Turnplate heating device used for drying or pyrolyzing coal material

A heating device and turntable technology, which is used in heating devices, indirect heating and dry distillation, lighting and heating equipment, etc., can solve the problems of gear deformation, the inability of the pinion to fully mesh with the internal gear, and the easy jamming of dust in the roasting furnace. The effect of driving force, solving low power and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In the following, the present invention will be further described by using the following embodiments in conjunction with the accompanying drawings.

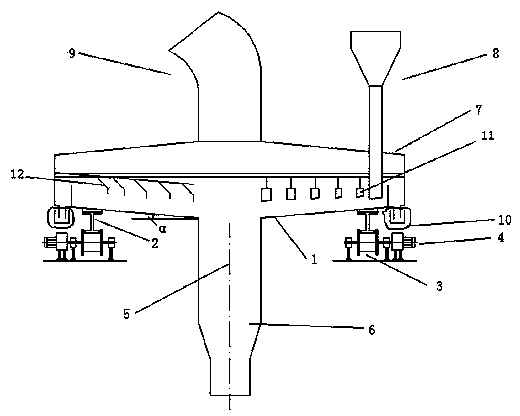

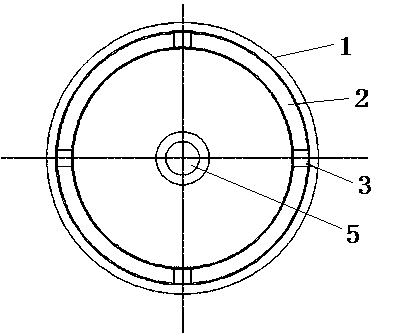

[0036] Such as figure 1 As shown, the present invention provides a turntable heating device for drying or pyrolyzing coal materials, including a turntable 1, the shape and size of the turntable 1 can use any commercially available type in the prior art, in this embodiment Among them, the side wall of the turntable 1 is vertically arranged, the side wall of the turntable 1 is perpendicular to the top, the angle α between the bottom of the turntable 1 and the horizontal plane is 5°, and the circle formed by the side wall of the turntable 1 and the bottom The radius of the corner is 50-80mm, the diameter of the top of the turntable 1 is 18-22m, the distance between the annular track 2 and the edge of the turntable 1 is 1m, and the distance between the feeding port and the edge of the turntable 1 is 9-22m of the turntable diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com