Polystyrene fiber adsorption material with surface grafted with beta-cyclodextrin, and preparation and application thereof

A polystyrene fiber, surface grafting technology, applied in adsorption water/sewage treatment, other chemical processes, water/sludge/sewage treatment, etc., can solve the problem of refractory, high toxicity, human health and ecological environment impact and other issues, to achieve the effects of good environmental compatibility, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

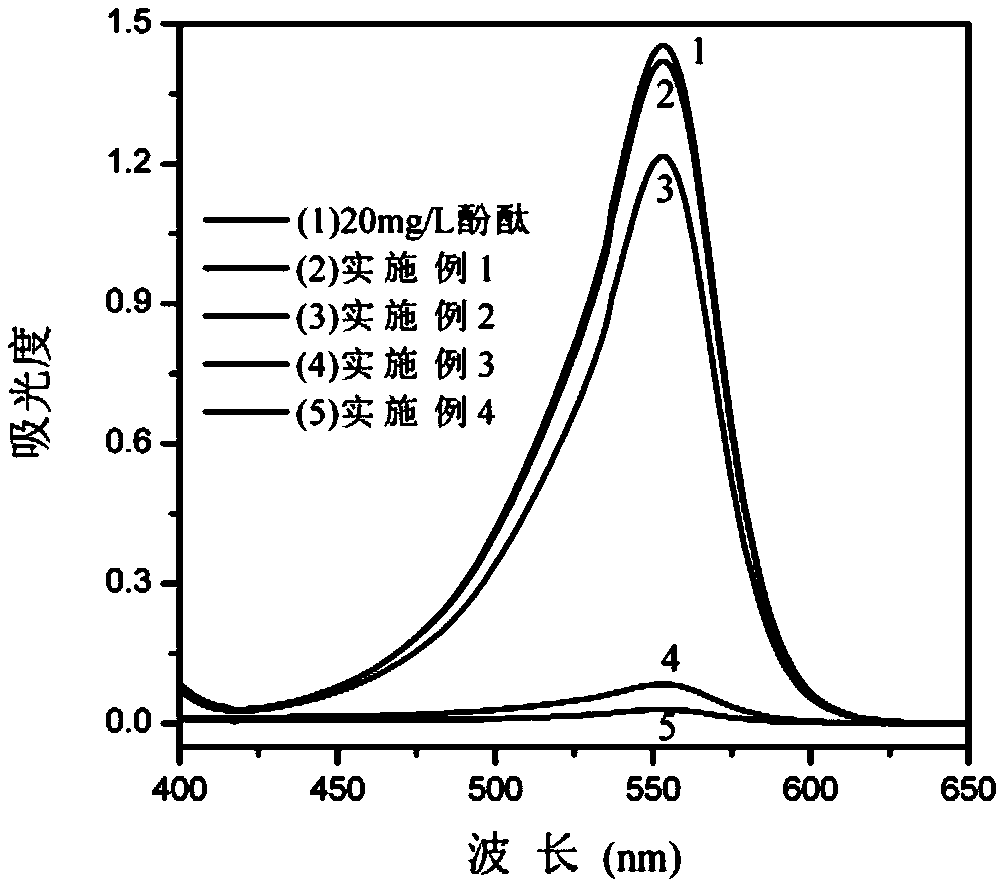

Examples

Embodiment 1

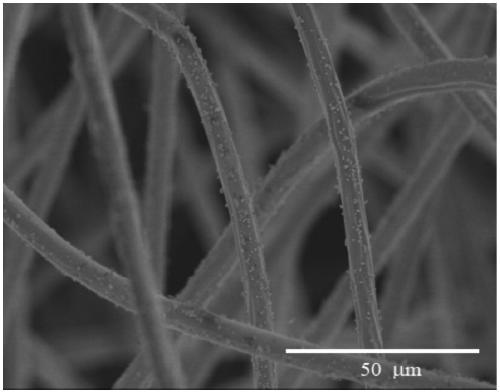

[0037] Preparation of a polystyrene fiber: preparing a polystyrene tetrahydrofuran spinning solution with a mass fraction of polystyrene (weight-average molecular weight Mw=275,000 g / mol) of 25%. The spinning voltage is 25KV, the receiving distance is 20cm, the drum is used as the receiving device, the injection speed is 1.5ml / h, and the electrospinning is carried out at room temperature. A polystyrene fiber (PS) is obtained by removing the non-volatile solvent in the spinning process.

Embodiment 2

[0039] A kind of preparation of aminated polystyrene fiber: the polystyrene fiber prepared in 200mg comparative example 1 is put into the 2.0g / L dopamine solution (solvent is 1.2g / L three hydroxymethylaminomethane solution) in a beaker, vibrate for 48h, take out the fiber, wash it three times with deionized water, dry it in vacuum to constant weight, and obtain the aminated polystyrene fiber (PS / PDA) with polydopamine nanoparticles on the surface ).

Embodiment 3

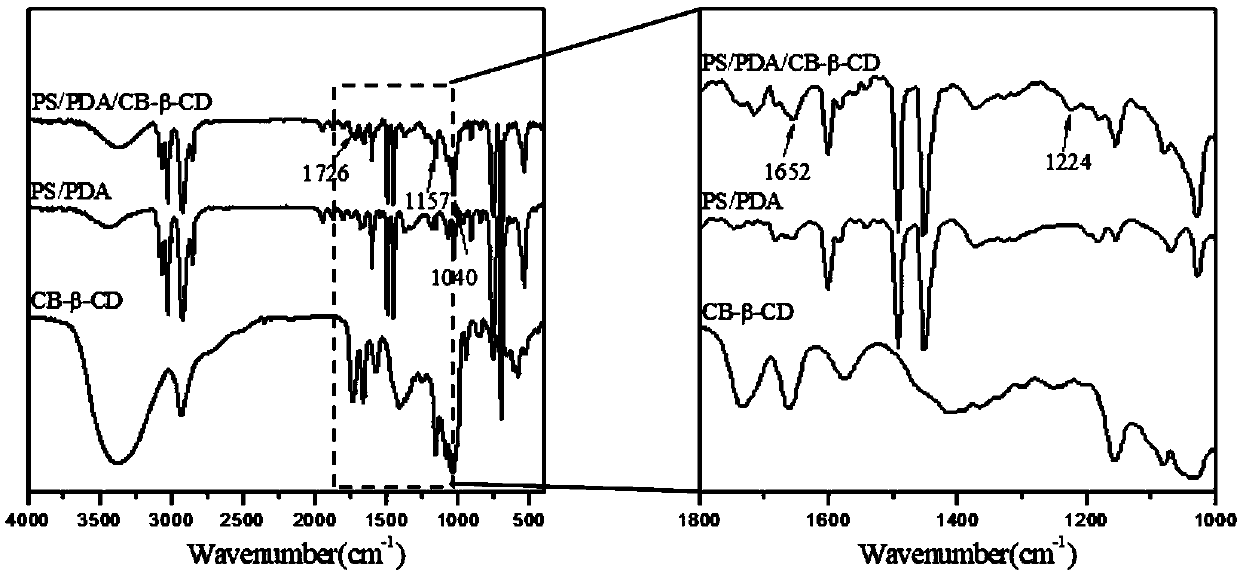

[0041] Preparation of a surface chemically grafted β-cyclodextrin polystyrene fiber adsorption material:

[0042] (1) Preparation of carboxylated β-cyclodextrin: Take 1.13g β-cyclodextrin, 0.10g succinic anhydride and 8mL DMF, stir to dissolve, then add 0.14mL triethylamine, heat the solution to 40°C for 24h . After the reaction was completed, after the solution was cooled to room temperature, 80 mL of chloroform was added to it until the precipitation was complete, the white flocculent precipitate was collected by centrifugation, washed with acetone, and dried in a vacuum drying oven to constant weight to obtain carboxylated β-ring Dextrin (CB-β-CD).

[0043] (2) Weigh 0.185g of carboxylated β-cyclodextrin and dissolve it in 10mL of MES buffer solution with pH=6.0, then add 0.144g of EDCI and 0.086g of NHS, and activate at 30°C for 8h to obtain activated carboxylated β-cyclodextrin dextrin.

[0044] (3) Add 0.02 g of the aminated polystyrene fiber prepared in Comparative E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com