Fiber material dispersing and feeding device

A technology of feeding device and fiber material, which is applied in the direction of sales of raw material supply device, clay preparation device, cement mixing device, etc. It can solve the problems of difficulty in adapting to requirements, low efficiency, and easy injury, so as to improve efficiency and quality, and simple operation , to ensure the effect of production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

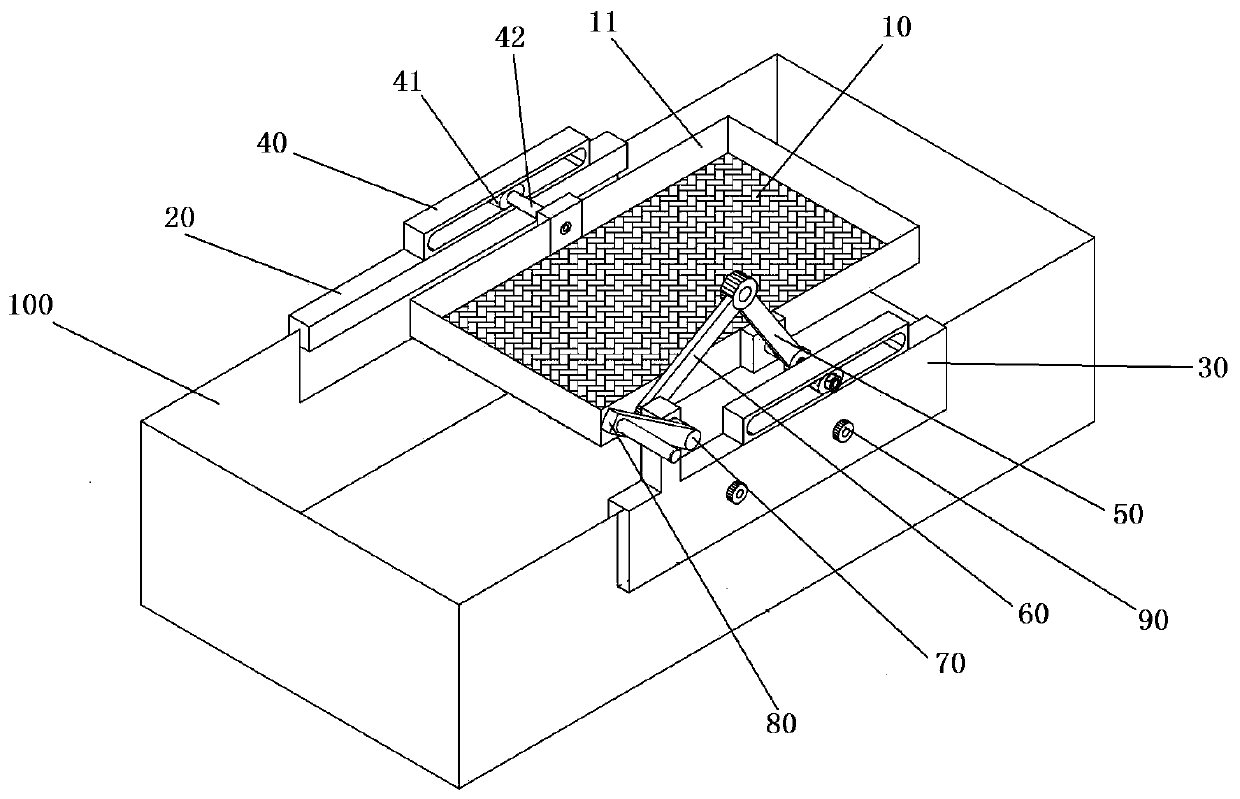

[0018] Please refer to figure 1 , a fiber material dispersion feeding device, comprising a screen 10, a first fixed frame 20 and a second fixed frame 30 oppositely arranged, the first fixed frame 20 and the second fixed frame 30 are respectively provided with a slide rail 40, the sliding The rail 40 is provided with a slide block 41, one side of the screen cloth 10 is fixedly connected with the slide block 41 on the first fixed mount 20 through the connecting shaft 42, and the other side of the screen cloth 10 is fixedly connected with the slide block 41 on the second fixed mount 30 through the connecting shaft. The blocks are fixedly connected, and a driving mechanism is provided on the first fixing frame 20 or the second fixing frame 30, and the driving mechanism drives the screen 10 to slide freely along the slide rail 40.

[0019] As can be seen from the above, when in use, the first fixed mount and the second fixed mount of the present invention are distributed and fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com