Mechanical compact spinning fiber bundling device

A fiber clustering and mechanical technology, applied in spinning machines, textiles, papermaking, drafting equipment, etc., to achieve good economic and social benefits, reduce use costs, and eliminate anti-encircling arcs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

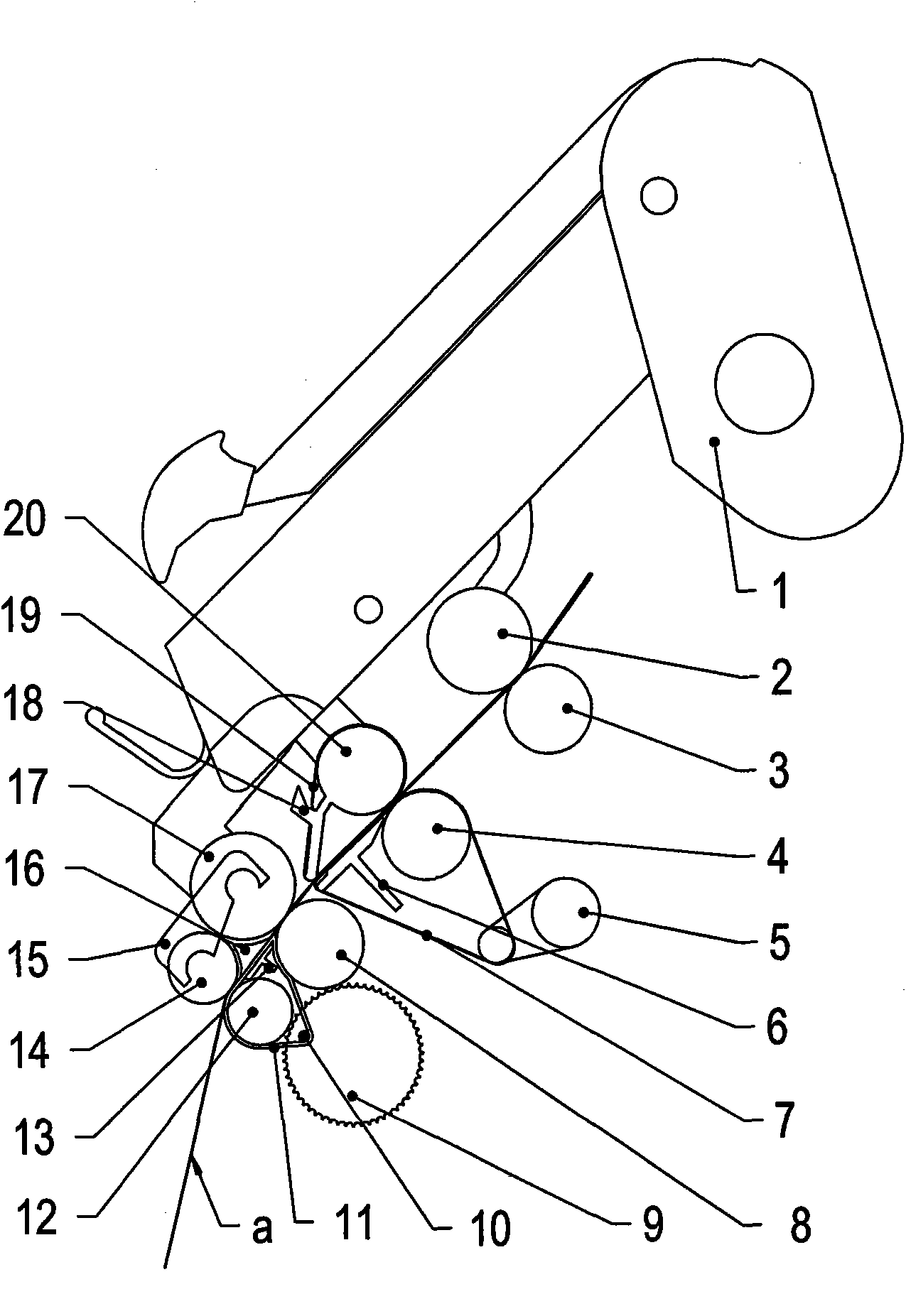

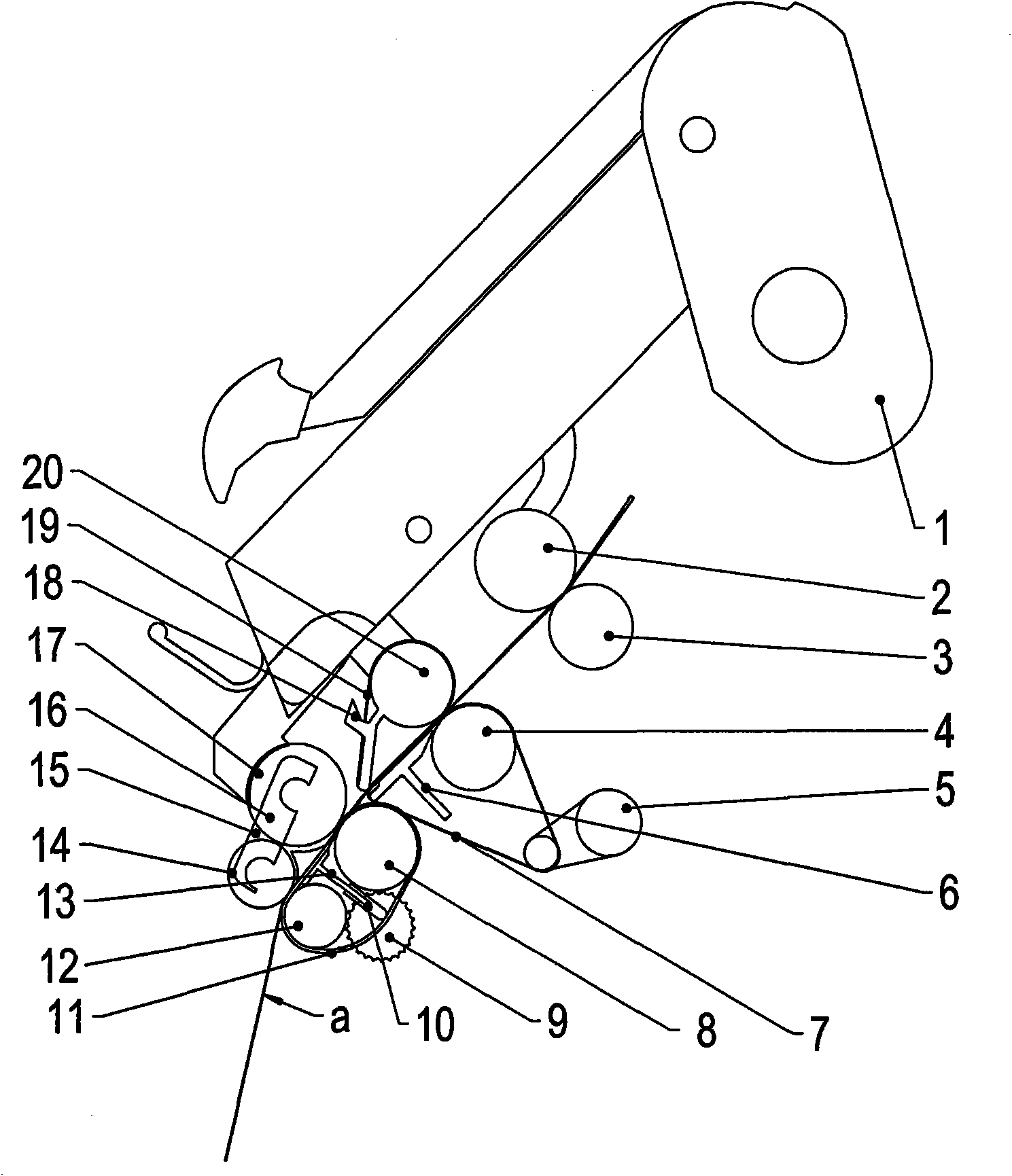

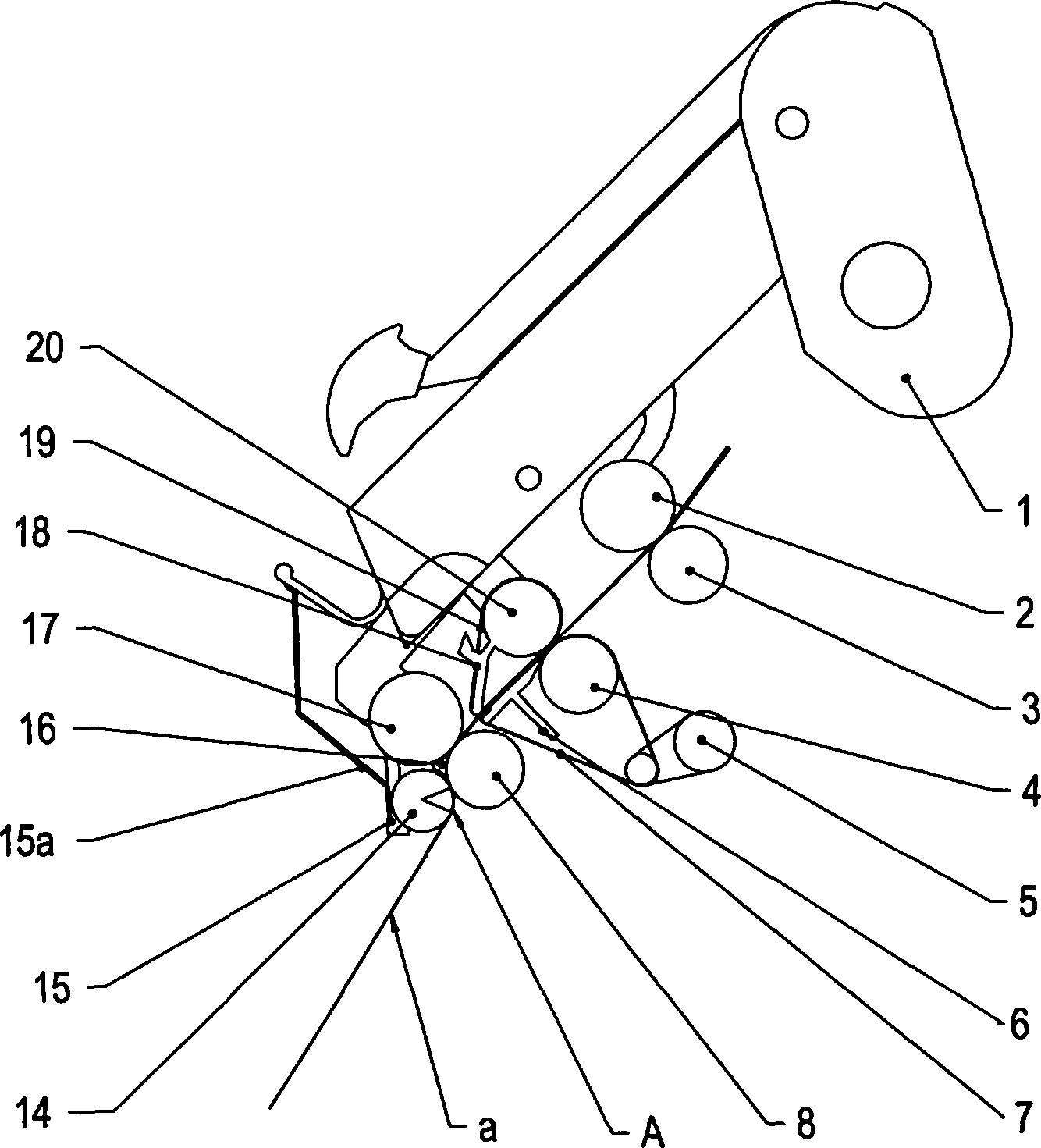

[0026] Such as Figure 1~2 As shown, the present invention is provided with a guide roller 12, a guide top roller 14, an apron 11, a bracket 13 and a cluster 16 at the front end of the front drafting area of the mechanical compact spinning device.

[0027] Yarn guide roller 12 takes several spindles as a unit, preferably 4 spindles, 6 spindles or 8 spindles as a unit, and along the length direction of the spinning machine, there is a quantity suitable for installation and spinning machine spindles at intervals. Such as Figure 11-12 As shown, the two ends of the guide roller 12 are equipped with bearings 12a, and the bearings 12a are directly installed on the roller seat 12c, or are installed on the roller seat 12c through the fixed seat 12b, and the roller seat 12c is provided with a bearing corresponding to the fixed seat 12b or the bearing 12a. The installation position and shape of the guide roller 12 can also be connected in the same way as the original spinning machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com