Guide pillar type hydraulic internal mold for straight web plate box girder

A guide post and web technology, applied in the mold and other directions, can solve the problems such as the inability to realize the integral hydraulic demoulding, the large change of the beam section size, and the increase of labor intensity, so as to achieve fast and convenient loading and unloading, and shorten the prefabrication period. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

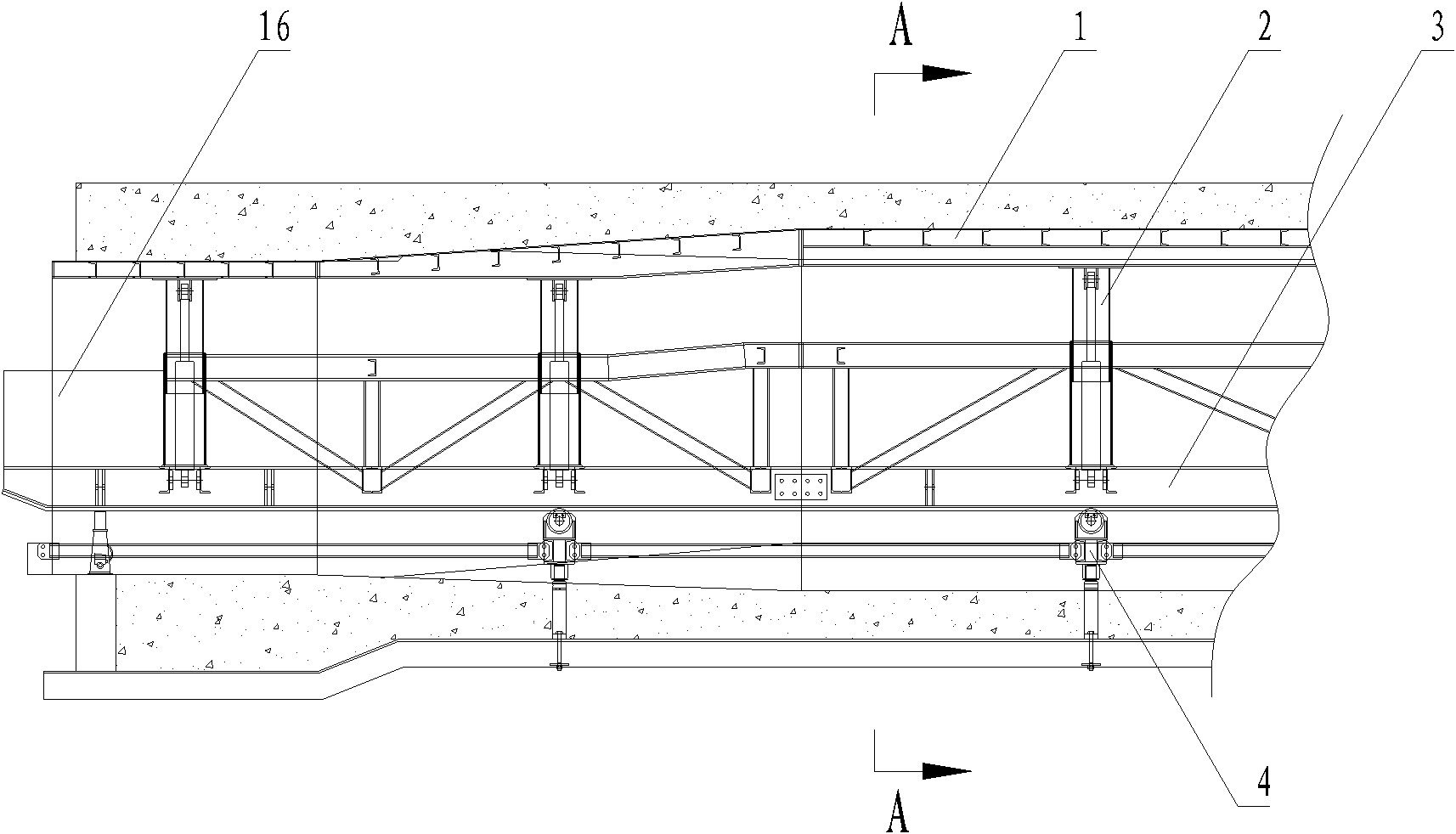

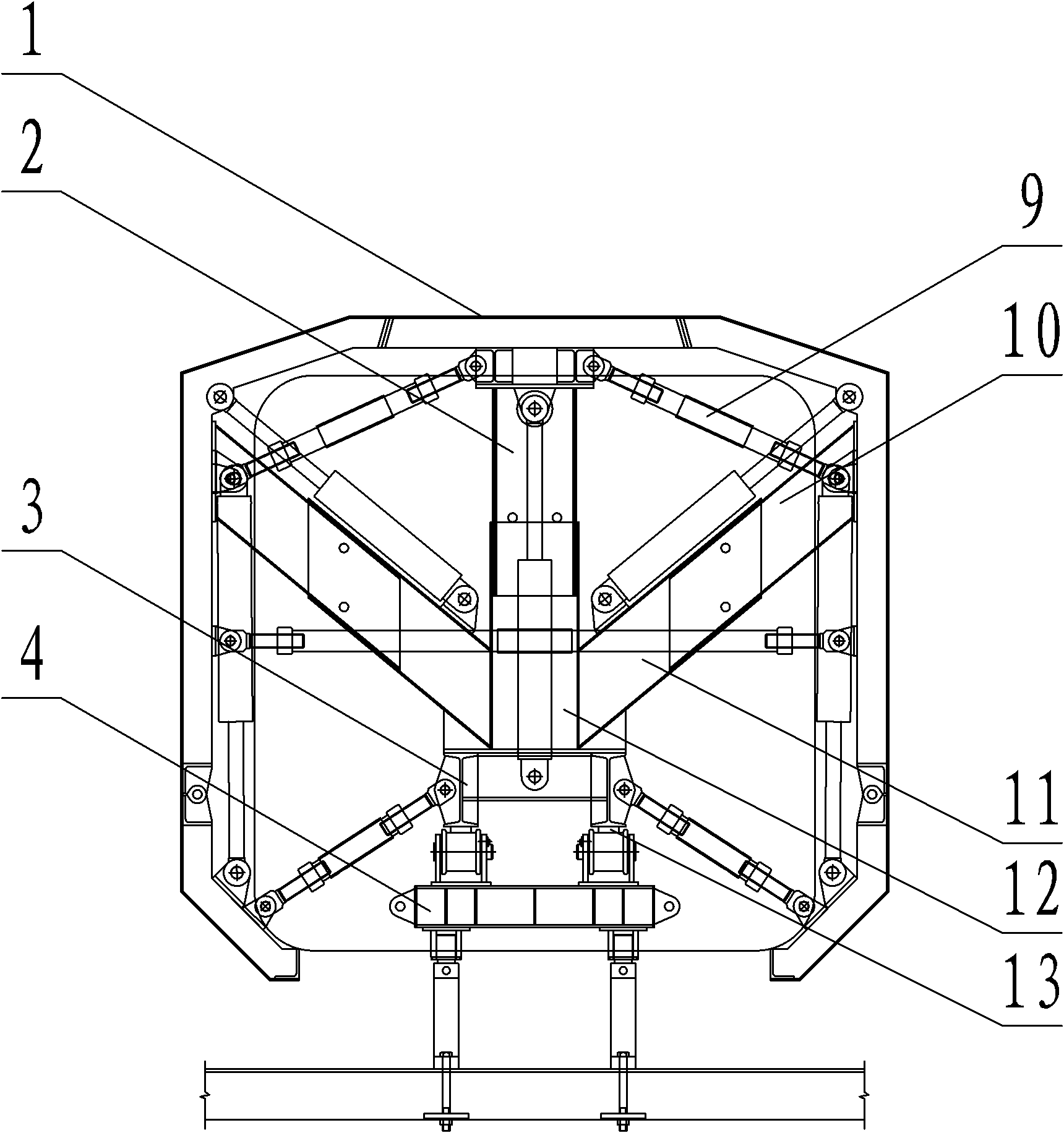

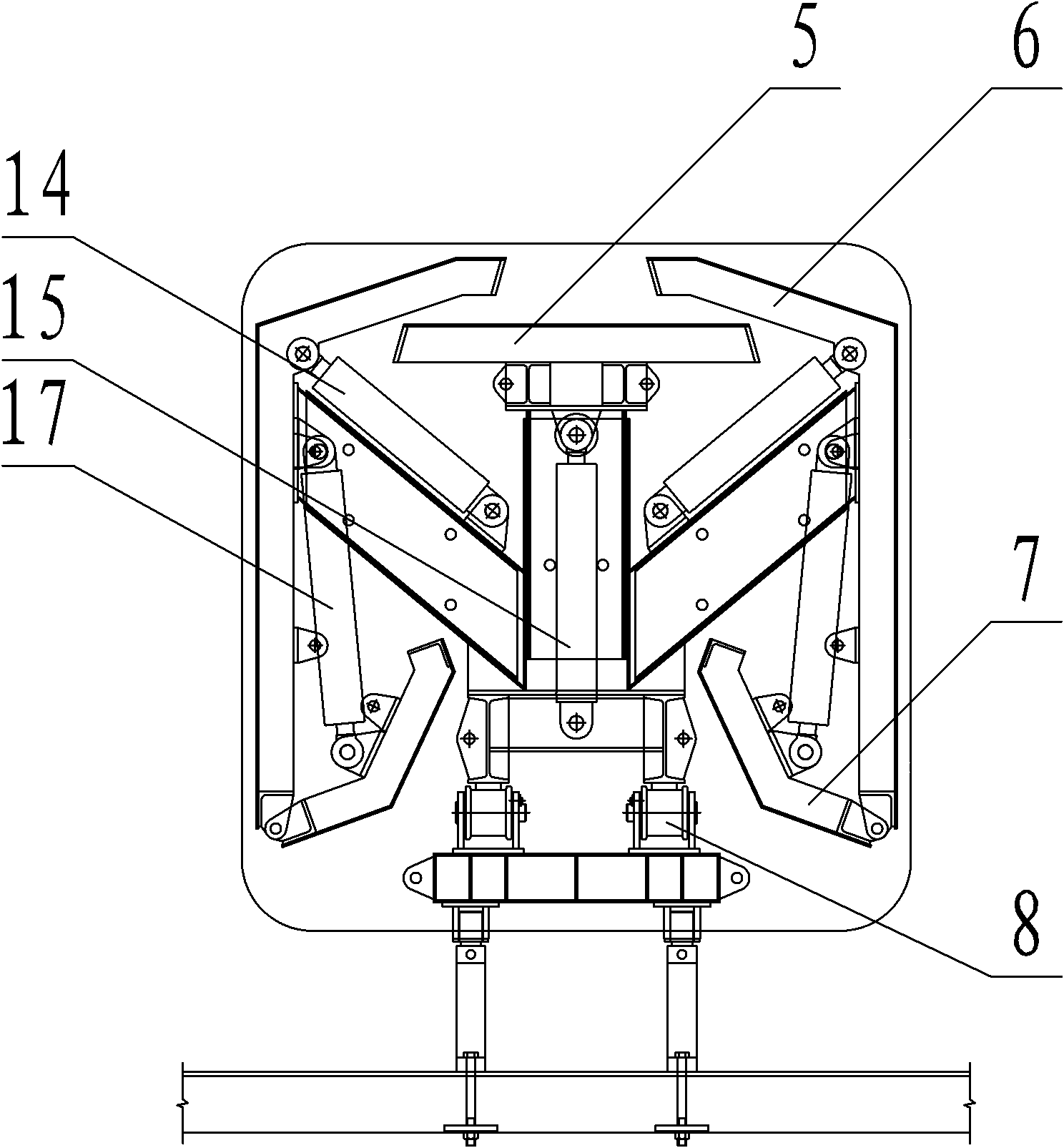

[0013] The specific implementation of the device will be described in detail below in conjunction with the accompanying drawings.

[0014] The guide column type hydraulic internal mold device provided by the present invention includes a template 1, a lifting guide column 2, a main beam 3, a support base 4, a telescopic strut 9, a lateral oil cylinder 14 and a jacking oil cylinder 15, wherein the main beam 3 A guide rail 13 is provided at the bottom, a jacking guide sleeve 12 and a side guide sleeve 11 are installed at the top, and an anti-roller 8 is installed on the support base 4 . Template 1 is made up of top mold template 5, upper movable mold template 6, and lower movable template 7, and upper movable mold template 6 and lower movable template 7 are all symmetrically arranged on both sides of said top mold template, and top mold template 5 is connected with jacking The guide columns 2 are connected, and the lifting guide column 2 is installed in the lifting guide sleeve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com