Export condensation and recovery purification method for coke oven raw gas of coal gangue pyrolysis gasification

A technology of pyrolysis gasification and coal gangue, which is applied in the direction of combustible gas purification, combustible gas purification/transformation, carbonization gas discharge device, etc., can solve the problems of unusable coal gangue, air pollution by spontaneous combustion, environmental pollution, etc., and achieve good The effect of economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

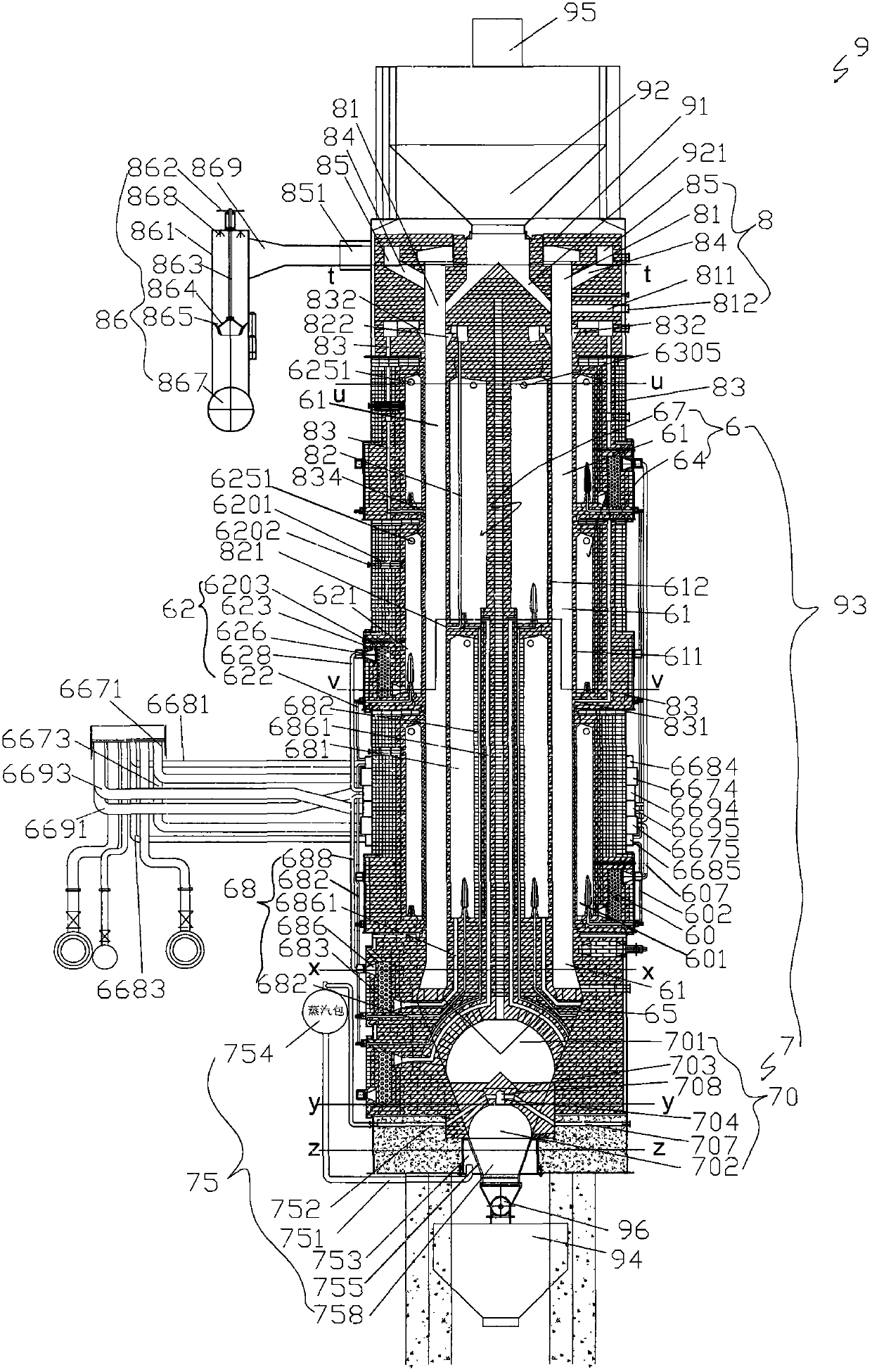

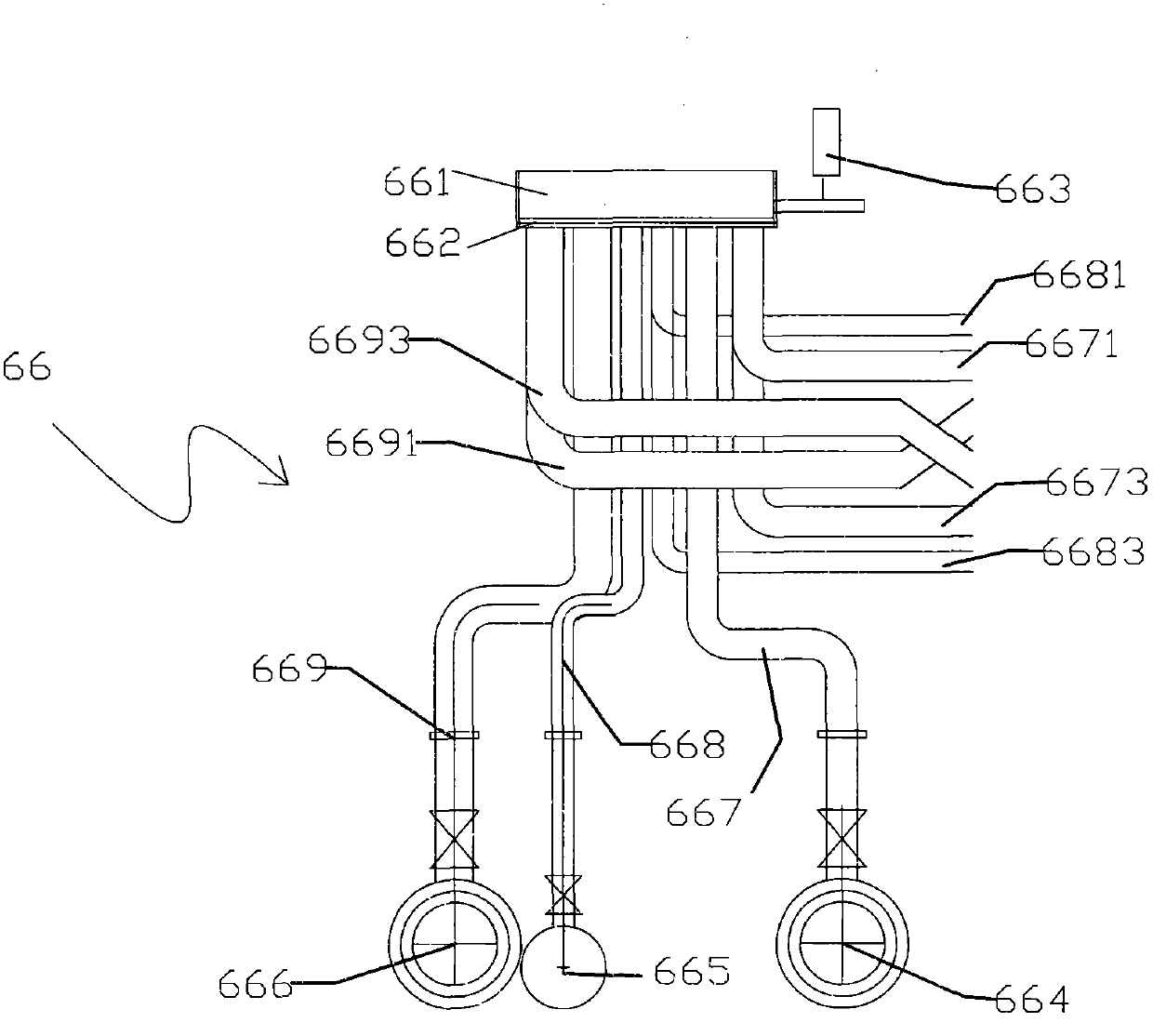

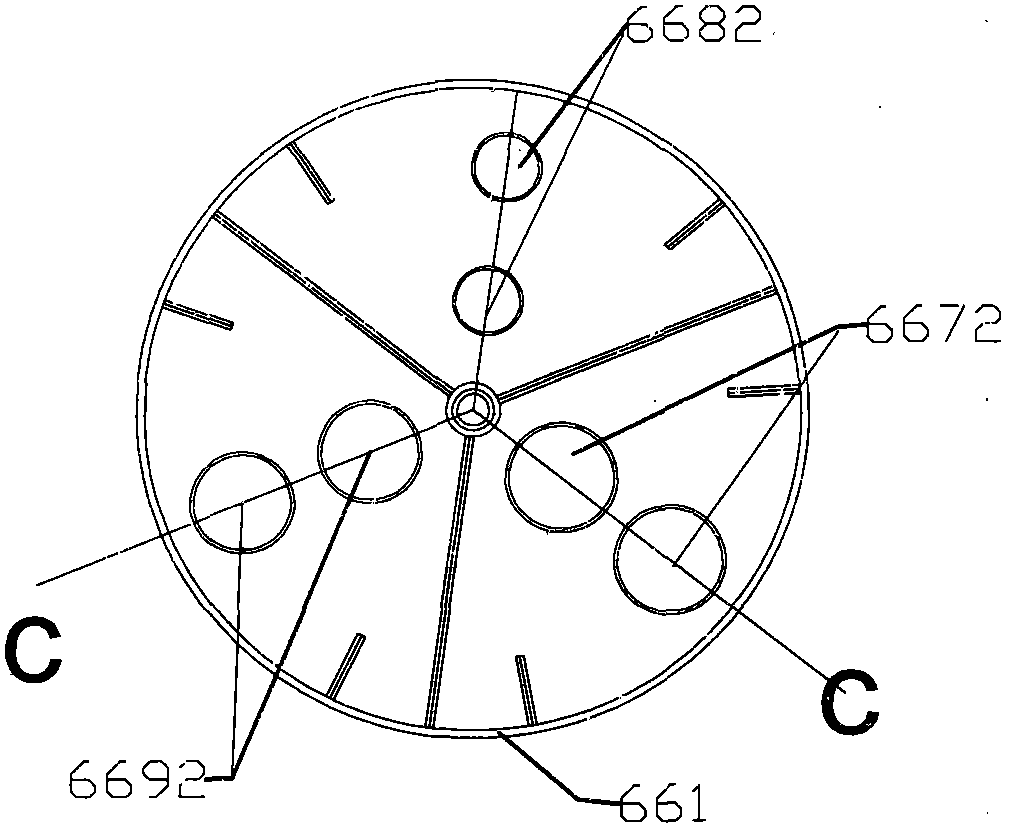

[0041] The specific embodiment of the comprehensive utilization of coal gangue pyrolysis gasification of the present invention is mainly introduced in detail below.

[0042] Part 1 Particle Size Control of Coal Gangue

[0043] The coal gangue is processed and crushed into a particle size of 0-20 mm, and the crushed coal gangue is dehydrated and dried within this particle size range, and the drying is sufficient and the dehydration efficiency is high, but this does not constitute a limitation on the coal gangue required by the present invention.

[0044] Part II Humidity Control and Dehydration of Coal Gangue

[0045] The waste coal gasification produced by coal gangue high temperature pyrolysis and water gas reaction is recovered and purified, and the hot waste gas generated after combustion of clean coal gas is used for humidity control and dehydration of crushed coal gangue pellets before being put into the furnace.

[0046] In order to keep the environment clean and tidy, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com