Device and method for improving ammonium sulfate crystal quality

A crystallization and quality technology, applied in the field of ammonia desulfurization, can solve the problems of poor crystal separation effect, low quality of ammonium sulfate crystals, low production efficiency, etc., and achieve the effects of being beneficial to dehydration, simple structure and improving crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

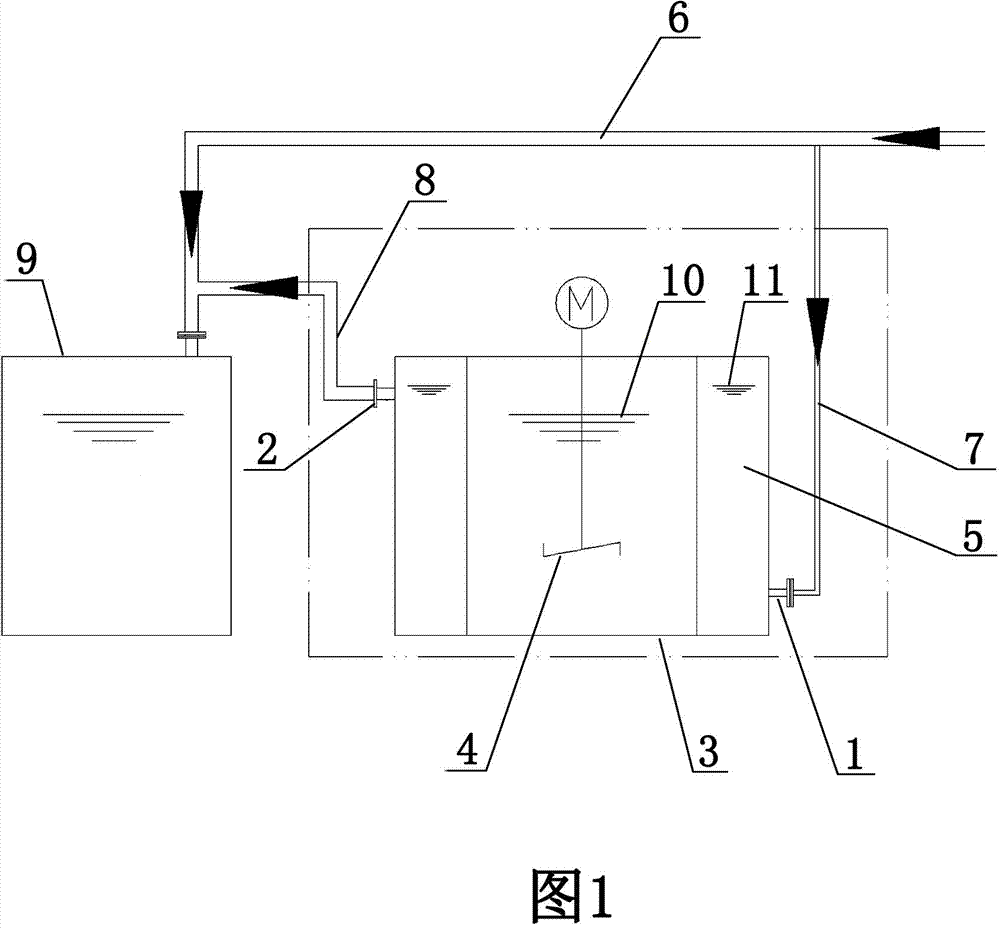

[0017] Examples see figure 1 As shown, the device for improving the crystallization quality of ammonium sulfate is composed of a slurry cooling tank 3 connected to the process water inlet pipe 6, and a low-speed top-feeding agitator that extends downward into the slurry 10 is installed in the slurry cooling tank 3. 4, a cooling interlayer 5 is arranged outside the slurry cooling kettle 3, the thickness of the cooling interlayer 5 is 100 mm, the lower part and the upper part of the cooling interlayer 5 respectively have a cooling water inlet 1 and a cooling water outlet 2, and the cooling water inlet 1 is connected to the process water inlet pipe The process water branch pipe 7 separated from 6 is connected, the cooling water outlet 2 is connected with the process water inlet pipe 6 through the cooling water outlet pipe 8, and the connection between the cooling water outlet pipe 8 and the process water inlet pipe 6 is close to the water inlet of the process water tank 9.

[001...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com