Cell heat shrink film packaging machine

A heat-shrinkable film and packaging machine technology, which is applied in the field of machinery, can solve the problems of difficult assembly, easy wear of the cam mechanism, and poor work stability, and achieve the effects of low assembly accuracy requirements, simple assembly process, and strong work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

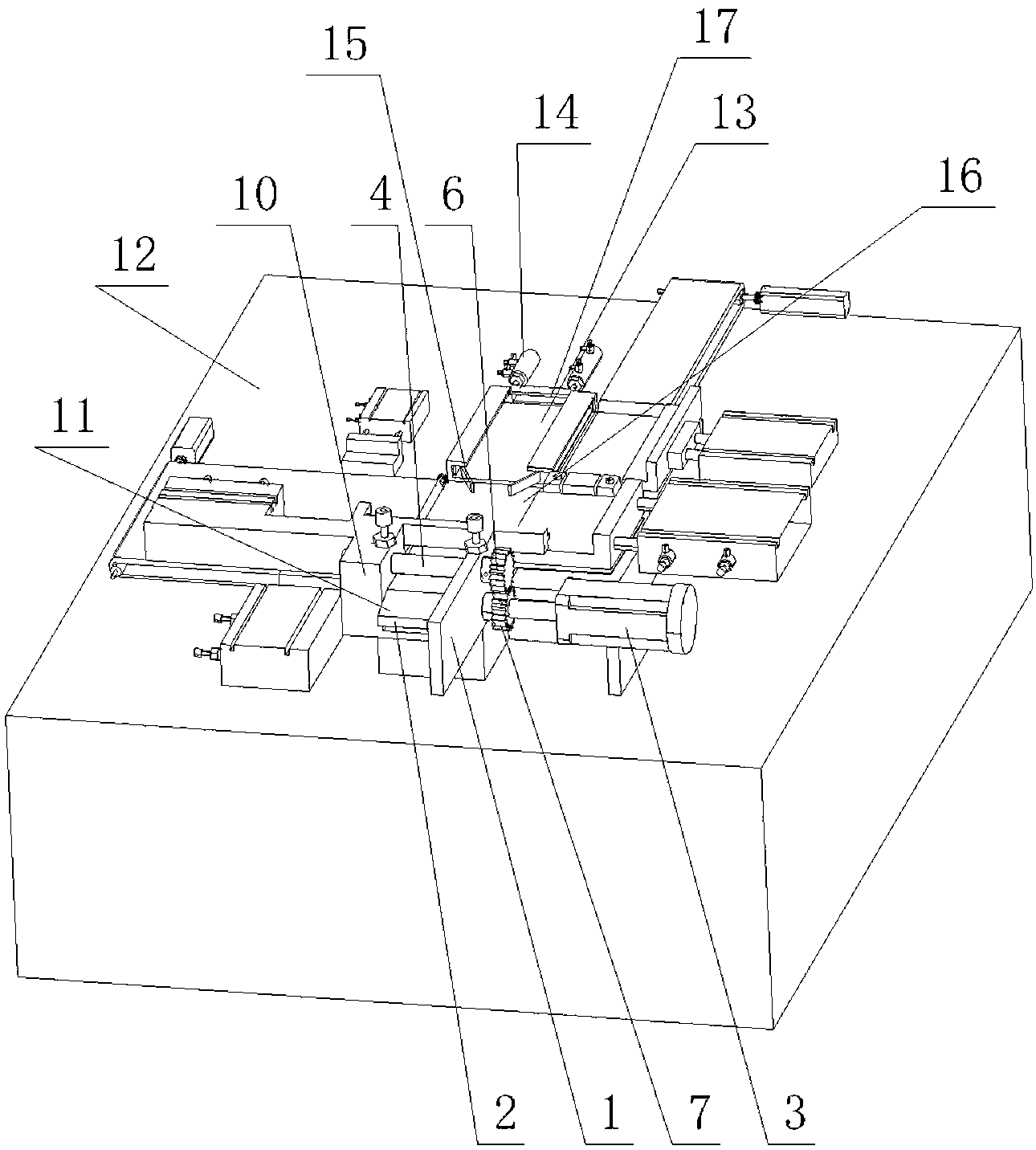

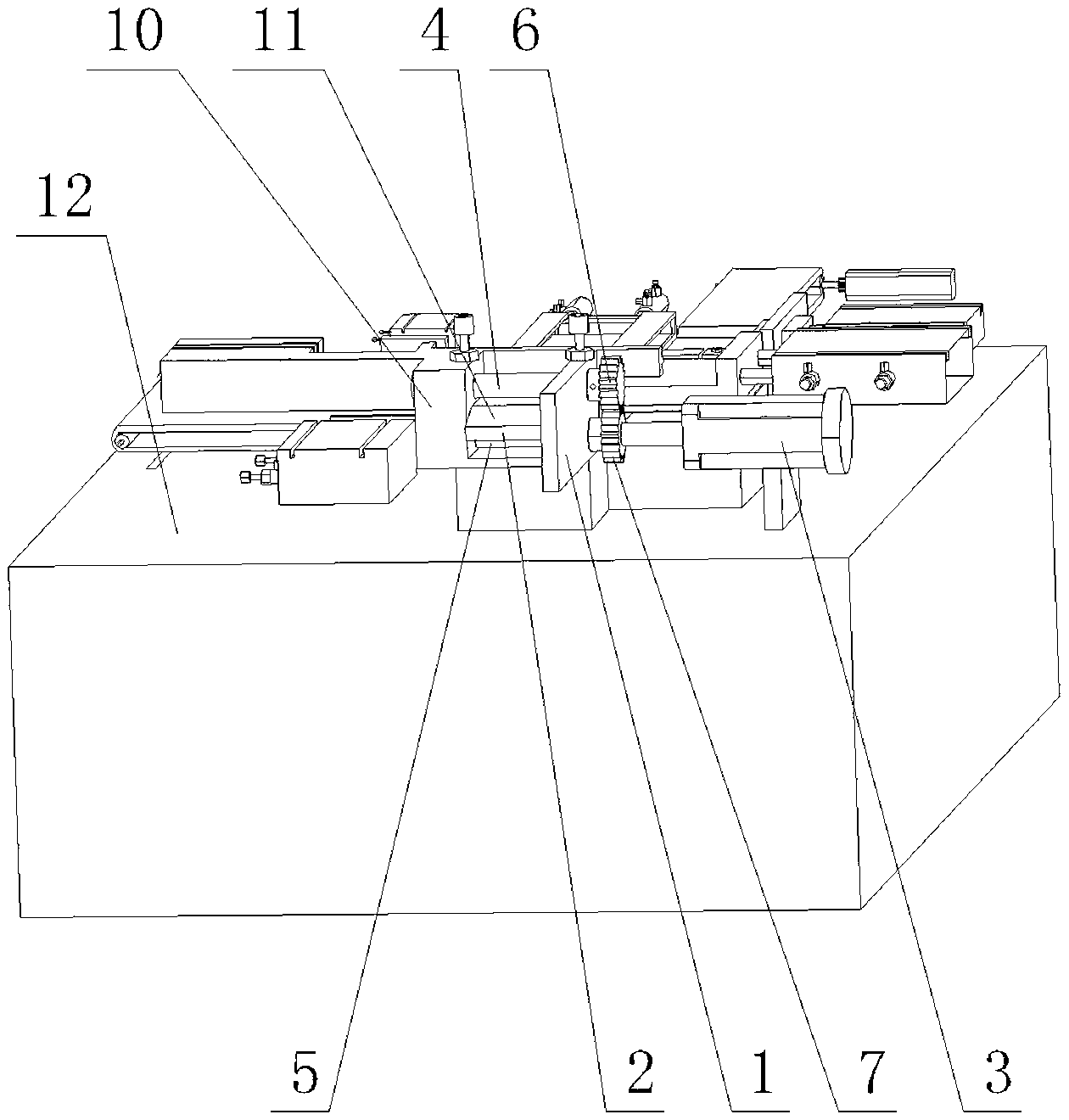

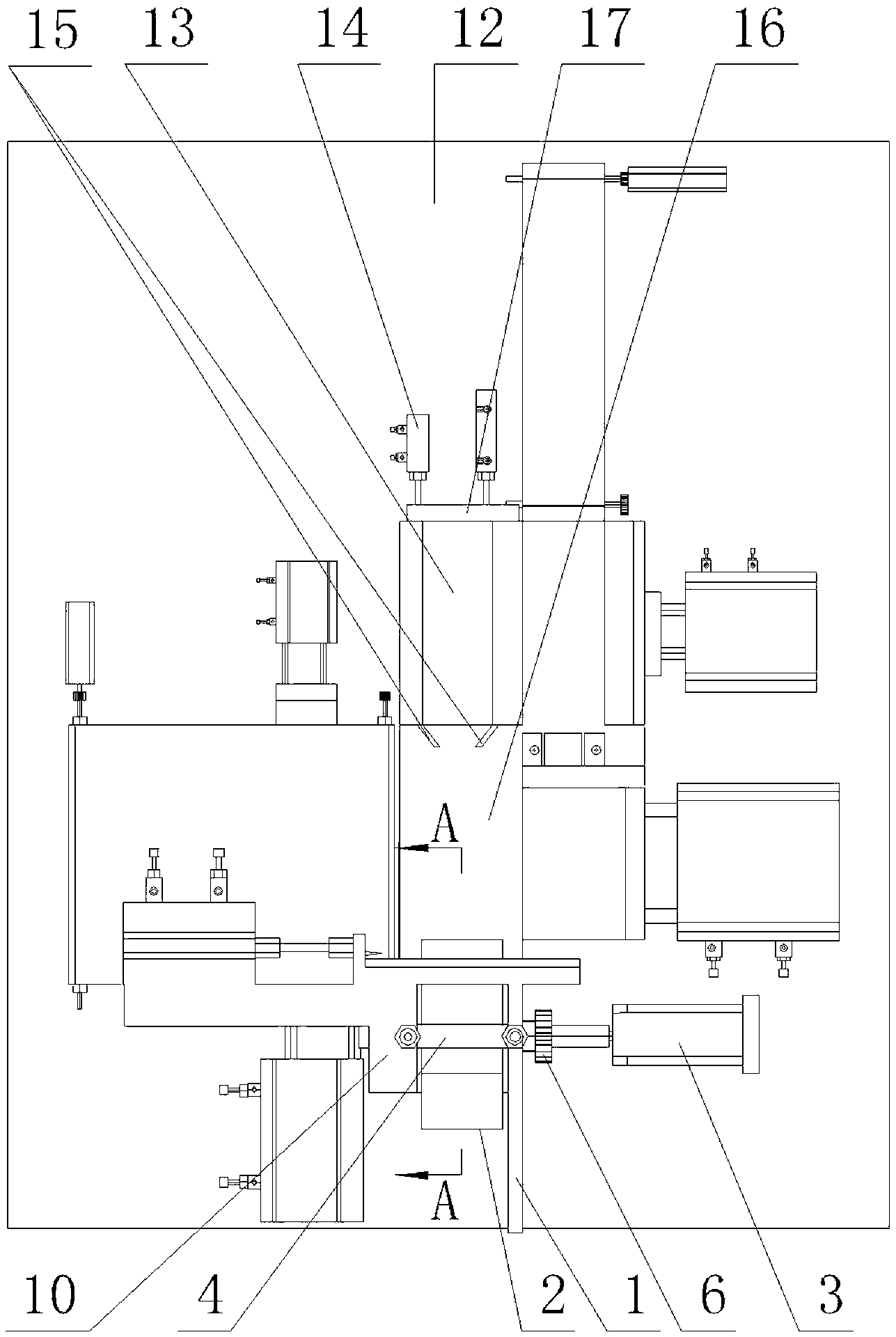

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the battery heat-shrinkable film packaging machine of the present invention includes a heat-shrinkable film conveying mechanism, and the heat-shrinkable film conveying mechanism includes a first support plate 1, a partition plate 2, a second support plate 10 and a stepping motor 3 . The upper pressing roller 4 and the lower pressing roller 5 are rotatably fitted on the first supporting plate 1 , and the ends of the upper pressing roller 4 and the lower pressing roller 5 away from the first supporting plate 1 can be rotatably fitted on the second supporting plate 10 . The casings of the first support plate 1 , the second support plate 10 and the stepping motor 3 are all fixed on the workbench 12 of the battery shrink film packaging machine. The out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com