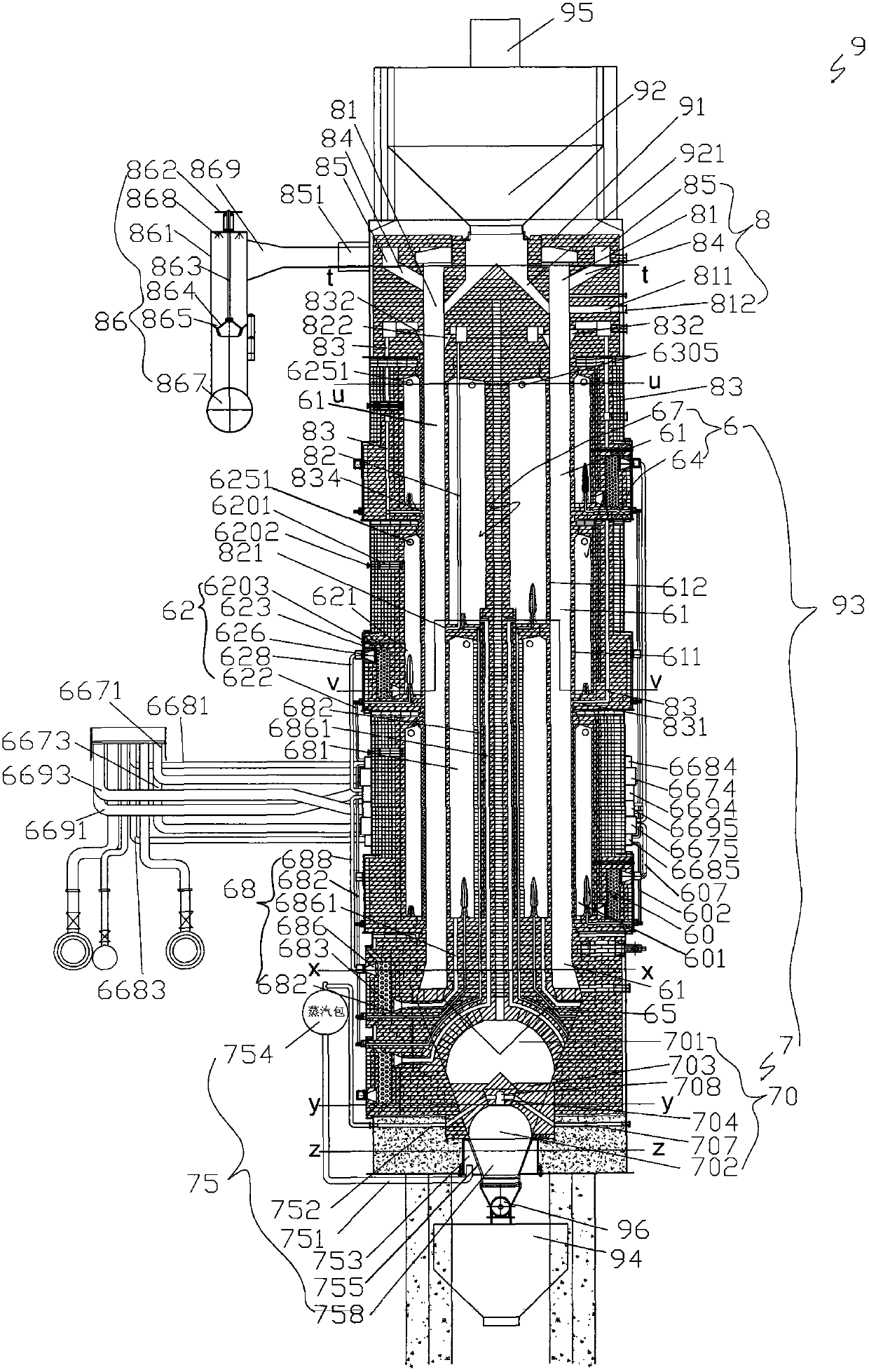

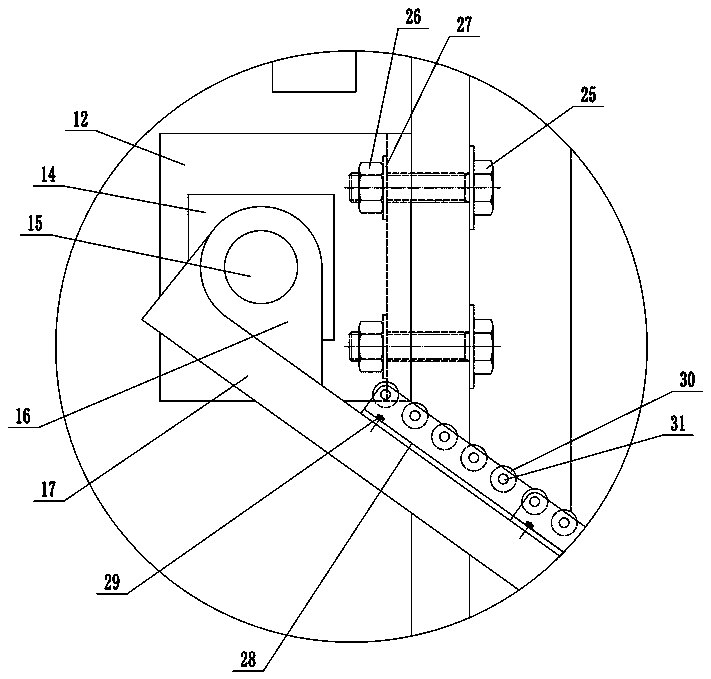

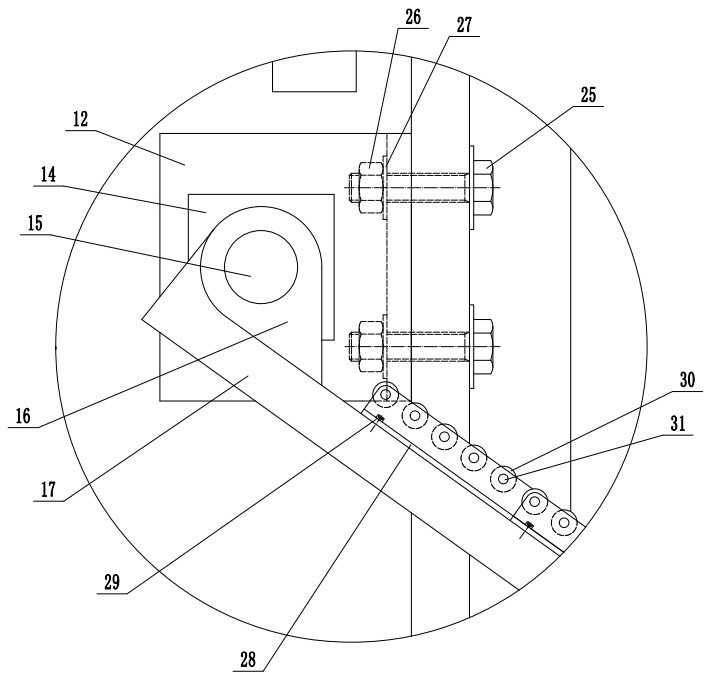

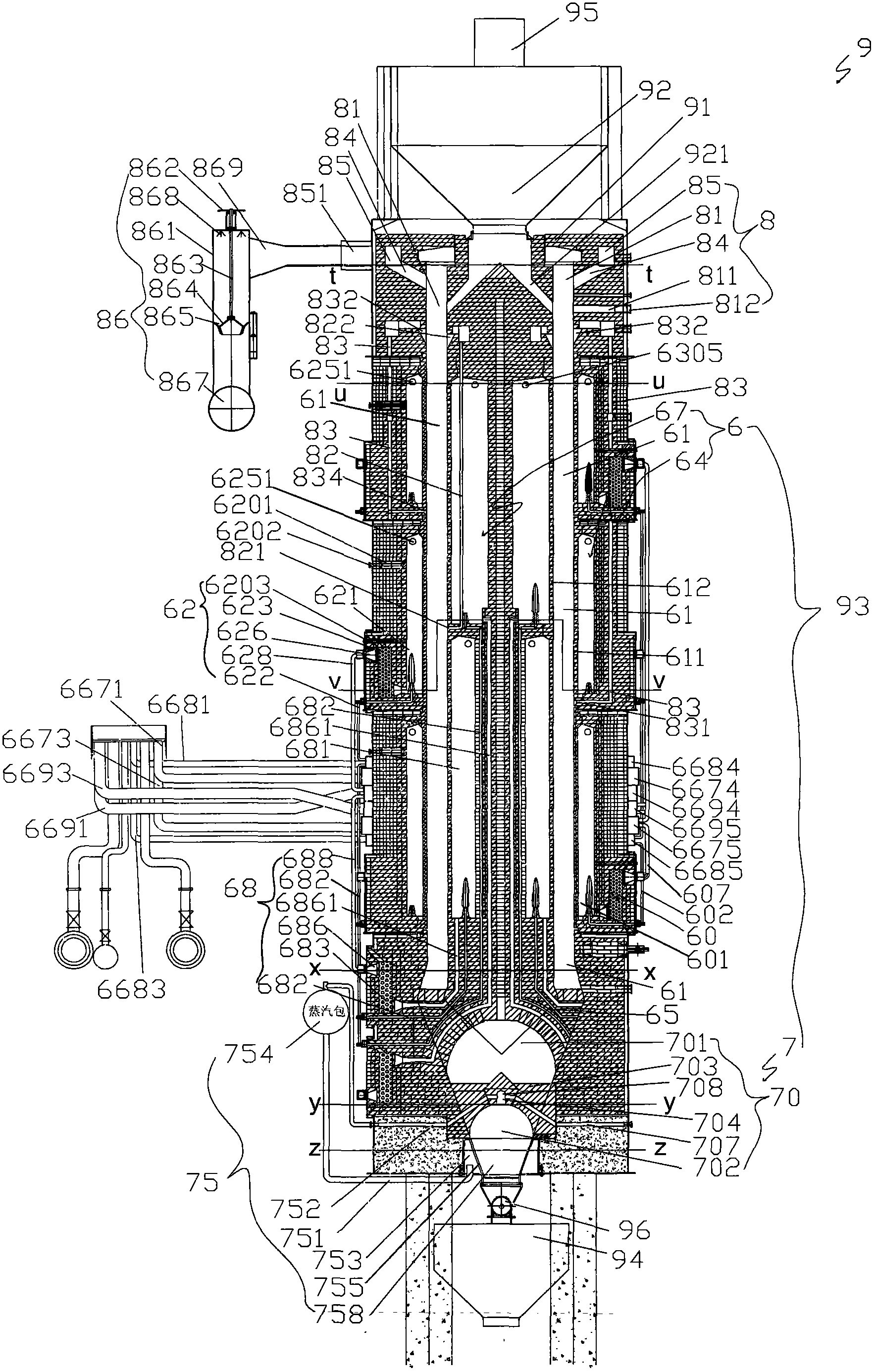

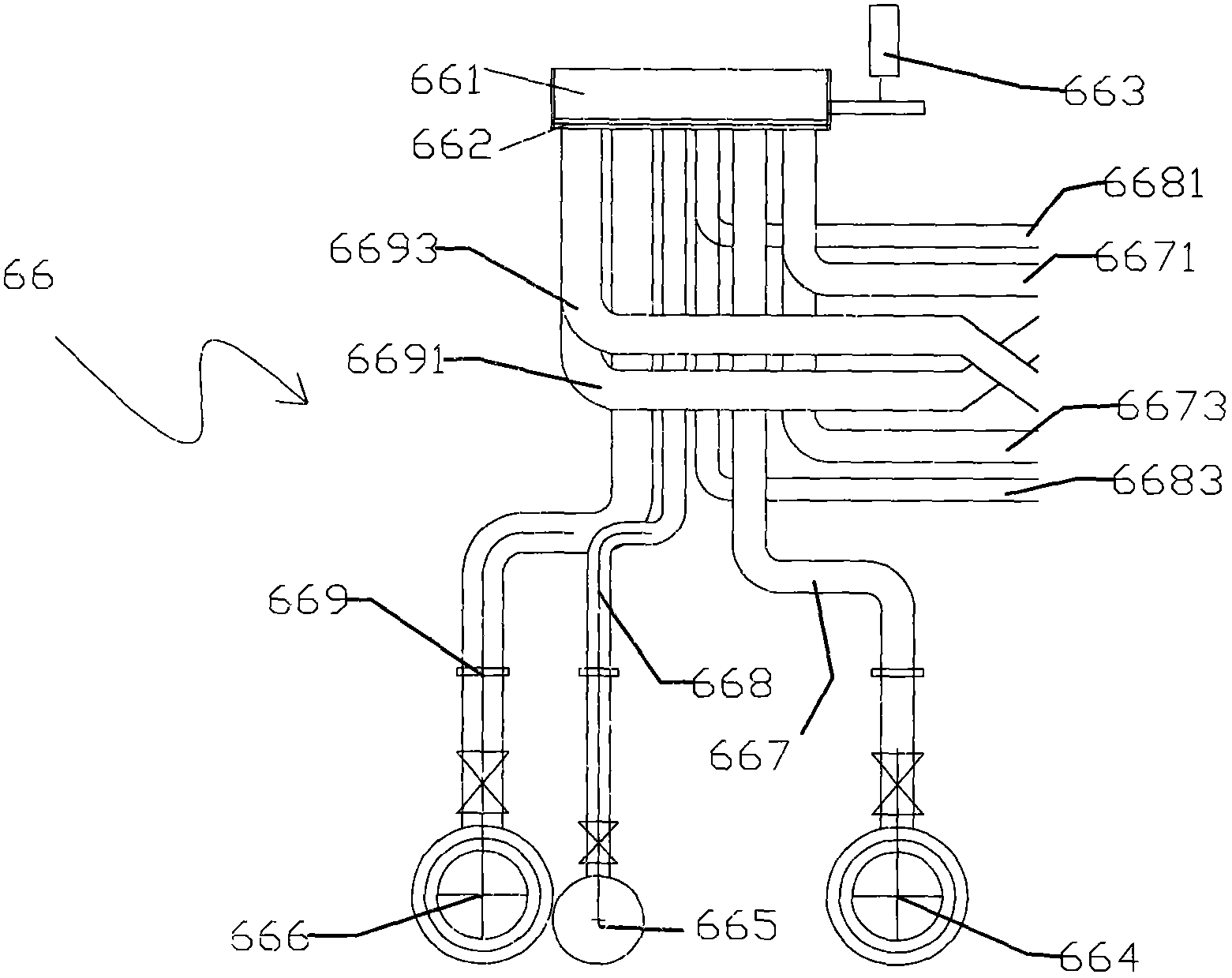

Hot waste gas active coke regeneration device combining pyrolysis and gasification of coal gangue and purification and combustion of raw gas

ActiveCN103242910AEasy to reuseNo need to increase energy consumptionCombustible gas coke oven heatingGas purification with selectively adsorptive solidsCombustionExhaust gas emissions

The invention discloses a hot waste gas active coke regeneration device combining pyrolysis and gasification of coal gangue and purification and combustion of raw gas, which comprises a coal gangue pyrolysis device and a water gas reaction device of a coal gangue pyrolysis and gasification device, a raw gas guiding device and an active coke regenerator, wherein the raw gas guiding device comprises a raw gas concentration chamber, an inner guiding channel, an outer guiding channel, a main guiding channel and a guiding loop; the active coke regenerator comprises a regenerator shell, a hot waste gas evaporation pipe network and an unsaturated active coke recovery bin; the regenerator shell is provided with an evaporation oil gas discharge pipe; the waste gas evaporation pipe network forms an independent loop and is arranged in the cavity of the regenerator shell; the bottom of the waste gas evaporation pipe network is provided with a hot waste gas intake pipe, and the top is provided with a hot waste gas discharge pipe; the purified raw gas is combusted; and the waste gas after combustion is transferred into the hot waste gas intake pipe of the active coke regenerator. According to the invention, saturated active coke adsorbed due to purification is heated and evaporated to become unsaturated active coke, thus facilitating the reutilization of the unsaturated active coke.

Owner:SHANXI XINLI ENERGY TECH

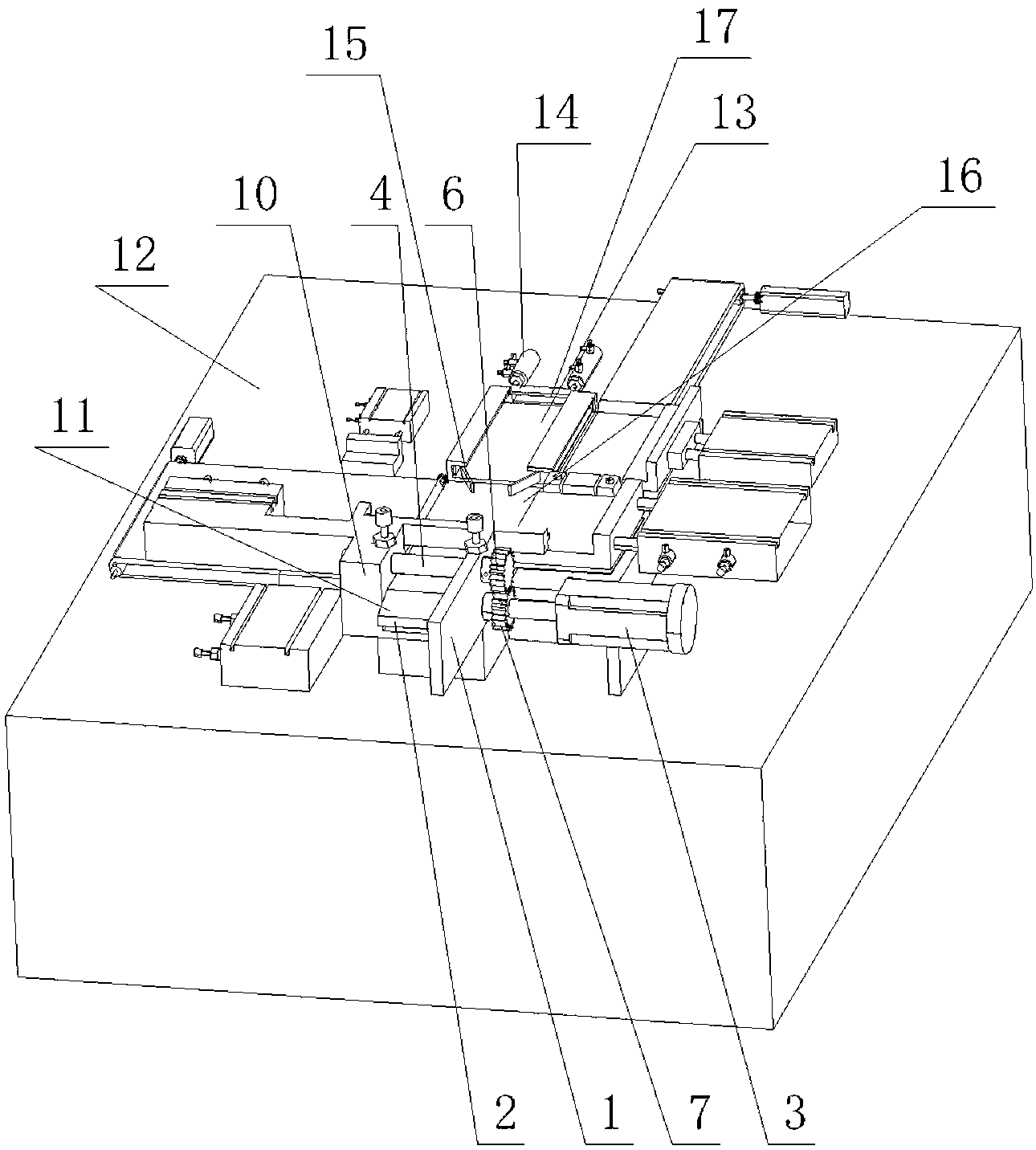

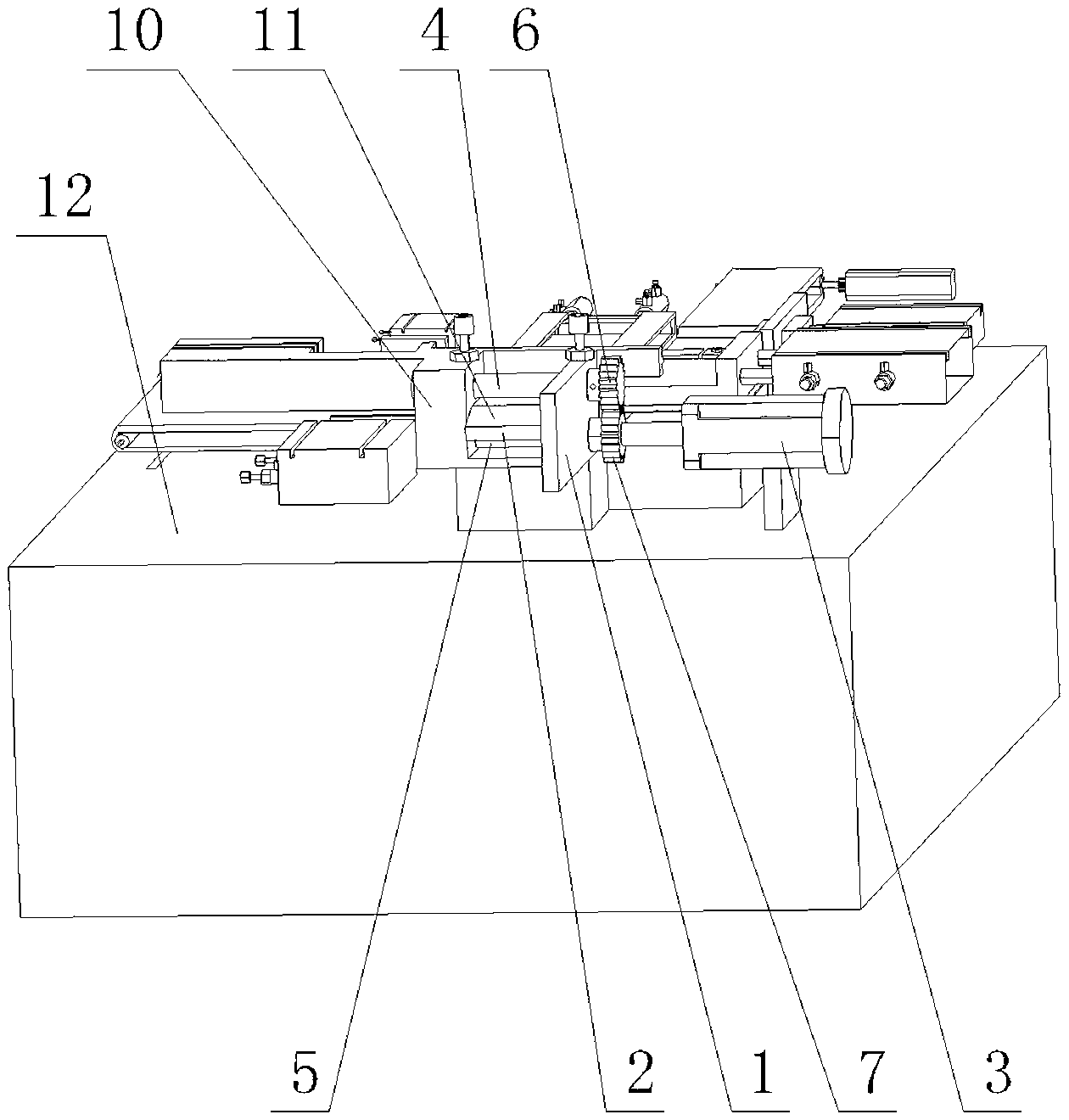

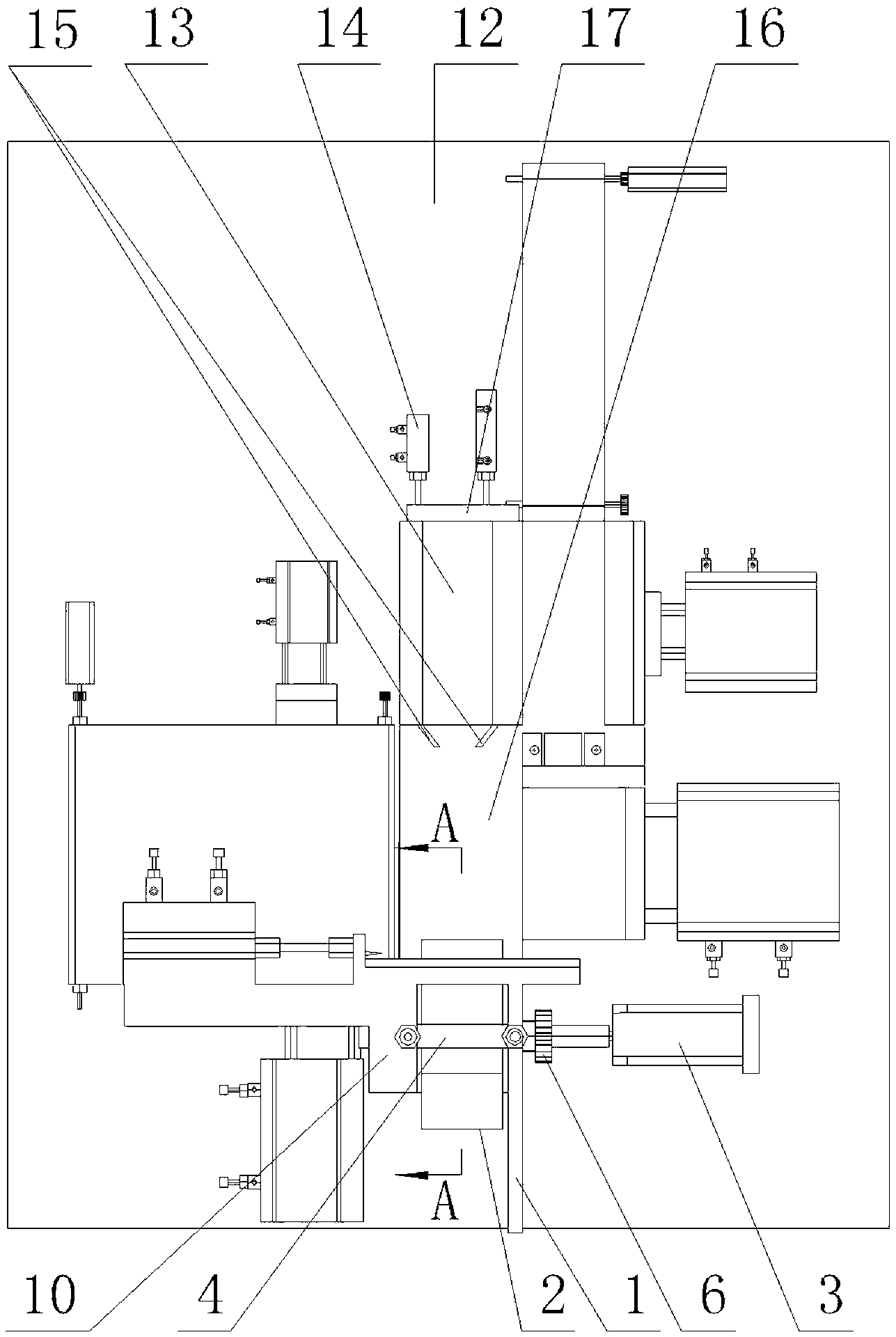

Cell heat shrink film packaging machine

ActiveCN102556423BStrong service lifeNot easy to damageWrapping material feeding apparatusGear drivePackaging machine

Owner:NINGBO FUBANG BATTERY

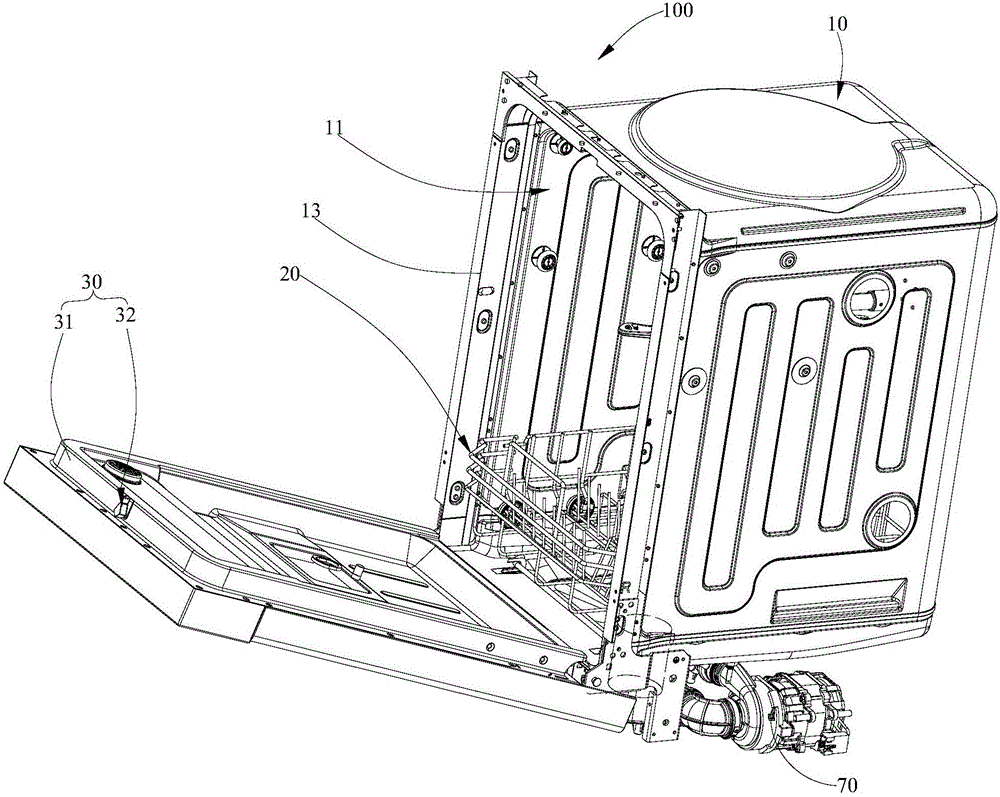

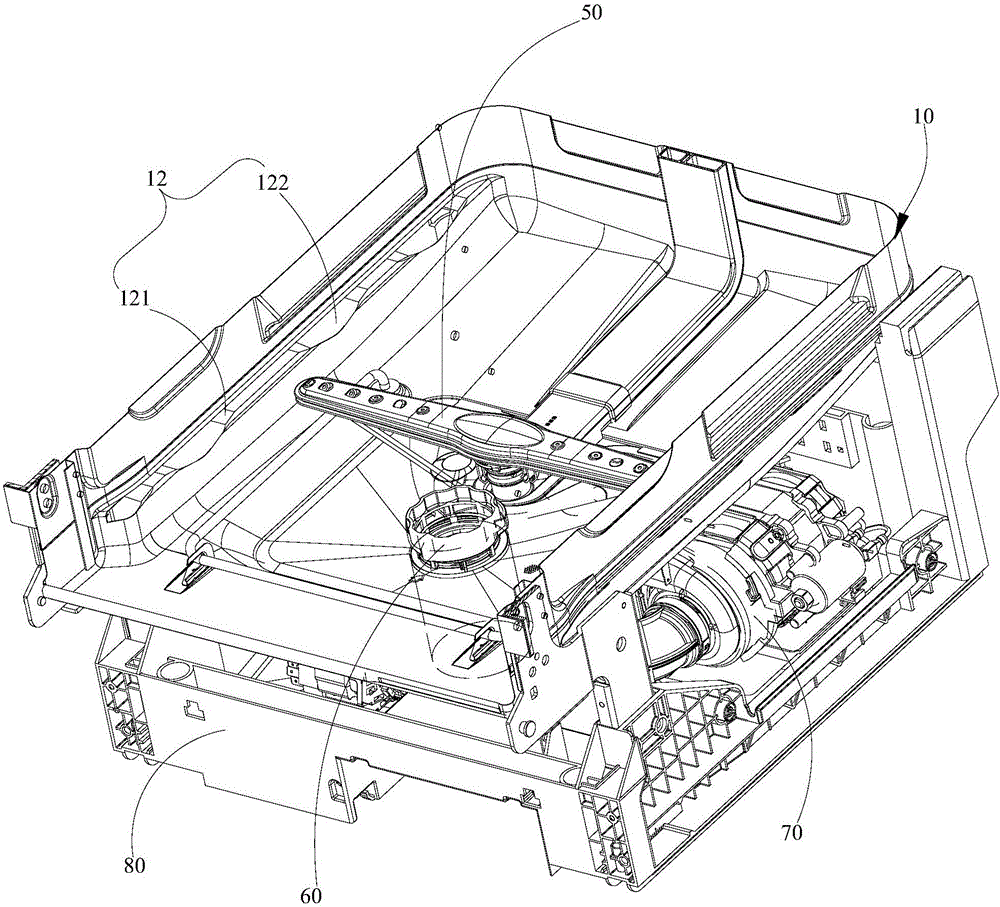

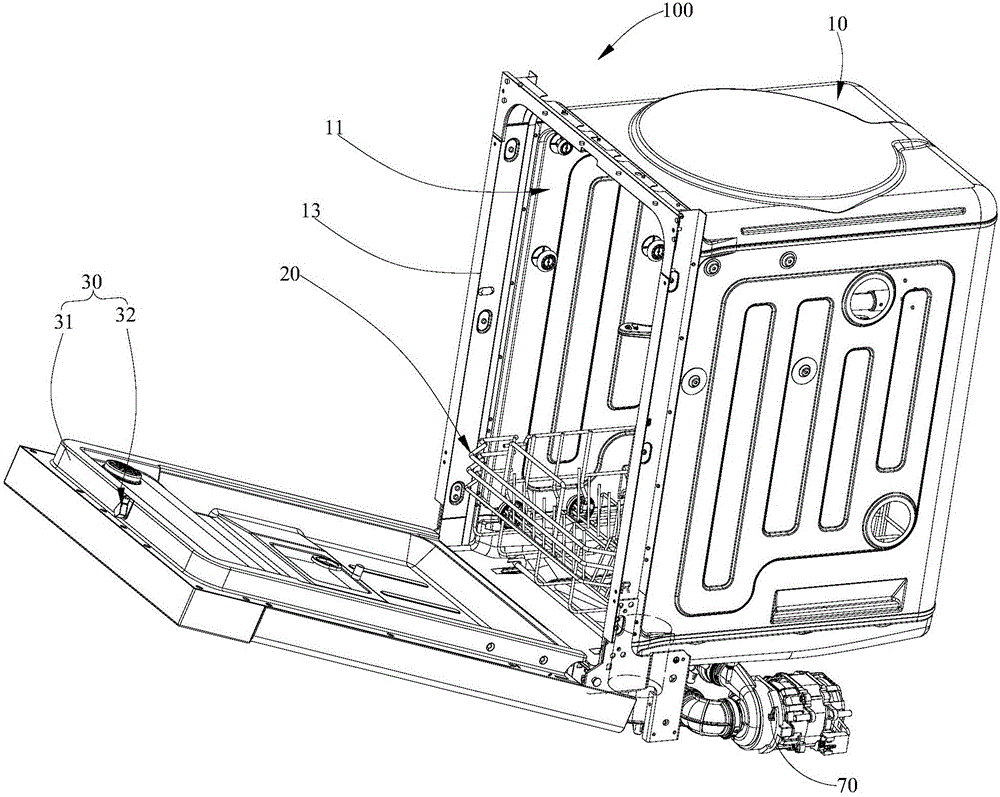

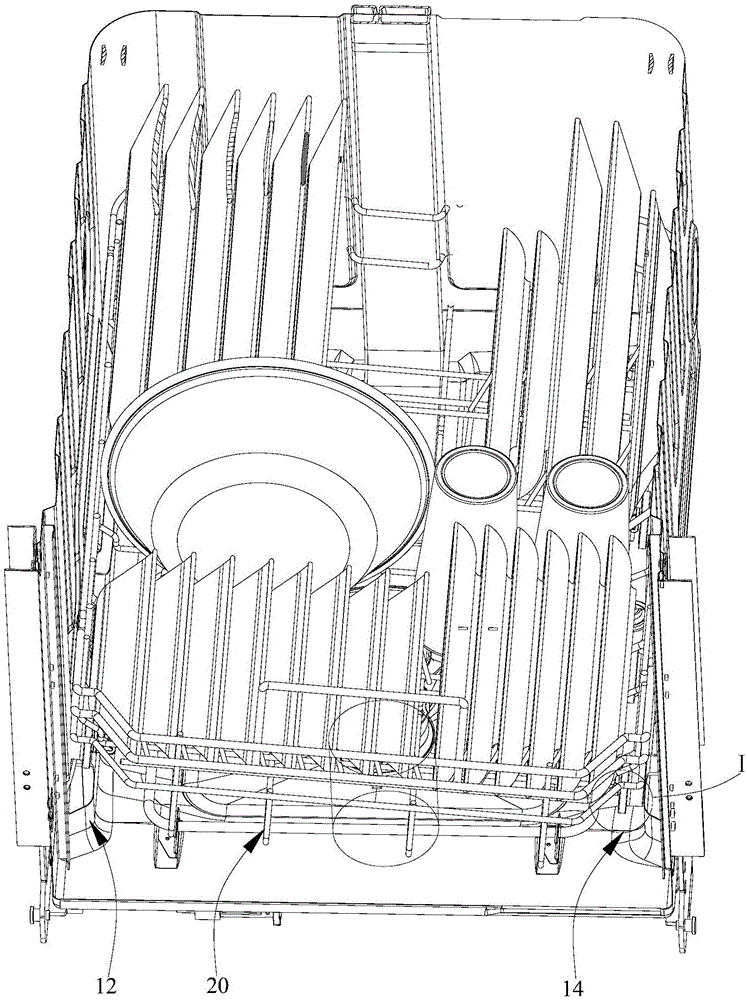

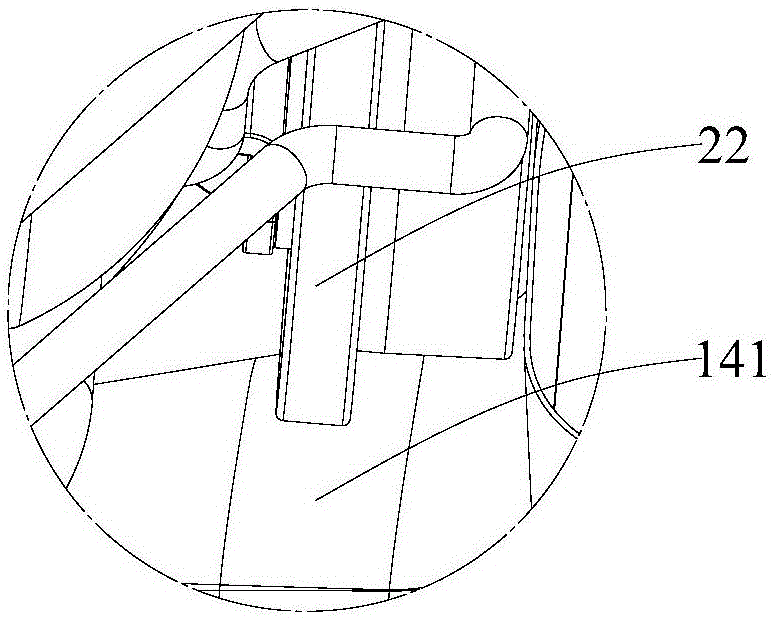

Dish washing machine

ActiveCN106419790AFast dryingImprove drying efficiencyTableware washing/rinsing machine detailsHome appliance efficiency improvementCold airEngineering

The invention discloses a dish washing machine, which comprises a tank, a bearing component and a door component, wherein a washing cavity and an opening, which communicates with the washing cavity, are formed in the tank; cavity platforms are arranged in the washing cavity; the cavity platforms comprise inclined planes; the bearing component is movably arranged on the cavity platforms; the door component comprises a door body; the door body is rotatably connected to the tank, so that an opening of the tank is opened or closed; the inclined planes are arranged in a mode of inclining towards the opening; when the opening is closed by virtue of the door body, the bearing component is accommodated in the washing cavity and is supported on the inclined planes; and when the opening is opened by virtue of the door body, the bearing component, under the effect of gravity thereof, is automatically moved towards the opening from the inclined planes. Since the bearing component, under the effect of gravity thereof, is automatically moved towards the opening from the inclined planes when the opening is opened by virtue of the door body, the bearing component can extend towards the opening, so that a contact area of high-temperature tableware on the bearing component with external cold air is increased, and subsequently, the drying speed of the dish washing machine is accelerated.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD +1

Semiconductor device with self-adaptive heat dissipation function

InactiveCN113985986AIncrease contact areaNo need to increase energy consumptionCleaning using toolsDigital processing power distributionDevice materialEngineering

The invention relates to the technical field of semiconductors, and discloses a semiconductor device with a self-adaptive heat dissipation function. The semiconductor device comprises a main board, a processor is arranged at the top of the main board, a heat conduction block sleeves the surface of the processor, the top of the processor is in contact with the bottom of a heat conduction plate, a fan is fixedly connected to the front part of the heat conduction block, the inner wall of the heat conduction plate is rotatably connected with cooling fins, the inner walls of the cooling fins are rotatably connected with a telescopic plate, the surfaces of the cooling fins are provided with a cleaning mechanism, and an air bag is arranged between the telescopic plate and the heat conduction plate. According to the semiconductor device of the invention, when the temperature of the processor rises, the air bag is heated and expands, due to the vertical limiting on the air bag by the telescopic plate, the air bag expands towards the two sides and pushes the cooling fins on the two sides to unfold, the direct contact area between the cooling fins and air can be increased, self-adaptive cooling can be achieved under the condition that the rotating speed of a fan is not changed, convenience is achieved, and energy consumption of a power source does not need to be increased.

Owner:黄华顺

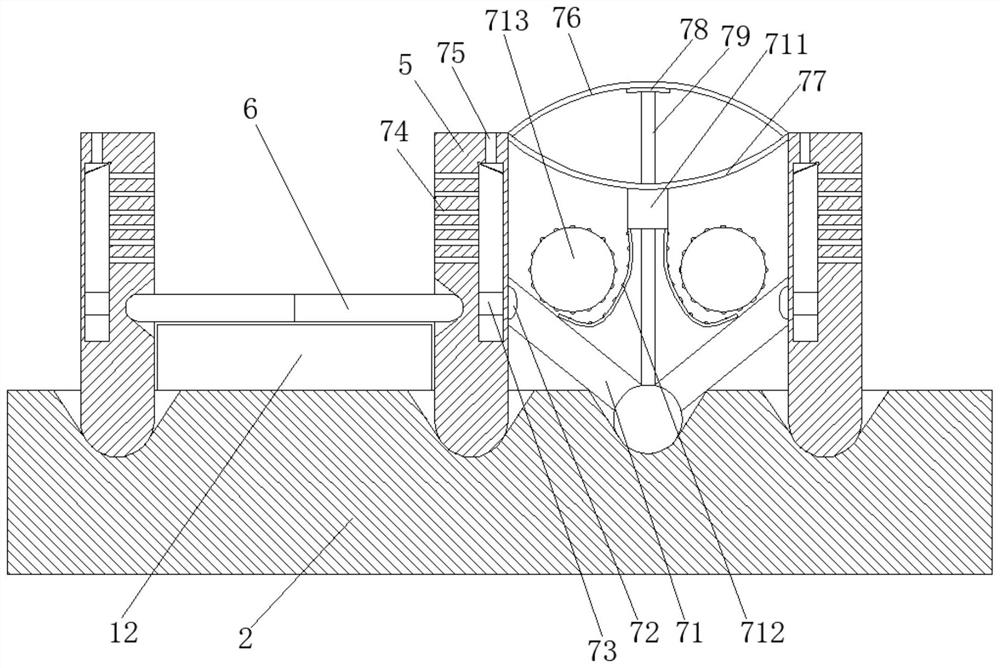

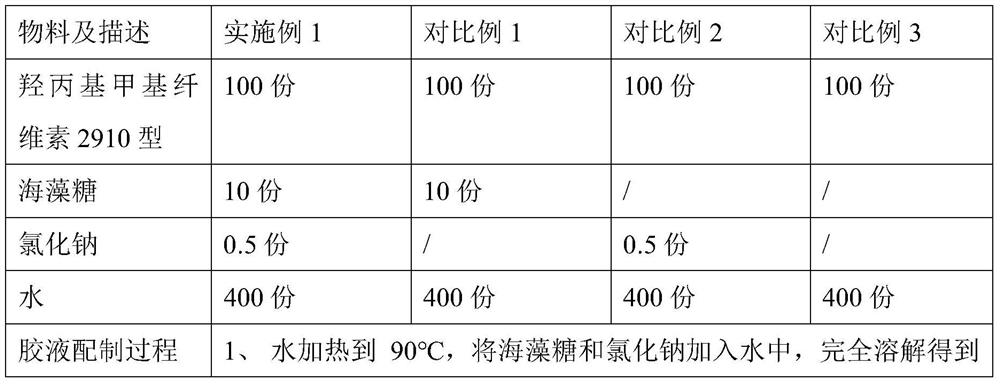

Thermosetting hydroxypropyl methylcellulose hollow capsule and preparation method thereof

PendingCN114209674AIncrease humidityRelative humidity does not need to be increasedInorganic non-active ingredientsCapsule deliveryCellulosePolymer science

The invention discloses a thermoset hydroxypropyl methylcellulose hollow capsule and a preparation method thereof. The thermoset hydroxypropyl methylcellulose hollow capsule is prepared from the following components in parts by weight: 90 to 120 parts of hydroxypropyl methylcellulose, 10 to 15 parts of trehalose, 0.5 to 0.6 part of sodium chloride and 50 to 450 parts of water. According to an existing production process, the problems of cracking and wrinkling are solved mainly by increasing the relative humidity in a dry environment to be larger than 80%, energy consumption is large, by means of the method, the relative humidity in the dry environment does not need to be increased, the relative humidity is only maintained to be 55%-75%, and energy consumption can be reduced; and meanwhile, the problems of cracking and wrinkling in batch production of the heat-setting hydroxypropyl methylcellulose hollow capsules can be solved.

Owner:JIANGSU LEFAN CAPSULE

Export condensation and recovery purification method for coke oven raw gas of coal gangue pyrolysis gasification

ActiveCN103224818AGood economic valueTake advantage ofGas purification with selectively adsorptive solidsGas purification by non-gaseous materials condensationCoal gangueBenzene

The invention discloses an export condensation and recovery purification method for the coke oven raw gas of coal gangue pyrolysis gasification. The method includes the steps of: (1) providing a heat source for coal gangue pyrolysis gasification by heat storage and exchange and alternate combustion of purified coal gas; (2) letting carbon in a coal gangue pyrolysis solid product encounter superheated steam to undergo a water gas reaction so as to generate water gas; (3) exporting coke oven raw gas; (4) spraying ammonia water on the exported coke oven raw gas to lower the temperature so as to form a mixed solution of coal tar and ammonia water; (5) subjecting the mixed solution of coal tar and ammonia water to precipitation separation; (6) leaving the cooled coke oven raw gas to active coke adsorption, applying the adsorbed clean gas to storage or combustion, and subjecting saturated active coke to evaporation regeneration; and (7) fractionating evaporation regenerated light oil, crude benzene, a three-oil mixture, anthracene oil and other ingredients. The method provided in the invention recovers and purifies the coke oven raw gas in coal gangue pyrolysis gasification, realizes extraction and utilization of carbon, oil, gas and other substances in the coke oven raw gas, and has good economic value.

Owner:SHANXI XINLI ENERGY TECH

Thermal-cycle continuous pyrolysis-gasification comprehensive device for coal gangues

ActiveCN103205278BLower discharge temperatureNo need to increase energy consumptionIndirect and direct heating destructive distillationGas purification with selectively adsorptive solidsExhaust fumesProcess engineering

The invention provides a thermal-cycle continuous pyrolysis-gasification comprehensive device for coal gangues. The thermal-cycle continuous pyrolysis-gasification comprehensive device for coal gangues comprises a coal gangue pyrolysis-gasification furnace, a raw coke oven gas condensing device, a raw coke oven gas recycling and purifying device, a furnace coal gangue heat waste gas humidifying and dehydrating device and tail gas water-spraying purifier, wherein a raw coke oven gas guide-out device of the coal gangue pyrolysis-gasification furnace is communicated with the raw coke oven gas condensing device; and the raw coke oven gas condensing device is communicated with the raw coke oven gas recycling and purifying device. The purified raw coke oven gas is combusted; the combusted waste gas is fed to the furnace coal gangue heat waste gas humidifying and dehydrating device; and the dehydrated waste gas is exhausted through the tail gas water-spraying purifier. Besides, the combusted waste gas is fed to an active coke regenerator of the raw coke oven gas recycling and purifying device; and the waste gas regenerated by the active coke regenerator is fed to a waste gas heat exchange dehydrator or the tail gas water-spraying purifier. The thermal-cycle continuous pyrolysis-gasification comprehensive device for the coal gangues is prominent in environmental protection benefit by utilizing the pyrolysis-gasification of the coal gangues and not consuming extra energy resources, and is considerable in economic value.

Owner:SHANXI XINLI ENERGY TECH

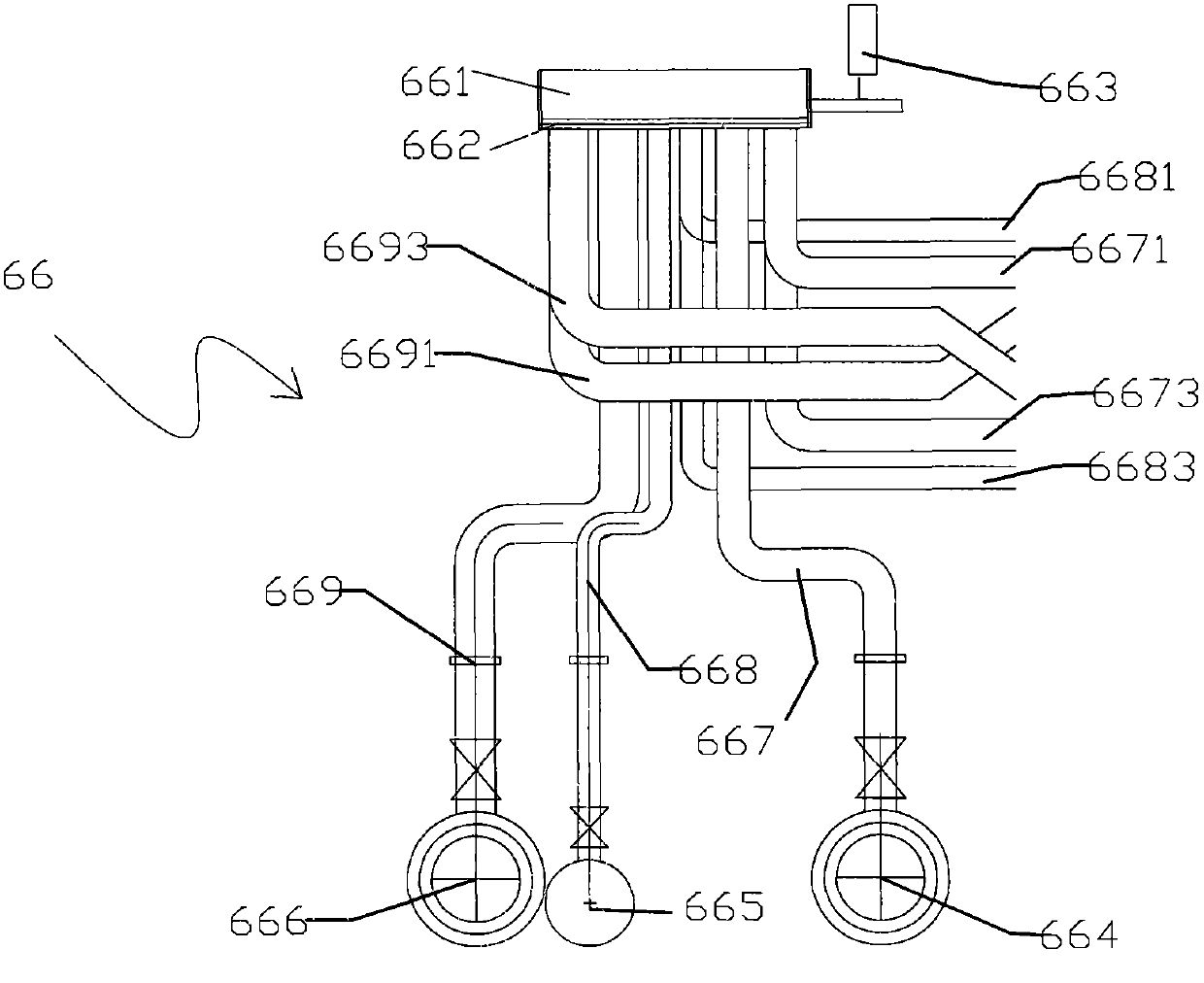

Gangue pyrolysis gasification raw gas purification combustion recycle method

ActiveCN103275765AAchieve pressure controlEfficient combustionCombustible gas coke oven heatingCombustible gas productionWater vaporProduct gas

The invention discloses a gangue pyrolysis gasification raw gas purification combustion recycle method. The method comprises the following steps of 1, through purified-gas thermal-storage heat-exchange alternant combustion carried out by an external gas heating device and an internal gas heating device of a gangue pyrolysis device, providing a heat source to gangue pyrolysis in a pyrolysis gasification chamber in a high temperature environment, 2, through a water gas reaction device, feeding high temperature water vapor into the pyrolysis gasification chamber from the lower part so that the high temperature water vapor contacts with the high-temperature gangue pyrolysis products in the pyrolysis gasification chamber and undergoes a water gas reaction to produce water gas, 3, exporting the raw gas which comprises the gas produced by gangue pyrolysis and the water gas produced by the water gas reaction, 4, feeding the raw gas into an active parching recoverer, carrying out active coke adsorption, and transporting the adsorbed clean gas into the external gas heating device and the internal gas heating device for combustion by clean gas output pipes. Through utilization of combustion of carbon, oil and gas in gangue, a cost is reduced.

Owner:SHANXI XINLI ENERGY TECH

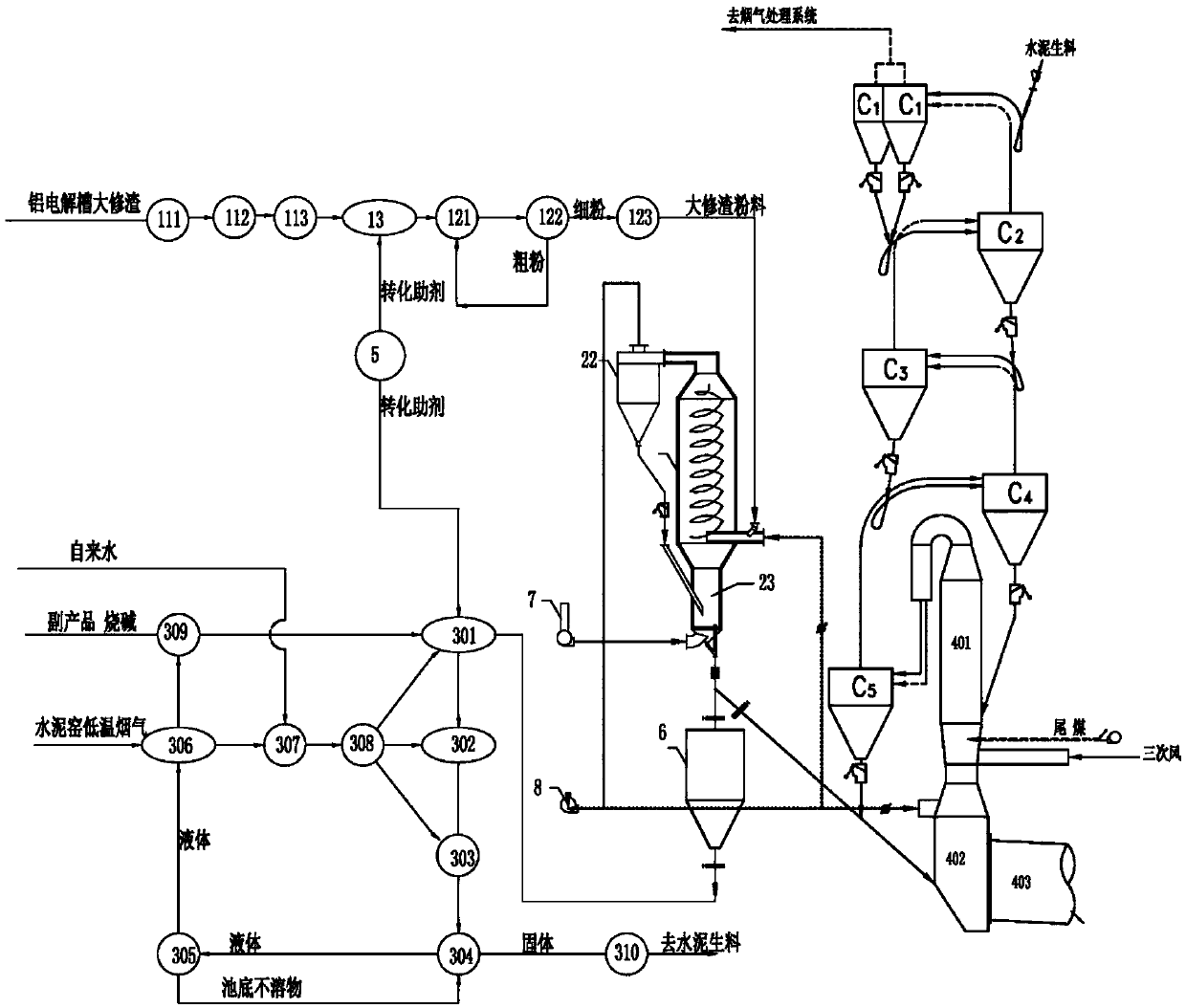

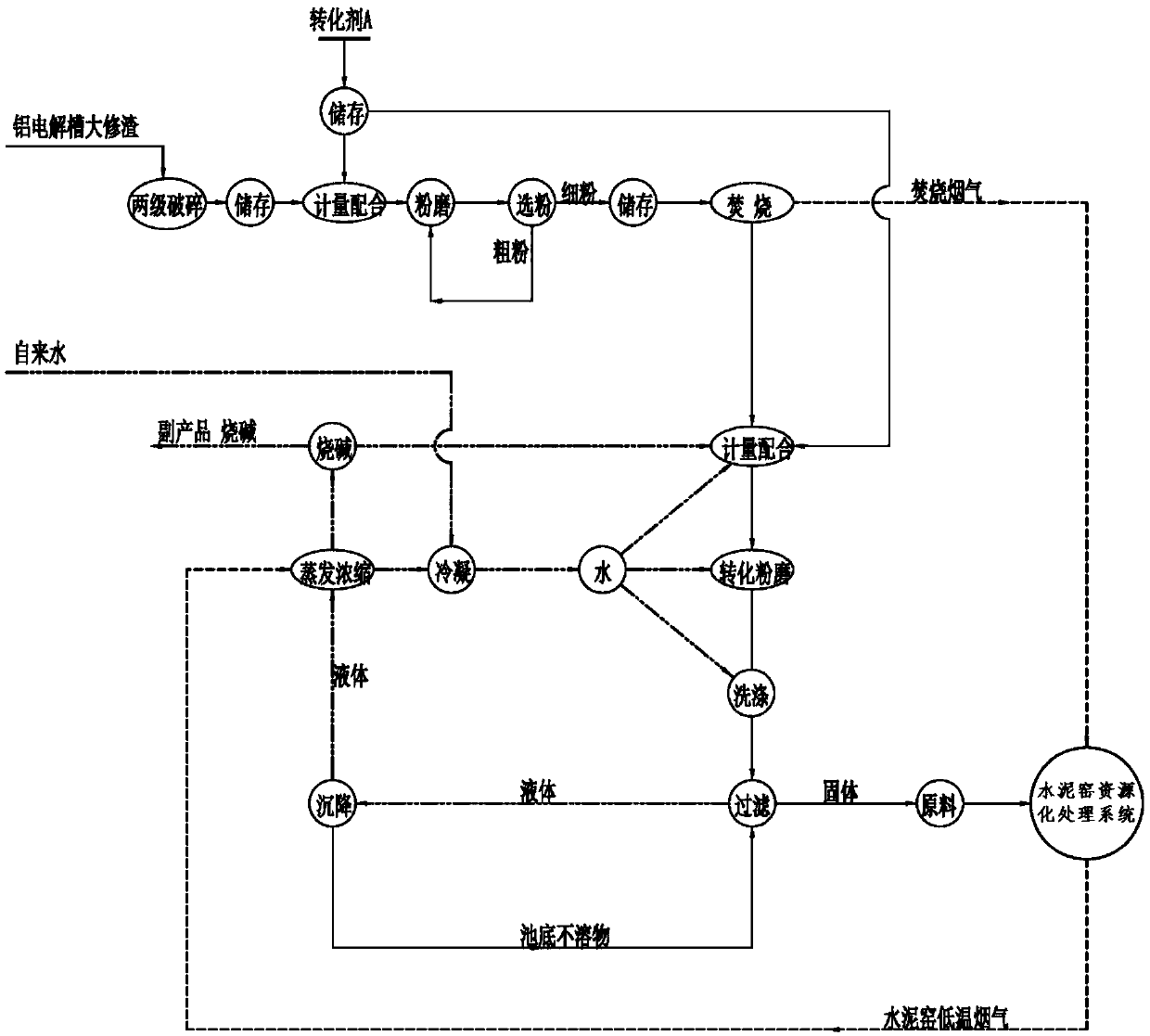

System and method for treating overhauling slag of aluminum cell by cement kiln bypass incinerating

ActiveCN108679628AEliminate the risk of secondary pollutionPromote safe productionIndirect carbon-dioxide mitigationIncinerator apparatusCyanideSlag

The invention provides a system and method for treating overhauling slag of an aluminum cell by cement kiln bypass incinerating. The system comprises an overhauling slag crushing system, a cement kilnbypass incinerating system, a conversion and dealkalizing system and a cement kiln resourceful treatment system which are sequentially connected. The method comprises the steps of S1, crushing and powdering the overhauling slag; S2, performing cement kiln bypass incinerating and disinfecting; S3, performing conversion and dealkalizing; and S4, performing resourceful treatment on a cement kiln. According to the system and the method, a suspension combined incinerating furnace is arranged at a cement kiln bypass; the crushed overhauling slag is incinerated under the conditions of high temperature, rich oxygen and long staying time, so that carbon materials in the overhauling slag can fully burn, and moreover, cyanide in the overhauling slag can be oxidized to remove the toxicity under high-temperature aerobic and alkaline conditions; the cinder obtained after incinerating of the overhauling slag is washed through alkaline liquid in order to be converted into a mineralizer containing fluorite for the cement kiln, and a caustic soda byproduct can be obtained, and as a result, the harmless, resourceful, ultimate and massive treatment of the overhauling slag of the aluminum cell can beachieved.

Owner:长沙中硅环保科技有限公司

Method for humidity adjustment by gangue pyrolysis gasification raw gas combustion hot-exhaust gas

ActiveCN103275764ALower discharge temperatureNo need to increase energy consumptionCombustible gas coke oven heatingChemical industryEcological environmentAtmospheric air

The invention discloses a method for damping by gangue pyrolysis gasification raw gas combustion hot-exhaust gas. The method comprises the following steps of 1, through thermal-storage heat-exchange alternate combustion of purified gas, providing a heat source to gangue pyrolysis gasification, 2, producing water gas by a water gas reaction of carbon in solid products produced by gangue pyrolysis and the overheated water vapor, 3, exporting raw gas, and 4, purifying the exported raw gas, carrying out thermal-storage heat-exchange alternate combustion, and carrying out humidity-adjustment dehydration of gangue particles before being fed into the furnace by the hot-exhaust gas obtained by combustion. The method does not consume extra energy consumption, saves a cost, cools hot-exhaust gas, is conducive to discharge of low-temperature exhaust gas into the atmosphere and realizes ecological environment protection.

Owner:SHANXI XINLI ENERGY TECH

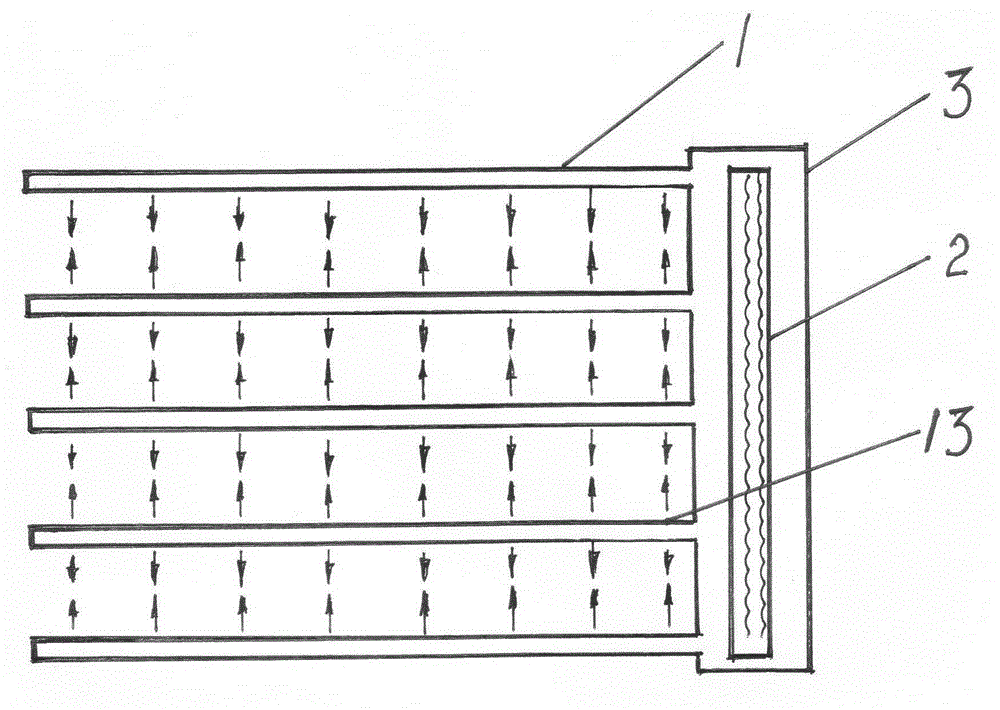

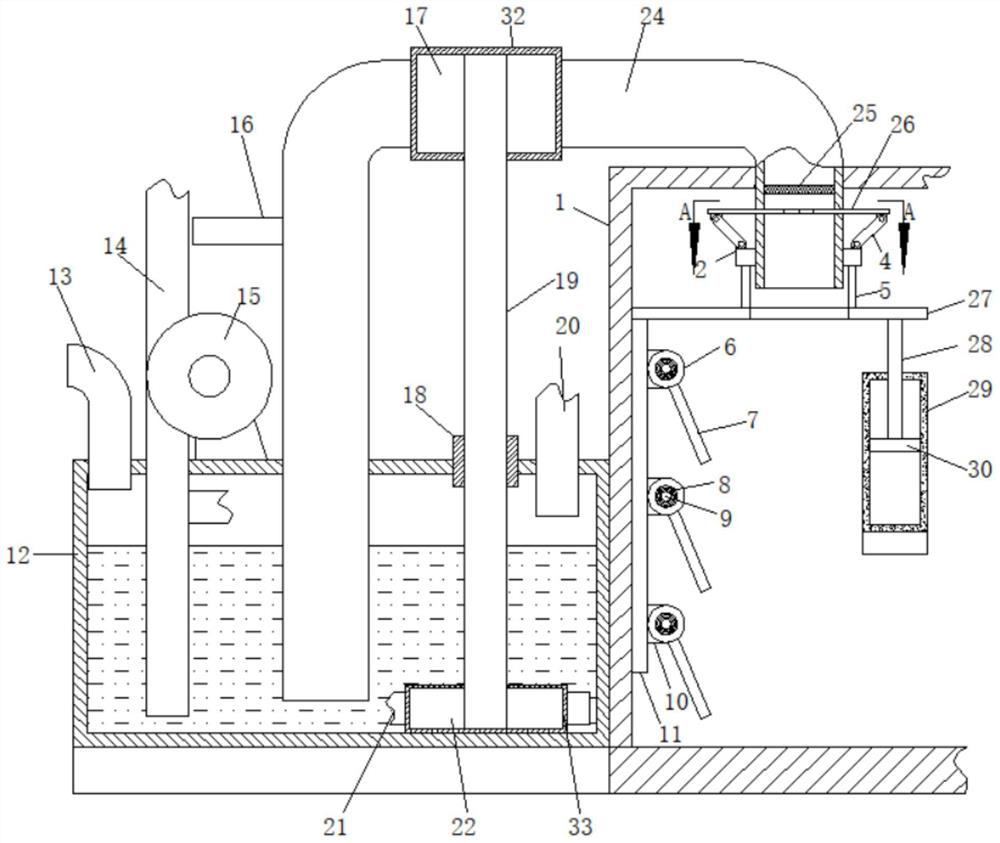

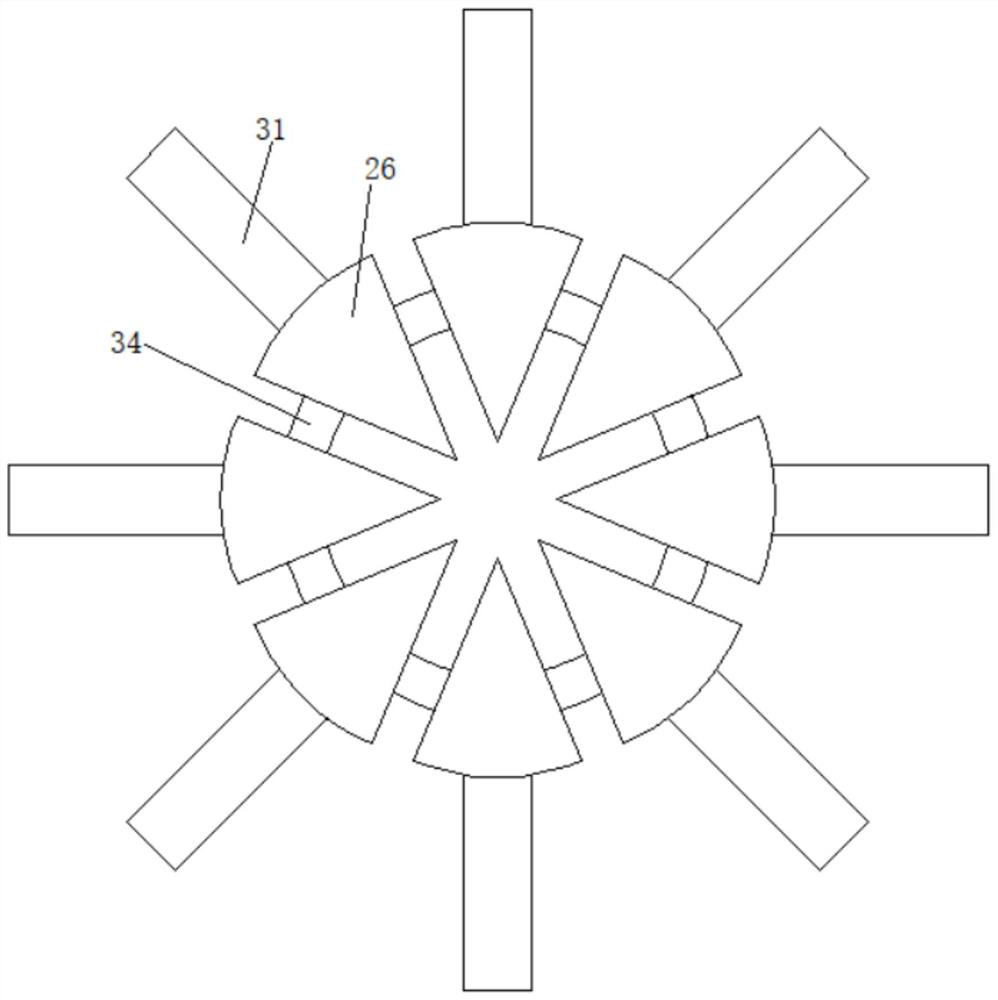

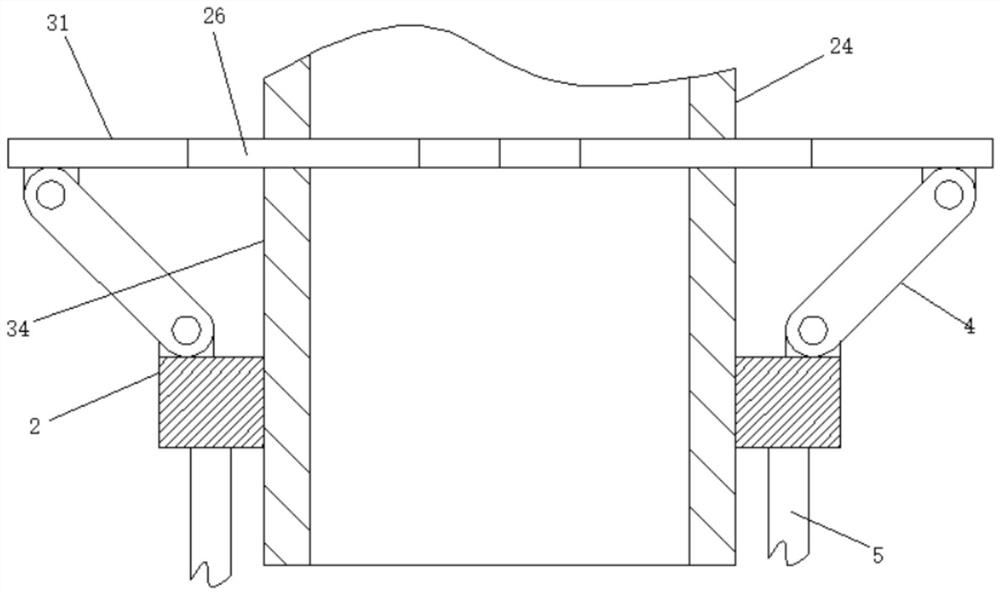

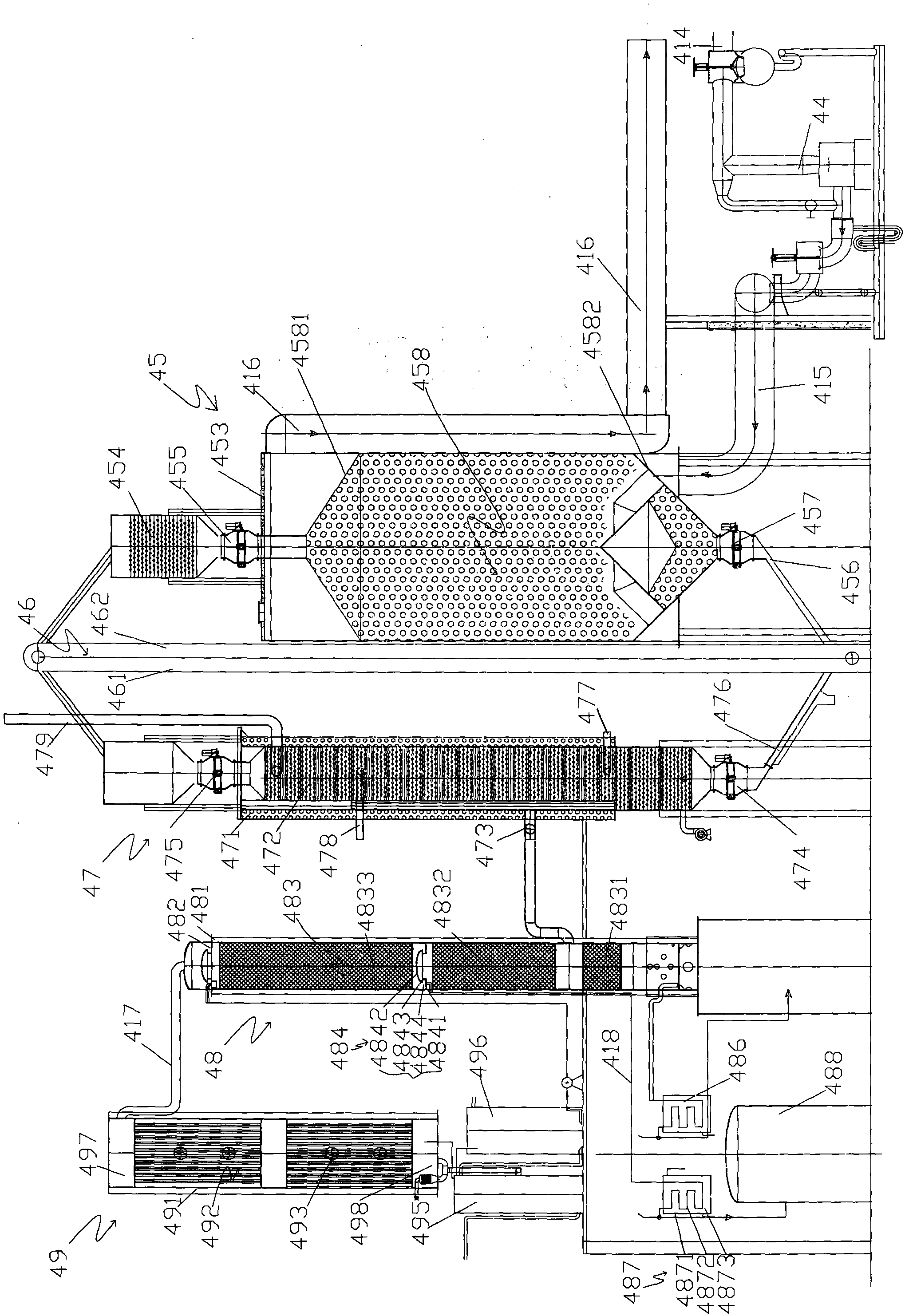

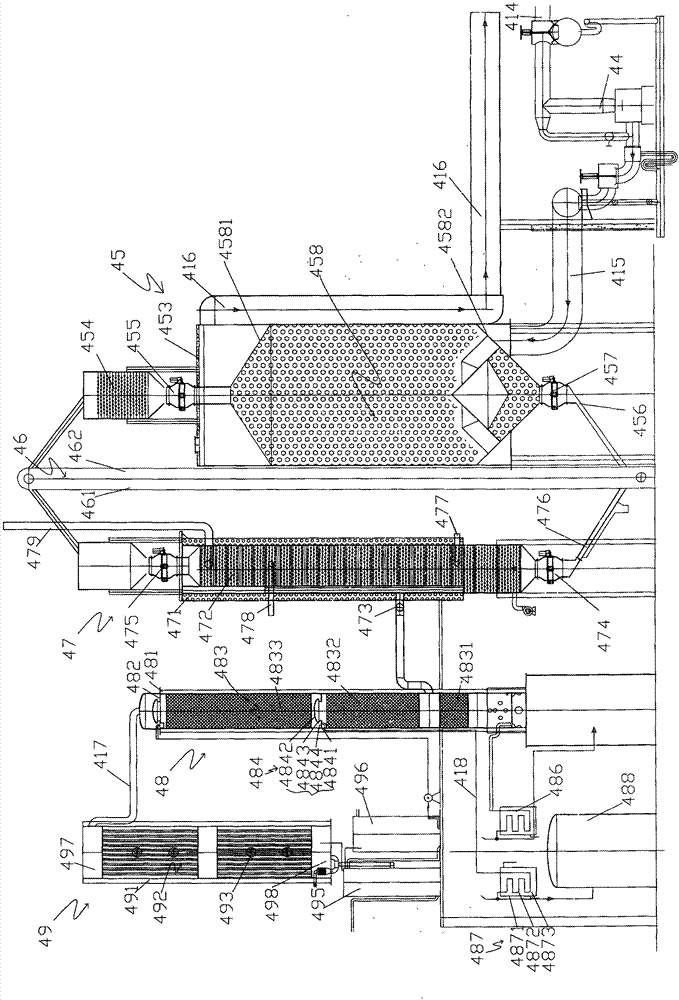

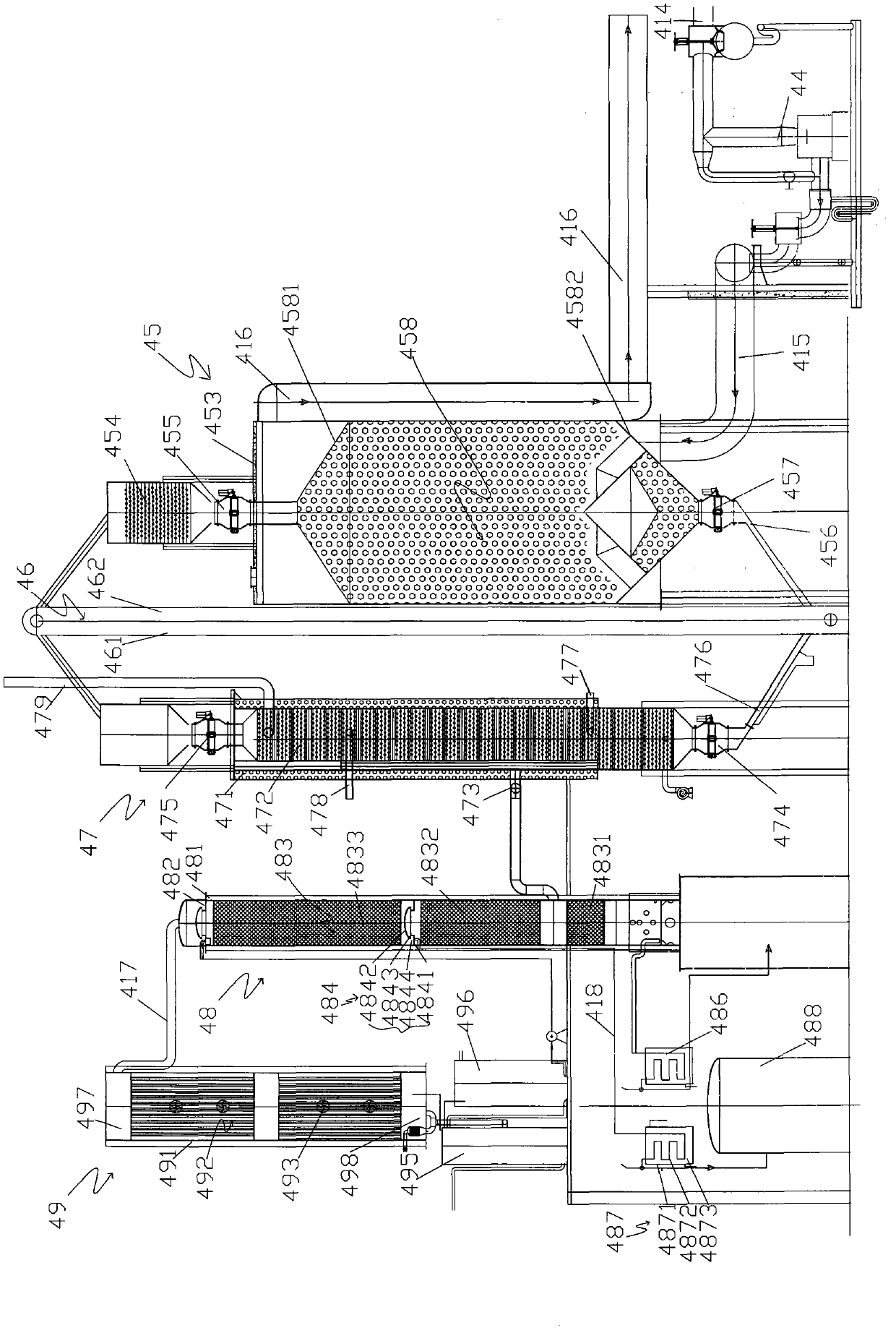

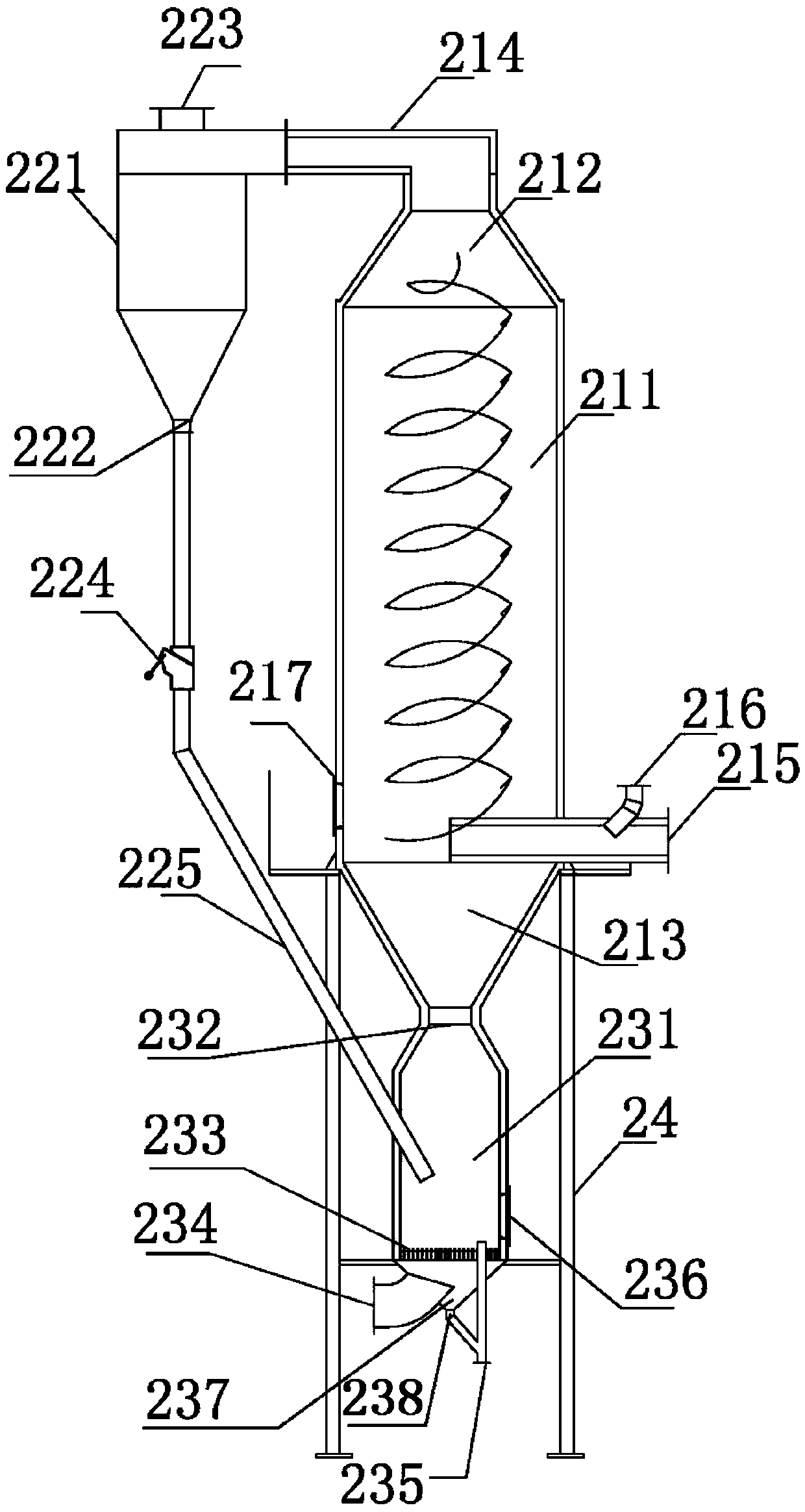

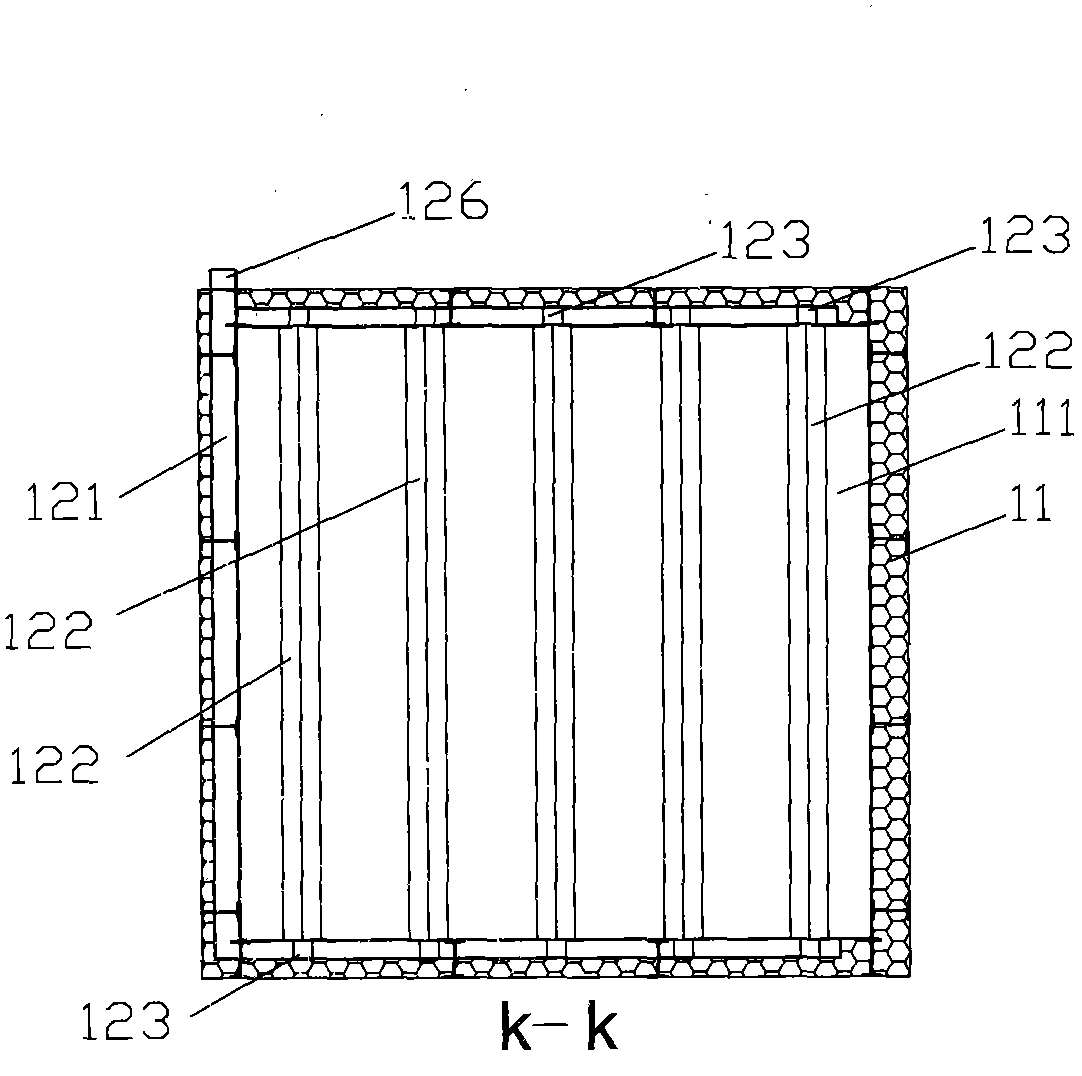

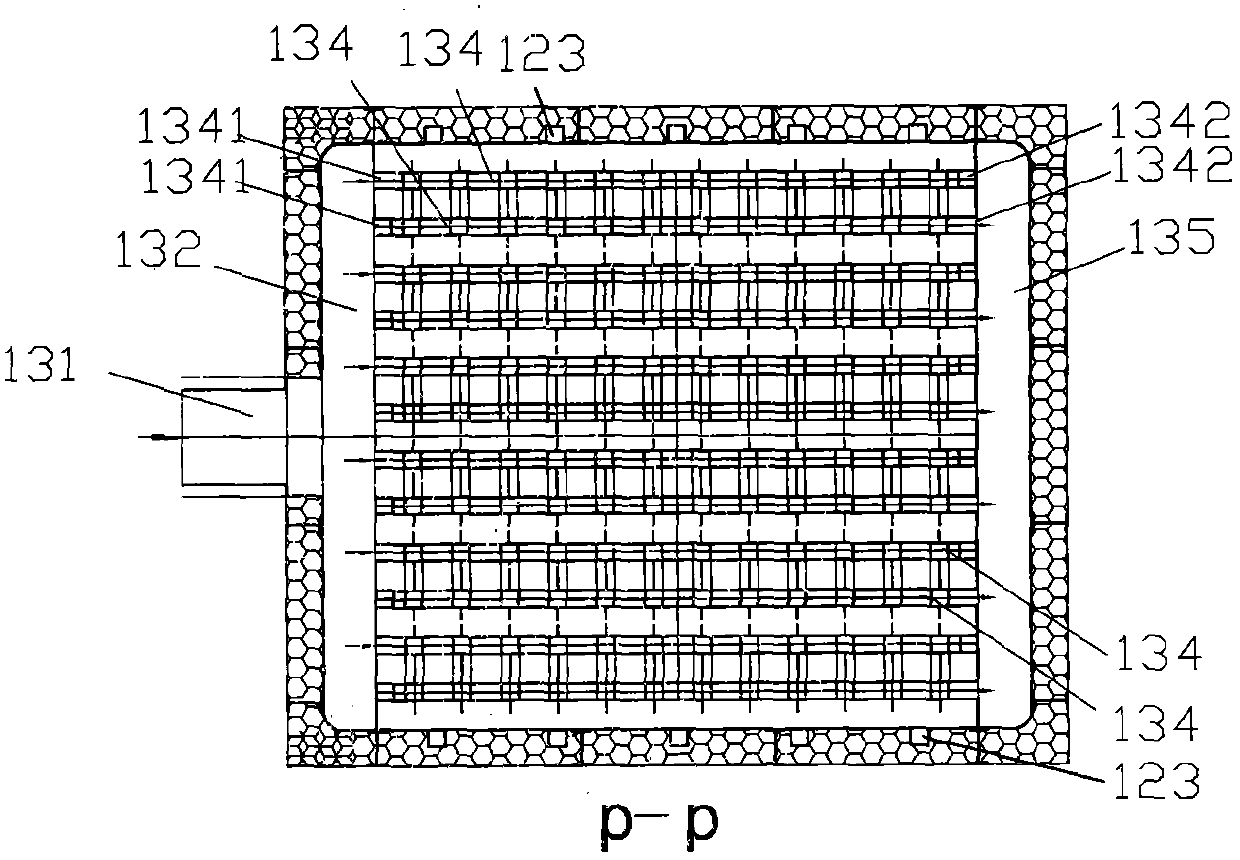

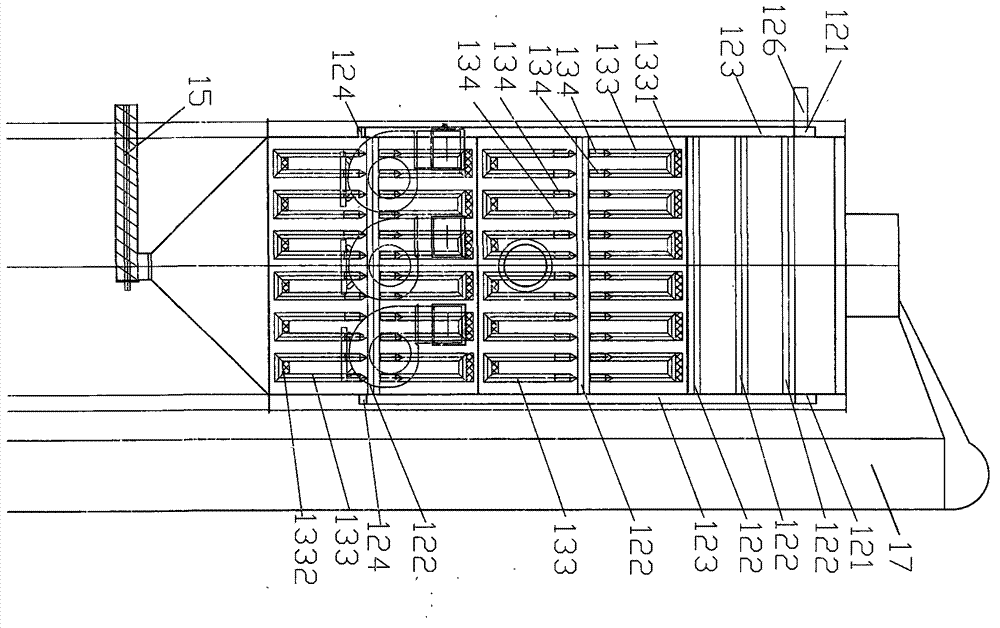

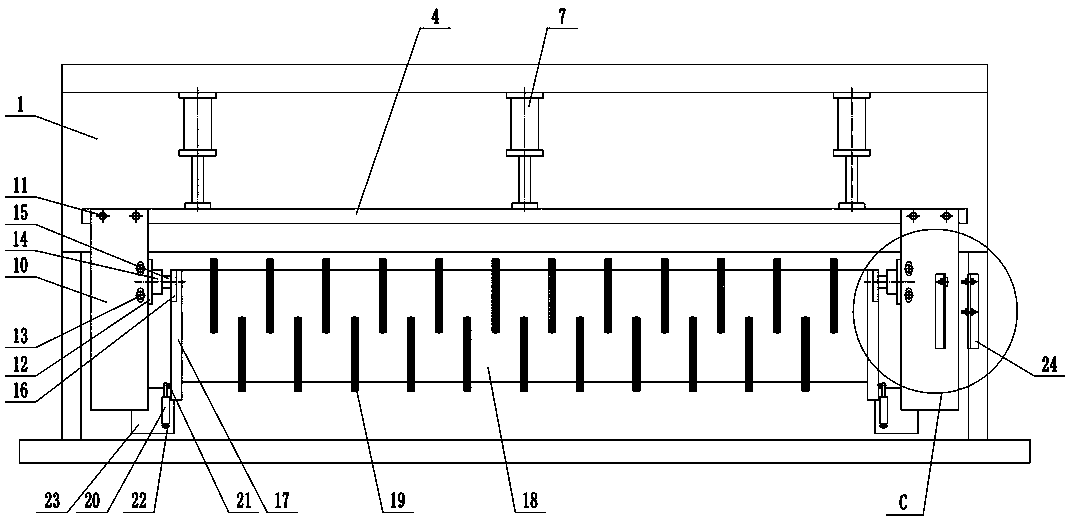

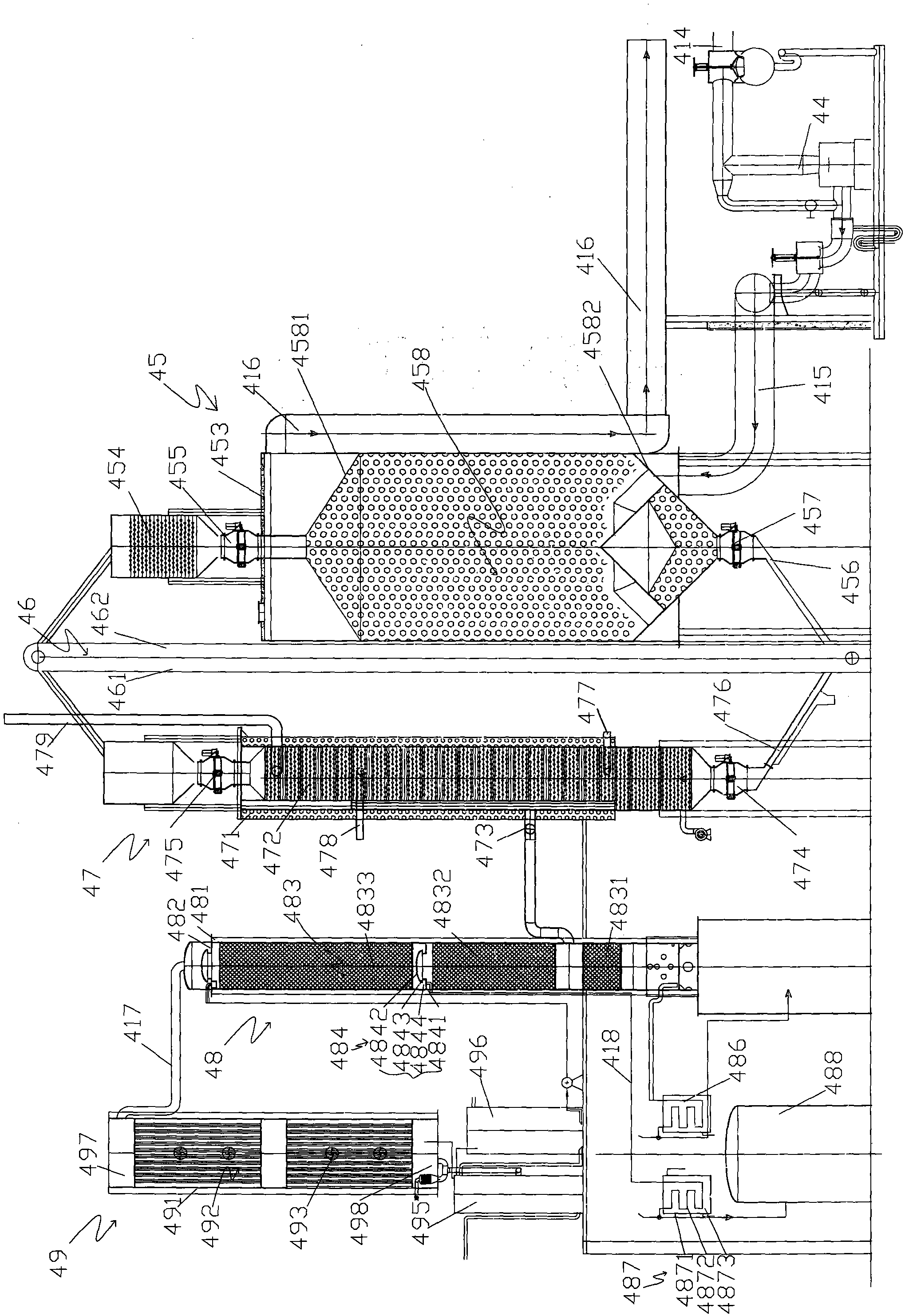

Continuous thermal cycle coal gangue pyrolysis gasification humidifying and tail gas purifying device

ActiveCN103242908ALower discharge temperatureNo need to increase energy consumptionCombination devicesCombustible gas coke oven heatingWater vaporExhaust fumes

The invention provides a continuous thermal cycle coal gangue pyrolysis gasification humidifying and tail gas purifying device which comprises a coal gangue pyrolysis gasification device, a crude gas guiding device, a furnace coal gangue hot waste gas humidifying dehydrating device, and a tail gas showering purifier, wherein the coal gangue pyrolysis gasification device consists of a coal gangue pyrolysis device and a water gas reaction device; the coal gangue pyrolysis device consists of a pyrolysis gasification chamber, an external gas heating device and an internal gas heating device; the water gas reaction device consists of a material cooling device and a steam generation device; the furnace coal gangue hot waste gas humidifying dehydrating device consists of a water vapor discharge guider and a waste gas heat exchange dehydrator; the tail gas showering purifier consists of a purifying cylinder, an atomized sprinkler, a stainless steel filter screen mesh layer, a tail gas deflector, a water tank, an impounding reservoir and a spray water pump; and raw gas guided from the raw gas guiding device is purified and then burnt, the burnt waste gas is sent to the waste gas heat exchange dehydrator to dehydrate coal gangue aggregates in the furnace, and the dehydrated waste gas is purified and discharged by using the tail gas showering purifier.

Owner:SHANXI XINLI ENERGY TECH

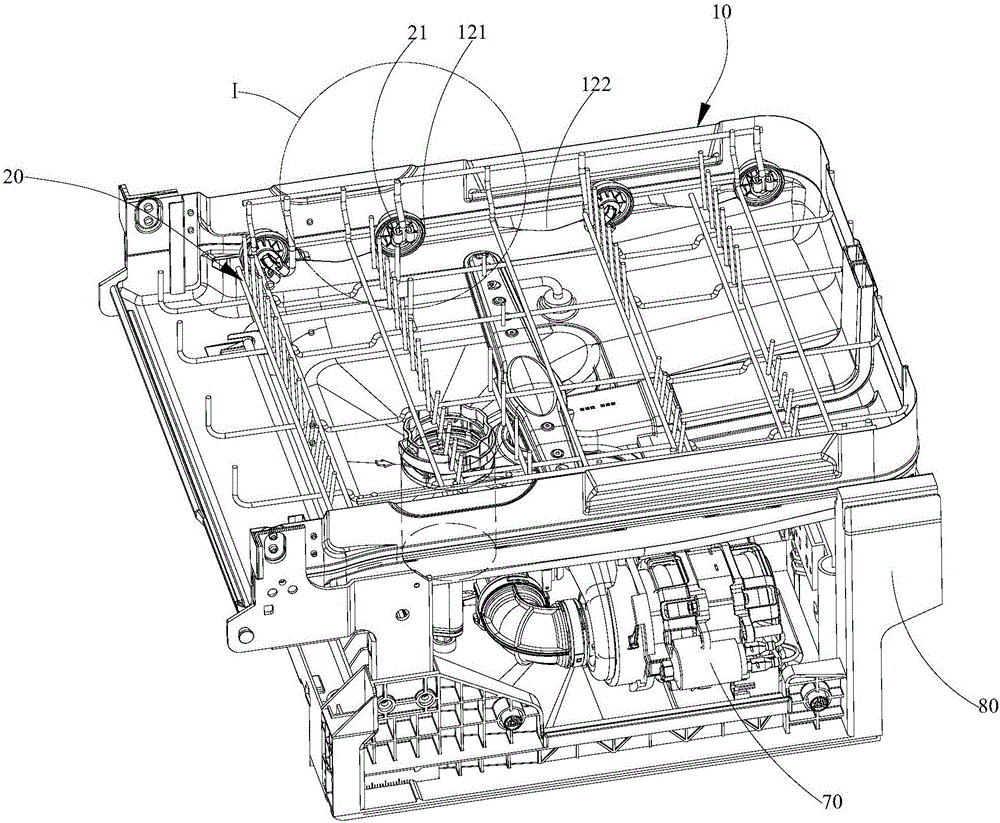

Dish-washing machine

ActiveCN106419793AImprove cleanlinessFast dryingTableware washing/rinsing machine detailsEngineeringMechanical engineering

The invention discloses a dish-washing machine. The dish-washing machine comprises a liner, a bearing component and a door component. The liner is formed and provided with a washing cavity and an opening communicated with the washing cavity. A first cavity platform and a second cavity platform are alternately and oppositely installed in the washing cavity. The first cavity platform comprises a first inclined plane, and the second cavity platform comprises a second inclined plane. The position of the first inclined plane is higher than the position of the second inclined plane relatively. The bearing component is moveably installed on the first cavity platform and the second cavity platform. The door component comprises a door body. The door body is rotatably connected with the liner so as to open or close the opening. Both the first inclined plane and the second inclined plane are inclined to the opening. While the door body closes the opening, the bearing component is received in the washing cavity and is supported on the first inclined plane and the second inclined plane; and while the door body opens the opening, the bearing component is freely moved from the first inclined plane and the second inclined plane to the opening under the gravity action of the bearing component. The dish-washing machine has the better washing effect and drying effect.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

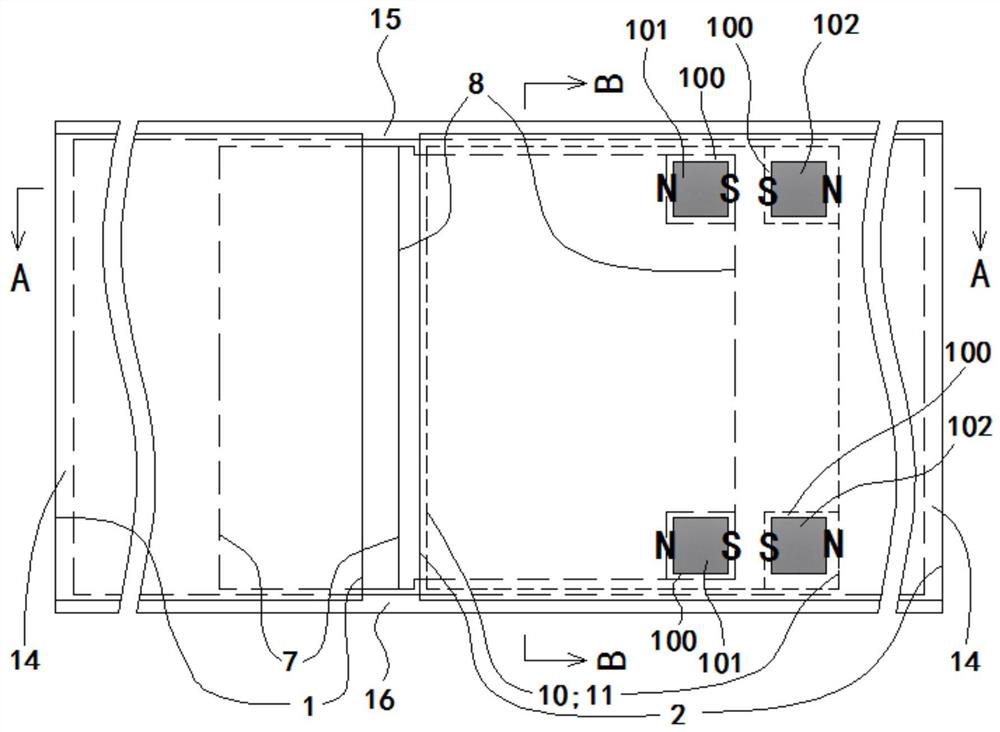

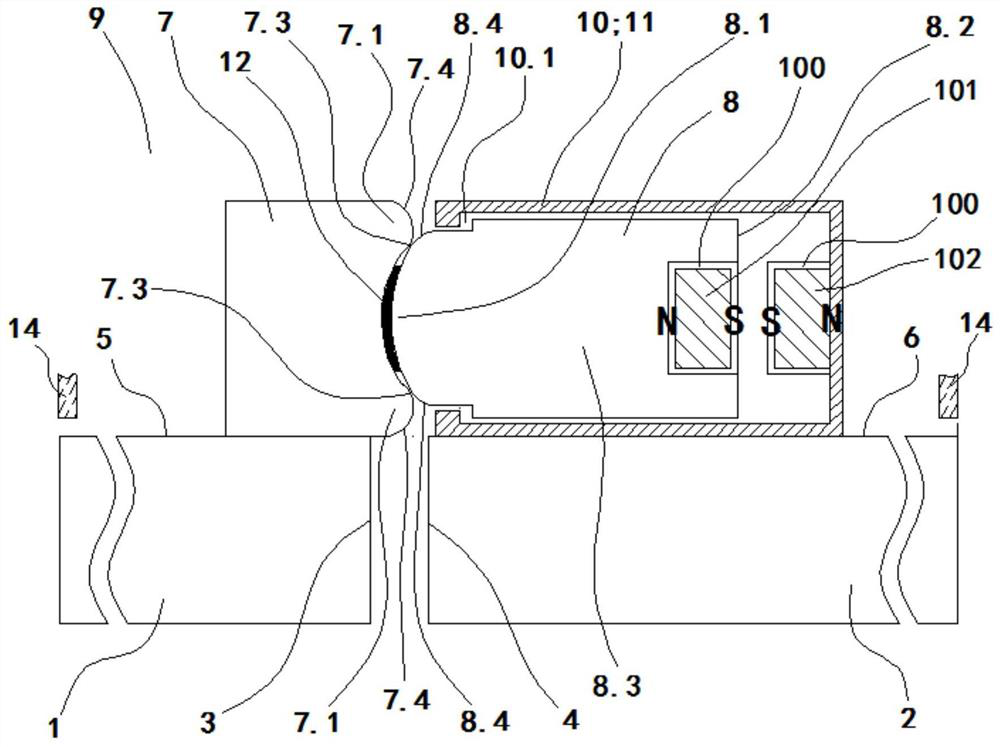

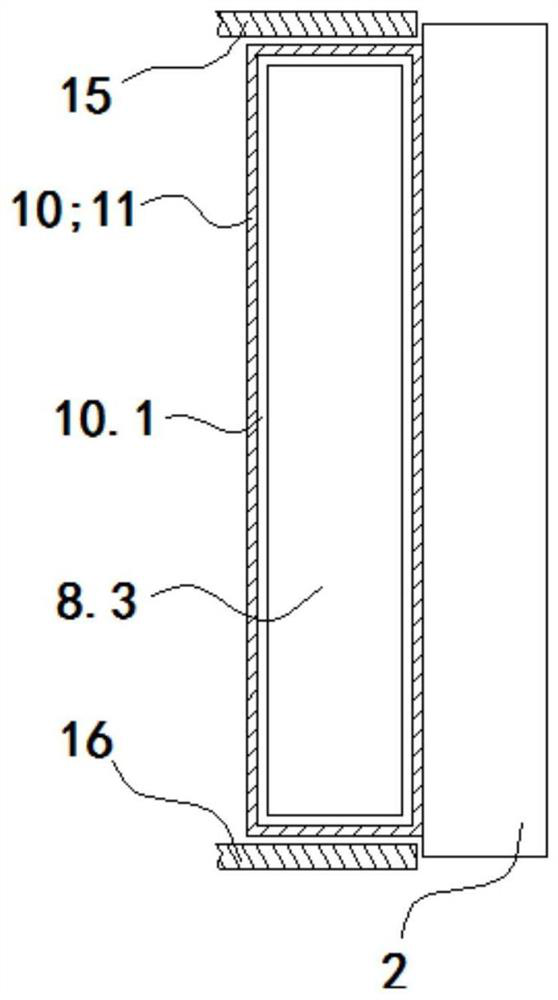

Double-door gap closing device of side by side combination refrigerator

InactiveCN111649525ASimple structureFew partsDomestic cooling apparatusLighting and heating apparatusIceboxHome appliance

The invention relates to the technical field of household appliance manufacturing, in particular to a double-door gap closing device of a side by side combination refrigerator. Gap baffle plates for closing longitudinal gaps of two doors are longitudinally arranged on the back side walls of two door bodies (1) and (2), separately, wherein one of the gap baffle plates is a fixed gap baffle plate (7) with the top being a concave surface and the other of the gap baffle plates is a slidable gap baffle plate (8) capable of moving transversely with the top being a convex surface. The slidable gap baffle plate (8) with the top being the convex surface can lean against the fixed gap baffle plate (7) with the top being the concave surface under the magnetic action of magnetic substances: a magnet (101) and a magnet (102), so that the top end of the top (8.1) of the gap baffle plate (8) with the top being the convex surface leans against a convex area on the top of the fixed gap baffle plate (7)with the top being the concave surface in a state that the two door bodies are closed, and the gap between the two doors of the refrigerator is closed. By applying the refrigerator manufactured by the scheme, an operator can open and close the doors conveniently and safely.

Owner:陈永康

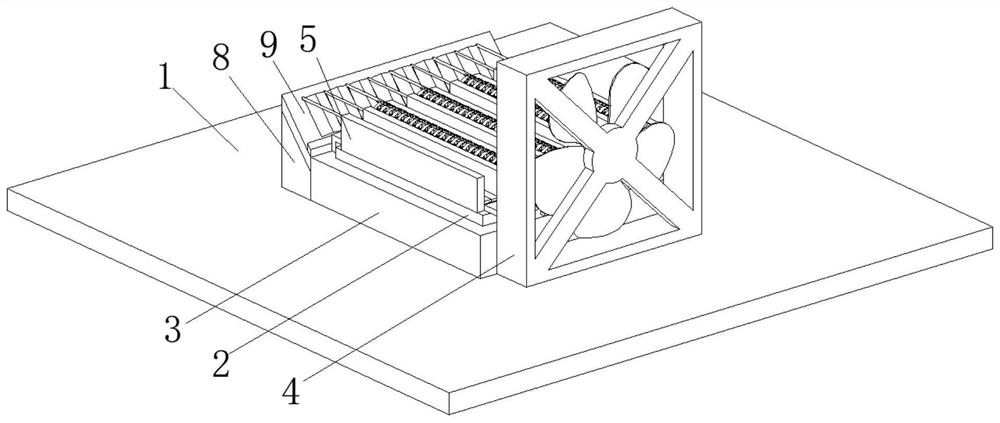

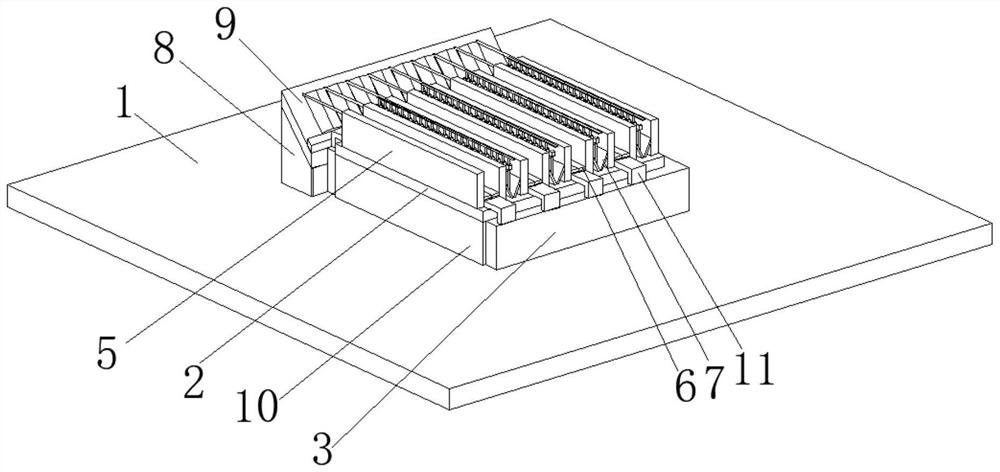

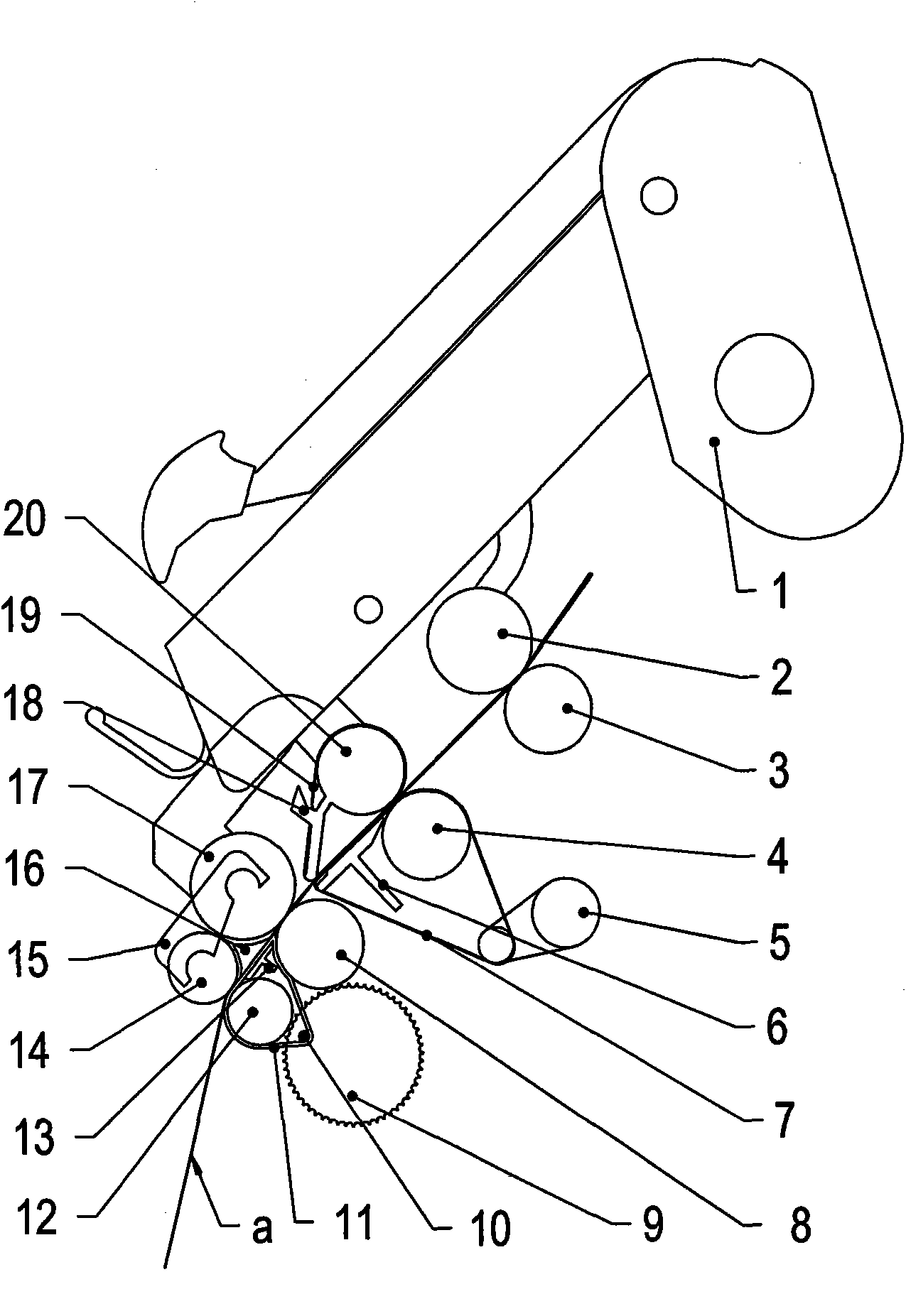

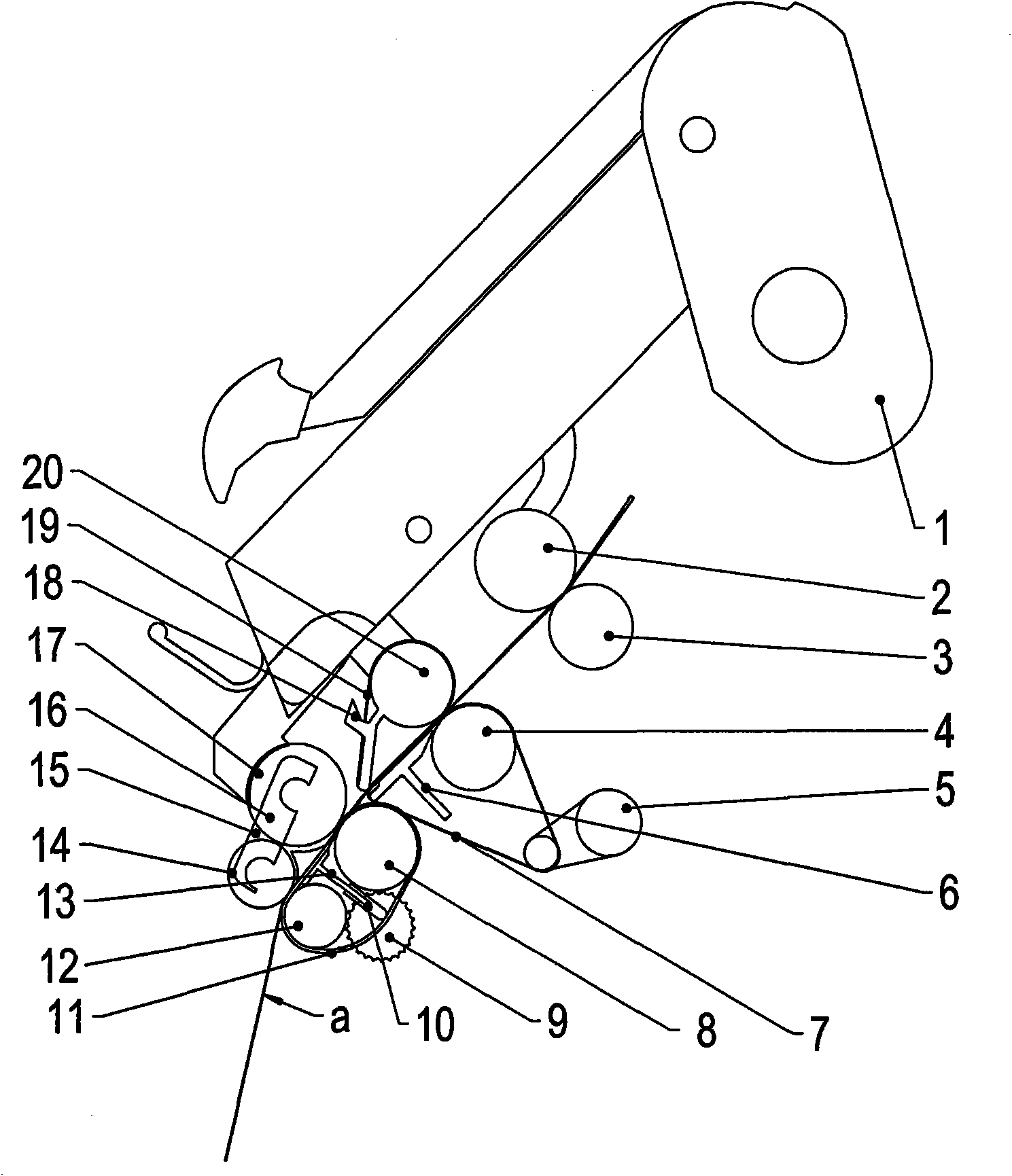

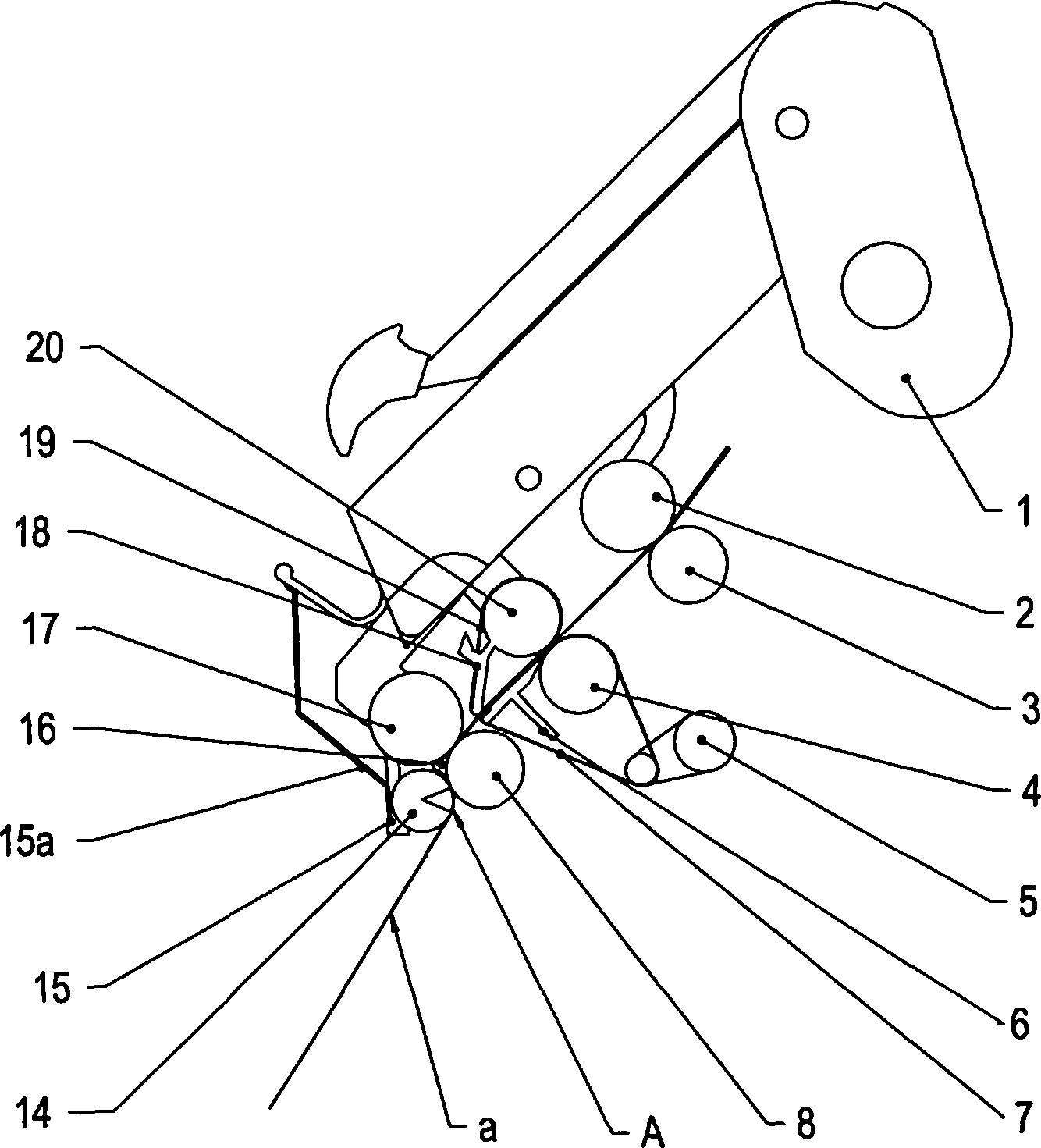

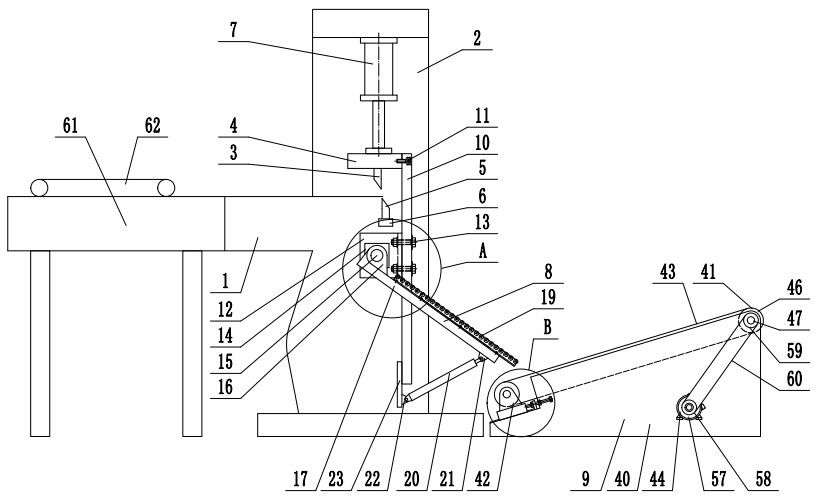

Mechanical compact spinning fiber bundling device

InactiveCN102465365ANo need to increase energy consumptionCompact spinningDrafting machinesYarnFiber bundle

The invention relates to a mechanical compact spinning fiber bundling device, which belongs to fiber bundling devices which realize compact spinning according to a mechanical principle. The device comprises a yarn guiding leather roller 14 which is arranged in front of a front leather roller 17 and a front roller 8, and a bundling device 16. A permanent magnet is embedded in the bundling device, and funnel-shaped fiber channels which are reduced gradually are formed on the bundling device along a fiber moving direction. A yarn guiding roller 12 is arranged in front of the front roller, a leather collar 11 is sleeved on the yarn guiding roller, and a bracket 13 is arranged inside the leather collar. The leather collar wraps the yarn guiding roller and the bracket, or the leather collar wraps the yarn guiding roller, the bracket and the front roller. A gear 9 is arranged between the front roller and the yarn guiding roller and matched with gears at the corresponding positions of the front roller and the yarn guiding roller. The compact spinning can be realized under the condition that energy consumption is not increased, and a counter-wrapping arc can be effectively eliminated, so that spinning evenness, snicks, nubs and neps are not worsened.

Owner:RIZHAO YUXIN MOTIVE POWER

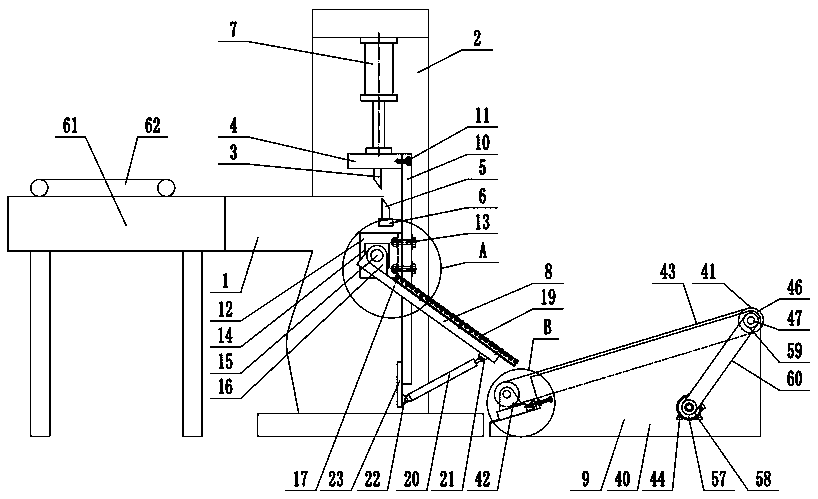

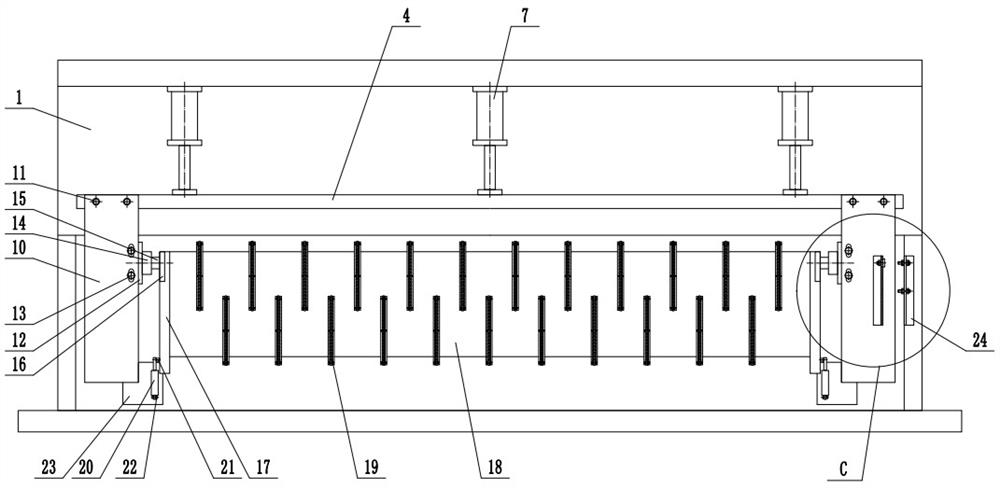

Automatic blanking and outputting equipment of gate type plate shearing machine

ActiveCN111451565APrecise feeding facilitates the realization ofConducive to stable blankingShearing machinesMetal working apparatusStructural engineeringMachine

The invention provides automatic blanking and outputting equipment of a gate type plate shearing machine, and belongs to the technical field of metal plate machining. The equipment comprises a blanking guiding device and an automatic outputting device. Two synchronous frames of the blanking guiding device are mounted at the two ends of the rear side of an upper knife switch frame through synchronous frame connecting screws correspondingly, blanking frame swinging rods are arranged on blanking bearing seats in a swinging manner through blanking swinging supporting lugs and blanking swinging supporting shafts, a blanking platform is mounted on the two blanking swinging rods, guiding assemblies are arranged on the blanking platform in a staggered manner at equal intervals, guiding wheels of the guiding assemblies are evenly distributed and rotationally arranged on a guiding frame through guiding wheel supporting shafts, and an outputting curtain of the automatic outputting device is arranged on a fixed outputting roller and a movable outputting roller in a surrounding manner. The blanking guiding device is used for carrying out blanking guiding on shorn plates, the blanked plates areautomatically output through the outputting device, bumps and scratches of the plates are effectively avoided, the automation degree is high, and the labor intensity is greatly reduced.

Owner:ZHEJIANG HUASHUN METAL MATERIAL CO LTD

Low-temperature plasma device for wall-breaking digestion of excess sludge

PendingCN114409226ARealize intelligent automatic continuous processingRealize continuous processingSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesProcess engineeringEnvironmental geology

The invention discloses a low-temperature plasma device for wall-breaking digestion of excess sludge, which is characterized in that a box body of the device is obliquely arranged, so that the excess sludge flows from a sludge inlet to a sludge outlet under the action of gravity, continuous treatment of the excess sludge is realized, and additional energy consumption is not needed; and the automatic feedback control unit is used for controlling and adjusting the inclination angle of the box body and / or the operating parameters of the plasma generation unit and / or the operating parameters of the air inlet unit based on real-time monitoring of the sludge at the outlet, so that intelligent automatic continuous treatment of the residual sludge is realized.

Owner:中国光大绿色技术创新研究院有限公司 +2

Device and method for improving ammonium sulfate crystal quality

ActiveCN102167356BUniform cooling effectIncreased form factorAmmonia compoundsPhysical chemistryEnvironmental engineering

The invention discloses a device and a method for improving ammonium sulfate crystal quality. In the device, a main body consists of a size cooling kettle which is connected with a process water feeding pipe; a stirrer which is extended downward into size is arranged in the size cooling kettle; a cooling interlayer is arranged outside the size cooling kettle; the upper part and the lower part of the cooling interlayer are provided with a cooling water inlet and a cooling water outlet respectively; the cooling water inlet is connected with a process water branch pipe which is separated from the process water feeding pipe; the cooling water outlet is connected with the process water feeding pipe through a cooling water outlet pipe; and the connection part of the cooling water outlet pipe and the process water feeding pipe is close to a water inlet of a process water box. A bypass is separated from the process water feeding pipe and size enters the process water box through the cooling interlayer outside the size cooling kettle; and by reducing the size temperature, the contour dimensions of crystals are increased and dehydration is facilitated. The device has a simple structure, is convenient to install, obviously improve the ammonium sulfate crystal quality, and can be widely applied to crystal treatment of thiamine in desulfuration by an ammonia method, and energy consumption of a system is not needed to be increased.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG +1

An automatic blanking output device of a gate shearing machine

ActiveCN111451565BPrecise feeding facilitates the realization ofConducive to stable blankingShearing machinesMetal working apparatusControl engineeringStructural engineering

The invention provides an automatic blanking output device of a gate-type shearing machine, which belongs to the technical field of metal plate processing. It includes a blanking guide device and an automatic output device. The two synchronous frames of the blanking guide device are respectively installed on the two ends of the rear side of the upper gate tool holder through the synchronous frame connecting screws. The blanking swing support shaft can be swingably set on the blanking bearing seat, the blanking platform is installed on the two blanking frame swing rods, the guide components are equidistantly arranged on the blanking platform, and the guide wheels of the guide components are supported by the guide wheels. The shafts are evenly distributed and rotatably arranged on the guide frame, and the output curtain of the automatic output device is arranged around the fixed output roller and the movable output roller. The invention utilizes the blanking guide device to realize the blanking guidance of the cut boards, and after blanking, the output device realizes automatic output, effectively avoids bumping and scratching of the boards, has a high degree of automation, and greatly reduces the labor intensity.

Owner:ZHEJIANG HUASHUN METAL MATERIAL CO LTD

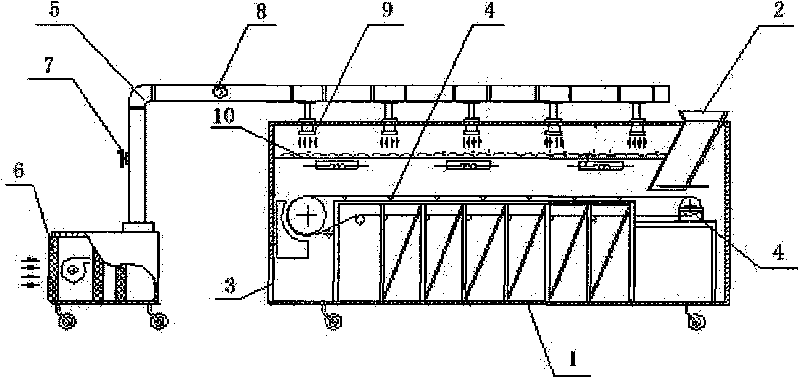

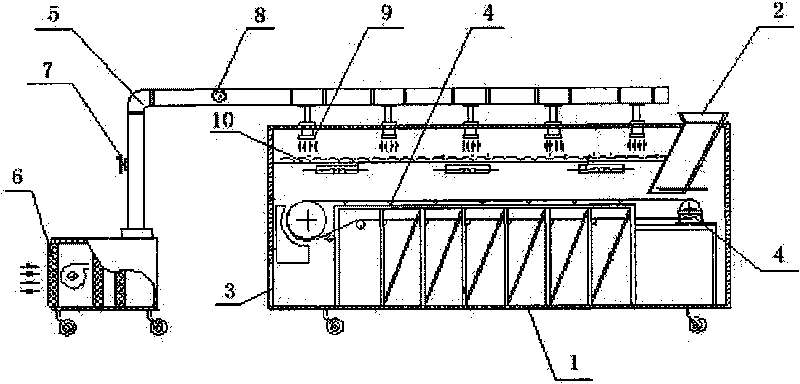

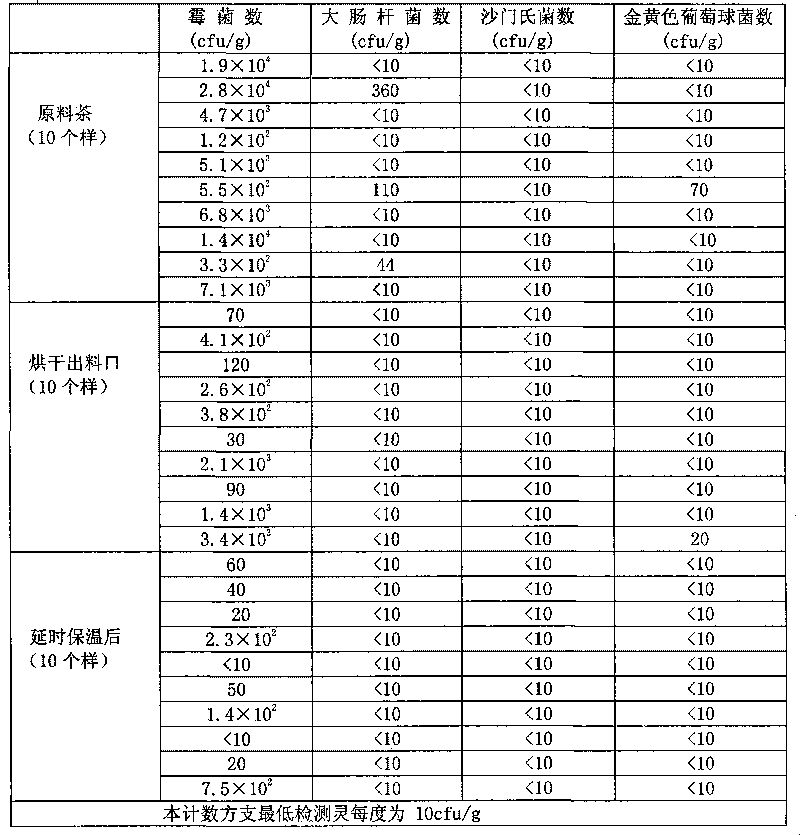

Method and device for killing harmful bacteria in tea in tea making process

InactiveCN101711538AMeet the requirementsSynergistic effect is obviousPre-extraction tea treatmentAir atmosphereThermal insulation

The invention relates to a microbian heat-treatment sterilization method and a device thereof for removing mould fungus, colibacillus and other pathogens in tea. The invention processes mould fungus, colibacillus and other pathogens in deactivated tea by designing a time-delay thermal insulation sterilization method and a device thereof. The method for killing harmful bacteria in tea in the tea making process is realized in a way as follows: the tea which is heat-treated in the tea making process is processed by thermal insulation in the pure air atmosphere at 40-80 DEG C for some time, and packaged in the pure air. The invention designs the time-delay thermal-insulation and the pure air treatment in view of the prior heat drying mode for tea in China, thereby enhancing the effect of the tea heat treatment on killing harmful bacteria. The device is simple and easy to realize, and does not need to increase large amounts of energy consumption on the basis of the original heat treatment. The invention has high practicability and popularization value.

Owner:湖南出入境检验检疫局检验检疫技术中心

Coal gangue pyrolysis gasification raw coal gas purification combustion heat exhaust gas activated coke regeneration method

ActiveCN103224814BEasy to reuseNo need to increase energy consumptionCombustible gas coke oven heatingGas purification with selectively adsorptive solidsExhaust fumesCoke oven

The invention discloses a method for active coke regeneration through hot exhaust gas obtained by purification and combustion of coke oven raw gas in coal gangue pyrolysis gasification. The method includes the steps of: (1) providing a heat source for coal gangue pyrolysis gasification by heat storage and exchange and alternate combustion of purified coal gas; (2) letting carbon in a coal gangue pyrolysis solid product encounter superheated steam to undergo a water gas reaction so as to generate water gas; (3) exporting coke oven raw gas; and (4) purifying and combusting the exported coke oven raw gas, and evaporating purification adsorbed saturated active coke by the combusted hot exhaust gas to regenerate unsaturated active coke. According to the method provided in the invention, afterheat of the hot exhaust gas generated by purification and combustion of recycled coke oven raw gas in coal gangue pyrolysis gasification is employed to evaporate saturated active coke for regeneration, no extra energy consumption is needed, heating equipment is saved, and the economic value of cyclic utilization can be obtained.

Owner:SHANXI XINLI ENERGY TECH

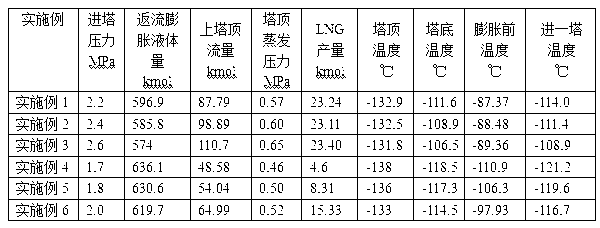

Method for extracting helium from natural gas

ActiveCN102735020BEfficient use ofIncrease cooling temperatureSolidificationLiquefactionTowerPressure reduction

The invention discloses a method for extracting helium from natural gas. The method comprises the following steps: (A) the natural gas containing helium is conveyed into a main heat exchanger for cooling; (B) the mixture obtained by cooling in step (A) is conveyed, into a separating tower; after the mixture is heated, at least one part of the steam is cooled at the tower top by a condensation evaporator, primary coarse helium is obtained; and after purification of the primary coarse helium, a coarse helium product is obtained; (C) a part of liquid at the bottom of the separating tower enters the condensation evaporator at the tower top by a pipeline after pressure reduction and throttling, and carries out heat exchange with the steam in step (B) as a cold source of the condensation evaporator; and (D) according to the need of cold-amount balance, whether an LNG (Liquefied Natural Gas) product obtained after heat exchange between the cold source in step (C) and the steam in step (B) needs to be acquired from the condensation evaporator is determined. The invention has the advantages that the conception is ingenious, the process is simple, the operation of the process is stable, thecold amount is easy for balance, and the energy consumption and the cost are greatly reduced.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com