Self-compacted concrete pouring technique for assembling mold

A self-compacting concrete and combined mold technology, applied in the field of concrete pouring, can solve the problems of difficult operation of vibrating, large power consumption, large volume and weight, etc., and achieve the effect of eliminating the need for vibrating process, ensuring quality and speed of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

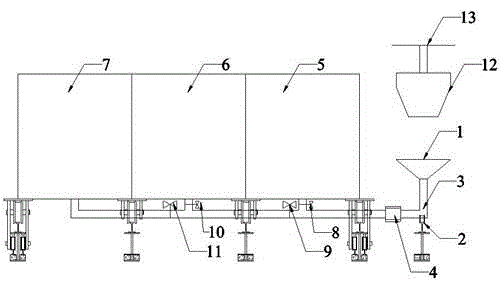

[0008] Specific embodiment: As shown in the figure, a group of composite molds is 9m long and 3.5m wide, and it is divided into three parts 5, 6, 7, which can prepare three prefabricated wallboards at the same time. The self-compacting concrete is put into the hopper 1 by the automatic distributing machine 12, pumped into the three parts 5, 6, and 7 of the combined mold by the peristaltic pump 8, and the shut-off valves 8, 9, 10, and 11 can be opened at the same time, so that the three parts of the combined mold 5 , 6, 7 pour self-compacting concrete at the same time; or first close the shut-off valves 10 and 11, open the shut-off valves 8 and 9, pour a part 5 of the combination mold, close the shut-off valves 8 and 11 after the part 5 is poured, and open the shut-off valves 9 and 9 10. Pouring the other part 6 of the combination mold. After the part 6 is poured, close the stop valves 8 and 10, open the stop valves 9 and 11, and pour the third part 7 of the combination mold. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com