Adjusting and detecting device for cutting edge gap of rotary cutter and detecting method thereof

A gap adjustment and detection device technology, which is applied in the direction of shearing devices, measuring devices, electrical devices, etc., can solve the problems of affecting the shearing quality of steel plates and shortening the service life of disc shearing blades, etc., and achieves simple structure and strong use The effect of life and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

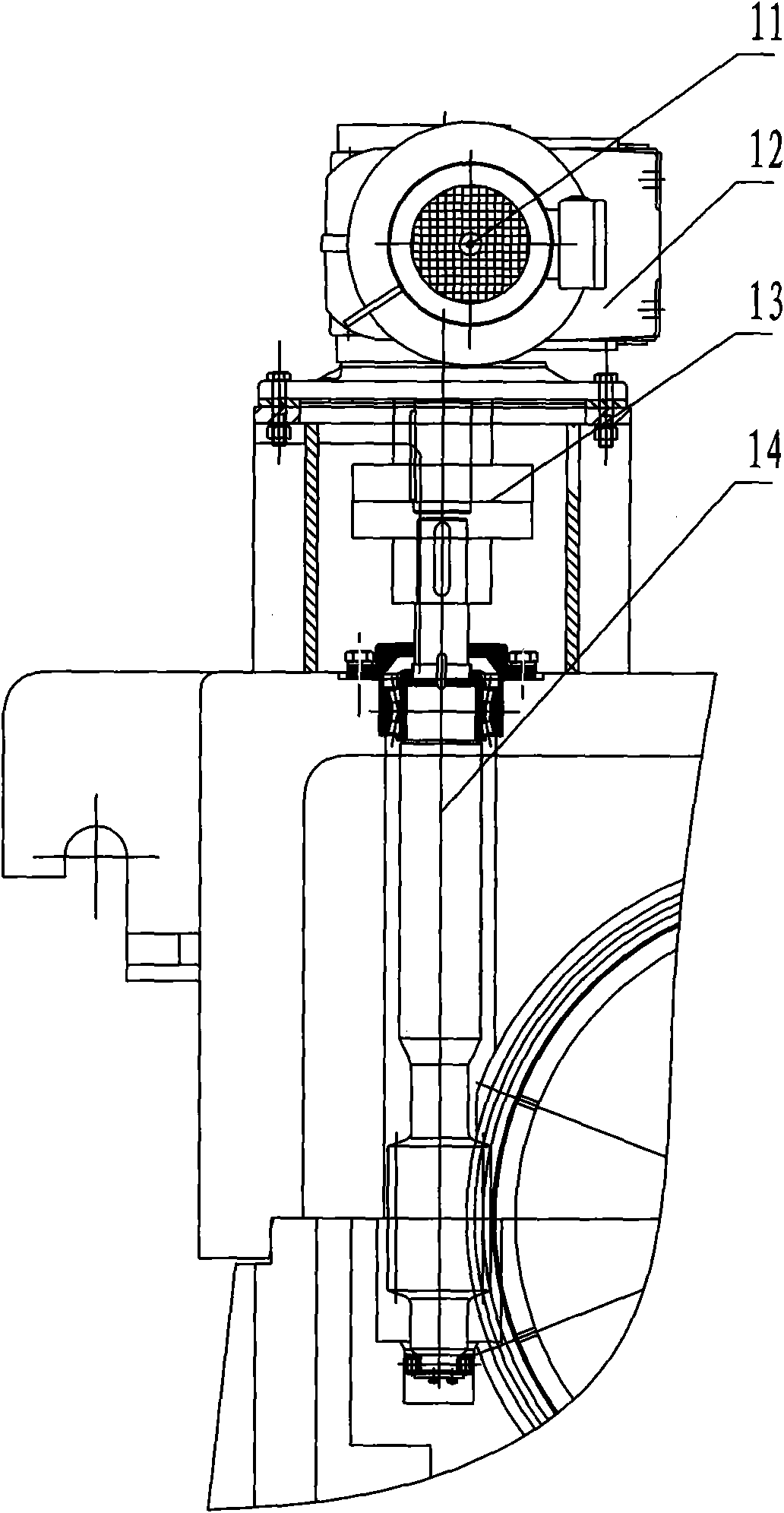

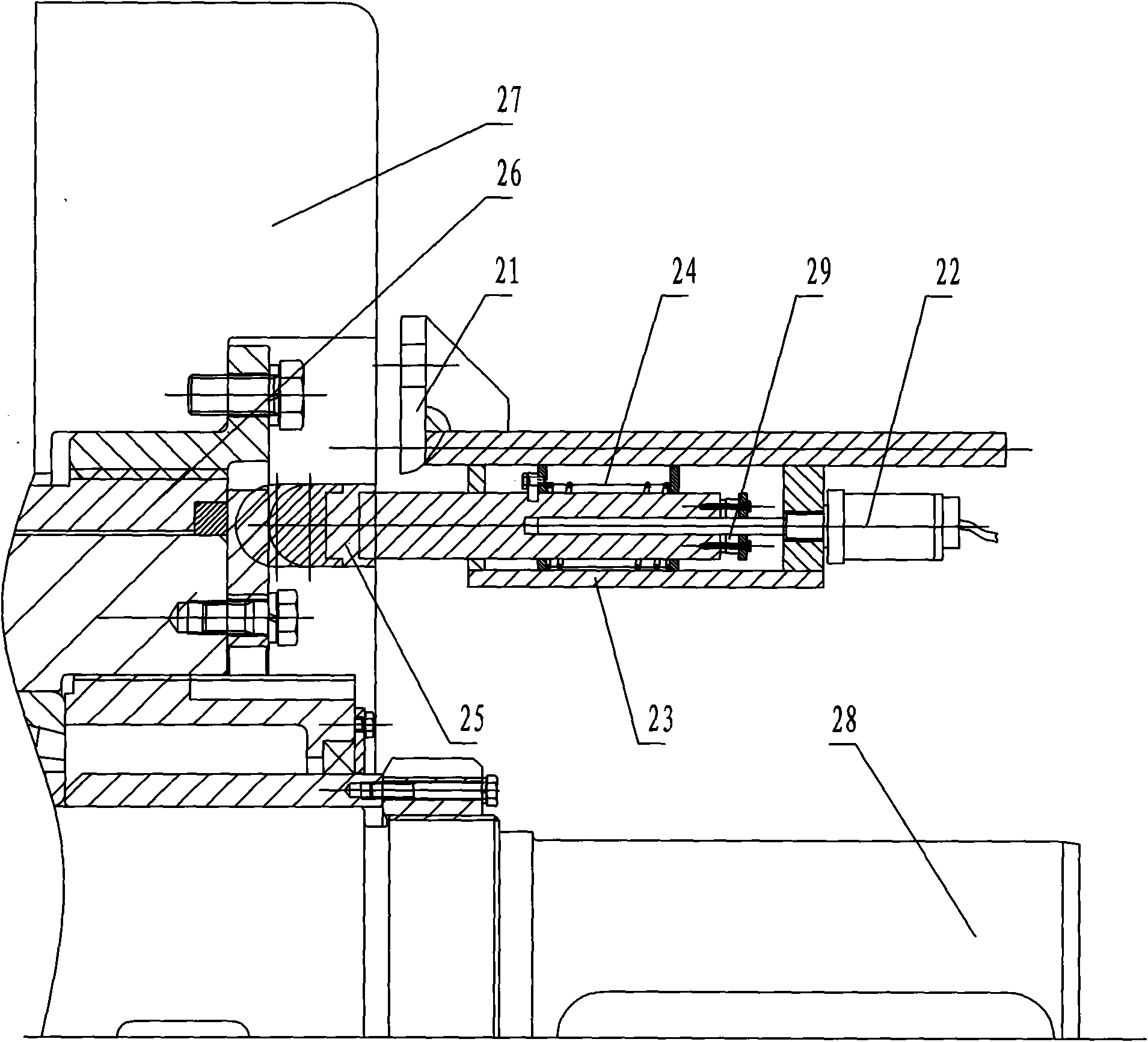

[0021] The present invention will be further described below in conjunction with the drawings. Such as figure 2 As shown, a disc shear blade gap adjustment and detection device is installed on the transmission side of the upper knife shaft assembly 26 of the disc shear. The device includes an upper case 21, a displacement sensor 22, a lower case 23, a spring 24, and a follower Rod 25, the upper box body 21 is mounted on the disc shear body 27 by bolts, the lower box body 23 is connected to the upper box body 21 by bolts, and the upper box body forms a complete closed The box body, the follower rod 25 is tightly pressed on the outside of the upper knife shaft assembly 26 by a spring 24, the displacement sensor 22 itself has a movable magnet 29, which is connected to the upper box body 21 and the lower box by thread At the center of the closed box formed by the body 23, the movable magnet 29 is connected to the follower rod 25 by bolts. The displacement sensor 22 is a digital ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com