Lignite upgrading device

A lignite and turntable technology, applied in lighting and heating equipment, indirect heating and carbonization, indirect heat exchangers, etc., can solve the problems that the gear transmission cannot drive the turntable to rotate, the gears cannot be fully meshed, and the dust particles are easy to get stuck, etc., to achieve moisture The effect of high content, saving energy and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

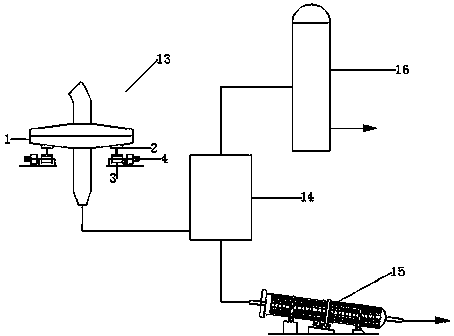

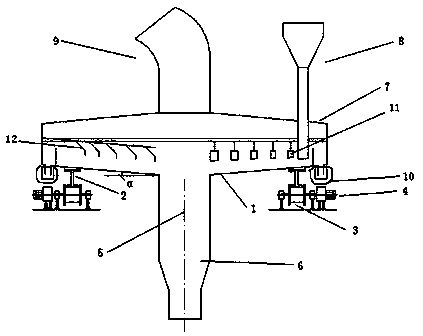

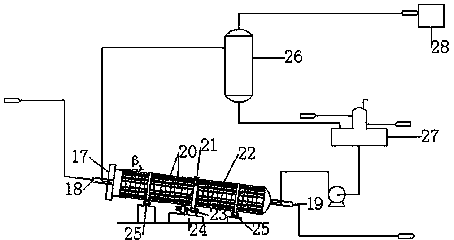

[0051] The lignite upgrading device of the present invention is as figure 1 As shown, it includes a rotary heater 13, which is provided with an inlet and an outlet; a gas-solid separator 14, which is provided with an inlet, a gas outlet and a solid outlet, and is used for gas-solid separation of the cracked coal material. The rotary heater 13 The outlet of the gas-solid separator 14 is in communication with the inlet of the gas-solid separator 14. The gas-solid separator 14 is any conventional equipment that can realize gas and solid separation in the prior art. In this embodiment, the gas-solid separator 14 is a cyclone separator; a semi-coke cooler 15 is provided with a feed port 18 and a discharge port 19, and the solid outlet of the gas-solid separator 14 communicates with the feed port 18 of the semi-coke cooler 15, The semi-coke cooler 15 is any equipment in the prior art that can realize semi-coke cooling; the tar condenser 16 is provided with an inlet, an oil outlet an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com