Method for extracting helium from natural gas

A natural gas and steam technology, used in liquefaction, solidification, lighting and heating equipment, etc., can solve the problems of difficult cooling balance and unstable process operation, achieve stable process operation, increase product output value and comprehensive economic benefits, and increase energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0029] A method for extracting helium from natural gas of the inventive method comprises the following steps:

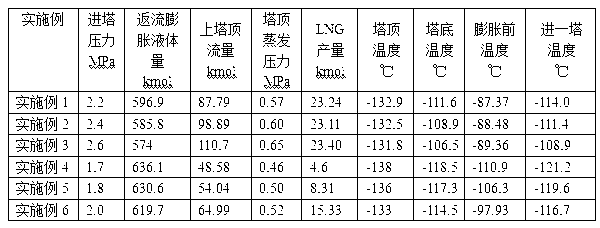

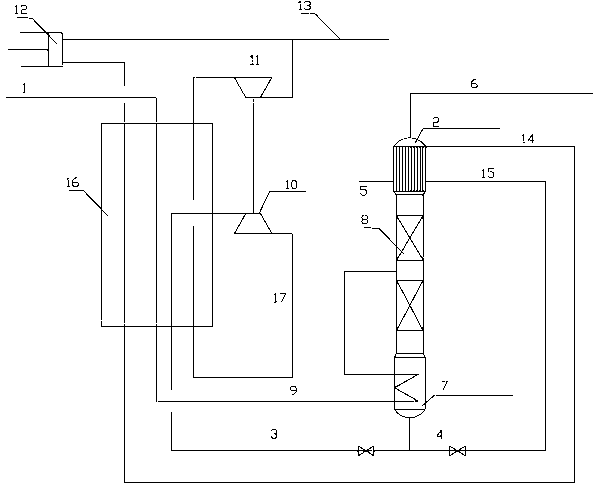

[0030] Helium-containing raw natural gas 1 entering the helium extraction device through the pipeline Intake volume: 704.9 kmol per hour, temperature: 40 ° C, after deep CO removal 2 1. After the water purification treatment, pressurization treatment is carried out, and the pressure is 4Mpa. The raw natural gas exchanges heat with the main heat exchanger 16 to obtain a mixture 9, which enters the first-stage helium extraction separation tower 8 (one tower) through pipelines for low-temperature rectification, and its inlet pressure is 2.2-2.6 Mpa. Most of the liquid 4 obtained from the bottom 7 of the separation tower passes through the throttling valve as the backflow expansion liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com